South Asian Journal of Engineering and Technology Vol.3, No.

4 (2017) 28–36

ISSN No: 2454-9614

Advanced Android Controlled Pick and Place Robotic ARM Using

Bluetooth Technology

[Link], [Link], [Link], [Link]

Electronics and Communication Engineering, Shree Venkateshwara Hi-Tech Engineering College, Erode, Tamilnadu,, India.

Received: 05/01/2017, Revised: 20/02/2017 and Accepted: 28/03/2017

Abstract

Mankind has always strived to give life like qualities to its artifacts in an attempt to find substitutes for himself to carry

out his orders and also to work in a hostile environment. The popular concept of a robot is of a machine that looks and works like

a human being. The industry is moving from current state of automation to Robotization, to increase productivity and to deliver

uniform quality. One type of robot commonly used in industry is a robotic manipulator or simply a robotic arm known as pick

and place robot. In this paper pick and place robot is been designed which performs its operation by using android via object

detection application and PIC microcontroller. The robotic arm will be controlled by the android application device at t he

transmitting end, which send the signal i.e. ASCII code, to Bluetooth module (HC-05) which is employed as an interface between

Mobile and robotic arm. Transmitter sends the command to the receiver to control the movement of the robotic arm. At the

receiving end four motors are interfaced to the microcontroller which is responsible for movement of robotic arm. The output

from the mobile will be send through Bluetooth to the microcontroller and that will allow the motor to move in order to pick and

place the object.

Keywords: Robotic arm, Microcontroller, Joint Actuator, Android application device, Sensors

1. Introduction

Robotics is the branch of engineering science and Technology related to robots, and their design,

manufacture, application, and structural disposition. Robotics is related to electronics, mechanics, and software.

Robotics research today is focused on developing systems that exhibit modularity, flexibility, redundancy, fault-

tolerance, a general and extensible software environment and seamless connectivity to other machines, some

researchers focus on completely automating a manufacturing process or a task, by providing sensor based

intelligence to the robot arm, while others try to solidify the analytical foundations on which many of the basic

concepts in robotics are built. In this highly developing society time and man power are critical constraints for

28

� South Asian Journal of Engineering and Technology Vol.3, No.4 (2017) 28–36

completion of task in large scales. The automation is playing important role to save human efforts in most of the

regular and frequently carried works. One of the major and most commonly performed works is picking and placing

from source to destination.

Present day industry is increasingly turning towards computer-based automation mainly due to the need for

increased productivity and delivery of end products with uniform quality. The inflexibility and generally high cost of

hard-automation systems, which have been used for automated manufacturing tasks in the past, have led to a broad

based interest in the use of robots capable of performing a variety of manufacturing functions in a flexible

environment and at lower costs. The pick and place robot is a microcontroller based mechatronic system that detects

the object, picks that object from source location and places at desired location. For detection of object, android

object detection application is been developed by using java language. Pick and place robots are robots that can be

programmed to literally pick an object up and place it somewhere. These robots are popular among business owners

who require speedy and precise automation applications and material handling systems. The existing pick and place

robots are based on every movement of robotic arm will be controlled by the remote controlled device. Human

intervention is required in order to move the robot from one place to other which requires the need of pc and internet

connections. Thus these factors results in complexity and cost. Thus all these drawbacks are overcome by designing

a pick and place robot that works on android via object detection application development and PIC microcontroller.

[Link] Review

Robots have their historical past though they came into existences only in 1961 when Unimation Inc, USA

introduced the first servo- controlled industrial robots. Early development dating back to 500B.C shows that the

Egyptians, Indians, the Chinese, and the Romans built many automatics puppets which imitate the movement of

animals and birds. The Chinese built many amusing devices that depicted sequential motions. Also, the early men

discovered many mechanisms and exhibited their innovation skill in building ships and introduced looms to weave.

This ushered in the industrial revolution. In the 1940s, remote teleported master- slave manipulators were

developed. Later, force feedback and kinesthetic sensory elements were added to them to facilitate better control.

Tele-operated devices were used in mars exploration in 1976. In 1948, the transition was invented at Bell

laboratories U.S.A. In 1952, IBM‟s first commercial computer IBM 701 was introduced. Then came numerically

controlled tools in which various slides of machines were displaced by numerical commands through suitable

hardware. The development of NC (numerically controlled) machine tools has, therefore, been a turning point in the

development of robotics.

The planet corporation in 1959 introduced a pick and place robot. In 1961, the first industrial robot was

commercialized by Unimation Inc. Microprocessor technology was brought by INTEL in 1961. The real robot

development process continued between 1968 and 1982 when various models of robots were developed by leading

robot scientists in different universities, national laboratories and different industrial houses in the USA, Japan,

France, UK, and other European countries. Some of the robot models of historical interest are the Versatran by

29

� South Asian Journal of Engineering and Technology Vol.3, No.4 (2017) 28–36

AMF, developed in (1963) and Cincinnati Milacron introduced in (1974), Irb-6 by ASLA in (1978). The Kawasaki

and Hitachi groups in Japan have also contributed a lot in developing various sensors to make robots „think‟

intelligently. Various robot institutions propagate the ideas and ideologies of robotics to the profession. Some of the

pioneering institutions are the Japan industrial Robot Association (JIRA, 1971), Robot Institute of America (RIA,

1975), British Robot Association (BRA, 1977) and Robotics Interaction / SME, to mention a few [1][2][3].

[Link] Analysis

This section describes the functions of the various units of the work and the algorithm/approaches used

during its development.

Mode Of Operation

When the operator issues a command from the android mobile phone to the robotic arm all necessary tasks

will be carried out by sending signals to the microcontroller via the transceiver. The microcontroller then issues

command to the respective channels that makes up the communication links. The electric motor response will

depend on the type of command issued; and the direction, speed and motion of the motor is regulated by the

microcontroller. The rotation of the powered motor moves the affected link connected to the motor and this in effect

affects the movement of the robotic arm.

System Description

The robotic arm has five degrees of freedom. It made of various links forming an open chain. The

arrangement of these links depends on the adopted design. The arm has a rotating base that is resting on the upper

region of the vehicle. The arm terminates with a gripper or a specialized tool holder; it has five (5) degrees of

freedom. The first three links of the arm form the body and which helps to place the tool holder at the desired

position at a location inside the workspace or environment. The remaining three links make up the wrist of the

robotic arm and are used to define the orientation of the robotic arm end points. For the purpose of analysis, the

robotic arm will made of joints, which will be named as wrist, elbow, shoulder, and base [4]. The preliminary sketch

from which the detailed design was made is based on the sketch.

30

� South Asian Journal of Engineering and Technology Vol.3, No.4 (2017) 28–36

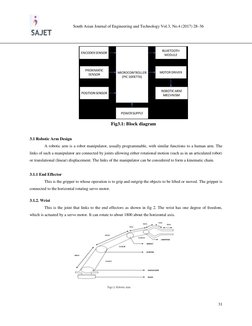

Fig3.1: Block diagram

3.1 Robotic Arm Design

A robotic arm is a robot manipulator, usually programmable, with similar functions to a human arm. The

links of such a manipulator are connected by joints allowing either rotational motion (such as in an articulated robot)

or translational (linear) displacement. The links of the manipulator can be considered to form a kinematic chain.

3.1.1 End Effector

This is the gripper to whose operation is to grip and outgrip the objects to be lifted or moved. The gripper is

connected to the horizontal rotating servo motor.

3.1.2. Wrist

This is the joint that links to the end effectors as shown in fig 2. The wrist has one degree of freedom,

which is actuated by a servo motor. It can rotate to about 1800 about the horizontal axis.

31

� South Asian Journal of Engineering and Technology Vol.3, No.4 (2017) 28–36

3.1.3 Shoulder

This is the joint between links C and the base and has 1 degree of freedom which is actuated by a Dc motor

(servo motor). It can also rotate to about 180o by link C. A gearing system is also used to actuate the motion.

3.1.4 Elbow

This is the joint between links B and C and it has one degree of freedom actuated by a rc servo motor. It

can rotate to about 1800 (by design) by link A. The motion about the elbow is actuated by a set of gear brains

connected to the links and the Dc motors.

3.1.5 Base

This is the joint between the robotic arm and the vehicle; it has 1 degree of freedom which is actuated by a

Dc connected to the gear in the link C. The Dc motor is similar to that used in the shoulder but a different gearing

arrangement. The base rotates to about 1800. The base is the platform on which the arm stands and it carries the

weight of the arm which in turns determine maximum load the robotic are can lift. The circuit board wiring and

other attachments are fixed to the base.

3.2 Design Consideration

The following were put into consideration in the design process.

i. Electrical actuators DC servo are chosen instead of hydraulic and pneumatic actuators because of the

little power requirement and its light weight which is suitable for this design.

ii. The materials which will be used for the design will be light in weight so as to reduce the weight

concentration on the base and the shoulder.

iii. Hollow rectangular bars and sheets instead of blocks are chosen for the links because of their light

weight and stability and to reduce the weight of the arm.

iv. The power supply source will be from a recharge able nickel metal hydride (Ni-MH) batteries

v. A continuous path controller was chosen (PIC microcontroller was used).

vi. The torque is fully balanced by the inertia of the electric motors (see force analysis) and the speed is

greatly reduced by gear sets attached to the electric motors.

vii. Materials used for the fabrication were locally sourced from available materials.

3. 2 Design Analysis of Robotic Manipulator

In this aspect numerous calculations was done in order to attain the required servo mechanism that will

meet the specification on this work.

32

� South Asian Journal of Engineering and Technology Vol.3, No.4 (2017) 28–36

Moment = force x perpendicular distance ………………………………. 3.1

Assuming that the weight of the material is negligible since it light compare to the servo specification. W0

=56g, W1=56g, W2=56g, W3=36g

Moment sustained at the shoulder M1

M1= (0.036 x 47) + (0.056 x 40) + (0.056 x 18) = 4.94 [kg-cm] But actual torque of the shoulder servo =

13 [kg-cm] Excess torque = Actual servo torque – Calculated torque ……………….3.2 Therefore excess available

torque at the shoulder = 13 – 4.94 = 8.06 [kg-cm]

Moment sustained at the elbow M2

M2 = (0.056 x 22) + (0.036 x 29) = 2.276 [kg-cm] But actual torque of the shoulder servo = 13 [kg-cm]

Excess torque = Actual servo torque – Calculated torque ……………….3.2 Therefore excess available torque at the

shoulder = 13 – 4.94 = 8.06 [kg-cm]

Moment sustained at the elbow M2

M2 = (0.056 x 22) + (0.036 x 29) = 2.276 [kg-cm] But actual torque of the Arm servo = 13 [kg-cm] Excess

available torque at the shoulder = 13 - 2.276 [kg-cm]

Moment sustained at wrist = (0.056 x 7) = 0.392 [kg-cm] But actual torque at the wrist servo = 13 [kg-cm]

Excess torque =13 – 0.392 = 12.608 [kg-cm]

Moment sustained at the base = (23-5 x 0.204) = 4.97 [kg-cm]

Excess torque = 13 – 4.97 = 8.206 [kg-cm]

From the design analysis made the maximum load the robotic manipulator can lift successfully is determine

by the base servo. From the above analysis the excess torque of the base is 8.20 [kg-cm]. Hence the calculated

maximum load is 8.206 [kg]. The actual load will be less than the calculated value because the weight of the

material used in constructing the arm was light and was not taken into consideration.

33

� South Asian Journal of Engineering and Technology Vol.3, No.4 (2017) 28–36

3.3 Sensors

3.3.1 Proximity Sensor

A proximity sensor is a sensor able to detect the presence of nearby objects without any physical contact.

Proximity sensor used to detect the object in nearby robotic arm.

3.3.2 Position Sensor

A Position sensors sense the angular position of the robotic arm. Position sensors are typically used on

machine-tool controls, elevators, automobile throttle controls, and numerous other applications.

3.3.3 Encoder Sensor

A linear encoder is a sensor, transducer or read head paired with a scale that encodes position. The sensor

reads the scale in order to convert the encoded position into an (Analog signal) analog or digital signal, which can

then be decoded into position by a digital readout (DRO) or motion controller.

3.4 Bluetooth Module (Hc-05)

This module is capable of communicating with PC, mobile phone or any other Bluetooth enabled device. It

is interfaced with the microcontroller over the serial UART port of micro-controller.

34

� South Asian Journal of Engineering and Technology Vol.3, No.4 (2017) 28–36

3.5 Motor Driver (L293d)

It is required to supply sufficient current to motors as microcontrollers can’t supply that much current.

Working Principle

The robotic arm will be controlled by the android application device at the transmitting end, which sends

the signal to Bluetooth module (HC-05) which is employed as an interface between Mobile and robotic arm.

Proximity sensor detects the object nearby robotic arm and position sensor sense the angular position of the robotic

arm. Sensing output given to microcontroller. Microcontroller commands sent to the receiver to control the

movement of the robotic arm. At the receiving end four motors are interfaced to the microcontroller which is

responsible for movement of robotic arm. Robotic arm pick and place the object in desired position.

4. Conclusion

The designs of an Android Controlled pick and place robotic arm has been completed. A prototype was

built and confirmed functional. This system would make it easier for man to unrivalled the risk of handling

suspicious objects which could be hazardous in its present environment and workplace. Complex and complicated

duties would be achieved faster and more accurately with this design.

35

� South Asian Journal of Engineering and Technology Vol.3, No.4 (2017) 28–36

References

1. Ankit Gupta, Mridul Gupta, NeelakshiBajpai, Pooja Gupta, Prashant Singh, “Efficient Design and Implementation of 4-Degree of Freedom

Robotic Arm”, International Journal of Engineering and Advanced Technology (IJEAT) ISSN: 2249 – 8958, Volume-2, June 2013.

2. B.O. Omijeh, R. Uhunmwangho, M. Ehikhamenle, “Design Analysis of a Remote Controlled Pick and Place Robotic Vehicle”, International

Journal of Engineering Research and Development, Volume 10, PP.57-68, May 2014.

3. Gilgueng Hwang, “Development of a Human-Robot- Shared Controlled Teletweezing system”IEEE transactions control system technology,

vol. 15, no. 5, september 2007

4. Guangming Song. [2011] “Automatic Docking System for Recharging Home Surveillance Robots” IEEE Transactions on Consumer

Electronics, Vol. 57, No. 2.

5. Mohamed Naufal Bin Omar, “Pick and Place Robotic Arm Controlled By Computer”, Faculty of Manufacturing Engineering, April 2007.

6. Sanjay Lakshminarayan, Shweta Patil, “Position Control of Pick and Place Robotic Arm”, Department of Electrical Engineerin g MS Ramaiah

Technology, Bangalore, India.

36