Professional Documents

Culture Documents

Topic Sheet No 11 - Dropped Objects HS-091ENG 1

Topic Sheet No 11 - Dropped Objects HS-091ENG 1

Uploaded by

Shafick GabungaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Topic Sheet No 11 - Dropped Objects HS-091ENG 1

Topic Sheet No 11 - Dropped Objects HS-091ENG 1

Uploaded by

Shafick GabungaCopyright:

Available Formats

Doc. No.

: HS-091ENG

Date of Issue: 16/05/17 Safety and Health:

Issue No.: 001 Topic Sheet No. 11

Page 1 of 4 Dropped objects

A topic sheet prepared by © IRATA International (2017)

SAFETY AND HEALTH TOPIC SHEET NO. 11:

DROPPED OBJECTS

A safety and health ‘topic sheet’ aimed at raising awareness of hazards in the rope access industry.

The series may be of use as a toolbox talk.

1 INTRODUCTION

1.1 The IRATA Work & Safety Analysis 2016 identifies 32 cases of ‘falling or dropped objects’. The

report notes that 24 were items dropped by rope access technicians (6 of which were rope

access equipment, e.g. ropes, slings, karabiners, etc.). The remainder of falling objects were

mainly rock, masonry and assorted materials. One object, dropped by a third party, struck and

injured a technician on rope. Only four of the falling or dropped objects resulted in actual injury,

all ‘minor’ with one exception. This was one of the two ‘major’ injuries; facial fractures caused

by falling rock penetrating protective netting.

1.2 ‘Falling or dropped objects’ is one of three consistently significant areas of concern for rope

access technicians. The following advice outlines the risk management measures that should

be considered when planning jobs.

2 HIERARCHY OF CONTROLS

2.1 The risk presented by dropped objects can be managed by adopting an hierarchical approach

(see Figure 1), with the level of protection reducing as the lower levels are reached.

Level of protection

High Elimination

Engineering controls

Administrative controls

Low Personal protective equipment

Figure 1 - Hierarchy of controls

4.3 This hierarchy is similar to the framework set out by the ‘hierarchy of fall protection’: avoid;

prevent; mitigate (i.e. minimise the distance and consequences of a falling or dropped object).

4.4 Some measures are ‘collective’ (and ‘passive’), e.g. safety nets. Others are ‘personal’ (and

‘active’), e.g. tool lanyards. It is important to select suitable equipment, taking account of the

mass of the object being retained and the situation in which it is to be used.

4.5 There are two types of falling or dropped object:

(a) Static An object that may drop from its previous static position under its own

mass, e.g. a light fitting that drops due to its fasteners coming loose over time.

(b) Dynamic An object that drops from its previous static position due to the force

applied by a person, wind, equipment, machinery or moving object, e.g. an object

being knocked off a platform and dropping to a level below.

UNCONTROLLED WHEN PRINTED

Doc. No.: HS-091ENG

Date of Issue: 16/05/17 Safety and Health:

Issue No.: 001 Topic Sheet No. 11

Page 2 of 4 Dropped objects

3 ELIMINATION

3.1 Where possible, the elimination of a hazard - or avoidance - must always be the preferred

option.

3.2 Undertake ‘pre-job’ checks or surveys to look for potential problems, e.g. bolts left on ledges,

loose or unstable masonry, projections or tangle threats, etc.

3.3 This is particularly important after a period of bad weather, on new sites, after third party

operations in the same vicinity, etc.

3.4 Ensure that pockets are empty and inspect carefully any tools prior to starting work, e.g. loose

hammer heads, poor security fixings for lanyards, etc. Consider special precautions when

using ‘high energy’ hand tools.

3.5 Do try and carry too many items.

4 ENGINEERING CONTROLS

4.1 If the hazard cannot be eliminated, engineering controls are the preferred approach to risk

reduction. This involves the use of equipment to reduce the potential for dropped objects (or,

preferably, prevent them from being dropped), or to reduce the risk if an object does fall.

4.2 Examples include:

• temporary covers being placed around and/or over openings;

• work clothing has pockets these should be capable of being securely closed; preferably,

don't put loose items in pockets;

• tools being transported in securely closed containers, e.g. when being lifted between

levels;

• lightweight hand tools, communication equipment, etc. being tethered to the technician;

• replacing a hand held torch with a helmet mounted head torch;

• heavier tools and components being separately tethered;

• using safety netting to catch tools or equipment that cannot be tethered, e.g. bolts;

• providing ‘hard’ barriers, toe boards, etc. to form an exclusion zone, where it is not

possible to prevent dropped objects.

5 ADMINISTRATIVE CONTROLS

5.1 Administrative controls, to be used in conjunction with the other controls in the hierarchy,

involve providing:

• information and warnings to technicians about hazards that are present;

• procedures and instruction on how to carry out the work safely;

• supervision to ensure that any procedures are being followed;

• management processes to determine any ‘lessons learnt’.

5.2 Examples of administrative controls are:

• hazard awareness, e.g. at induction;

• warning signs, to highlight any hazards to the workers;

UNCONTROLLED WHEN PRINTED

Doc. No.: HS-091ENG

Date of Issue: 16/05/17 Safety and Health:

Issue No.: 001 Topic Sheet No. 11

Page 3 of 4 Dropped objects

• planning activities to avoid situations where work is being carried out at multiple levels

simultaneously;

• lookouts to prevent people entering an area below where technicians are working;

• high levels of workplace housekeeping, i.e. keeping works areas clear of loose material

or objects;

• operating systems to check that all tools and components have been removed from, or

secured in, the work area prior to completion of the task;

• processes for reporting, investigating and learning from hazardous observations and

incidents involving falling objects (and developing a culture in which reporting is

encouraged).

6 PERSONAL PROTECTIVE EQUIPMENT

6.1 This is the last method of protecting an employee.

6.2 Industrial safety helmets provide limited protection only, due to the high level of kinetic energy

that falling and dropped objects possess. A helmet protects the head only, so other areas of

the body are unprotected from dropped objects and serious injuries can easily be suffered, e.g.

face.

7 ACTION

7.1 Review your management system for falling object and risk management procedure(s).

8 REFERENCES

9.1 Further information can be found in:

(a) IRATA International code of practice for industrial rope access (Third edition, September

1

2016) :

o Part 1, Clause 1.4.2.6

o Part 2, Clauses 2.11.8.1 and 2.11.8.2

o Annex M, Use of tools and other work equipment

2

(b) IRATA Work and Safety Analysis 2016 (Edition 3.1, October 2015)

9.2 For a list of current (and past) ‘safety communications’ by IRATA, see www.irata.org

9 RECORD FORM

9.1 An example Safety and Health Topic Sheet: Record Form is given below. Members may have

their own procedure(s) for recording briefings to technicians and others.

1

www.irata.org/default.php?cmd=215&doc_id=4336

2

www.irata.org/pdf%20downloads/WASA%202016.pdf

UNCONTROLLED WHEN PRINTED

Doc. No.: HS-091ENG

Date of Issue: 16/05/17 Safety and Health:

Issue No.: 001 Topic Sheet No. 11

Page 4 of 4 Dropped objects

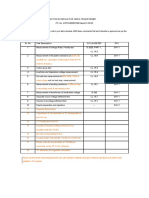

IRATA SAFETY AND HEALTH TOPIC SHEET – RECORD FORM

Site:

Date:

Topic(s) for discussion: Topic Sheet No. 11: Dropped objects

Reason for talk:

Start time: Finish time:

Attended by

Please sign to verify understanding of briefing

Print name: Signature:

Continue overleaf (where necessary)

Matters raised by employees: Action taken as a result:

Continue overleaf (where necessary)

Briefing leader

I confirm I have delivered this briefing and have questioned those attending on the topic discussed.

Print name: Signature: Date:

Comments:

UNCONTROLLED WHEN PRINTED

You might also like

- SBP-108 Dropped Object Prevention (3.04.24)Document7 pagesSBP-108 Dropped Object Prevention (3.04.24)Philippe AlexandreNo ratings yet

- Dropped Object Prevention PlanDocument11 pagesDropped Object Prevention PlanMd. Nazrul IslamNo ratings yet

- Dropped Object Prevention PlanDocument11 pagesDropped Object Prevention PlanMd. Nazrul IslamNo ratings yet

- HandlingDocument5 pagesHandlingShahid BhattiNo ratings yet

- 15 Aerial Lifts Tool Box TalkDocument3 pages15 Aerial Lifts Tool Box TalkMugilan SelvarajuNo ratings yet

- Working at Height - Training Presentation 1 of 2Document19 pagesWorking at Height - Training Presentation 1 of 2Mang Mando11No ratings yet

- Drop Object Prevention PlanDocument8 pagesDrop Object Prevention PlanAui Piando100% (1)

- Demolition Hazards and Heirarchy of ControlDocument14 pagesDemolition Hazards and Heirarchy of ControlMel DowleyNo ratings yet

- 32 Fall Protection Tool Box Talk Tnvdb0Document2 pages32 Fall Protection Tool Box Talk Tnvdb0Godfrey TamaneNo ratings yet

- Dropped Object PreventionDocument15 pagesDropped Object PreventionAriel Dela CruzNo ratings yet

- Topic Sheet No 22 - Belief-Based Safety HS-251ENGDocument5 pagesTopic Sheet No 22 - Belief-Based Safety HS-251ENGPhilNo ratings yet

- Safety Concepts: Dr. Mus'ab Abdul RazakDocument34 pagesSafety Concepts: Dr. Mus'ab Abdul RazakDivyashini MohanNo ratings yet

- Working at Height - Training PresentationDocument37 pagesWorking at Height - Training PresentationMang Mando11No ratings yet

- Fall ProtectionDocument37 pagesFall ProtectionNaseh AlamNo ratings yet

- Final Test of System Safety - Julian Hanggara AdigunaDocument6 pagesFinal Test of System Safety - Julian Hanggara AdigunaThe Minh NguyenNo ratings yet

- HIRAC - Work - at - Height - Template PDFDocument8 pagesHIRAC - Work - at - Height - Template PDFRohma Desi ThirtasariNo ratings yet

- Hazard Identification & Hierarchy of Hazard ControlsDocument10 pagesHazard Identification & Hierarchy of Hazard ControlsDeris IsabelNo ratings yet

- Safty Quisten Micro For ExternalDocument10 pagesSafty Quisten Micro For ExternalDBZ ShotsNo ratings yet

- Safety Start With YouDocument39 pagesSafety Start With YouCarlos Alberto Ferreira FilhoNo ratings yet

- Dropped Objects: Fabrication Site Construction Safety Recommended Practice - Hazardous ActivitiesDocument2 pagesDropped Objects: Fabrication Site Construction Safety Recommended Practice - Hazardous ActivitiesMuhammad Saqib AsifNo ratings yet

- Topic I Layers of Protection and Analysis - Safety Integrity LevelDocument16 pagesTopic I Layers of Protection and Analysis - Safety Integrity LevelJulius ChavezNo ratings yet

- Rizal Technological University College of Engineering, Architecture and TechnologyDocument82 pagesRizal Technological University College of Engineering, Architecture and TechnologyJulius ChavezNo ratings yet

- Management Chapter 4 Study MaterialDocument26 pagesManagement Chapter 4 Study MaterialVirendra PatilNo ratings yet

- Fall Protection Training SlidesDocument101 pagesFall Protection Training SlidesJMK3rdNo ratings yet

- Note Pdshe - Hazard Identification ControlDocument40 pagesNote Pdshe - Hazard Identification ControlĐina ĐaŕañNo ratings yet

- Safety Management - Module2Document27 pagesSafety Management - Module2Atienza ArjayNo ratings yet

- HSE-BMS-004 Supervisors TrainingDocument29 pagesHSE-BMS-004 Supervisors TrainingUche S Osigwe100% (1)

- Safety Checklist Working at Heights in ConstructionDocument4 pagesSafety Checklist Working at Heights in ConstructionkamranNo ratings yet

- CP For WAHDocument54 pagesCP For WAHIlluga Ta PhromNo ratings yet

- Working at HeightsDocument9 pagesWorking at HeightsQueenie FloresNo ratings yet

- Drop Object WordDocument13 pagesDrop Object WordPrimelift Safety Resources Limited100% (1)

- Construction Safety Focus: Preventing Falls From Height in Building & ConstructionDocument1 pageConstruction Safety Focus: Preventing Falls From Height in Building & ConstructionZeljkoNo ratings yet

- ISBN Construction Safety Focus Preventing Falls From Height in Building and Construction 2016 07 PDFDocument1 pageISBN Construction Safety Focus Preventing Falls From Height in Building and Construction 2016 07 PDFZeljkoNo ratings yet

- Case Study - AJDocument11 pagesCase Study - AJAjay NNo ratings yet

- Planning Fall Rescue Plan 1Document6 pagesPlanning Fall Rescue Plan 1MwagachristianNo ratings yet

- Admin Safety Brief Topics (24th To 28th Oct 2022)Document5 pagesAdmin Safety Brief Topics (24th To 28th Oct 2022)AlbertNo ratings yet

- Guidelines On Working at HeightDocument29 pagesGuidelines On Working at HeightMohd Obaidullah100% (1)

- Tower Crane Technical Information Note: Construction Plant-Hire AssociationDocument3 pagesTower Crane Technical Information Note: Construction Plant-Hire Associationlambok leonardoNo ratings yet

- Imb SH Hse 0016Document56 pagesImb SH Hse 001601095902062ahmedNo ratings yet

- Code of Practice For Working Safely at HeightDocument56 pagesCode of Practice For Working Safely at HeightAsri Abdullah100% (1)

- HIRAC Work at Height FedUniDocument7 pagesHIRAC Work at Height FedUnitemter100% (1)

- HIRAC Work at HeightDocument7 pagesHIRAC Work at HeightMitchRappNo ratings yet

- Personal & Process Safety For PO-1Document44 pagesPersonal & Process Safety For PO-1Aftab Ahmed MemonNo ratings yet

- JCDC The UA and The Decision To Err FactorsDocument26 pagesJCDC The UA and The Decision To Err FactorsConstructionpm CpmNo ratings yet

- Basic Safety Procedures Cont.Document28 pagesBasic Safety Procedures Cont.Margarette ReyesNo ratings yet

- Mechanical HazardsDocument2 pagesMechanical HazardsVimal SudhakaranNo ratings yet

- Share Notes in Introduction To Industrial Security AdministrationDocument15 pagesShare Notes in Introduction To Industrial Security AdministrationJheanelle CabreraNo ratings yet

- The Hierachy of ControlsDocument3 pagesThe Hierachy of ControlsEmranNo ratings yet

- Student Name Date Hand Out Date: Hand in DeadlineDocument13 pagesStudent Name Date Hand Out Date: Hand in DeadlinemaysNo ratings yet

- Degraded ModesDocument12 pagesDegraded ModesSpeedbirdNo ratings yet

- DroppedObjectsPreventionStandard - Eng 05 05 17 PDFDocument15 pagesDroppedObjectsPreventionStandard - Eng 05 05 17 PDFAndrew LiddellNo ratings yet

- Drop Object Prevention Plan PDFDocument11 pagesDrop Object Prevention Plan PDFOchulor Isaac100% (1)

- Fall Protection PlanDocument15 pagesFall Protection PlanMuhammad Usman75% (4)

- Construction Manpower Safety: Research ActivityDocument10 pagesConstruction Manpower Safety: Research ActivityNo OneNo ratings yet

- Project Hazard Alert - Working at Heights Dropped Objects PreventionDocument1 pageProject Hazard Alert - Working at Heights Dropped Objects PreventionUkay ArdianoNo ratings yet

- The Handbook of Safety Engineering: Principles and ApplicationsFrom EverandThe Handbook of Safety Engineering: Principles and ApplicationsRating: 4 out of 5 stars4/5 (1)

- Metrics and Methods for Security Risk ManagementFrom EverandMetrics and Methods for Security Risk ManagementRating: 5 out of 5 stars5/5 (1)

- Physical Security in the Process Industry: Theory with ApplicationsFrom EverandPhysical Security in the Process Industry: Theory with ApplicationsNo ratings yet

- OSCE Checklist Respiratory ExaminationDocument2 pagesOSCE Checklist Respiratory ExaminationputriNo ratings yet

- MlistDocument13 pagesMlistSumanth MopideviNo ratings yet

- Delhi CompDocument10 pagesDelhi CompPatrick AdamsNo ratings yet

- The Bottled LeopardDocument4 pagesThe Bottled LeopardSebastian Alegale Zamora0% (1)

- Consumer Product Safety Slides With AudioDocument50 pagesConsumer Product Safety Slides With AudioAlejandra GilNo ratings yet

- Time Travel: A Journey To The Fourth DimensionDocument2 pagesTime Travel: A Journey To The Fourth DimensionasmauulhusnaNo ratings yet

- Air Show Stuff Magazine - Sep 2013Document92 pagesAir Show Stuff Magazine - Sep 2013Aviation/Space History LibraryNo ratings yet

- 06 Advanced MOSFET PDFDocument153 pages06 Advanced MOSFET PDFmayurNo ratings yet

- FG52806 - 12-04-2010Document13 pagesFG52806 - 12-04-2010Roberto Carlos100% (1)

- 16MVA Transformer Test Schedule CommentsDocument1 page16MVA Transformer Test Schedule CommentsAmany HamdyNo ratings yet

- 5G50ME-C9.6-HPSCR - LS - 100.0 - RPM - 8600 - KW DataDocument9 pages5G50ME-C9.6-HPSCR - LS - 100.0 - RPM - 8600 - KW DatawalacrNo ratings yet

- Kesan-Kesan Positif Dan Negatif Pengangkutan DaratDocument51 pagesKesan-Kesan Positif Dan Negatif Pengangkutan DaratMohd AfandiNo ratings yet

- WorldCement May 2018 PreviewDocument30 pagesWorldCement May 2018 PreviewRetal Mohamed100% (1)

- PMBLDC-Simulink - Permanent Magnet Brushless DC Motor Simulink Model.Document5 pagesPMBLDC-Simulink - Permanent Magnet Brushless DC Motor Simulink Model.Kidus DawitNo ratings yet

- Operating Instructions: Bitzer KühlmaschinenbauDocument11 pagesOperating Instructions: Bitzer KühlmaschinenbauothmaniomarNo ratings yet

- t2 Chem Revision Ex 5Document7 pagest2 Chem Revision Ex 5Nicholas Ow100% (1)

- Analysis of Constituents in Jamaica Quassia Extract, A Natural Bittering AgentDocument4 pagesAnalysis of Constituents in Jamaica Quassia Extract, A Natural Bittering AgentwisievekNo ratings yet

- D1 PRE BOARD PROF. EDUCATION Flordeluna An Education Student Was Asked by Prof.Document17 pagesD1 PRE BOARD PROF. EDUCATION Flordeluna An Education Student Was Asked by Prof.Joycelyn dagaleNo ratings yet

- Sales ContactDocument2 pagesSales ContacthanumsaavNo ratings yet

- Hse Requirements To ContractorDocument5 pagesHse Requirements To Contractorivansssss100% (1)

- Wstda Standard Web SlingsDocument36 pagesWstda Standard Web SlingslsgmzNo ratings yet

- FLab-10 EXP10Document12 pagesFLab-10 EXP10Carl Kevin CartijanoNo ratings yet

- CBSE Class 10 Biology Heredity & Evolution NotesDocument12 pagesCBSE Class 10 Biology Heredity & Evolution NotesAnonymous rePT5rCrNo ratings yet

- Install Windows XP On SATA WithoDocument63 pagesInstall Windows XP On SATA WithodacrysNo ratings yet

- API676 DatasheetDocument2 pagesAPI676 DatasheetLuvys Garcia MartinezNo ratings yet

- Geometrical Modulus of A Casting and Its Influence On Solidification ProcessDocument7 pagesGeometrical Modulus of A Casting and Its Influence On Solidification ProcessRa BalamuruganNo ratings yet

- 1 s2.0 S0032386110010372 Main PDFDocument21 pages1 s2.0 S0032386110010372 Main PDFNia SyafiqqNo ratings yet

- Biophysical Chemistry UpadhyayDocument1,194 pagesBiophysical Chemistry UpadhyayDestinifyd Mydestiny75% (12)

- Health9 - q1 - Mod7 - Home Gardening As An Environmental Project - v3Document25 pagesHealth9 - q1 - Mod7 - Home Gardening As An Environmental Project - v3HARLEY L. TAN100% (6)

- 8696Document3 pages8696Mohd Mohsin KhanNo ratings yet