Professional Documents

Culture Documents

Acoplamiento Bowex (Triturador) Instrucciones de Montaje

Uploaded by

NoeCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Acoplamiento Bowex (Triturador) Instrucciones de Montaje

Uploaded by

NoeCopyright:

Available Formats

®

KTR Kupplungstechnik BoWex KTR-N 40110 E

GmbH Operating-/Assembly Instructions sheet: 1

D-48407 Rheine D e s i g n 0 0 1 , 0 0 2 , 0 0 3 a n d 0 0 6 edition: 6

BoWex® curved-tooth gear couplings are flexible shaft connections. They are able to

compensate for shaft displacement caused by, as an example, inaccuracies in production,

heat expansion, etc.

Table of Contents

1 Technical Data

2 Hints

2.1 General Hints

2.2 Safety and Advice Hints

2.3 General Hints to Danger

2.4 Proper Use

3 Storage

4 Assembly

4.1 Components of the Couplings

4.2 Hint regarding the finish bore

4.3 Assembly of the Hubs

4.4 Displacements - Alignment of the Couplings

5 Enclosure A

Hints and instructions regarding the use in hazardous areas

5.1 Control intervals for couplings in hazardous areas

5.2 Checking of torsional backlash

5.3 Approximate values of wear

5.4 Permissible coupling materials in the hazardous area

5.5 Marking of coupling for the hazardous area

5.6 Starting

5.7 Breakdowns, causes and elimination

5.8 Certificate of Conformity according to the EG Standards 94/9/EG

dated 23 March 1994

Urheberschutz Gezeichnet: 17.01.03 Sha/Tn Ersatz für: Verteiler

gemäß DIN 34 Geprüft: 17.01.03 Sha Ersetzt durch: W K V VA M KC

®

KTR Kupplungstechnik BoWex KTR-N 40110 E

GmbH Operating-/Assembly Instructions sheet: 2

D-48407 Rheine D e s i g n 0 0 1 , 0 0 2 , 0 0 3 a n d 0 0 6 edition: 6

1 Technical Data

® ®

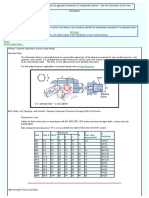

picture 1: BoWex junior plug-in coupling (2 parts) picture 2: BoWex junior M coupling (3 parts)

Table 1:

BoWex® junior plug-in coupling and BoWex® junior M coupling

torque finish bore thread for setscrews

® [Nm] [mm] [mm]

BoWex max. speed

size hub plug-in sleeve [1/min]

TA

TKN TK max. component 1b D1 component 2b D2 G1 t1 t2

[Nm]

d1 d2

Ø6, Ø7, Ø8, Ø9 22

Ø10, Ø11 25

14 5 10 Ø10, Ø11 25 M5 6 8 1,4 6000

Ø12, Ø14 26 Ø12, Ø14 26

Ø12, Ø14 27

Ø14, Ø15 29

19 8 16 Ø16 30 M5 6 10 1,4 6000

Ø19 32 Ø19 35

Ø10, Ø11, Ø12 26

Ø14 32

Ø14, Ø15, Ø16 32

24 12 24 M5 6 10 1,4 6000

Ø18, Ø19, Ø20 36 Ø19, Ø20 36

Ø24 38 Ø24 40

Table 2:

BoWex® junior plug-in coupling and BoWex® junior M coupling

dimensions

®

BoWex [mm]

size

DH l1; l2 E E1 M; N M1 F G L L1 LH LH1

14 40 23 4 2 6,5 8 23 17 50 48 37 40

19 48 25 4 2 8,5 10 23 19 54 52 37 42

24 52 26 4 2 7,5 9 25 20 56 54 41 45

Urheberschutz Gezeichnet: 17.01.03 Sha/Tn Ersatz für: Verteiler

gemäß DIN 34 Geprüft: 17.01.03 Sha Ersetzt durch: W K V VA M KC

®

KTR Kupplungstechnik BoWex KTR-N 40110 E

GmbH Operating-/Assembly Instructions sheet: 3

D-48407 Rheine D e s i g n 0 0 1 , 0 0 2 , 0 0 3 a n d 0 0 6 edition: 6

1 Technical Data

® ®

picture 3: BoWex design M picture 4: BoWex design I

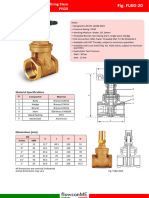

Table 3:

BoWex® design M and design I

max. dimensions threads for

® pilot bore 2)

BoWex finish [mm] setscrews [mm]

size un- pilot bore 1) TA

DH D l1; l2 l3 E M; N L LH DZ G t

bored bore d1; d2 [Nm]

M-14 x - 15 40 25 23 10 4 6,5 50 37 33 M5 6 2

M-19 x - 20 48 32 25 10 4 8,5 54 37 39 M5 6 2

M-24 x - 24 52 36 26 14 4 7,5 56 41 45 M5 6 2

M-28 x - 28 66 44 40 13 4 19 84 46 54 M8 10 10

M-32 x - 32 76 50 40 13 4 18 84 48 63 M8 10 10

M-38 x - 38 83 58 40 13 4 18 84 48 69 M8 10 10

M-42 x - 42 92 65 42 13 4 19 88 50 78 M8 10 10

M-48 x - 48 95 68 50 13 4 27 104 50 78 M8 10 10

27 15 /

M-65 x 65 132 96 55 16 4 23 114 68 110 M10 3) 17

70 lg. 20

I-80 - 25 80 175 124 90 20 6 46,5 186 93 145 M10 20 17

I-100 - 35 100 210 152 110 22 8 63 228 102 176 M12 30 40

I-125 - 45 125 270 192 140 30 10 78 290 134 225 M16 40 80

1) tip circle of the hub

2) position of the threads for setscrews BoWex M-14 to M-24 opposite the keyway; BoWex M-28 to I-125 on the keyway

3) hub length 55 mm t = 15 mm, 70 mm t = 20 mm

2 Hints

2.1 General Hints

Please read through these mounting instructions carefully before you set the coupling into operation.

Please pay special attention to the safety instructions!

®

The BoWex coupling is approved for the use in hazardous areas.

When using the coupling in hazardous areas please observe the special hints and instructions

regarding safety in enclosure A.

The mounting instructions are part of your product. Please keep them carefully and close to the coupling.

The copyright for these mounting instructions remains with KTR Kupplungstechnik GmbH.

Urheberschutz Gezeichnet: 17.01.03 Sha/Tn Ersatz für: Verteiler

gemäß DIN 34 Geprüft: 17.01.03 Sha Ersetzt durch: W K V VA M KC

®

KTR Kupplungstechnik BoWex KTR-N 40110 E

GmbH Operating-/Assembly Instructions sheet: 4

D-48407 Rheine D e s i g n 0 0 1 , 0 0 2 , 0 0 3 a n d 0 0 6 edition: 6

2 Hints

2.2 Safety and Advice Hints

STOP DANGER ! Danger of injury to persons.

CAUTION ! Damages on the machine possible.

!

F ATTENTION ! Pointing to important items.

PRECAUTION ! Hints concerning explosion protection.

2.3 General Hints of Danger

DANGER !

STOP With assembly, operation and maintenance of the coupling it has to be made sure that the

entire drive train is protected against unintentional engagement. You can be seriously hurt

by rotating parts. Please make absolutely sure to read through and observe the following

safety instructions.

• All operations on and with the coupling have to be performed taking into account "safety first".

• Please make sure to disengage the power pack before you perform your work.

• Protect the power pack against unintentional engagement, e. g. by providing hints at the place of engagement

or removing the fuse for current supply.

• Do not touch the operation area of the coupling as long as it is in operation.

• Please protect the coupling against unintentional touch. Please provide for the necessary protection devices

and caps.

2.4 Proper Use

You may only assemble, operate and maintain the coupling if you

• carefully read through the mounting instructions and understood them

• had technical training

• are authorized to do so by your company

The coupling may only be used in accordance with the technical data (see table 1 to 3 in chapter 1).

Unauthorized modifications on the coupling design are not admissible. We do not take any warranty for resulting

damages. To further develop the product we reserve the right for technical modifications.

The BoWex® described in here corresponds to the technical status at the time of printing of these mounting

instructions.

Urheberschutz Gezeichnet: 17.01.03 Sha/Tn Ersatz für: Verteiler

gemäß DIN 34 Geprüft: 17.01.03 Sha Ersetzt durch: W K V VA M KC

®

KTR Kupplungstechnik BoWex KTR-N 40110 E

GmbH Operating-/Assembly Instructions sheet: 5

D-48407 Rheine D e s i g n 0 0 1 , 0 0 2 , 0 0 3 a n d 0 0 6 edition: 6

3 Storage

The coupling hubs are supplied in preserved condition and can be stored at a dry and roofed place for 6 - 9

months.

The features of the coupling sleeves remain unchanged for up to 5 years in case of favourable stock conditions.

CAUTION !

The storage rooms may not include any ozone-generating devices, like e. g. fluorescent

! light sources, mercury-vapour lamps or electrical high-voltage appliances.

Humid storage rooms are not suitable.

Please make sure that there is no condensation. The best relative air humidity is under

65%.

4 Assembly

Basically the coupling is supplied in individual parts. Before assembly the coupling has to be controlled for

completeness.

4.1 Components of the Couplings

Design from nylon

Components of BoWex® junior plug-in coupling design No. 001

Component Quantity Designation

1 1 hub

2 1 plug-in sleeve

3 2 setscrew DIN 916

®

picture 5: BoWex junior plug-in coupling

Components of BoWex® junior M coupling design No. 002

Component Quantity Designation

1 2 hub

2 1 sleeve

3 2 setscrew DIN 916

®

picture 6: BoWex junior M coupling

Urheberschutz Gezeichnet: 17.01.03 Sha/Tn Ersatz für: Verteiler

gemäß DIN 34 Geprüft: 17.01.03 Sha Ersetzt durch: W K V VA M KC

®

KTR Kupplungstechnik BoWex KTR-N 40110 E

GmbH Operating-/Assembly Instructions sheet: 6

D-48407 Rheine D e s i g n 0 0 1 , 0 0 2 , 0 0 3 a n d 0 0 6 edition: 6

4 Assembly

4.1 Components of the Couplings

Design from steel/nylon

Components of BoWex® M coupling (size 14 - 65) design No. 003

Component Quantity Designation

1 2 hub

2 1 M-sleeve

3 2 setscrew DIN 916

®

picture 7: BoWex M coupling

Components of BoWex I coupling (size 80 - 125) design No. 006

Component Quantity Designation

1 2 hub

2 1 I-sleeve 1)

3 2 circlips 1)

2 setscrew DIN 916

1) Circlips and sleeve are delivered pre-assembled.

®

picture 8: BoWex I coupling

4.2 Hint regarding the finish bore

DANGER !

STOP The maximum permissible bore diameters d (see

table 1 to 3 in chapter 1 - Technical Data) must not be

exceeded. If these figures are disregarded, the coupling

may tear. Rotating particles may cause serious danger.

• Hub bores (steel hubs) machined by the customer have to

observe concentric running or axial running, respectively

(see picture 9).

• Please make absolutely sure to observe the figures for dmax.

• Carefully align the hubs when the finish bores are brought

in.

• Please provide for a setscrew or an end plate for the axial

fastening of the hubs.

picture 9: concentric running

and axial running

Table 4: Setscrews

® 1) 1) 1)

BoWex size 14 19 24 28 32 38 42 48 65 80 100 125

screw size M5 M5 M5 M8 M8 M8 M8 M8 M10 M10 M12 M16

tightening torque TA [Nm] 2 2 2 10 10 10 10 10 17 17 40 80

® ®

1) tightening torques of the BoWex junior plug-in coupling and BoWex junior M coupling TA = 1,4 Nm

Urheberschutz Gezeichnet: 17.01.03 Sha/Tn Ersatz für: Verteiler

gemäß DIN 34 Geprüft: 17.01.03 Sha Ersetzt durch: W K V VA M KC

®

KTR Kupplungstechnik BoWex KTR-N 40110 E

GmbH Operating-/Assembly Instructions sheet: 7

D-48407 Rheine D e s i g n 0 0 1 , 0 0 2 , 0 0 3 a n d 0 0 6 edition: 6

4 Assembly

4.3 Assembly of the Hubs

F

ATTENTION !

We recommend to check bores, shaft, keyway and feather key for dimensional accuracy

before assembly.

Heating the hubs slightly (approx. 80 °C) allows for an easier installation onto the shaft.

PRECAUTION !

Please pay attention to the danger of ignition in hazardous areas.

DANGER !

STOP Touching the heated hubs causes burns.

We would recommend to wear safety gloves.

CAUTION !

For the assembly please make sure that the distance dimension E (see table 2 and 3) is kept

! to ensure that the sleeve can be moved axially.

Disregarding this hint may cause damage on the coupling.

• Assemble the hubs onto the shaft of driving and driven side.

• Move the power packs in axial direction until the dimension E is achieved.

• If the power packs are already firmly assembled, axial movement of the hubs on the shafts allows for

adjusting the dimension E.

• Fasten the hubs by tightening the setscrews DIN 916 with cup point.

4.4 Displacements - Alignment of the Couplings

The displacement figures shown in tables 5 and 6 offer sufficient safety to compensate for environmental

influences like, for example, heat expansion or lowering of foundation.

CAUTION !

In order to ensure a long lifetime of the coupling and to avoid dangers regarding the use in

! hazardous areas, the shaft ends must be accurately aligned.

Please absolutely observe the displacement figures indicated (see tables 5 and 6). If the

figures are exceeded, the coupling is damaged.

In case of a use in hazardous areas for the explosion group IIC (marking II 2G c IIC T4),

only the half displacement figures (see tables 5 and 6) are permissible.

Please note:

• The displacement figures mentioned in tables 5 and 6 are maximum figures which must not arise in parallel.

If radial and angular displacement arises at the same time, the permissible radial displacements of the

coupling halves have to be reduced as follows:

∆Kr

∆Krperm = ∆Kr − • ∆Ww

2∆Kw

∆Ww = angular shaft displacement

• The displacement figures mentioned are general figures that apply up to an ambient temperature of 80 °C,

ensuring a sufficient service life of the BoWex® coupling.

Displacement figures between the speeds indicated have to be interpolated accordingly. If necessary, please

ask about the displacement for the corresponding coupling type.

• Please check with a dial gauge, ruler or feeler whether the permissible displacement figures of tables 5 and 6

can be observed.

Urheberschutz Gezeichnet: 17.01.03 Sha/Tn Ersatz für: Verteiler

gemäß DIN 34 Geprüft: 17.01.03 Sha Ersetzt durch: W K V VA M KC

®

KTR Kupplungstechnik BoWex KTR-N 40110 E

GmbH Operating-/Assembly Instructions sheet: 8

D-48407 Rheine D e s i g n 0 0 1 , 0 0 2 , 0 0 3 a n d 0 0 6 edition: 6

4 Assembly

4.4 Displacements - Alignment of the Couplings

angular displacements radial displacements axial displacements radial and angular displacements

picture 10: displacements

Example for the misalignment

combinations given in picture 11:

Example 1:

∆KR = 30%

∆KW = 70%

Example 2:

∆KR = 60%

∆KW = 40%

∆Ktotal = ∆KR + ∆KW ≤ 100 % picture 11: combinations of displacement

Table 5: Displacement figures

® ®

BoWex junior plug-in coupling and BoWex junior M coupling

coupling size 14 19 24

max. axial displacement ∆Ka [mm] ±1 ±1 ±1

max. radial displacement with n=1500 1/min ∆Kr [mm] 0,1 0,1 0,1

max. radial displacment with n=3000 1/min ∆Kr [mm] 0,1 0,1 0,1

∆Kw max. angular displacement with n=1500 1/min [degree] 1,0 1,0 0,9

∆Kw max. angular displacement with n=3000 1/min [degree] 0,7 0,7 0,6

Table 6: Displacement figures

BoWex® design M and design I

coupling size 14 19 24 28 32 38 42 48 65 80 100 125

max. axial displacement ∆Ka [mm] ±1 ±1 ±1 ±1 ±1 ±1 ±1 ±1 ±1 ±1 ±1 ±1

max. radial displacement

0,30 0,30 0,35 0,35 0,35 0,40 0,40 0,40 0,45 0,45 0,45 0,45

with n=1500 1/min ∆Kr [mm]

max. radial displacment

0,20 0,20 0,23 0,23 0,23 0,25 0,25 0,25 0,28 0,28 0,28 0,28

with n=3000 1/min ∆Kr [mm]

∆Kw max. angular displacement

1,0 1,0 0,9 0,9 0,9 0,9 0,9 0,9 0,7 0,6 0,6 0,4

with n=1500 1/min [degree]

∆Kw max. angular displacement

0,7 0,7 0,6 0,6 0,6 0,6 0,6 0,6 0,5 0,4 0,4 0,3

with n=3000 1/min [degree]

Urheberschutz Gezeichnet: 17.01.03 Sha/Tn Ersatz für: Verteiler

gemäß DIN 34 Geprüft: 17.01.03 Sha Ersetzt durch: W K V VA M KC

®

KTR Kupplungstechnik BoWex KTR-N 40110 E

GmbH Operating-/Assembly Instructions sheet: 9

D-48407 Rheine D e s i g n 0 0 1 , 0 0 2 , 0 0 3 a n d 0 0 6 edition: 6

5 Enclosure A

Hints and instructions regarding the use in hazardous areas

design 003: hub / sleeve / hub

Enclosure A only valid for BoWex M coupling (type 003).

5.1 Control intervals for couplings in hazardous areas

explosion group control intervals

A checking of the circumferential backlash and a visual check of the sleeve must be

effected after 3,000 operating hours for the first time, after 6 months at the latest.

If you note an unconsiderable or no wear at the sleeve after this first inspection, the further

inspections can be effected, in case of the same operating parameters, respectively after

6,000 operating hours or after 18 months at the latest.

II 2G c IIB T4

If you note a considerable wear during the first inspection, so that a change of the sleeve

would be recommended, please find out the cause according to the table „Breakdowns“, as

far as possible.

The maintenance intervals must be adjusted according to the changed operating

parameters.

A checking of the circumferential backlash and a visual check of the sleeve must be

effected after 2,000 operating hours for the first time, after 3 months at the latest.

If you note an unconsiderable or no wear at the sleeve after this first inspection, the further

inspections can be effected, in case of the same operating parameters, respectively after

4,000 operating hours or after 12 months at the latest.

II 2G c IIC T4

If you note a considerable wear during the first inspection, so that a change of the sleeve

would be recommended, please find out the cause according to the table „Breakdowns“, as

far as possible.

The maintenance intervals must be adjusted according to the changed operating

parameters.

BoWex® coupling

®

picture 12: BoWex coupling

Here the backlash between the hub and the nylon toothing must be checked by a torsional backlash, separately

from the drive and the driven end.

The friction / wear may only be Xmax. of the original toothing strength before the nylon sleeves must be

exchanged.

When reaching the torsional backlash ∆Smax, the nylon sleeve must be exchanged immediately, irrespective of

the inspection intervals.

Urheberschutz Gezeichnet: 17.01.03 Sha/Tn Ersatz für: Verteiler

gemäß DIN 34 Geprüft: 17.01.03 Sha Ersetzt durch: W K V VA M KC

®

KTR Kupplungstechnik BoWex KTR-N 40110 E

GmbH Operating-/Assembly Instructions sheet: 10

D-48407 Rheine D e s i g n 0 0 1 , 0 0 2 , 0 0 3 a n d 0 0 6 edition: 6

5 Enclosure A

Hints and instructions regarding the use in hazardous areas

5.2 checking of torsional backlash

CAUTION !

To check the torsional backlash the turned off drive aggregate must be secured against

! unintended turning on.

Drive end

• Turn the hub in opposite direction to the direction of drive.

CAUTION !

Here the sleeve may not be axially displaced from its wear position.

!

• Mark sleeve and hub (see picture 13).

• Turn the hub in the direction of drive and measure the torsional backlash ∆Smax.

• When reaching the torsional backlash ∆Smax the nylon sleeve must be exchanged.

Driven end

• Turn the hub in the direction of drive.

CAUTION !

Here the sleeve may not be axially displaced from its wear position.

!

• Mark sleeve and hub (see picture 13).

• Turn the hub in opposite direction to the direction of drive and measure the torsional backlash ∆Smax.

• When reaching the torsional backlash ∆Smax the nylon sleeve must be exchanged.

picture 13: marking of the sleeve and the hub

Urheberschutz Gezeichnet: 17.01.03 Sha/Tn Ersatz für: Verteiler

gemäß DIN 34 Geprüft: 17.01.03 Sha Ersetzt durch: W K V VA M KC

®

KTR Kupplungstechnik BoWex KTR-N 40110 E

GmbH Operating-/Assembly Instructions sheet: 11

D-48407 Rheine D e s i g n 0 0 1 , 0 0 2 , 0 0 3 a n d 0 0 6 edition: 6

5 Enclosure A

Hints and instructions regarding the use in hazardous areas

5.3 Approximate values of wear

If the torsional backlash is ≥ ∆Smax. [mm] / friction ≥ Xmax. [mm], the nylon sleeves must be exchanged.

The reaching of the exchange values depends on the operating conditions and the existing operating

parameters.

CAUTION !

In order to ensure a long lifetime of the coupling and to avoid dangers regarding the use in

! hazardous areas, the shaft ends must be accurately aligned.

Please absolutely observe the displacement figures indicated (see tables 5 and 6). If the

figures are exceeded, the coupling is damaged.

picture 14: sleeve in new condition picture 15: wear of sleeve

Table 7:

limits of wear each hub limits of wear each hub

BoWex ® BoWex ®

friction torsional backlash friction torsional backlash

size size

Xmax. [mm] ∆Smax. [mm] Xmax. [mm] ∆Smax. [mm]

14 0,8 1,3 45 1,0 1,8

19 0,8 1,4 48 1,0 1,8

24 1,0 1,5 65 1,4 2,5

28 1,0 1,6 80 1,6 2,7

32 1,0 1,7 100 1,8 3,1

38 1,0 1,7 125 2,0 3,5

42 1,0 1,7

5.4 Permissible coupling materials in the hazardous area

explosion group permitted coupling materials / size

IIB BoWex M14 to M65 with sleeve material PA (light)

BoWex M14 to M19 with sleeve material PA (light)

IIC

BoWex M14 to M65 with sleeve material PA12CF15 (black)

In the explosion groups IIB and IIC only the following material combinations may be used:

steel - steel

stainless steel - stainless steel

Aluminium as coupling material is generally excluded for the explosion area.

Urheberschutz Gezeichnet: 17.01.03 Sha/Tn Ersatz für: Verteiler

gemäß DIN 34 Geprüft: 17.01.03 Sha Ersetzt durch: W K V VA M KC

®

KTR Kupplungstechnik BoWex KTR-N 40110 E

GmbH Operating-/Assembly Instructions sheet: 12

D-48407 Rheine D e s i g n 0 0 1 , 0 0 2 , 0 0 3 a n d 0 0 6 edition: 6

5 Enclosure A

Hints and instructions regarding the use in hazardous areas

5.5 Marking of coupling for the hazardous area

Couplings for the use in hazardous areas are marked for the respectively permissible conditions of use.

Explosion group IIC: e. g. II 2G c IIC T4

In the marking II 2G c IIC T4 the explosion group IIB is included.

5.6 Starting

Before putting the coupling into operation, check the tightness of the grub screws in the hubs, the alignment and

the distance dimension E and correct, if necessary, and also check all screw connections regarding the stipulated

tightening torques dependent on the type of coupling.

If used in hazardous areas, the grub screws must be additionally secured against self-loosening to

fix the hub, e. g. with Loctite (medium strength).

Last but not least, the coupling protection against unintended contact must be fixed.

Coupling protection in the hazardous area.

Covering of the coupling

The couplings must be provided with firm coverings (if possible, made from stainless steel)

protecting the couplings against falling objects. There can be regular openings in the coverings

which may not exceed the following dimensions:

circular openings rectangular openings

diameter in mm side length in mm

top surface of the covering 4 4

side parts of the covering 8 8

The distance between the cover and the rotating parts must be at least 5 mm.

The cover must be electrically conductive and be included in the equipotential bonding. Bellhousings made from

aluminium and damping rings (NBR) can be used as connecting element between pump and electro motor if the

magnesium part is below 7,5 %. The cover may only be taken off after having stopped the unit.

During operation, please pay attention to

• strange running noises

• occurring vibrations.

CAUTION !

If you note any irregularities at the coupling during operation, the drive unit must be turned

! off immediately. The cause of the breakdown must be found out with the table

„Breakdowns“ and, if possible, be eliminated according to the proposals. The possible

breakdowns mentioned can be hints only. To find out the cause all operating factors and

machine components must be considered.

Urheberschutz Gezeichnet: 17.01.03 Sha/Tn Ersatz für: Verteiler

gemäß DIN 34 Geprüft: 17.01.03 Sha Ersetzt durch: W K V VA M KC

®

KTR Kupplungstechnik BoWex KTR-N 40110 E

GmbH Operating-/Assembly Instructions sheet: 13

D-48407 Rheine D e s i g n 0 0 1 , 0 0 2 , 0 0 3 a n d 0 0 6 edition: 6

5 Enclosure A

Hints and instructions regarding the use in hazardous areas

5.7 Breakdowns, Causes and Elimination

danger hints for

breakdowns causes elimination

hazardous areas

1) put the unit out of operation

2) eliminate the reason for the

misalignment (e. g. loose foundation

misalignment

bolts, break of the engine fixing, heat

micro friction at the danger of ignition due

expansion of unit components, change

toothing of the nylon to hot surfaces

of the assembly dimension E of the

change of the sleeve

coupling)

running noises

3) checking of wear see under point

and / or occurring

Control

vibrations

1) put the unit out of operation

2) check alignment of coupling

loose screws for

danger of ignition due 3) tighten the screws to secure the hubs

axial securement of

to hot surfaces and secure against self-loosening

hubs

4) checking of wear see under point

Control

1) put the unit out of operation

2) disassemble the coupling and remove

break of the nylon

rests of the sleeve

sleeve / toothing

--- 3) check coupling parts and exchange

due to high shock

damaged coupling parts

energy / overload

4) insert sleeve, assemble coupling parts

5) find out the reason of overload

1) put the unit out of operation

operating

2) check the operating parameters and

break of the nylon parameters do not

select a larger coupling (consider

sleeve / toothing correspond to the ---

installation space)

performance of the

3) assemble new coupling size

coupling

4) check alignment

1) put the unit out of operation

2) disassemble the coupling and remove

rests of the sleeve

mistake in service of

--- 3) check coupling parts and exchange

the unit

damaged coupling parts

4) insert sleeve, assemble coupling parts

5) instruct and train the service staff

Urheberschutz Gezeichnet: 17.01.03 Sha/Tn Ersatz für: Verteiler

gemäß DIN 34 Geprüft: 17.01.03 Sha Ersetzt durch: W K V VA M KC

®

KTR Kupplungstechnik BoWex KTR-N 40110 E

GmbH Operating-/Assembly Instructions sheet: 14

D-48407 Rheine D e s i g n 0 0 1 , 0 0 2 , 0 0 3 a n d 0 0 6 edition: 6

5 Enclosure A

Hints and instructions regarding the use in hazardous areas

5.7 Breakdowns, Causes and Elimination

danger hints for

breakdowns causes elimination

hazardous areas

1) put the unit out of operation

2) disassemble the coupling and remove

rests of the sleeve

danger of ignition due 3) check coupling parts and exchange

drive vibrations

to hot surfaces damaged coupling parts

4) insert sleeve, assemble coupling parts

5) check alignment, correct if necessary

6) find out the reason for the vibrations

1) put the unit out of operation

2) disassemble the coupling and remove

ambient / contact

rests of the sleeve

temperatures which

3) check coupling parts and exchange

are too high for the danger of ignition due

excessive wear at damaged coupling parts

sleeve, max. to hot surfaces

the sleeve toothing 4) insert sleeve, assemble coupling parts

permissible

5) check alignment, correct if necessary

-20 °C / +80 °C

6) check and regulate ambient / contact

temperature

e. g. contact with 1) put the unit out of operation

aggressive liquids / 2) disassemble the coupling and remove

oils, ozone- rests of the sleeve

influence, too high 3) check coupling parts and exchange

ambient --- damaged coupling parts

temperatures etc. 4) insert sleeve, assemble coupling parts

effecting a physical 5) check alignment, correct if necessary

change of the 6) make sure that further physical changes

sleeve of the sleeve are excluded

F

ATTENTION !

KTR does not assume any liabilities or guarantees regarding the use of spare parts and

accessories which are not provided by KTR and for the damages resulting here from.

Urheberschutz Gezeichnet: 17.01.03 Sha/Tn Ersatz für: Verteiler

gemäß DIN 34 Geprüft: 17.01.03 Sha Ersetzt durch: W K V VA M KC

®

KTR Kupplungstechnik BoWex KTR-N 40110 E

GmbH Operating-/Assembly Instructions sheet: 15

D-48407 Rheine D e s i g n 0 0 1 , 0 0 2 , 0 0 3 a n d 0 0 6 edition: 6

5 Enclosure A

Hints and instructions regarding the use in hazardous areas

5.8 Certificate of Conformity

Certificate of Conformity

corresponding to EG Standard 94/9/EG dated 23 March 1994

and to the legal regulations

The manufacturer - KTR Kupplungstechnik GmbH, D-48432 Rheine - states that the

BoWex - curved-tooth gear couplings

described in these mounting instructions and explosion-proof designed correspond to Article 1 (3) b)

of Standard 94/9/EG and comply with the general Safety and Health Requirements according to

enclosure II of Standard 94/9/EG.

The couplings are certified according to Type Examination Certificate IBExU02ATEXB002 X.

According to article 8 (1) of Standard 94/9/EG the technical documentation is deposited with the:

IBExU

Institut für Sicherheitstechnik GmbH

Fuchsmühlenweg 7

09599 Freiberg

Rheine, 02.08.02 ppa. i. V.

Date Dr. Norbert Partmann Josef Schürhörster

Engineering Manager Product Manager

Urheberschutz Gezeichnet: 17.01.03 Sha/Tn Ersatz für: Verteiler

gemäß DIN 34 Geprüft: 17.01.03 Sha Ersetzt durch: W K V VA M KC

You might also like

- Bowex: KTR-N Sheet: Edition: 40115 en 1 of 11 2Document11 pagesBowex: KTR-N Sheet: Edition: 40115 en 1 of 11 2globalindosparepartsNo ratings yet

- Re 17342 2022-07Document52 pagesRe 17342 2022-07Ali Emre YıldırımNo ratings yet

- Service Instructions for CR PumpsDocument19 pagesService Instructions for CR PumpsriskiriskNo ratings yet

- Instruccionesaacoples KTRDocument16 pagesInstruccionesaacoples KTRDênis DáyolNo ratings yet

- Grundfosliterature - CRI Ensambles 1 A 5Document17 pagesGrundfosliterature - CRI Ensambles 1 A 5Rudo RockNo ratings yet

- Grundfosliterature-79607Document15 pagesGrundfosliterature-79607Carlos BorgesNo ratings yet

- Head ClearancesDocument2 pagesHead ClearancesMohan Rao0% (2)

- Grundfosliterature 2616Document22 pagesGrundfosliterature 2616Sal MendezNo ratings yet

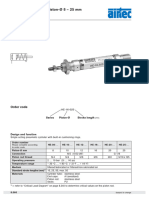

- Iso Roundline Cylinders: - OrdersDocument1 pageIso Roundline Cylinders: - OrdersSolve CTINo ratings yet

- Stainless Steel Ball Valves: ARKH Wafer Type With Welding EndsDocument4 pagesStainless Steel Ball Valves: ARKH Wafer Type With Welding EndsLizeth MontoyaNo ratings yet

- Cutting Data Catalogue PDFDocument138 pagesCutting Data Catalogue PDFlyxuandatbkNo ratings yet

- ROTEX Flex Coupling GR Instruction ManualDocument21 pagesROTEX Flex Coupling GR Instruction ManualIzzi Al-AkbarNo ratings yet

- HKD Push-In Anchor: Basic Loading Data (For A Single Anchor) : HKD-S /-EDocument8 pagesHKD Push-In Anchor: Basic Loading Data (For A Single Anchor) : HKD-S /-EsorengbhanuNo ratings yet

- Machine Design Practice July 2019 Assignment IIT MadrasDocument39 pagesMachine Design Practice July 2019 Assignment IIT MadrasVishwajit HegdeNo ratings yet

- Technische Fiche Homa TP53M262 D Nieuw 2014Document3 pagesTechnische Fiche Homa TP53M262 D Nieuw 2014Marnix VanbavinckhoveNo ratings yet

- Re 17327 - 2022-10Document36 pagesRe 17327 - 2022-10ashfaq shaikhNo ratings yet

- CylinderDocument39 pagesCylinderapi-3854910100% (1)

- Bowex-Elastic: KTR-N Sheet: Edition: 40113 EN 1 of 21 6Document21 pagesBowex-Elastic: KTR-N Sheet: Edition: 40113 EN 1 of 21 6влад камрNo ratings yet

- E 20x Miniature-Float-Switches ENDocument8 pagesE 20x Miniature-Float-Switches ENYuriPasenkoNo ratings yet

- Final Page Size: A5 (148mm X 210mm)Document20 pagesFinal Page Size: A5 (148mm X 210mm)RJ BevyNo ratings yet

- Grundfos InstructionDocument22 pagesGrundfos InstructionSajeev NerurkarNo ratings yet

- DESPIECE 22 Hp.Document88 pagesDESPIECE 22 Hp.Natanael Adriel Aguilar AldazNo ratings yet

- Wrench ClearancesDocument2 pagesWrench ClearancesRowan JoguilonNo ratings yet

- S02 Rock DrillDocument60 pagesS02 Rock DrillAlejandro LazzariniNo ratings yet

- Datasheet Din 931Document6 pagesDatasheet Din 931Jelena DNo ratings yet

- Catalogo de Acoples Rotex 2Document36 pagesCatalogo de Acoples Rotex 2cmaradiagaNo ratings yet

- VMO-BCR-ABCRM01-VMO-51-AD04-011 Rev.03 Stat.2 - Bulk Tank Ø6300x5600Document2 pagesVMO-BCR-ABCRM01-VMO-51-AD04-011 Rev.03 Stat.2 - Bulk Tank Ø6300x5600AAAAAAANo ratings yet

- MTG 320i - FSC - UD - 3.5m - 45° - LED (4,035,928) - 20200225 - 095705Document21 pagesMTG 320i - FSC - UD - 3.5m - 45° - LED (4,035,928) - 20200225 - 095705khoi nguyenvanNo ratings yet

- HIT-HY 150 Injection Mortar With RebarDocument8 pagesHIT-HY 150 Injection Mortar With RebarNguyễn AnhNo ratings yet

- Economical HLC Light duty metal anchorsDocument6 pagesEconomical HLC Light duty metal anchorsLuis RoaNo ratings yet

- DC 5 A/T Practice: Ssangyong Motor CompanyDocument32 pagesDC 5 A/T Practice: Ssangyong Motor CompanyMigue SalazarNo ratings yet

- Screw in Plug Type Connectors HX HLDocument8 pagesScrew in Plug Type Connectors HX HLra5tr@No ratings yet

- STIHL 021 023 025 Parts DiagramDocument23 pagesSTIHL 021 023 025 Parts DiagramTodd Lukes100% (6)

- Ejot WN-1451Document1 pageEjot WN-1451Diogo DoiNo ratings yet

- Iso Roundline Cylinders: - OrdersDocument58 pagesIso Roundline Cylinders: - OrdersBülent KabadayiNo ratings yet

- One - Touch Fittings: Series: WP2Document12 pagesOne - Touch Fittings: Series: WP2PrashantNo ratings yet

- Cyl Block 320D2Document1 pageCyl Block 320D2lilikNo ratings yet

- BX62 ManualDocument16 pagesBX62 ManualVida AndrijauskienėNo ratings yet

- Figure 9 - Dimensions of PN 25 FlangesDocument2 pagesFigure 9 - Dimensions of PN 25 FlangesSamir TahaNo ratings yet

- 3 FLBG-20Document1 page3 FLBG-20FareethAbdullahNo ratings yet

- Amplificador 2.1 Con TDA2030 - BOM - PCBWay - PCBWay CommunityDocument3 pagesAmplificador 2.1 Con TDA2030 - BOM - PCBWay - PCBWay Communitylgbnicaragua01No ratings yet

- MTB 500i W R TXM Technical ManualDocument26 pagesMTB 500i W R TXM Technical ManualSaranyoo CHOOTIMASNo ratings yet

- Corona Piñon coRMincaDocument1 pageCorona Piñon coRMincaWilliam VillamizarNo ratings yet

- MTB500iWRTXM /22°/L241/H50 44,0350,3494,637Document29 pagesMTB500iWRTXM /22°/L241/H50 44,0350,3494,637Saranyoo ChootimasNo ratings yet

- K3VL Swash Plate Pump Service ManualDocument37 pagesK3VL Swash Plate Pump Service ManualJonathan Giraldo100% (1)

- RE 10 030/03.00 External Gear Pump Type G2, Series 4X: Up To 22.4 CM Up To 250 Bar NS 4 To 22 Replaces: 04.99Document12 pagesRE 10 030/03.00 External Gear Pump Type G2, Series 4X: Up To 22.4 CM Up To 250 Bar NS 4 To 22 Replaces: 04.99Paris AndreadisNo ratings yet

- Minex - S Permanent Magnetic Coupling: KTR-N Sheet: Edition: 46510 EN 1 of 20 5Document20 pagesMinex - S Permanent Magnetic Coupling: KTR-N Sheet: Edition: 46510 EN 1 of 20 5HyungTae JangNo ratings yet

- GB HeDocument14 pagesGB HeMoutaz IsmailNo ratings yet

- Hydraulic Rock Drill HLX 5 Water FlushinDocument19 pagesHydraulic Rock Drill HLX 5 Water FlushinSales Aydinkaya100% (1)

- Esquema Soporte TV SalonDocument22 pagesEsquema Soporte TV SalonpablosantNo ratings yet

- ABO Ball ValveDocument6 pagesABO Ball ValveSunil BajpaiNo ratings yet

- Part Catalogue Alamarine Jet 245Document34 pagesPart Catalogue Alamarine Jet 245husninfajarul418No ratings yet

- Grinnell Mechanical Products Rigid Coupling - Patented General Description Technical DataDocument4 pagesGrinnell Mechanical Products Rigid Coupling - Patented General Description Technical DataСергей КолесниковNo ratings yet

- Service Procedure #THP-100: Commercial Steering SystemsDocument2 pagesService Procedure #THP-100: Commercial Steering SystemsMauricio Ariel H. OrellanaNo ratings yet

- FFX Side Mounting Float Switch - New - 1663825112Document16 pagesFFX Side Mounting Float Switch - New - 1663825112onlynameNo ratings yet

- Engineering Drawing from the Beginning: The Commonwealth and International Library: Mechanical Engineering DivisionFrom EverandEngineering Drawing from the Beginning: The Commonwealth and International Library: Mechanical Engineering DivisionRating: 4.5 out of 5 stars4.5/5 (3)

- Parts and Functions of The MotherboardDocument4 pagesParts and Functions of The MotherboardIbrahim ObaidullahNo ratings yet

- Music Hall Mmf2.1 Turntable ManualDocument13 pagesMusic Hall Mmf2.1 Turntable ManualtodwilliNo ratings yet

- Medições BateriaDocument4 pagesMedições BateriaFrancisco José da Costa GomesNo ratings yet

- Doosan. Powerful Solutions.: Portable Air CompressorsDocument24 pagesDoosan. Powerful Solutions.: Portable Air Compressorsjesus finolNo ratings yet

- Understanding Flexible Manufacturing Systems (FMSDocument37 pagesUnderstanding Flexible Manufacturing Systems (FMSSumanAgarwal100% (1)

- Elaspeed Cold Shrink Splices 2010Document3 pagesElaspeed Cold Shrink Splices 2010moisesramosNo ratings yet

- Changzhou Haochen Imp. & Exp. Co., LTD.: Packing ListDocument4 pagesChangzhou Haochen Imp. & Exp. Co., LTD.: Packing ListChrisPalacinCustodioNo ratings yet

- XUV700 Accessories E-BrochureDocument18 pagesXUV700 Accessories E-BrochureAnand KhatalNo ratings yet

- Manual de Usuario Stihl 009 (53 Páginas)Document1 pageManual de Usuario Stihl 009 (53 Páginas)toyioriginalNo ratings yet

- Raychem Technical Handbook 2012 2013Document60 pagesRaychem Technical Handbook 2012 2013Pep VasilevaNo ratings yet

- AS-100 Tower Crane Safety System Installation ManualDocument67 pagesAS-100 Tower Crane Safety System Installation Manualbaraa alkhabbazNo ratings yet

- Manual Multi9 General ElectricDocument84 pagesManual Multi9 General ElectricElio DíazNo ratings yet

- Capacitors in Series:in This Capacitors in Parallel: Resistors in Series: in Series Resistors in Parallel: in ParallelDocument1 pageCapacitors in Series:in This Capacitors in Parallel: Resistors in Series: in Series Resistors in Parallel: in ParallelmazharzulqarnainNo ratings yet

- Panasonic KX NT 346 Ip System Phone BlackDocument24 pagesPanasonic KX NT 346 Ip System Phone BlackTeguh SulistiyonoNo ratings yet

- Blackhawk Pump Manual 2018Document75 pagesBlackhawk Pump Manual 2018Ivan MaltsevNo ratings yet

- TX109LRS ManualDocument1 pageTX109LRS ManualKerwin CastañedaNo ratings yet

- Terex Jaques Jaw Crusher ST-Series-JawBrochureDocument12 pagesTerex Jaques Jaw Crusher ST-Series-JawBrochureCarlos Ediver Arias RestrepoNo ratings yet

- Remove Install Drive Flange at Rear AxleDocument3 pagesRemove Install Drive Flange at Rear AxleGeorgeNo ratings yet

- Catalogue SWRK55.Document10 pagesCatalogue SWRK55.daryonoNo ratings yet

- Toyota QuoteDocument3 pagesToyota Quoteakhil.s .kumarNo ratings yet

- Section 1 Simple Circuits: Practice Problems: SolutionDocument5 pagesSection 1 Simple Circuits: Practice Problems: SolutionGULOED Jama JosopHNo ratings yet

- Instructions For The Removal and Fitment of Wheel CylindersDocument1 pageInstructions For The Removal and Fitment of Wheel CylindersRachel Du PreezNo ratings yet

- MG Gloster - Launch Brochure PDFDocument28 pagesMG Gloster - Launch Brochure PDFsumitNo ratings yet

- BimmerTech F22 - F87 Alpha One Speakers Installation Instructions and User GuideDocument17 pagesBimmerTech F22 - F87 Alpha One Speakers Installation Instructions and User GuideGullwing Motor ServiceNo ratings yet

- (Link by Clamp Type Valves) Models: V400 V450 V500 V650 V700 V350Document2 pages(Link by Clamp Type Valves) Models: V400 V450 V500 V650 V700 V350mbgprsmsNo ratings yet

- Optoma X316 XGA Desktop DLP ProjectorDocument2 pagesOptoma X316 XGA Desktop DLP ProjectorWebAntics.com Online Shopping StoreNo ratings yet

- 56 143 5TC Coupler Brake Installation Service InstructionsDocument4 pages56 143 5TC Coupler Brake Installation Service InstructionsIvan PachecoNo ratings yet

- CDI Troubleshooting Guide - 2012Document125 pagesCDI Troubleshooting Guide - 2012Ron100% (3)

- Knockdown Chair Project PlansDocument13 pagesKnockdown Chair Project Planssirgil2250% (6)

- Analog 4 Wire Video Intercom - Quick Start Guide - V1.1.1Document18 pagesAnalog 4 Wire Video Intercom - Quick Start Guide - V1.1.1Kairos TvNo ratings yet