Professional Documents

Culture Documents

ITP Aluminium Anode Manufacture - Setangga Coal Terminal Project

ITP Aluminium Anode Manufacture - Setangga Coal Terminal Project

Uploaded by

Erlina SihotangOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ITP Aluminium Anode Manufacture - Setangga Coal Terminal Project

ITP Aluminium Anode Manufacture - Setangga Coal Terminal Project

Uploaded by

Erlina SihotangCopyright:

Available Formats

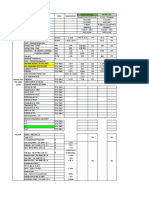

ALUMINIUM ANODE CATHODIC PROTECTION FOR JETTY PILES - SETANGGA COAL TERMINAL

DOCUMENT TITTLE DOCUMENT NO. REV.

INSPECTION AND TEST FOR PRODUCTION

WIK/WRK-STG-001/ITP/2022 0 Page 1-1

CATHODIC PROTECTION AT MANUFACTURE

WITNESSED BY

ACTIVITY DESCRIPTION SCOPE REFERENCE DOCUMENT ACCEPTANCE CRITERIA FREQUENCY / TIMING RECORD FORM

WIKON WIKA REKON

1 Design and Drawing

1.1. Drawing REVIEW WIK-E2-AND-DWG-WRK-01-R1 following the planned design Per Design R A

2 Pre Inspection Meeting − P H

3 Inspection of Aluminium Anode Material Test Spectrometer NACE RP 0492 - 1999 SECTION 3.3 Aluminium Alloy Ingot 2 specimen/batch QR - P - 001 P SW

− Copper : 0.01% Max

− Iron : 0.07% Max

− Silicon : 0.05% Max

− Titanium : 0.01% Max

− Mangan 0.01% Max

− Aluminium : Remainder

Aluminium Alloy Anode GALVALUM III Series

− Zinc : 2 - 4 %

− Indium : 0.01 - 0,02%

− Copper : 0.006% Max

− Iron : 0.12% Max

− Silicon : 0.08 - 0.20%

− Other : 0.02% Max

− Aluminium : Remainder

4 Weight, Dimension, Visual & Crack Inspection −

4.1. Weight in the aluminium alloy anode Test and Measurement NACE RP 0492 - 1999 SECTION 3.3 − Net weight shall be ±3% each type of anode 10% of total qty QR - P - 001 P SW

(procedure WIKON)

An agreed sample of anode shall be weighted, to confirm

− general compliance with the design net weight.

Total supplied net weight shall not be below the nominal net

−

contract weight.

4.2. Dimension Test and Measurement NACE RP 0492 - 1999 SECTION 3.4 − The average dimension of the anode ± 3% of nominal 10% of total qty QR - P - 001 P SW

dimension (procedure WIKON)

4.3. Visual Inspection Visual and Measurement NACE RP 0492 - 1999 SECTION 3.9 Shrinkage depressions shall not exceed 10% of QR - P - 001 P SW

10% of total qty

− the thickness of the anode as measured from the

(procedure WIKON)

uppermost corner to the bottom of the depression.

4.4. Cracks in Cast Anodic Materials Visual and Measurement NACE RP 0492 - 1999 SECTION 3.10 − Longitudinal cracks of width ≤0.5 mm (0.02) in. and length 10% of total qty QR - P - 001 P SW

<20% of the anode length. (procedure WIKON)

− Circumferential/transverse cracks of

width ≤0.5 mm (0.02 in.) and length <50% of the

internal anode diameter.

- depth >50% of the thickness of the anode material is

unacceptable

5 Open Potential Measurement Test and Measurement Refer to NACE RP 0176 2003 and DNV RP B401 - Open Circuit Potential Seawater ≤ -1.05 V (Vs Ag/AgCl) at 1/15 Ton QR - P - 001 P SW

2010 seawater temperature 10° to 30°C (DNV RP B401 2010)

Note : Contractor shall provide the record format of measurement data

ABBREVIATIONS AND DEFINITIONS

A - Client "Approval" required of the applicable activity of procedure

H - For "Hold" Inspection a mandatory gold shall be applied to the production schedule and the test shall be performed with the Client or Client's representative in attendence

W - For "Witness" inspection, the Client or Client's representative requires notification of the inspection timing. However, the inspection is performed as scheduled and if the Client or Client's representative is not present, the

R - In "Review" inspection, Client or Client's representative shall review the appropriate inspection document/certification but does not require a formal notification of inspection timing. The inspection is normally performed as

- If the contractor is not present the vendor can be proceed to the next step

S - "Surveillance" comprises all Client or Client's representative activities performed to verify that goods meet the specified requirements, including audit design review.

P - "Providing" Vendor inspection/Test, the inspection or/end test that perform by vendorad their workshop or designed place

WRK - Setangga Coal

Quality Control

Terminal Project

Record No. : Client :

QR - P - 001 WRK PRODUCTION QUALIFICATION TEST

Item: FOR CATHODIC PROTECTION AT MANUFACTURE

As per drawing

Location : WIKA PPC FACTORY - BOGOR

Drawing No. : WIK-E2-AND-DWG-WRK-01-R1

ITP for Anode Manufacturing Works

DATE INSPECTOR

ITEM JUDGEMENT

COMPLETE WIKON WIKA REKON

Design and Drawings

Pre Inspection Meeting

Inspection of Sacrificial Anode Material

Weight, Dimension, Visual & Crack Inspection

Destruction Test

Potential Measurement Test

REMARKS :

WIKON INSPECTOR : DATE :

WIKA REKON INSPECTOR : DATE :

You might also like

- Aerospace Material Specification: Aluminum Alloy 2024, Plate and SheetDocument8 pagesAerospace Material Specification: Aluminum Alloy 2024, Plate and SheetyouNo ratings yet

- General Configuration On Approval Alerts and Notifications in SAP SRMDocument4 pagesGeneral Configuration On Approval Alerts and Notifications in SAP SRMarunkotaNo ratings yet

- Aggregate Planning Assignment AnswersDocument4 pagesAggregate Planning Assignment AnswersqertusaNo ratings yet

- POWER LAB Manual PDFDocument82 pagesPOWER LAB Manual PDFHamda KhalilNo ratings yet

- TDC - SAE 8620 - Rev-04Document2 pagesTDC - SAE 8620 - Rev-04ramanjotgill.ramanNo ratings yet

- Aerospace Material SpecificationDocument7 pagesAerospace Material SpecificationdaNo ratings yet

- Aerospace Material SpecificationDocument6 pagesAerospace Material SpecificationMohammad LavasaniNo ratings yet

- Pf-Emco#218-63p Rev.bDocument6 pagesPf-Emco#218-63p Rev.bPhung Cam VanNo ratings yet

- TDC - Sad 1040VDocument2 pagesTDC - Sad 1040Vramanjotgill.ramanNo ratings yet

- SAE AMS4011E Aluminum, Foil and Light Gage Sheet 99.45al (1145-0) AnnealedDocument11 pagesSAE AMS4011E Aluminum, Foil and Light Gage Sheet 99.45al (1145-0) AnnealeddaNo ratings yet

- Inconel 625 Tech DataDocument6 pagesInconel 625 Tech Dataraj.clarence7No ratings yet

- Technical Report: Thermocouple Extension & Compensating Cable Thermocouple Extension & Compensating CableDocument3 pagesTechnical Report: Thermocouple Extension & Compensating Cable Thermocouple Extension & Compensating CableIsioma1No ratings yet

- Malingo000000000 Aluminium IngotDocument6 pagesMalingo000000000 Aluminium IngotDanang AfriNo ratings yet

- TDC 35C8Document2 pagesTDC 35C8ramanjotgill.ramanNo ratings yet

- Tests - Mechanical Properties: Material Brand, Source, Tests Etc. Units RequirementDocument6 pagesTests - Mechanical Properties: Material Brand, Source, Tests Etc. Units RequirementNandika MilindaNo ratings yet

- Date.4th October, 2021 FCO No. 1648/2021: FCO - Electro COPPER CATHODE 99.99% Virgin, RUSSIAN ORIGIN - No.AAADocument2 pagesDate.4th October, 2021 FCO No. 1648/2021: FCO - Electro COPPER CATHODE 99.99% Virgin, RUSSIAN ORIGIN - No.AAAFattahNo ratings yet

- Section 1: Identification: Rev Level: Rev DateDocument8 pagesSection 1: Identification: Rev Level: Rev DatesdsdvsdvsdNo ratings yet

- Nickel Alloys: Alloy 825 (UNS N08825)Document1 pageNickel Alloys: Alloy 825 (UNS N08825)joceth3632No ratings yet

- CP & TestingDocument8 pagesCP & TestingAkash SainNo ratings yet

- Material Safety Data Sheet: Aluminium Remelt Ingot: MSDS-NS-01Document6 pagesMaterial Safety Data Sheet: Aluminium Remelt Ingot: MSDS-NS-01Nur Cholis HadiNo ratings yet

- Velosi Integrity & Safety Pakistan Pvt. LTD: Ultrasonic Examination A-Scan ReportDocument1 pageVelosi Integrity & Safety Pakistan Pvt. LTD: Ultrasonic Examination A-Scan ReportAli TahirNo ratings yet

- Satip J 003 01Document9 pagesSatip J 003 01Mirza BaigNo ratings yet

- Sae Ams 4353-2014Document5 pagesSae Ams 4353-2014Hani YilmazNo ratings yet

- Key Facts Typical Wire Analysis: - Bossweld 316LSIDocument1 pageKey Facts Typical Wire Analysis: - Bossweld 316LSIAli TalebiNo ratings yet

- DZR BrassDocument1 pageDZR BrasssmrdojeNo ratings yet

- Material Specification: TitleDocument3 pagesMaterial Specification: Titlevijay waghNo ratings yet

- Tests - Mechanical Properties: Material Brand, Source, Tests Etc. Units RequirementDocument2 pagesTests - Mechanical Properties: Material Brand, Source, Tests Etc. Units RequirementNandika MilindaNo ratings yet

- CHBHCUYFVSDDocument1 pageCHBHCUYFVSDedrNo ratings yet

- Vacuum Deposition Guide: MaterialsDocument28 pagesVacuum Deposition Guide: MaterialsjorgeNo ratings yet

- Inspection Certificate 21.1914: RequiredDocument1 pageInspection Certificate 21.1914: RequiredMichał IlińskiNo ratings yet

- Jis H 5302 Adc12Document1 pageJis H 5302 Adc12Hazem MahmoudNo ratings yet

- 1008 - TDS - Falcon Slag-Vesrion 1.3Document1 page1008 - TDS - Falcon Slag-Vesrion 1.3Sridhara GowdaNo ratings yet

- Hilti TypesDocument1 pageHilti TypesFor AccounNo ratings yet

- 2023 Em12k Uvc401 S22100 024Document1 page2023 Em12k Uvc401 S22100 024hars wisNo ratings yet

- Aerospace Material SpecificationDocument5 pagesAerospace Material SpecificationMohammad LavasaniNo ratings yet

- Charoong Thai Wire & Cable Public Company Limited: CTW - Aluminum RodDocument1 pageCharoong Thai Wire & Cable Public Company Limited: CTW - Aluminum RodAchint KumarNo ratings yet

- Tests - Mechanical Properties: Material Brand, Source, Tests Etc. Units RequirementDocument8 pagesTests - Mechanical Properties: Material Brand, Source, Tests Etc. Units RequirementNandika MilindaNo ratings yet

- En 0011 1312 00 Ed5Document2 pagesEn 0011 1312 00 Ed5cybula.michalNo ratings yet

- LM6 Casting Alloy PDFDocument2 pagesLM6 Casting Alloy PDFSankarNo ratings yet

- Nycolube 127 TDSDocument1 pageNycolube 127 TDSpokleNo ratings yet

- B 350 - B 350M - 01 - Qjm1mc9cmzuwts1sruqDocument5 pagesB 350 - B 350M - 01 - Qjm1mc9cmzuwts1sruqYasiru AkalankaNo ratings yet

- Reduction Gear H - 4151Document1 pageReduction Gear H - 4151Dimitrios MikrosNo ratings yet

- QAP - Screen Box - Rev 00 StampedDocument1 pageQAP - Screen Box - Rev 00 StampedRaj KumarNo ratings yet

- Esab Ok 55 (3.2 MM)Document1 pageEsab Ok 55 (3.2 MM)DHANEESH VELLILAPULLINo ratings yet

- Magnesium Anodes: Sacrificial Anode, Cathodic ProtectionDocument2 pagesMagnesium Anodes: Sacrificial Anode, Cathodic ProtectionJoy Arief JanuarNo ratings yet

- Technical Review: (Minimum Score Required 75%)Document4 pagesTechnical Review: (Minimum Score Required 75%)Deepak HoleNo ratings yet

- Zincalume G550 Steel: Metallic Coated - MC Structural - SDocument1 pageZincalume G550 Steel: Metallic Coated - MC Structural - SEwo50 New0% (1)

- Inconel 600 Technical Data: Type AnalysisDocument3 pagesInconel 600 Technical Data: Type Analysisorangelanaya-1No ratings yet

- A 102 Â " 93 R00 QTEWMI1SRUQDocument4 pagesA 102 Â " 93 R00 QTEWMI1SRUQJoffre ValladaresNo ratings yet

- Anodos MartyDocument2 pagesAnodos MartyEmilsa EsturbanNo ratings yet

- L80 - Continental AlloysDocument2 pagesL80 - Continental Alloystoxa0707No ratings yet

- SATIP-P-104-01 Rev 7 FinalDocument4 pagesSATIP-P-104-01 Rev 7 FinalHatemS.MashaGbehNo ratings yet

- Sa 182 Gr. F6a Cl.1Document1 pageSa 182 Gr. F6a Cl.1Lionell LogeshNo ratings yet

- Si PB MN Fe Cu Mo Ti W Al Ni NB CR V: 2nd Match: CDA 151 3rd Match: CDA 174xx Low Be CuDocument2 pagesSi PB MN Fe Cu Mo Ti W Al Ni NB CR V: 2nd Match: CDA 151 3rd Match: CDA 174xx Low Be CuRahmat FadhilaNo ratings yet

- Annexure 2A - ITP For CS LTCS Welded Fittings To A 234 WPBW A 420WPL6W For Normal NACE IBRDocument3 pagesAnnexure 2A - ITP For CS LTCS Welded Fittings To A 234 WPBW A 420WPL6W For Normal NACE IBRPranav JadhavNo ratings yet

- AMS 5571 J-2012 - Eng.Document6 pagesAMS 5571 J-2012 - Eng.Tetiana100% (1)

- Product Specifications: Specifications For Continuous Cast ProductsDocument4 pagesProduct Specifications: Specifications For Continuous Cast ProductsvejanidbNo ratings yet

- Key Facts Typical Wire Analysis: - Bossweld 71T-1Document1 pageKey Facts Typical Wire Analysis: - Bossweld 71T-1cj elec techNo ratings yet

- Ams 5391 HDocument9 pagesAms 5391 HEhab HarbNo ratings yet

- Full CatalogDocument36 pagesFull Cataloglearsipi061No ratings yet

- OK 55.00 2.5x350mm - LOT - SFV05174Document1 pageOK 55.00 2.5x350mm - LOT - SFV05174DHANEESH VELLILAPULLINo ratings yet

- High Vibration of GA-101DDocument17 pagesHigh Vibration of GA-101DHabibie RahmanNo ratings yet

- KTM 950 Adventure - Super Enduro - Supermoto, 990 Adventure - Super DukeDocument9 pagesKTM 950 Adventure - Super Enduro - Supermoto, 990 Adventure - Super DukeCamilo VillamizarNo ratings yet

- Artificial Trees For Atmospheric Carbon Capture-A ReviewDocument7 pagesArtificial Trees For Atmospheric Carbon Capture-A ReviewVenkatNo ratings yet

- LOCG GEN Guideline 001 Rev 0 LoadoutDocument20 pagesLOCG GEN Guideline 001 Rev 0 Loadoutpssrijit100% (3)

- THD Analysis of Matrix Converter Fed LoadDocument5 pagesTHD Analysis of Matrix Converter Fed Loadjoseph86177No ratings yet

- Matlab Scripts For Hilbert TransformDocument31 pagesMatlab Scripts For Hilbert TransformMarcos ManzanoNo ratings yet

- Quick Release Couplings: HT-Series ISO16028 Flushface InterchangeDocument3 pagesQuick Release Couplings: HT-Series ISO16028 Flushface InterchangerweidlingNo ratings yet

- Mirage-III-Flight Model Identification - GPDocument17 pagesMirage-III-Flight Model Identification - GPStorebror100% (1)

- Lubrizol 1038 - Auto Gear Oil - TdsDocument3 pagesLubrizol 1038 - Auto Gear Oil - TdsPranit More Arabian Petroleum LimitedNo ratings yet

- Catalogo TANDocument20 pagesCatalogo TANCesar MessiasNo ratings yet

- Prime Cut MsdsDocument2 pagesPrime Cut MsdsMarvin BarahonaNo ratings yet

- Service Manual-Amt Transmission Chery QQDocument46 pagesService Manual-Amt Transmission Chery QQRoberto Bruno70% (10)

- Firelite LWDocument2 pagesFirelite LWgermanddNo ratings yet

- Properties of Waves WorksheetDocument3 pagesProperties of Waves WorksheetKerry-Ann WilliamsNo ratings yet

- DIPR PaliDocument19 pagesDIPR Paliap7singhNo ratings yet

- The Glorious Glasgow Haskell Compilation System User's Guide, Version 7.6.3Document313 pagesThe Glorious Glasgow Haskell Compilation System User's Guide, Version 7.6.3dmhftchshNo ratings yet

- For Distributor Customer Enrollments: Following These 4 Easy Steps Will Register You For Shell Lubecoach Academy!Document2 pagesFor Distributor Customer Enrollments: Following These 4 Easy Steps Will Register You For Shell Lubecoach Academy!Pablo Luis Ojeda PaezNo ratings yet

- Installation, Operation and Maintenance Manual CD, HL & NC Ranges Dri-Prime PumpsDocument44 pagesInstallation, Operation and Maintenance Manual CD, HL & NC Ranges Dri-Prime PumpsMohamed Badian TraoreNo ratings yet

- Section 33 - Work Programme Specification (Conventional)Document16 pagesSection 33 - Work Programme Specification (Conventional)ag shafiee .adzmey100% (1)

- 06 Scba Pass FdnyDocument96 pages06 Scba Pass FdnyHualy DelgadoNo ratings yet

- Dental WaxfinalDocument80 pagesDental WaxfinalSimoun FeirNo ratings yet

- Navis Works Training in HyderabadDocument3 pagesNavis Works Training in HyderabadFuturegen AmeerpetNo ratings yet

- EE-210. Signals and Systems Homework 4: 5 AprilDocument9 pagesEE-210. Signals and Systems Homework 4: 5 AprilMuhammad AsifNo ratings yet

- UntitledDocument17 pagesUntitledShüßhû KätârëNo ratings yet

- Python Fundamentals IIDocument4 pagesPython Fundamentals IIاشفاق احمدNo ratings yet

- Dokaflex CanadaDocument68 pagesDokaflex CanadarafiNo ratings yet

- Database Management Systems LabDocument57 pagesDatabase Management Systems LabChandra Sekhar D100% (1)