Professional Documents

Culture Documents

25.00mm Class B Mix Design Submittal 2022 1622 - v13

Uploaded by

Don PopinoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

25.00mm Class B Mix Design Submittal 2022 1622 - v13

Uploaded by

Don PopinoCopyright:

Available Formats

U.S.

Department of Transportation

Federal Highway Administration

Federal Lands Highway

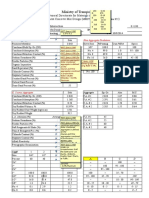

WORKSHEET FOR A MARSHALL MIX DESIGN

AASHTO T 245

Project: Date: 10/12/2022

Contractor: East End Asphalt Class & Grading of mixture: Class B - 25.0mm

Asphalt supplier: Petroleum Products Supply (San Juan, PR) Grade of asphalt: PG 64-22

Sources for: Aggregates: Heavy Materials Mineral filler: NA

Testing laboratory name: SME Phone: 734-260-0430

Testing performed by: Ean White (SME)

Testing reported by: Kyle Anderson (SME)/Jason Schwartzenberger, P.E. (SME)

English Metric

SUMMARY OF THE PROPOSED JOB-MIX-FORMULA

1. Percent asphalt by mass of total mix1, (Pb) 5.65 9. Specific gravity of binder (Gb) 1.019

2. Air voids (Va) 4.0 10. Specific gravity of mineral filler

15.3 11. Dust-to-Binder ratio (DP) 0.8

3. Voids in mineral aggregate (VMA)

4. Maximum specific gravity (Gmm ) 2.482 12. Moisture susceptibility test results: 2

5. Recommended plant mixing temperature, °F 307 a. Dry strength,

(Attach Temperature Viscosity Curve) b. Wet strength,

6. Effective specific gravity of aggregate (Gse) 2.699

2031 c. Index of retained strength, %

7. Marshall stability, lbf

8. Marshall flow, 0.01 inches 14.30

Gradation Designation: C Is RAP included in Mix Design? Yes No

GRADATION TARGET VALUES AND

ALLOWABLE DEVIATIONS SPECIFIC GRAVITY AND ABSORPTION

Job Mix Target Value Allowable Fine Coarse

Combined

Sieve Sizes Formula Specification Deviation4 Aggregate Aggregate

Aggregate

Target Value 3 Range % % (AASHTO T 84) (AASHTO T 85)

1½ inch 100.0 100

1 inch 98.3 90-100 — Bulk SG (Gsb ) 2.650 2.660 2.655

3/4 inch 89.5 90 —

1/2 inch 79.9 5 Bulk SSD SG 2.685 2.693 2.689

3/8 inch 69.7 6

No. 4 47.8 7 Apparent SG (Gsb) 2.750 2.756 2.753

No. 8 31.9 19-45 5

No. 30 13.6 4 Absorption 1.40 % 1.35 % 1.37 %

No. 50 9.6 3

No. 200 4.9 1-7 2

1

Establish asphalt cement content (percent by mass of mix) to the nearest 0.01 percent.

2

See contract for moisture susceptibility test method: AASTHO T 165/T 167 or AASTHO T 283.

3

Establish target values to the nearest 0.1 percent as a part of the job mix formula.

4

Allowable deviations plus or minus from established target values.

Form FHWA 1622 (Rev 03-11) Page 1 of 5

Note: In production

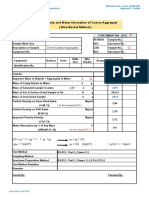

WORKSHEET FOR A MARSHALL MIX DESIGN (Continued) Dust - 3.5%

Hotbin #1 - 31.0%

Material Stockpile Description Blend Ratio

Stockpile

A Hot Bin #1 34.5 %

B Hot Bin #2 10.0 %

C Hot Bin #3 10.0 %

D Hot Bin #4 10.5 %

E Hot Bin #5 35.0 %

Total 100 %

Stockpile Gradation

Stockpile Stockpile Stockpile Stockpile Stockpile Blended Job Mix

Sieve A B C D E Stockpile Formula Specification

Size 34.5 % 10.0 % 10.0 % 10.5 % 35.0 % Gradation Target Values Limits

1½ inch 100.0 100.0 100.0 100.0 100.0 100.0 100.0 100

1 inch 100.0 100.0 100.0 100.0 95.0 98.3 98.3 90-100

3/4 inch 100.0 100.0 100.0 100.0 70.0 89.5 89.5 90

1/2 inch 100.0 100.0 100.0 82.0 48.0 79.9 79.9

3/8 inch 100.0 50.0 99.0 22.0 37.0 64.7 69.7

No. 4 100.0 0.0 6.0 0.0 22.0 42.8 47.8

No. 8 77.0 0.0 0.0 0.0 13.0 31.1 31.9 19-45

No. 30 27.0 0.0 0.0 0.0 5.0 11.1 13.6

No. 50 9.6 0.0 0.0 0.0 4.0 4.7 9.6

No. 200 4.9 0.0 0.0 0.0 2.9 2.7 4.9 1-7

Aggregate Properties

Property Result Specification Property Result Specification

LA Abrasion, % - Grading C 19.0 35 Max Fractured Faces, % - 1 Face 100 90 Min

AASHTO T 96 ASTM D 5821

Sand Equivalent

Sodium Sulfate Soundness, % 2. 12 Max 56 45 Min

AASHTO T 176, Alt method

AASHTO T 104

#2, reference method

Durability index (Coarse)

Other:

AASHTO T 210

Durability index (Fine)

Other:

AASHTO T 210

Form FHWA 1622 (Rev 03-11) Page 2 of 5

WORKSHEET FOR A MARSHALL MIX DESIGN (Continued)

Trial Number 1 2 3

% Asphalt by mass of total mix, (Pb) 4.70 5.20 5.70

Effective Binder Content (Pbe) 4.11 4.61 5.11

Specimen height, in

Marshall Stability, lbf 2299 2249 2431 2200 2250 2132 2009 1825 2129

Marshall Flow, 0.01 inche 10.00 10.00 11.00 12.00 12.00 13.00 14.00 15.00 15.00

Bulk specific gravity, (Gmb) 2.352 2.350 2.364 2.370 2.375 2.369 2.386 2.372 2.379

Bulk unit mass, lbs/yd³ 146.4 146.3 147.1 147.5 147.8 147.5 148.5 147.6 148.1

Max. specific gravity, (Gmm ) 2.516 2.495 2.478

Dust-to-Binder ratio, (DP) 1.2 1.1 1.0

% Air voids, (Va ) 6.5 6.6 6.0 5.0 4.8 5.1 3.7 4.3 4.0

% Voids in mineral aggregate, (VMA) 15.6 15.7 15.2 15.4 15.2 15.4 15.3 15.8 15.5

Average Marshall Stability value, lbf 2326 2194 1988

Average Marshall Flow value, 0.01 inches 10.33 12.33 14.67

Average % Air voids, (Va ) 6.4 5.0 4.0

Average % Voids in mineral aggregate, (VMA) 15.5 15.3 15.5

Trial Number 4 5 6

% Asphalt by mass of total mix, (Pb) 6.20

Effective Binder Content (Pbe) 5.62

Specimen height, in

Marshall Stability, lbf 1825 1805 1917

Marshall Flow, 0.01 inche 15.50 15.50 16.00

Bulk specific gravity, (Gmb) 2.399 2.416 2.412

Bulk unit mass, lbs/yd³ 149.3 150.4 150.1

Max. specific gravity, (Gmm ) 2.465

Dust-to-Binder ratio, (DP) 0.9

% Air voids, (Va ) 2.7 2.0 2.2

% Voids in mineral aggregate, (VMA) 15.3 14.7 14.8

Average Marshall Stability value, lbf 1849

Average Marshall Flow value, 0.01 inches 15.67

Average % Air voids, (Va ) 2.3

Average Voids in mineral aggregate, (VMA) 14.9

Test Results for Each of the Individual Moisture Susceptibility Test Specimens

Percent asphalt binder: AASHTO T 165/T 167 AASHTO T 283

Specimen Dia: 6 inch 4 inch

Antistrip, type, amount:

Freeze cycle: Yes No

Sample I.D. Average

Height Dry

Wet

Bulk Specific Dry

Gravity Wet

Air Dry

Voids Wet

Dry

Strength Wet

Retained Strength, %

Form FHWA 1622 (03-11) Page 3 of 5

WORKSHEET FOR A HVEEM MIX DESIGN (Continued)

graph it

Design Curves for Proposed Job Mix Formula (JMF)

AIR VOIDS (Va) MARSHALL FLOW

8.0 16.0

7.0 15.0

6.0 14.0

% Air voids (Va )

0.01 inches

5.0 13.0

4.0 12.0

3.0 11.0

2.0 10.0

1.0 9.0

4.00 4.50 5.00 5.50 6.00 6.50 7.00 7.50 4.00 4.50 5.00 5.50 6.00 6.50 7.00 7.50

% Asphalt binder (Pb) % Asphalt binder (Pb)

MARSHALL STABILITY VMA

2,400.0 16.0

2,300.0 15.8

2,200.0

Voids in mineral aggregate

15.6

2,100.0 15.4

lbf

2,000.0 15.2

1,900.0 15.0

1,800.0 14.8

1,700.0 14.6

4.00 4.50 5.00 5.50 6.00 6.50 7.00 7.50 4.00 4.50 5.00 5.50 6.00 6.50 7.00 7.50

% Asphalt binder (Pb) % Asphalt binder (Pb)

Form FHWA 1622 (Rev 03-11) Page 4 of 5

You might also like

- Marshall Test WorksheetDocument5 pagesMarshall Test WorksheetMoslem AghapourNo ratings yet

- Worksheet For Superpave Asphalt Concrete Mix Design Aashto R 35Document4 pagesWorksheet For Superpave Asphalt Concrete Mix Design Aashto R 35deenhanifah695No ratings yet

- Sample Information: Asphalt Test Certification ReportDocument5 pagesSample Information: Asphalt Test Certification ReportweamNo ratings yet

- DBM Mix DesignDocument22 pagesDBM Mix DesignImran Khan56% (9)

- Quality Harian HotmixDocument8 pagesQuality Harian HotmixDady RiadiNo ratings yet

- For GSB GR V & WMMDocument16 pagesFor GSB GR V & WMMSasanka SekharNo ratings yet

- Test Report: Consulting Engineers Group LTDDocument9 pagesTest Report: Consulting Engineers Group LTDImran Khan100% (1)

- Report For Soil Sampling TestDocument92 pagesReport For Soil Sampling TestArham SheikhNo ratings yet

- Wakaaladda Horumarinta Wadooyinka: Free Zone ProjectDocument7 pagesWakaaladda Horumarinta Wadooyinka: Free Zone ProjectsacsewNo ratings yet

- Mix Design of Semi Dense Bituminous ConcreteDocument18 pagesMix Design of Semi Dense Bituminous ConcreteRahul GoyalNo ratings yet

- Elongation Test Bs. 812 Part (1) : Client: Ministry of Public Work and HousingDocument5 pagesElongation Test Bs. 812 Part (1) : Client: Ministry of Public Work and Housingm8877223No ratings yet

- DBM Gupta ConstructionDocument24 pagesDBM Gupta Constructionimran khanNo ratings yet

- Pembangunan Jalan Tol Semarang-Batang SEKSI4&5: Aashto T 27 - 82 / Astm C. 33Document40 pagesPembangunan Jalan Tol Semarang-Batang SEKSI4&5: Aashto T 27 - 82 / Astm C. 33Budhi KurniawanNo ratings yet

- JMF CTB Rev1Document6 pagesJMF CTB Rev1Central NetNo ratings yet

- Mastic-Mix DesignDocument10 pagesMastic-Mix DesignVaasu KotyadaNo ratings yet

- R.E Wall Test SummaryDocument1 pageR.E Wall Test SummaryBiplab dattaNo ratings yet

- TM 004Document11 pagesTM 004yassir dafallaNo ratings yet

- A 5 EE 437 Evaluation of Hydrated Lime EDocument8 pagesA 5 EE 437 Evaluation of Hydrated Lime Emohanadakkila1991No ratings yet

- Mix Design of DBM Grading-I: Project NameDocument34 pagesMix Design of DBM Grading-I: Project NameStupidity TalksNo ratings yet

- Afco Material Teating Laboratory: Extraction and Gradation of Paving MixtureDocument4 pagesAfco Material Teating Laboratory: Extraction and Gradation of Paving MixtureEhsanullah HarooniNo ratings yet

- Mix Design ACW14 JKR Specification 1998 (2020)Document11 pagesMix Design ACW14 JKR Specification 1998 (2020)محمد رفيق عبدالله100% (1)

- SDBC Design CalculationsDocument30 pagesSDBC Design Calculationsakst1976200095% (19)

- HAIL-BBC-Design Class - C (23.07.2019)Document127 pagesHAIL-BBC-Design Class - C (23.07.2019)mido_20067581No ratings yet

- Analysis of Compacted Paving Mixture: Mixture or Trial NumberDocument1 pageAnalysis of Compacted Paving Mixture: Mixture or Trial NumberOloyNo ratings yet

- TM 002Document11 pagesTM 002yassir dafallaNo ratings yet

- Bahla-BBC - 18.01.24Document3 pagesBahla-BBC - 18.01.24Okla OkiloaNo ratings yet

- Asphalt Mix (Cover X) PDFDocument11 pagesAsphalt Mix (Cover X) PDFSurendren SurenkkNo ratings yet

- The Effect of Warm Mix Asphalt Additive (Sasobit®) On Determination of Optimum Bitumen ContentDocument7 pagesThe Effect of Warm Mix Asphalt Additive (Sasobit®) On Determination of Optimum Bitumen ContentGolam MasudNo ratings yet

- Application of Fly Ash To Concrete Paving Block: Karasawa, A., Suda, S., Naito, H. and Fujiwara, HDocument9 pagesApplication of Fly Ash To Concrete Paving Block: Karasawa, A., Suda, S., Naito, H. and Fujiwara, HDarshan mNo ratings yet

- Costing FlowconDocument1 pageCosting Flowconquality.rudrapurNo ratings yet

- Marshal Mix Design BATCHING, MIXING AND COMPACTION 16th January 2015Document11 pagesMarshal Mix Design BATCHING, MIXING AND COMPACTION 16th January 2015Bernard Kitosi100% (1)

- Draft Letter Regarding Source Approval For Bituminous Mecadam grade-II With BPCL - VG - 30 BitumenDocument3 pagesDraft Letter Regarding Source Approval For Bituminous Mecadam grade-II With BPCL - VG - 30 BitumenAmol Jadhav100% (1)

- Group 2 Agg Density - DataDocument4 pagesGroup 2 Agg Density - DataHind AwadNo ratings yet

- TM 003Document12 pagesTM 003yassir dafallaNo ratings yet

- 9.marshall Trial Compaction Ac WC25092020Document20 pages9.marshall Trial Compaction Ac WC25092020Ramdan Pramedis SetyaNo ratings yet

- DION 6631 Series TDSDocument3 pagesDION 6631 Series TDSEldiyar AzamatovNo ratings yet

- Afco Material Teating Laboratory: Extraction and Gradation of Paving MixtureDocument4 pagesAfco Material Teating Laboratory: Extraction and Gradation of Paving MixtureEhsanullah HarooniNo ratings yet

- Characteritics of Hot Mix Asphalt With Oily-Sludge-Modified Buton Rock Asphalt Madi HermadiDocument5 pagesCharacteritics of Hot Mix Asphalt With Oily-Sludge-Modified Buton Rock Asphalt Madi HermadiMadi HermadiNo ratings yet

- BWC B SampleDocument6 pagesBWC B Sampleمختبر الحرمينNo ratings yet

- QMS For Flexible Pavements - BLR PDFDocument46 pagesQMS For Flexible Pavements - BLR PDFniranjanchouNo ratings yet

- Laboratory Test Report: MIX DESIGN of M20 CONCRETE (Pakur Variety)Document8 pagesLaboratory Test Report: MIX DESIGN of M20 CONCRETE (Pakur Variety)SubhadipNo ratings yet

- Stirling: Buwekula Jinja BpitDocument2 pagesStirling: Buwekula Jinja BpitWilber Turyasiima100% (1)

- Soil Test Report: Materials Testing LaboratoryDocument6 pagesSoil Test Report: Materials Testing LaboratoryVero YonduaiNo ratings yet

- Metsaboard Prime FBB Eb en IsoDocument1 pageMetsaboard Prime FBB Eb en IsoFrancisco Vidal igamoNo ratings yet

- Bituminous Mix DesignDocument62 pagesBituminous Mix DesignShaim RehanNo ratings yet

- ProctorDocument1 pageProctorAdnan YousafNo ratings yet

- Labratory TESTING FORMSDocument71 pagesLabratory TESTING FORMSMesfin Derbew100% (1)

- Afco Material Teating Laboratory: Extraction and Gradation of Paving MixtureDocument4 pagesAfco Material Teating Laboratory: Extraction and Gradation of Paving MixtureEhsanullah HarooniNo ratings yet

- METSABOARDDocument1 pageMETSABOARDAlex GonzalezNo ratings yet

- BREN DBM Grade-IIDocument12 pagesBREN DBM Grade-IIJoydeep NeogiNo ratings yet

- Zain Ali Zain L1F17BSCE0003 Pavement and Foundation Engineering Lab Experiment # 03Document5 pagesZain Ali Zain L1F17BSCE0003 Pavement and Foundation Engineering Lab Experiment # 03zain aliNo ratings yet

- TABEL ANSAR Kelompok 13Document51 pagesTABEL ANSAR Kelompok 13Muhammad Dewangga RamadanNo ratings yet

- DMF Ac WCDocument14 pagesDMF Ac WCIlman HidayatNo ratings yet

- Metsaboard Pro FSB Cup en IsoDocument1 pageMetsaboard Pro FSB Cup en IsooleoproteusNo ratings yet

- Test 2Document10 pagesTest 2Jayasurya GottapuNo ratings yet

- Tumpu 2020 IOP Conf. Ser. - Earth Environ. Sci. 419 012029Document8 pagesTumpu 2020 IOP Conf. Ser. - Earth Environ. Sci. 419 012029Sahrul MahmudNo ratings yet

- Draft TQ LetterDocument6 pagesDraft TQ LetterMotaz AbdallahNo ratings yet

- Mix Design FormsDocument13 pagesMix Design FormsTk SubhashNo ratings yet

- C.B.R CombinedDocument9 pagesC.B.R Combinedusman ali usman aliNo ratings yet

- FRC - PavementsDocument39 pagesFRC - PavementsDon PopinoNo ratings yet

- 7 Key Benefit's of Macro Fiber ConcreteDocument2 pages7 Key Benefit's of Macro Fiber ConcreteDon PopinoNo ratings yet

- JSIR FibrepaperDocument6 pagesJSIR FibrepaperDon PopinoNo ratings yet

- PDFDocument176 pagesPDFnaba1577No ratings yet

- Indigenous Creative Crafts L2Document29 pagesIndigenous Creative Crafts L2MariaClaretteJoyMaramag100% (1)

- Kingtex UH8000 User Manual PDFDocument21 pagesKingtex UH8000 User Manual PDFAlexNo ratings yet

- 27 - Hofmann - Slew Bearings Brochure - A4Document2 pages27 - Hofmann - Slew Bearings Brochure - A4Jorge VillalobosNo ratings yet

- Artigo Cenibra Lodo Biológico 02 - 2021Document10 pagesArtigo Cenibra Lodo Biológico 02 - 2021Marcelo SilvaNo ratings yet

- Types of Joints in Rigid PavementDocument14 pagesTypes of Joints in Rigid PavementNIDHI JARIWALANo ratings yet

- Jis A5523-2021Document5 pagesJis A5523-2021benedick barquinNo ratings yet

- What Is Screw Different Types of Screw Explained in Detail Notes PDFDocument16 pagesWhat Is Screw Different Types of Screw Explained in Detail Notes PDFPankaj ShahNo ratings yet

- POWER System Guide-CARBOLINEDocument8 pagesPOWER System Guide-CARBOLINESurung P. Kreison (CARBOLINE)No ratings yet

- Asme Marking-And-Mechanical-Properties-Of-Steel-FastenersDocument3 pagesAsme Marking-And-Mechanical-Properties-Of-Steel-Fastenersjyoti prakash singhNo ratings yet

- Radiographic Testing Report: Aries Marine Client Class / TpiDocument1 pageRadiographic Testing Report: Aries Marine Client Class / TpiKyNo ratings yet

- One Felco Wh4 Fdas Osm - RemovedDocument3 pagesOne Felco Wh4 Fdas Osm - Removedjezer busbusNo ratings yet

- Exercise #1 IE 213 (Industrial Materials & Processes)Document4 pagesExercise #1 IE 213 (Industrial Materials & Processes)Earl Mathew DangcalanNo ratings yet

- ABB Wire Termination Catalogue EN CANDocument254 pagesABB Wire Termination Catalogue EN CANAlvinNo ratings yet

- Cold Clean-Out Block: PurposeDocument2 pagesCold Clean-Out Block: PurposeAlson LeeNo ratings yet

- Value Analysis and Value EngineeringDocument50 pagesValue Analysis and Value EngineeringGautam BeingHuman AilaniNo ratings yet

- Sika RaintiteDocument3 pagesSika RaintiteHoneyNo ratings yet

- GFRPDocument15 pagesGFRP4si21cv008No ratings yet

- Fastener Spacing and Margin DataDocument13 pagesFastener Spacing and Margin DataLONG VUNo ratings yet

- Concept of Phantom Bills and It Costing in Discrete ManufacturingDocument27 pagesConcept of Phantom Bills and It Costing in Discrete Manufacturingsambashiva01No ratings yet

- Astm B265Document8 pagesAstm B265Đào Trung NguyênNo ratings yet

- 4mitsubishi DB-130EDocument25 pages4mitsubishi DB-130EDiego De La FuenteNo ratings yet

- Anchor Allied Factory - UAEDocument28 pagesAnchor Allied Factory - UAEnunnaraoNo ratings yet

- Thermal Insulation For Hot-Temperature Service: Functional SpecificationDocument69 pagesThermal Insulation For Hot-Temperature Service: Functional SpecificationAshraf AmmarNo ratings yet

- GlassvenDocument8 pagesGlassvenAloo KennedyNo ratings yet

- Machining and Machine Tools Lab ManualDocument33 pagesMachining and Machine Tools Lab ManualMail Bot100% (1)

- Liner-Roof - Brochure - Download KalzipDocument8 pagesLiner-Roof - Brochure - Download KalzipSegun StephenNo ratings yet

- PHD Thesis On Metal Matrix CompositesDocument8 pagesPHD Thesis On Metal Matrix Compositesdwr11wf4100% (2)

- Sef Fence and Guard HouseDocument6 pagesSef Fence and Guard HouseLovely CamposanoNo ratings yet

- 02Document1 page02Sindy JimenezNo ratings yet

- EPAL TRW EPAL2 2edition Section2 Part2 GBDocument45 pagesEPAL TRW EPAL2 2edition Section2 Part2 GBGabriele AsnaghiNo ratings yet