Professional Documents

Culture Documents

Aluminum Selecti TTQVG

Uploaded by

a.kamyabiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aluminum Selecti TTQVG

Uploaded by

a.kamyabiCopyright:

Available Formats

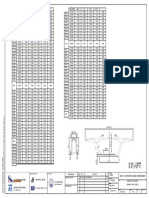

Pure Aluminum -

METAL GROUPS Aluminum - Copper Aluminum - Magnesium AL-Mg2Si AL - Zinc AL - Castings METAL GROUPS

Aluminum Manganese

1100, 1060, 5086, 511.0, 512.0 6061,6005 7005, 7021 413.0, 443.0 319.0, 333.0

BASE FILLER 2014, 2036 2219 3003, 3004, 5005, 5050 5083, 513.0, 514.0

5454

6063,6070 7039, 7046 444.0, 356.0 354.0, 355.0 FILLER BASE

1070, 1080,

METAL METAL 1350 Alclad 3003 Alclad 3004 5052, 5652

5456, 5383

535.0 6151,6201 7146 A356.0, 357.0

C355.0, 380.0 METAL METAL

5154, 5254 6351,6951,6082 710.0, 711.0 359.0

WELD METAL WELD METAL

PROPERTIES PROPERTIES

319.0, 333.0 2319 B A A A A A A A B A A A A A A A B A A A A A A A 2319 319.0, 333.0

354.0, 355.0 4043/4943** B A A A A A C C C B C A A B C C C B C A A B C B BA A A A C B B A A A A C AA A A A A D B B A A A A C B B A A A A C B B A A A A C 4043/4943** 354.0, 355.0

C355.0, 380.0 4145 A A B A A A D A B C B A A A D A B C B A A A D A A B A A A D A A B A A A D A A B A A A D A A B A A A D A A B A A A D A C B B A A A D 4145 C355.0, 380.0

413.0, 443.0 4043/4943** A A A A A A C B B A A A A B C B B A A A A B C A A A A A A D A A A A A A D A B A A A A D A B A A A A C A D B A A A C A D A A A A C C 4043/4943** 413.0, 443.0

4145 A A B B A D A A B A A A D A A B A A A D A A B B A D A C B B A D A C B B A B C D 4145

444.0, 356.0 A356.0 A A A A A

444.0, 356.0

A C A A356.0

A356.0, 357.0 A357.0 A A A A A A C B A357.0 A356.0, 357.0

359.0 5356 B A B B A A A A A A B 5356 359.0

4043/4943** A DC A A D B BA A A C B BA A A C A DC A A D A D C B A D BD C B A D A DC B A D B D C BA D 4043/4943**

7005, 7021 4145 A A B A A D A A B A A D 4145 7005, 7021

7039, 7046 5183 B A B A A B B A B A A B B A B A A B A A B A A B A A B A A B A A B A A B A A B A A B A A B A A B A A B A A C B 5183 7039, 7046

5356 B BA A A A B BA A A A B B A A A A A B A A A A A BA A A A A B A A A A A B A A A A A B A A A A A B A A A C A 5356

7146 5554 B C C A A A A B B C A A A A B B C A A A B B C A A A A B B C A A A A B B C A A A A C B 5554 7146

710.0, 711.0 5556 B A B A A B B A B A A B B A B A A B A A B A A B A A B A A B A A B A A B A A B A A B A A B A A B A A B A A C B 5556 710.0, 711.0

5654 C C A A B B B C A A A B BC A A A B BC A A A B BC A A A A B C A A A C B 5654

4043** A D C A A C B BA A A C B B A A A C A D C A A C A D C A A C A D C A A D AD B A A B D 4043**

6061,6005

4145

4943**

A

A

C

C

D B A

C A A

D A A B A A

C

D A A B A A D A C

A C

D B A

C A A

D BC

C A C

D

C

B

A

A

A

D

C A C C A A D AC B A A A D

4145

4943** 6061,6005 Filler Metal Selection for Aluminum Welding

6063,6070 5183 B A B A B B A B A B BA B A B B A B C B B A A B A A B B A B C A B B A B C A B BA A C A B 5183 6063,6070

6151,6201 5356

5554

B B A A A B B A A A B B A A A B

C

B

C

A

A

C A

B A B

A

B

A

B

B

C

A

A

A

A

A

A

A

B

B

C

B

C

A

A

C

B

A

A

A

B

B

C

B

C

A

A

C A

A A A

D

B

BB

CC

A

A

C A A

B B A C B

5356

5554 6151,6201 This chart is a tool that is designed to help you select the most

6351,6951,6082 5556 B A B A B B A B A B BA B A B B A B C B B A A B A A B B A B C A B B A B C A B BA A C A B 5556 6351,6951,6082 appropriate filler metal, taking into consideration base metal, the

5654 C C A B A B C A A B B C C A B A B C C A B B B CC A B B B 5654

application, and the desired weld metal properties.

5183 B A B B A B B A B A A B B A B B A B AA BB A B A A B B A B A A B B A B A A B B A B 5183

5454

5356

5554

B

C

B

C

A

A

B A

A A A

A

B

B

C

B

C

A

A

B A

A A A

A

B

B

C

B

C

A

A

B A

A A A

A

B

AB

CC

A B

AA A A

A A

B

A

B

B

C

A

A

B

A

A

A

A

B

A

B

B

C

A B

A A

A

A

A

B

A

B

B

C

A

A

B

A A

A

A

A

B

5356

5554 5454

How to use the Chart

5556

5654

B A B B A B B A B B A B B A B B A B AA

BC

BB

AB

A

B

B

B

A A B B A B A A B B A B A A B B A B 5556

5654

1. Determine which of the weld metal properties are most important for your

B C A A B B B C A B B B

511.0, 512.0 5183 B A B B A B B A B B A B B A B B A B AA BB B B A A B A A B A A B B B B 5183 511.0, 512.0 application. (Table located on far left)

513.0, 514.0 5356

5554

B

C

B

C

A

A

B

A

A

A

A

B

B

C

B

C

A

A

B

A

A

A

A

B

B

C

B

C

A

A

B

A

A

A

A

B

AB

CC

A B

A A

A

B

A

B

A

B

B

C

A

A

A

A

A

A

A

B

A

B

B

C

A B

A A

A

B

A

B

5356

5554 513.0, 514.0 2. Locate the base metal to be welded in the blue left hand column and in the

535.0 5556 B A B B A B B A B B A B B A B B A B AA B B B B A A B A A B A A B B A B 5556 535.0 blue row across the top of the chart.

5154, 5254 5654 C C A A B B C C A A B B C C A A B B BC A A A B B C A A B B B C A A A B 5654 5154, 5254

5183 A A B A A B A A B A A B A A B A A B AA BA A B A * B A A B 5183

3. Locate the white box where the base metal row and column intersect.

5086, 5356 A B A A A A A B A A A A A B A A A A AB AA A A A * A A A A 5356 5086, 4. Examine the data in the white box and select the row that provides the best

5083, 5554 CC AA A B 5554 5083,

5556 A A B A A B A A B A A B A A BA A B AA BA A B A * BA A B 5556 match for your application based on the weld metal properties. (There may

5456, 5383 5654 BC A B A B 5654 5456, 5383

be more than one filler metal that is acceptable.)

4043/4943** A C C A A D A C C A A D A C C A A D A C CB A D 4043/4943**

5183 B A B A B B A B A B B A B A B AA BA A B 5183 Example: 5. Once you identify the row that gives you the properties you need, follow that

5005, 5050 5356 B BA A A B B A A A B B A A A AB AA A A 5356 5005, 5050

5052, 5652 5554 CC AA A A B 5554 5052, 5652 Welding 5454 base material that will be used as a row to the left or right until you come to a gray box. The filler metal located

5556 B A B A B B A B A B BA B A B AA BA A B 5556 support bracket for an industrial heater – This in that row in the gray box is the most suitable match.

5654 BC AB A B 5654

1100 D D A A A A C C A A A A C 1100

weldment will be subjected to sustained elevated 6. Economic Considerations:

4043/4943** A C C A A D A C C A A D A D D A A D 4043/4943** temperature of 250 to 300°F (121 to 149°C). If there is more than one filler metal that meets the design criteria

4145 B C D B A D B C D B A D 4145 3004,

3004 5183 C A B B B C A B C A B B A C C A B 5183 requirements, choose the most economical product. More than 85% of all

Alclad 3004 5356 C B B B A C B B C A A B B B C A A 5356 Alclad 3004 1. As the welded component is operating at aluminum filler metal that is used is 5356 or 4043. These two products are

5554 C C A B A A B 5554

5556 C A B B B C B C A B B A C C A B 5556 temperature above 150°F (66°C). easily acquired and, because of their production volume the cost of these

3003, 1100

4043/4943**

B

A

B

A

A A A A

B A A

A

D B A AA A D BA A A A

B A A A A

D A A B A A

A 1100

D 4043/4943**

3003, Elevated TEMPERATURE is the most products is generally less than others.

Alclad 3003 4145 A A C B A D A A BA A D A A B A A D A A C B A D 4145 Alclad 3003 important weld metal property.

2319 B A A A A A A A A A A A A A A A 2319

2219 4043/4943** B BA A A D B C BC A B D B C B C A B D 4043/4943** 2219 2. Left hand column 5454 (fifth from top), and top 5454

4145 A A B A A D A BCB A A D A BC B A A D 4145 row 5454 (fifth from right).

2319 C A A A A A A A 2319

2014, 2036 4043/4943** B BA A A D B CBC A B D 4043/4943** 2014, 2036 *5XXX Series Strength Ratings 3. See insert picture of intersecting row and column

4145 A A B A A D A BCB A A D 4145

(On Right). 5454

1100, 1060, 1070, 1100 B BA A A B A 1100 1100,1060,1070, Base Metal Filler Metal Strength Rating

1188 C A A A A A 1188 5356 C 4. There is only one row that has a rating for

1080, 1350 4043/4943** A AB A A D 4043/4943** 1080,1350 5086 5183 B elevated temperature.

5556 A 5. For this particular application we only have one

5356

5083 5183 B filler metal that is suitable for this application,

5556 A and that is filler metal 5554. All the other filler

5356 metals within the box have a blank rating for

5456, 5383 5183 5183 A A B B A B

5556 A elevated temperature which indicates that they 5454 5356 A B A B A A

5554 B C A A A A B

Note: Any strength rating will meet the minimum transverse tensile are not suitable for this particular welding 5556 A A B B A B

strength requirements of AWS D1.2, a blank rating typically will not. 5654 B C A B B B

application.

You might also like

- Aluminum Filler Metal Selection ChartDocument1 pageAluminum Filler Metal Selection ChartfogdartNo ratings yet

- Aluminum Selection ChartDocument1 pageAluminum Selection ChartFahri Risfa ZulfiNo ratings yet

- Aluminum Filler Metal Selection ChartDocument1 pageAluminum Filler Metal Selection ChartbrrrrzzzzNo ratings yet

- 1 No. Ver Bracing Required As Drawn MKD' - 1Vb-47: Bolt List For Assembly MKD' 1Vb-47 X 1 Dia. Qty. Bolt GradeDocument1 page1 No. Ver Bracing Required As Drawn MKD' - 1Vb-47: Bolt List For Assembly MKD' 1Vb-47 X 1 Dia. Qty. Bolt Grademo3azNo ratings yet

- Shaft Material SelectionDocument8 pagesShaft Material SelectionAnand BhiseNo ratings yet

- 6082 Aluminium AlloyDocument3 pages6082 Aluminium AlloyWeiso ChenNo ratings yet

- Recommended Cutting Speeds For Dapra SBN CuttersDocument1 pageRecommended Cutting Speeds For Dapra SBN CuttersEduardo Aleman ReynaNo ratings yet

- Master'S Bedroom Master'S Bedroom: Legend Switch 3 LightDocument1 pageMaster'S Bedroom Master'S Bedroom: Legend Switch 3 LightGrazel MDNo ratings yet

- MechanicalsealDocument7 pagesMechanicalsealSidne SilvaNo ratings yet

- Chute With Support Leg - R3Document1 pageChute With Support Leg - R3Karikalan JayNo ratings yet

- Hubbell Power Systems: Overhead Line Splices Automatic AluminumDocument1 pageHubbell Power Systems: Overhead Line Splices Automatic AluminumAzad RahmanNo ratings yet

- O6 Tool Steel: Chemical AnalysisDocument3 pagesO6 Tool Steel: Chemical AnalysischandraNo ratings yet

- Gfsec September 2020 KsaDocument6 pagesGfsec September 2020 KsaregallydivineNo ratings yet

- Lovely School of Architecture and Design Lsad, Lpu Topic:: Inner DimensionDocument1 pageLovely School of Architecture and Design Lsad, Lpu Topic:: Inner DimensionvimalNo ratings yet

- Chemical Analysis of A Sample50X50X6Document2 pagesChemical Analysis of A Sample50X50X6Amit ChaitNo ratings yet

- Kaiser Aluminum Hard Alloy Drawn Seamless Tube Capabilities PDFDocument7 pagesKaiser Aluminum Hard Alloy Drawn Seamless Tube Capabilities PDFanhthoNo ratings yet

- Alloy 6013 Tech Sheet 1Document4 pagesAlloy 6013 Tech Sheet 1IlyasNo ratings yet

- TK Schweisszusatzwerkstoffe GB PDFDocument132 pagesTK Schweisszusatzwerkstoffe GB PDFMohammed Ady GanjarNo ratings yet

- RB 624590 004Document1 pageRB 624590 004Er Md AamirNo ratings yet

- AMCRPS Installation-Guideline GB WebDocument28 pagesAMCRPS Installation-Guideline GB WebJoseph NNo ratings yet

- 50-40 - 50-42leDocument4 pages50-40 - 50-42leHendro NuryahyaNo ratings yet

- Ganzeboom Transmission Parts & Torque Converters: FWD 3 SpeedDocument2 pagesGanzeboom Transmission Parts & Torque Converters: FWD 3 SpeedAnonymous TMFgAgR09tNo ratings yet

- Jmi Pacific Limited Ch. Karnchang: Si Rat - Outer Ring Road ExpresswayDocument1 pageJmi Pacific Limited Ch. Karnchang: Si Rat - Outer Ring Road ExpresswaykeaoreNo ratings yet

- 4t40e - 4t45eDocument6 pages4t40e - 4t45eJD DionisioNo ratings yet

- Metals and Alloys - DensitiesDocument2 pagesMetals and Alloys - DensitiesAnonymous KTQZaINo ratings yet

- VietnamDocument6 pagesVietnamRyan Noverie PasorehNo ratings yet

- 4T40EDocument2 pages4T40EMarlonFabricioCayo0% (1)

- CE 405 Construction Material and Testing: Technological Institute of The PhilippinesDocument7 pagesCE 405 Construction Material and Testing: Technological Institute of The PhilippinesAdrian Neil PabloNo ratings yet

- S-1.1 Proposed Filling Station (Caltex Station) : Typical Column-Footing (C1-F1) DetailDocument1 pageS-1.1 Proposed Filling Station (Caltex Station) : Typical Column-Footing (C1-F1) DetailCarmela Andrea BuenafeNo ratings yet

- Classes of Pole Based On Horizontal Loads Ansi 05Document2 pagesClasses of Pole Based On Horizontal Loads Ansi 05JosePinosNo ratings yet

- D-EUGP1-TPT-F-LCS-CST-FWG1007-R1 - Top Slab - Part PlanDocument1 pageD-EUGP1-TPT-F-LCS-CST-FWG1007-R1 - Top Slab - Part PlanghansaNo ratings yet

- FWD 6 Speed: 002 Overhaul KitsDocument1 pageFWD 6 Speed: 002 Overhaul KitsAlex Maceira GraterolNo ratings yet

- BMW Service Inclusive & Plus Price ListDocument2 pagesBMW Service Inclusive & Plus Price Listhema shantiniNo ratings yet

- ZF4HP22 - 24Document4 pagesZF4HP22 - 24Bruce NigelNo ratings yet

- Project David Henderson 2 Ground Floor PlanDocument1 pageProject David Henderson 2 Ground Floor PlanJonathan DomeroNo ratings yet

- BR No. 50Document28 pagesBR No. 50Thrk TwrNo ratings yet

- ANDRE - Poland - Abrasive MaterialsDocument2 pagesANDRE - Poland - Abrasive MaterialsRaja Sekhar Reddy PaluruNo ratings yet

- Milling Feeds and SpeedsDocument1 pageMilling Feeds and SpeedsAlfian KamilNo ratings yet

- Lining Pattern & Bar Chart Line - 3Document10 pagesLining Pattern & Bar Chart Line - 3harikrushnaNo ratings yet

- PT - Timuraya Tunggal PT - Sarana Abadi Jaya Raya Tampak AtasDocument1 pagePT - Timuraya Tunggal PT - Sarana Abadi Jaya Raya Tampak AtasAhmad FauziNo ratings yet

- WZR KFSH Icu r01 Sheet A900 WZR KFSH TF SD Etd Enlarged Toilet Details TF 06Document1 pageWZR KFSH Icu r01 Sheet A900 WZR KFSH TF SD Etd Enlarged Toilet Details TF 06ezeyadahNo ratings yet

- Cartridge Selection Poster EnglishDocument1 pageCartridge Selection Poster EnglisharitharenNo ratings yet

- 6351 1500 WebDocument1 page6351 1500 Webmohamed bakryNo ratings yet

- R4a51 V4a51 R5a51 V5a51Document2 pagesR4a51 V4a51 R5a51 V5a51tony91750% (2)

- Aluminum SectionsDocument102 pagesAluminum SectionsDuy HaNo ratings yet

- TI KAL: A Chart To Choose The Right FastenerDocument2 pagesTI KAL: A Chart To Choose The Right Fastenervelu.gNo ratings yet

- U340e U341e U341fDocument8 pagesU340e U341e U341fWeligton GomesNo ratings yet

- Steel PlantDocument68 pagesSteel PlantRohithNo ratings yet

- Fahu 02Document9 pagesFahu 02Aiman AliNo ratings yet

- Changbao Specification For Perforating Gun REV.Document5 pagesChangbao Specification For Perforating Gun REV.PAULNo ratings yet

- Profile Products Associates Exhibitions Enquiry Contact UsDocument1 pageProfile Products Associates Exhibitions Enquiry Contact UsENGR 414No ratings yet

- Top Grades Tags: Home About Us Product E-Stock Selling List Contact UsDocument3 pagesTop Grades Tags: Home About Us Product E-Stock Selling List Contact Usarief setiawanNo ratings yet

- HSFG Part I Bolt & NutDocument1 pageHSFG Part I Bolt & NutvpjagannaathNo ratings yet

- 5754 Aluminum Sheet SuppliersDocument9 pages5754 Aluminum Sheet Supplierssanghvi overseas incNo ratings yet

- Gedung KMPS 2Document1 pageGedung KMPS 2eviNo ratings yet

- R4A51 / V4A51 / R5A51 / V5A51: RWD 4 & 5 SpeedDocument2 pagesR4A51 / V4A51 / R5A51 / V5A51: RWD 4 & 5 SpeedSthefany PereiraNo ratings yet

- Percentage Composition: Juliusleo M. Martin Teacher IIIDocument26 pagesPercentage Composition: Juliusleo M. Martin Teacher IIIjuliusleo martin100% (1)

- Dragline Cycle TimeDocument11 pagesDragline Cycle TimeanfiboleNo ratings yet

- Tic Tac Toe CodeDocument4 pagesTic Tac Toe CodeluisrogaNo ratings yet

- Full Download Test Bank For Public Health Nursing 10th Edition Stanhope PDF Full ChapterDocument36 pagesFull Download Test Bank For Public Health Nursing 10th Edition Stanhope PDF Full Chaptertheresagreensayxgiwkod100% (18)

- Preservation of Indigenous Culture of Bataan Through An Ayta Magbukon School of Living Tradition (SLT) ProgramDocument11 pagesPreservation of Indigenous Culture of Bataan Through An Ayta Magbukon School of Living Tradition (SLT) ProgramEuniz ReyesNo ratings yet

- Akcela Aceites Fichas TecnicasDocument44 pagesAkcela Aceites Fichas TecnicasGUILLERMO SEGURANo ratings yet

- Cultural Center RRL ForeignDocument4 pagesCultural Center RRL ForeignJoedel CapillanNo ratings yet

- OralCom q1 Mod3 Barrierstocommunciation v5Document33 pagesOralCom q1 Mod3 Barrierstocommunciation v5KryssssNo ratings yet

- Animal Breeding ManualDocument43 pagesAnimal Breeding ManualMELITO JR. CATAYLONo ratings yet

- US Declaration of Interdependence 1976Document10 pagesUS Declaration of Interdependence 1976FranSwizzle SimsNo ratings yet

- Brunei Shell EOI QualificationsDocument40 pagesBrunei Shell EOI QualificationsSyed Abdul RahmanNo ratings yet

- Cbse Class 12 English The Last Lesson Revision NotesDocument2 pagesCbse Class 12 English The Last Lesson Revision NotesryumaroronaNo ratings yet

- Daily Practice Problem Sheet 109: Gaurav AroraDocument3 pagesDaily Practice Problem Sheet 109: Gaurav AroraKushant BaldeyNo ratings yet

- Tu 5.2.3Document56 pagesTu 5.2.3Atul SinghNo ratings yet

- BBA Lecture NotesDocument36 pagesBBA Lecture NotesSaqib HanifNo ratings yet

- 2008 - An Optical, EPR and Electrical Conductivity Study of Blue Barium TitanateDocument8 pages2008 - An Optical, EPR and Electrical Conductivity Study of Blue Barium TitanateBeh NaatNo ratings yet

- Adaptations Lab - Birds BeaksDocument3 pagesAdaptations Lab - Birds BeaksABC7 WJLANo ratings yet

- 10.1.1.658.8175.ready Mix - 7 QCDocument8 pages10.1.1.658.8175.ready Mix - 7 QCsyamsu dhuhaNo ratings yet

- Dhyg 415 Study Guide Yezi Pang - 1Document117 pagesDhyg 415 Study Guide Yezi Pang - 1api-473128642No ratings yet

- Int Fire Alarm - CPL Okems Tu (HND)Document80 pagesInt Fire Alarm - CPL Okems Tu (HND)NjitnumNo ratings yet

- Chandramohan (2016) Duration (Stanford) PDFDocument448 pagesChandramohan (2016) Duration (Stanford) PDFmgrubisicNo ratings yet

- NCP IDNT Diagnosis-Etiology MatrixDocument15 pagesNCP IDNT Diagnosis-Etiology MatrixkapetaeNo ratings yet

- CrashUp Surface TensionDocument33 pagesCrashUp Surface TensionSameer ChakrawartiNo ratings yet

- Agnihotra Seminar Brochure FinalDocument14 pagesAgnihotra Seminar Brochure Finalarvind351No ratings yet

- Introduction: Digital Controller Design: SystemDocument13 pagesIntroduction: Digital Controller Design: Systembala_aeroNo ratings yet

- Response of Buried Pipes Taking Into Account Seismic and Soil Spatial VariabilitiesDocument8 pagesResponse of Buried Pipes Taking Into Account Seismic and Soil Spatial VariabilitiesBeh RangNo ratings yet

- B 16Document9 pagesB 16Trương Mỹ HạnhNo ratings yet

- Banerjee, 2020Document15 pagesBanerjee, 2020dwi ayuNo ratings yet

- Influence of Soil Structure Interaction On Seismic Demands - 2019 - EngineeringDocument15 pagesInfluence of Soil Structure Interaction On Seismic Demands - 2019 - Engineeringabubaker ahmedNo ratings yet

- Leed Practise Exams - Pool DDocument52 pagesLeed Practise Exams - Pool DTabish SuhailNo ratings yet