0% found this document useful (0 votes)

137 views13 pagesWarehouse Visualization Guide

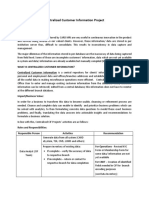

The document provides guidance on designing effective warehouse location labeling systems, outlining options for label layouts, materials, inclusion of barcodes and check digits, use of color coding, and collecting necessary information from customers to develop a customized labeling solution. Clear identification of storage locations is important for efficient warehouse management, and specialized labels can be designed and manufactured to meet specific system requirements.

Uploaded by

Andrés PacompíaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

137 views13 pagesWarehouse Visualization Guide

The document provides guidance on designing effective warehouse location labeling systems, outlining options for label layouts, materials, inclusion of barcodes and check digits, use of color coding, and collecting necessary information from customers to develop a customized labeling solution. Clear identification of storage locations is important for efficient warehouse management, and specialized labels can be designed and manufactured to meet specific system requirements.

Uploaded by

Andrés PacompíaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd