Professional Documents

Culture Documents

The Environmental Assessment of The Wood Combustion

Uploaded by

10 000 de cartiOriginal Title

Copyright

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe Environmental Assessment of The Wood Combustion

Uploaded by

10 000 de cartiU. P. B. Sci. Bull., Series C, Vol. 69, No.

4, 2007 ISSN 1454-234x

THE ENVIRONMENTAL ASSESSMENT OF THE WOOD

COMBUSTION

Cristian DINCA1, Adrian BADEA2 Tiberiu APOSTOL3

In this paper, the authors analysed the emissions from residential boilers

fired with wood logs, bark pellets, wood briquettes and wood pellets. Three boilers,

selected with respect to age, design, connection to heat storage tank, and type of

biofuel, were included in the study. The emissions collected comprised carbon

monoxide (CO), carbon dioxide (CO2), oxygen (O2), total organic carbons (TOC),

nitrogen oxides (NOx), polycyclic aromatic hydrocarbons (PAC) and 33 volatile

organic compounds (VOC).

We have used the Life Cycle Inventory method in order to identify the main

stressors generated by the wood combustion stage. In this purpose, we have

analysed one type of old boiler, one type of modern boiler and a multi-fuel boiler,

which can burn wood logs, bark pellets, wood briquettes and wood pellets. In this

article, we selected only the wood combustion stage because it’s the most important

according to the emissions produced.

Keywords: briquettes, pellets, combustion, LCA.

1. Introduction

Wood is a renewable resource and “environmentally friendly” compared

with other materials [1]. The renewable resource aspect can be substantiated when

forestry operations are accompanied by third party certification for sustainable

management practices. Unfortunately there is a large source of non-technical

information available to the public that discourages harvesting and the use of

wood products. In a publication by Watershed Media [2], reference is made

several times to the destruction of forest or harvesting old-growth wood in order

to build a wood-framed house. To address claims like these, the scientific

community world wide has been developing methodology that accurately assesses

the environmental impact a product or process my cause over its life cycle.

Life-cycle assessment (LCA) is one approach to accurately assess the

environmental burdens associated with the manufacturing of a product from

resource extraction to end-of-life. The development of the LCA methodology has

helped to quantify and provide information about a product where environmental

qualities were lacking [3]. A LCA is comprised of three interrelated components:

1

Asist. Prof, Power Engineering Department, University “Politehnica” of Bucharest, Romania

2

Prof., Power Engineering Department, University “Politehnica” of Bucharest, Romania

3

Prof., Power Engineering Department, University “Politehnica” of Bucharest, Romania

3rd International Conference on Energy and Environment

22-23 November 2007, Bucharest, Romania

92 Cristian Dinca, Adrian Badea, Tiberiu Apostol

1.) an inventory phase, 2.) an impact assessment phase, and 3.) an improvement

phase. By definition, it is an objective process to evaluate the environmental

burdens associated with a product, process or activity. The life-cycle inventory

(LCI) conducted in this study presents the quantitative results for three boilers

proposed. The LCI presented is focused on two main environmental assessments:

1.) energy requirements and 2.) emissions to the environment for the wood

combustion (by using different products of wood) . The LCI’s developed are in

accordance with the CORRIM Research Guidelines [4] and the International

Organization for Standardization (ISO) protocol for performing life-cycle

assessments [5]. In this paper we have presented the life cycle inventory in order

to identify the main emissions generated in the wood combustion stage.

The common types of residential combustion devices have been described

by, for instance [6]. Modern wood boilers are usually designed for downdraught

combustion and with a ceramic-lined burn-out zone (Fig. 1A), and are normally

connected to storage tanks. In old-type wood boilers up-draught combustion is

most common, and the boilers are water cooled. An example is shown in Fig. 1B.

Up-draught combustion is also typically used in wood stoves. In general,

development of wood boilers has led to combustion devices with increased

efficiency and decreased emissions.

Except for some work on particle emissions [7], information on emission

characteristics related to residential biofuel boilers is scarce. There is a need to

compare emissions from different techniques of biofuel boilers to ensure an

ecologically sustainable use of biofuels. Consequently, the present work focuses

on comparing gaseous and particulate emissions from old type and modern boilers

by means of systematic variation of combustion device, fuel quality, firing

behavior, and the influence of heat storage tank. Unsystematic irregularities

caused by user habits are avoided by performing tests in the laboratory. Instead,

user habits are simulated in a schematic way. The purpose of the comparison is to

determine the emission differences between old-type and modern residential

biofuel boilers and to quantify emission characteristics of different kind of biofuel

combustion.

3rd International Conference on Energy and Environment

22-23 November 2007, Bucharest, Romania

The environmental and economical assessment of the wood combustion 93

Fig. 1 A wood boiler designed for down-draught combustion (A), a wood

boiler designed for up-draught combustion (B), and a multi-fuel boiler (C),

which can burn wood logs, bark pellets, wood briquettes and wood pellets.

2. Life cycle inventory of the wood combustion

The chemical composition of the wooden fuels, pellets, briquettes and

wood logs, is similar (Table 1), except that the moisture content was

approximately 8 % in the pellets and briquettes, and 15 %, 26 %, or 38 % in the

wood logs. Wood logs, of birch, with moisture content of 15% are considered dry,

while higher moisture contents represent wet fuel. The ash content in the woody

fuels is low compared to bark pellets, which also has a higher fraction of nitrogen.

The length of the wood logs was about 500 mm. The cylindrical log was split

once or twice with a resulting transversal size of 100 mm. Wood and bark pellets

had a diameter of 8 mm and a length of 15–20 mm.

Table 1

Elemental analyses and heating values of the fuels [8]

Wood pellets Bark pellets Wood Wood logs

briquettes

Ash 0,5 3,7 0,3 0,3

Moisture 7,6 7,8 7,5 15/26/38

Lower heating value (MJ/kg) 19 20,1 18,9 19

Content

Carbon 50,2 52,1 50,6 50,6

Oxygen 43,2 37,8 42,7 42,7

Hydrogen 5,9 5,9 6,4 6,4

Nitrogen 0,08 0,48 0,05 0,05

Sulphur <0,01 0,03 <0,01 <0,01

Moisture – wt % wet fuel, other data wt % dry fuel

The emissions of CO, TOC, methane, non-methane VOC (NMVOC),

PAH, mass and number concentrations of particles, and NOx are presented in

3rd International Conference on Energy and Environment

22-23 November 2007, Bucharest, Romania

94 Cristian Dinca, Adrian Badea, Tiberiu Apostol

Table 2. To simplify the results, the emissions from all the operational cases of

Table 1 are sorted into groups and plotted against some related parameter, prior to

presenting the influence from combustion device, firing behavior, fuel quality,

and connection of heat storage tanks. Three groups of emissions were identified:

unburned emissions compounds, particles, and nitrogen oxides. Unburned

emissions compounds, i.e. CO and hydrocarbons, are a consequence of imperfect

combustion conditions, which can be explained by the well-known criteria for

favorable combustion: long enough residence time at sufficiently high

temperature with adequate mixing of air and combustible gases. We know that the

CO concentration increases with increased excess air. Consequently, oxygen was

not the limiting parameter for CO oxidation during poor combustion conditions.

Instead, high excess air can be suspected to cool the combustion chamber,

resulting in high CO emissions. Analyzing the data collected in the Table 2, we

could say that there are linear correlations between CO and TOC for wood boilers,

pellet burners, and oil burners, and obviously TOC is also influenced by the air

supply, just as CO, VOC (methane+NMVOC) and PAH.

Table 3

CO2, CO, TOC, particles and NOx emissions [8]

CO2 (%) CO TOC CH4 NMVOC PAH Particles NOx

Old type wood

8,4 4 100 660 - - - 87 65

boilers

Modern wood boilers 12,2 707 14 1 1,9 0,21 27 125

Pellet burners and

9,5 36 4 0,76 1,2 0,32 22 68

boilers

Emissions are in mg/MJ, where not other units are indicated

The particles emitted contain both organic material, i.e. unburnt solid

material, and inorganic material, i.e. ash particles. Regardless of combustion

conditions, ash particles always remain as a by-product. It can be seen (Table 3)

that the mass concentration of emitted particles was rather constant up to a

concentration of about 100 mg/MJ TOC. At higher concentration the particle

emission increased. The increase in mass concentration of particles during poorer

combustion conditions agrees with earlier work, for example by Muhlbaler Dasch

[9]. The enhancement of particle emission during poor combustion conditions is

due to carbonaceous particles. The number concentration of emitted particles also

increased for poor combustion conditions, as indicated by the dependence on TOC

(Table 3). Nitrogen oxides are formed from combustion air or from fuel nitrogen.

The importance of fuel nitrogen is implied by a correlation between the NOx

emissions and the fuel nitrogen content (Table 3). As seen in Table 3, no clear

effect of excess air on the NOx emissions could be observed, probably because of

a balance between the tendencies of excess air to increase the formation of NO

and of the falling temperature to reduce the formation (of fuel-NO).

3rd International Conference on Energy and Environment

22-23 November 2007, Bucharest, Romania

The environmental and economical assessment of the wood combustion 95

The low emissions of particles and unburned emissions compounds from

oil burners were expected, since small scale continuous combustion of a fluid fuel

can be better controlled than batch-wise (wood boilers) combustion of solid fuel

and semi-continuous combustion of pellets. However, it is possible to improve the

control of batch wise solid fuel combustion, as is shown in this study by

comparing old-type wood boilers with modern wood boilers. This can probably be

even better developed in the future. Pellet burners are new designs and can most

likely be further improved to emission levels comparable to those of oil burners.

Domestic pellet burners were developed in the 1980s, but not until the late 1990s

these devices contributed to significant shares of the market in countries like

Sweden, Denmark, and Austria [6]. Regardless of somewhat higher emissions of

particles and unburned emissions compounds from modern biofuel boilers

compared with oil burners, modern domestic biofuel boilers are ecologically

sustainable heating options as they do not contribute to the climate change.

Very large differences in emissions were observed between old-type and

modern biofuel boilers. In particular, high emissions of the greenhouse gas

methane were recorded for old-type wood boilers, which are the ones most

frequently installed in houses today. The effect on climate change from an old-

type wood boiler, because of high methane emissions, can be compared with

residential oil burners emitting CO2 by using the global warming potential

(GWP). This parameter expresses the impact of a gas on the climate change in

relation to CO2. GWP for methane is 21 kg CO2-equivalent/ kg methane [10]. The

emission from the worst old-type wood the methane emission was 4800 mg/MJ,

which gives around 100 000 mg CO2-equivalents/MJ. Consequently, an old-type

wood boiler may have more than twice as high an impact on climate change as an,

for example, oil boiler, besides high emissions of particles and unburned

emissions compounds.

3. Conclusions

There are high emissions of unburned emissions compounds and particles

from old-type residential biofuel boilers. The measured VOC compound with

highest concentration was methane in all cases, and as a consequence of methane

emissions, the influence on climate change of an old-type wood boiler could be

higher than that of an oil boiler, for example. As an example, substitution of an

old-type wood boiler with a modern wood boiler attached to a storage tank or with

a pellet boiler could reduce methane emissions 8 to 9000 times, at the same time

as the efficiency would increase. Installation of a heat storage tank in connection

to an old-type wood boiler could reduce the methane emission seven times and the

particle emission 21 times, thus improving the environmental performance to

some extent. A similar improvement was observed when changing firing behavior

3rd International Conference on Energy and Environment

22-23 November 2007, Bucharest, Romania

96 Cristian Dinca, Adrian Badea, Tiberiu Apostol

to charging smaller batches of wood logs. Modern wood boilers seem to maintain

their low emission performance also in the case of degradation of the fuel quality

in the form of increased moisture content. However, changing the fuel’s

composition from wood based fuel like wood logs, wood pellets, and wood

briquettes, to a fuel manufactured from a lower quality material, such as bark,

results in higher emissions of particles and NOx, because of higher ash and

nitrogen content in bark.

Increased emissions of CO were found at high excess air ratios. This

agrees with earlier studies on wood stoves [11], and is probably a result of cooling

of the combustion process. The enhanced emissions of CO were accompanied by

emissions of other unoxidised components: TOC, CH4, NMVOC, and PAH. The

mass concentration of emitted particles was rather independent of emission of

unburnt gaseous compounds up to a concentration of about 100 mg/MJ TOC, after

which the particle emission increased, probably because of high concentrations of

unburnt particulate matter. The mass concentration of particles was 180 times

larger in the worst old-type compared to the best modern boiler. The number of

particles emitted increased with increased emissions of unburned emissions

compounds. From the number and mass size distributions it can be concluded that

the emission of sub micron particles, especially ultrafine particles (size100 nm) is

enhanced by poorer combustion conditions.

Most biofuel boilers installed today are of the old type, and cause high

emissions of particles and unburned emissions compounds, as well as a climate

change effect comparable with oil burners. It is urgent from both environmental

and health point of view that they are replaced with modern residential wood

boilers attached to storage tanks, or pellet boilers.

REFERENCES

[1]. Lippke, B., J. Wilson, J. Perez-Garcia, J. Bowyer, and J. Meil, CORRIM: Life-cycle

environmental building materials. Forest Prod. J. 54(6):8–19, 2004.

[2] ***Watershed Media, Building with vision: Optimizing and finding alternative to wood. Vol.

2: The Wood Reduction Trilogy. Watershed Media Inc., Healdsburg, CA.

www.watershedmedia.org. 136 pp, 2001.

[3]. Hershberger, S, Insights gained in applying current life cycle inventory methodology to

western lumber as a competitive building material. Pp. 39–45 in Life cycle environmental

impact analysis for forest products. Forest Products Society, Madison, WI. No. 7294, 2001.

[4]. Kline, D. E, Southeastern oriented strandboard production. In CORRIM Phase I Final Report

Module E. Life cycle environmental performance of wood combustion. University of

Washington, Seattle, WA. 75 pp, 2004..

[5]. ***International Organization For Standardization (ISO), Environmental management—life

cycle assessment— principles, and framework. ISO 14040. First Edition 1997-06-15.

Geneva, Switzerland. 16 pp, 1991.

3rd International Conference on Energy and Environment

22-23 November 2007, Bucharest, Romania

The environmental and economical assessment of the wood combustion 97

[6]. Baxter,L., Coombes, P., Gifford,J., Guiu,G., Houmann Jakobsen,H.,Koppejan,J., Livingston,

W., Logie, R.,Loovan,S.,Nussbaumer, T.,Obenberge r, I.,Oravainen,H., Schenkel, Y.,Skreiberg,O ¨

.,Tullin,C., Handbook of Biomass Combustion and Co-Firing. Twente University Press,Enschede,

The Netherlands, pp. 93–110 (ISBN 9036517737), 2002.

[7]. Wieser,U.,Gaegauf,C., In: Proceeding of the Conference: First World Conference and

Exhibition on Biomass for Energy and Industry,Sevilla, 805-808. Address of responsible

organizations: Energia TA,Piazza Savonarola 10,I-50132 Florence,Italy, WIP,Sylvenstei nstrasse

2, D-81369 Munich,Germany, 2000.

[8]. Johansson,L.S., Leckner, B.,Tullin,C.,Sjovall,P., Particle emissions from biomass combustion

in small combustors. Biomass and Bioenergy 25,435–446, 2003.

[9] Muhlbaler Dasch, J., Particulate and gaseous emissions from wood-burning fireplaces.

Environmental Science and Technology 16 (10),639–645, 1982.

[10]. ***IPCC Guidelines for National Greenhouse Gas Inventories Revised

(IPCC/UNEP/OECD/IEA 1997), http://www. ipcc-nggip.iges.or.jp/public/gl/invs1 .htm, 1996.

[11] Nussbaumer,T., Combustion and co-combustion of biomass: fundamentals, technologies, and

primary measures for emission reduction. Energy and Fuels 17 (6), 1510–1521, 2003.

3rd International Conference on Energy and Environment

22-23 November 2007, Bucharest, Romania

98 Cristian Dinca, Adrian Badea, Tiberiu Apostol

3rd International Conference on Energy and Environment

22-23 November 2007, Bucharest, Romania

You might also like

- Reed Briquettes Provide Clean Domestic HeatingDocument4 pagesReed Briquettes Provide Clean Domestic HeatingDan ErvinNo ratings yet

- Combustion and Co-Combustion of Biomass: Fundamentals, Technologies, and Primary Measures For Emission ReductionDocument12 pagesCombustion and Co-Combustion of Biomass: Fundamentals, Technologies, and Primary Measures For Emission ReductionLisa FosterNo ratings yet

- Chapter 3 explores conventional and alternative fuelsDocument49 pagesChapter 3 explores conventional and alternative fuelsmharitmsNo ratings yet

- Emission Reduction Measures for Pollutants from Biomass CombustionDocument5 pagesEmission Reduction Measures for Pollutants from Biomass CombustionmanuelNo ratings yet

- zanziV2A 17Document4 pageszanziV2A 17luaweb123No ratings yet

- How To Improve Boiler EfficiencyDocument6 pagesHow To Improve Boiler EfficiencyPawan GoyalNo ratings yet

- Fluidized Bed Combustion Fly Ash Leaching A Column StudyDocument14 pagesFluidized Bed Combustion Fly Ash Leaching A Column Studyduygu esmerNo ratings yet

- Chemical Fractionation Methods for Biofuel and Waste Fuel CharacterizationDocument11 pagesChemical Fractionation Methods for Biofuel and Waste Fuel CharacterizationAnonymous knICaxNo ratings yet

- 9th YSF Symposium Proceedings 2020-133-138Document6 pages9th YSF Symposium Proceedings 2020-133-138Udya DevarajaNo ratings yet

- Artikel Seminar Internasional IOP Unila 2019 - Ref 5Document8 pagesArtikel Seminar Internasional IOP Unila 2019 - Ref 5kemas ridhuanNo ratings yet

- Paper - Sample 50 PoundsDocument5 pagesPaper - Sample 50 PoundsAlex AdamsNo ratings yet

- Co-firing Biomass and Opportunity Fuels in Low NOx BurnersDocument12 pagesCo-firing Biomass and Opportunity Fuels in Low NOx BurnersAnatoly RapoportNo ratings yet

- Simulation of Methanol Synthesis in Packed Bed Reactor Based On Gas From Biomass GasificationDocument9 pagesSimulation of Methanol Synthesis in Packed Bed Reactor Based On Gas From Biomass GasificationHaris Surya HidayatNo ratings yet

- Thermogravimetric Analysis of The Combustion Characteristics of Oil Shale Semi-Coke/Biomass BlendsDocument12 pagesThermogravimetric Analysis of The Combustion Characteristics of Oil Shale Semi-Coke/Biomass BlendsRajendraNo ratings yet

- Paper R'02 - WEEE in PyromaatDocument7 pagesPaper R'02 - WEEE in PyromaatRahul AnkushNo ratings yet

- Biomass Torrefaction and Co-FiringDocument9 pagesBiomass Torrefaction and Co-FiringAmd MamdNo ratings yet

- Chemical Composition of Wood Chips and Wood PelletsDocument6 pagesChemical Composition of Wood Chips and Wood PelletsAhmed AlNoussNo ratings yet

- A. Dermibas 2009Document6 pagesA. Dermibas 2009Tony Jefferson Sales VilelaNo ratings yet

- Antal 2003Document22 pagesAntal 2003halimitbNo ratings yet

- Othman 2016 IOP Conf. Ser. Earth Environ. Sci. 32 012037Document6 pagesOthman 2016 IOP Conf. Ser. Earth Environ. Sci. 32 012037senthilNo ratings yet

- Heat and mass balances in the ULCOS Blast FurnaceDocument3 pagesHeat and mass balances in the ULCOS Blast FurnaceCofe MilkNo ratings yet

- Optimization of Post Combustion Carbon Capture Process-Solvent SelectionDocument11 pagesOptimization of Post Combustion Carbon Capture Process-Solvent SelectionYamini BNo ratings yet

- Catalysts: An Overview On Catalytic Hydrodeoxygenation of Pyrolysis Oil and Its Model CompoundsDocument22 pagesCatalysts: An Overview On Catalytic Hydrodeoxygenation of Pyrolysis Oil and Its Model CompoundsTusharNo ratings yet

- How To Use Pellet Binders During Making Pellets Processing CorrectlyDocument6 pagesHow To Use Pellet Binders During Making Pellets Processing CorrectlyM Syifaut TamamNo ratings yet

- Enve 4003Document9 pagesEnve 4003Ferdous ShamaunNo ratings yet

- Ignition and Devolatilization of Pulverized Bituminous Coal Particles During Oxygen Carbon Dioxide Coal CombustionDocument8 pagesIgnition and Devolatilization of Pulverized Bituminous Coal Particles During Oxygen Carbon Dioxide Coal CombustionthinhklNo ratings yet

- CO2 Pollution from Burning Fuels AnalyzedDocument7 pagesCO2 Pollution from Burning Fuels AnalyzedDinca DumitruNo ratings yet

- Heat and Mass Balances in The ULCOS Blast FurnaceDocument3 pagesHeat and Mass Balances in The ULCOS Blast FurnaceakshukNo ratings yet

- Experimental Research On The Novel Process of Iron Ore Direct ReductionDocument8 pagesExperimental Research On The Novel Process of Iron Ore Direct ReductionMariaNo ratings yet

- TB 03 Calculations Normalisations ConversionsDocument17 pagesTB 03 Calculations Normalisations ConversionsRaul BxinNo ratings yet

- Use of Biomass Gas in Running Internal Combustion Engine To Generate Electricity-A ReviewDocument7 pagesUse of Biomass Gas in Running Internal Combustion Engine To Generate Electricity-A Reviewkashipuranataraj69No ratings yet

- Wood Briquette TorrefactionDocument4 pagesWood Briquette TorrefactionJulian Andres PaezNo ratings yet

- 38.3 Electrical Cable Fire ToxicityDocument32 pages38.3 Electrical Cable Fire ToxicityRichard HollidayNo ratings yet

- Chem 113E Lecture 6Document22 pagesChem 113E Lecture 6Michael LabayoNo ratings yet

- Combustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasFrom EverandCombustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasNo ratings yet

- Intro To Solid Waste IncinerationDocument39 pagesIntro To Solid Waste IncinerationBalya MalkanNo ratings yet

- Fuels and CombustionDocument24 pagesFuels and Combustionmukirir47No ratings yet

- Tesis, ThesisDocument50 pagesTesis, ThesisJose MunozNo ratings yet

- Choosing the Right Coal for Power PlantsDocument14 pagesChoosing the Right Coal for Power PlantsMarvin E. VillanuevaNo ratings yet

- PFPI Biomass Carbon Accounting Overview AprilDocument11 pagesPFPI Biomass Carbon Accounting Overview AprilPaul BreaNo ratings yet

- Incineration - Gasification - PyrolysisDocument65 pagesIncineration - Gasification - Pyrolysistatchanok1525No ratings yet

- BiogasificationDocument10 pagesBiogasificationAsad MahmoodNo ratings yet

- Combustion and Emission Characteristics of Rice Husk in A Rectangular Fluidized Bed CombustorDocument4 pagesCombustion and Emission Characteristics of Rice Husk in A Rectangular Fluidized Bed CombustorfelramNo ratings yet

- A Review of Biogas Utilisation, Purification and Upgrading TechnologiesDocument17 pagesA Review of Biogas Utilisation, Purification and Upgrading TechnologiesXavier OrtizNo ratings yet

- BioRes 08 2 1520 C Dion LOC Biomass Gas Syngas Greenhouse CO2 3168 PDFDocument19 pagesBioRes 08 2 1520 C Dion LOC Biomass Gas Syngas Greenhouse CO2 3168 PDFSecret SecretNo ratings yet

- Sustainability 04 00462Document29 pagesSustainability 04 00462mbenattiakNo ratings yet

- Biogasification of Lignite Coal: Adi Krishna Print This Article Email This ArticleDocument25 pagesBiogasification of Lignite Coal: Adi Krishna Print This Article Email This ArticleSetyo Kf SariNo ratings yet

- Experimental Analysis of Minimum Ignition Temperature of Coal Dust Layers in Oxy-Fuel Combustion AtmospheresDocument10 pagesExperimental Analysis of Minimum Ignition Temperature of Coal Dust Layers in Oxy-Fuel Combustion AtmospheresAnand SehgalNo ratings yet

- Characteristics of Spent Coffee Ground As A Fuel and Combustion Test in A Small Boiler PDFDocument15 pagesCharacteristics of Spent Coffee Ground As A Fuel and Combustion Test in A Small Boiler PDFMJundiNo ratings yet

- Characteristics of Spent Coffee Ground As A Fuel and Combustion Test in A Small BoilerDocument15 pagesCharacteristics of Spent Coffee Ground As A Fuel and Combustion Test in A Small BoilerMJundiNo ratings yet

- Environmental Impact and Forecast of Pollutants From Coke Oven Gas and Natural Gas CombustionDocument4 pagesEnvironmental Impact and Forecast of Pollutants From Coke Oven Gas and Natural Gas CombustionIJERDNo ratings yet

- 1989 - Utilization of BiogasDocument14 pages1989 - Utilization of BiogasDavid LɘonardoNo ratings yet

- Assignment 3Document3 pagesAssignment 3Oluwatobiloba OlowoyoNo ratings yet

- Characteristics of Biomass Charcoal Briquetttes and Pollutant Emission Reduction For Sulfur and Nitrogen During CombustionDocument10 pagesCharacteristics of Biomass Charcoal Briquetttes and Pollutant Emission Reduction For Sulfur and Nitrogen During Combustiongabrielpio654No ratings yet

- Coffee Husk Briquettes: A New Renewable Energy SourceDocument5 pagesCoffee Husk Briquettes: A New Renewable Energy SourceMJundiNo ratings yet

- Karakteristik Emisi Industri Pulp Dan Kertas Dalam Konteks Pencemaran UdaraDocument11 pagesKarakteristik Emisi Industri Pulp Dan Kertas Dalam Konteks Pencemaran Udaraajeng ekaNo ratings yet

- Effects of Temperature and Particle Size On Bio-Char Yield From Pyrolysis of Agricultural Residues PDFDocument6 pagesEffects of Temperature and Particle Size On Bio-Char Yield From Pyrolysis of Agricultural Residues PDFRAISA GERZONNo ratings yet

- Experimental investigation of bio-butanol laminar non-premixed flameletsDocument9 pagesExperimental investigation of bio-butanol laminar non-premixed flameletsMarcus NabackNo ratings yet

- Diagram de Va KrevelenDocument4 pagesDiagram de Va KrevelenJoão13@No ratings yet

- Load Profiling For The Electricity MarketDocument8 pagesLoad Profiling For The Electricity Market10 000 de cartiNo ratings yet

- A Multi-Agent Genetic Algorithm For The Solution of The Economic Dispatch ProblemDocument8 pagesA Multi-Agent Genetic Algorithm For The Solution of The Economic Dispatch Problem10 000 de cartiNo ratings yet

- Optimization of A Sofc System: Influence of Design and Operation Parameters On System EfficincyDocument8 pagesOptimization of A Sofc System: Influence of Design and Operation Parameters On System Efficincy10 000 de cartiNo ratings yet

- Private Investment For Building A Small Hydropower Plant at Zetea Dam BasisDocument8 pagesPrivate Investment For Building A Small Hydropower Plant at Zetea Dam Basis10 000 de cartiNo ratings yet

- Using Renewable Sources in The Pulp and Paper MillsDocument6 pagesUsing Renewable Sources in The Pulp and Paper Mills10 000 de cartiNo ratings yet

- 1 - Introduction Rheology Subject and LanguageDocument8 pages1 - Introduction Rheology Subject and LanguageRicardo FarinaNo ratings yet

- Wave Energy of The Romanian CoastwiseDocument8 pagesWave Energy of The Romanian Coastwise10 000 de cartiNo ratings yet

- Team Rafale - Presentation AlphaDocument48 pagesTeam Rafale - Presentation AlphaFerencz Tiberiu Balint100% (1)

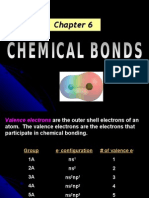

- Chapter 6 - Chemical BondsDocument41 pagesChapter 6 - Chemical BondsDn ZackNo ratings yet

- Sulphur Limit: A Guide For Ships Calling To Port of SingaporeDocument6 pagesSulphur Limit: A Guide For Ships Calling To Port of SingaporeDeepakNo ratings yet

- Invited Speaker - Vitor Sokolov PDFDocument21 pagesInvited Speaker - Vitor Sokolov PDFAndar ApriadiNo ratings yet

- Criteria For Vacum TestDocument7 pagesCriteria For Vacum TestlightsonsNo ratings yet

- Introduction To Fitness-For-Service (FFS) API 579-1 / ASME FFS-1 2007Document25 pagesIntroduction To Fitness-For-Service (FFS) API 579-1 / ASME FFS-1 2007Rabindra RaiNo ratings yet

- Republic of The Philippines Professional Regulation Commission ManilaDocument17 pagesRepublic of The Philippines Professional Regulation Commission ManilaPRC BaguioNo ratings yet

- API 520 Part 1, Edition 2008, Annex C, Sec. C.2.1 PRVDocument5 pagesAPI 520 Part 1, Edition 2008, Annex C, Sec. C.2.1 PRVManton ArksNo ratings yet

- Carboxylic Acids and Their Derivatives.Document31 pagesCarboxylic Acids and Their Derivatives.AmanyNo ratings yet

- New Expt 8 Spectroscopy Lab Chlorophyll With SpectroVisDocument12 pagesNew Expt 8 Spectroscopy Lab Chlorophyll With SpectroVisAdam Bryant PoonawalaNo ratings yet

- Safety Data Sheet: Section 1: Identification of The Chemical and of The SupplierDocument8 pagesSafety Data Sheet: Section 1: Identification of The Chemical and of The SupplierFikriey AbdullahNo ratings yet

- Model Paper 11th 2013 OnwardDocument93 pagesModel Paper 11th 2013 OnwardImran RashidNo ratings yet

- Chapter 10 Respiration - WorksheetDocument4 pagesChapter 10 Respiration - Worksheetapi-3728508100% (4)

- Chemistry of Hydrocarbon Experiment 16: ObjectiveDocument10 pagesChemistry of Hydrocarbon Experiment 16: ObjectiveWena Sta Maria100% (1)

- IS 2386 Part 2Document21 pagesIS 2386 Part 2Reshmita PallaNo ratings yet

- Switches For The Nuclear Power Industry: SOR Pressure, Vacuum and Temperature SwitchesDocument16 pagesSwitches For The Nuclear Power Industry: SOR Pressure, Vacuum and Temperature SwitchesClaudio HernandezNo ratings yet

- CH 5 - ProblemsDocument8 pagesCH 5 - ProblemsKhris Griffis89% (18)

- Materials and properties vocabularyDocument1 pageMaterials and properties vocabularycNo ratings yet

- EEC / Refractory Systems for Chemical and Hydrocarbon ProcessingDocument34 pagesEEC / Refractory Systems for Chemical and Hydrocarbon Processinggems_gce074325No ratings yet

- 35Document5 pages35sliversniperNo ratings yet

- The Bulk Modulus of RubberDocument5 pagesThe Bulk Modulus of Rubberjjhw2002303No ratings yet

- Internship Report on Ghee Manufacturing ProcessDocument36 pagesInternship Report on Ghee Manufacturing ProcessNuman TariqNo ratings yet

- Bacteria Nutrition RequirementsDocument14 pagesBacteria Nutrition RequirementsFuad Hasan Pranto 1921147049No ratings yet

- Catalog330 NORTONDocument68 pagesCatalog330 NORTONPeter JoselitoNo ratings yet

- Ficha Infenium P5096Document2 pagesFicha Infenium P5096yonaathan diazNo ratings yet

- Masterseal TC 257 D GREY Part ADocument10 pagesMasterseal TC 257 D GREY Part ADhiwagar MJNo ratings yet

- Nanomechanical Testing of Gum Metal: # Society For Experimental Mechanics 2009Document9 pagesNanomechanical Testing of Gum Metal: # Society For Experimental Mechanics 2009yerly ramirezNo ratings yet

- Advanced Power Generation Course OutlineDocument52 pagesAdvanced Power Generation Course Outlineluter alexNo ratings yet

- Bcga Code of Practice CP 20: Bulk Liquid Oxygen Storage at Production SitesDocument55 pagesBcga Code of Practice CP 20: Bulk Liquid Oxygen Storage at Production Sitesfadlul akbar herfiantoNo ratings yet

- PDF NiticuDocument7 pagesPDF NiticuSantu BhattacharyaNo ratings yet

- CP BIO: Ch. 7 The Cell MembraneDocument31 pagesCP BIO: Ch. 7 The Cell MembraneJohn Lester BerdinNo ratings yet