Professional Documents

Culture Documents

6063 Profiles

Uploaded by

BPP-Tech PythonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

6063 Profiles

Uploaded by

BPP-Tech PythonCopyright:

Available Formats

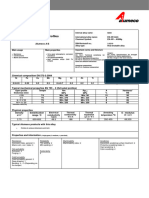

Data Sheet

Internal alloy name: 6063

EN AW 6063 - Profiles International alloy name: EN AW 6063

Chemical Symbol: EN AW – AlMg0,7Si

Alumeco A/S DIN-Werkstoff no.: 3.3208

Alloy type: Heat treatable alloy

Main usage Main properties Important norms and literature

Extrusion: Usages:

• Constructions • Very good atmospheric corrosion EN 13195: Specifications for wrought

EN 755-1: Technical conditions for

• Anodizing in general resistance products for marine applications

inspection and delivery

• Automotive • Very good workability EN 602: Usage in the food industry

EN 755-2: Mechanical properties

• Forgings • Decoration anodisation Series EN 755-3 to EN 755-9: Tolerances

• Marine and offshore • Heat treatable alloys (Soft T4 on dimensions and forms for different

temper) extrusions

Chemical composition:

EN 573-3: Chemical composition

Chemical composition (%) EN 573-3

Si Fe Cu Mn Mg Cr Zn Ti Other elements

Each together

0.20-0.60 0.35 0.10 0.10 0.45-0.90 0.10 0.10 0.10 0.05 0.15

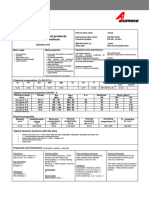

Typical mechanical properties EN 755 - 2

Product group Temper Rm Rp0,2 A Hardness*

Dimension (mm) MPa MPa % min. HB

Rod/Bar ≤ 150 T4 Min. 130 Min. 65 14 50

Rod/Bar ≤ 150 T6 Min. 215 Min. 170 10 75

Tubes T6 Min. 215 Min. 170 10 75

Wall thickness ≤ 25

Profiles T4 Min. 130 Min. 65 14 50

Wall thickness ≤ 25

Profiles T6 Min. 215 Min. 170 8 75

Wall thickness ≤ 10

* Information values only

Physical properties

Density Solidification Electrical Thermal Thermal Annealing E - modulus

g/cm³ range conductivity conductivity expansion temperature ⁰C (N / mm²)

°C %IACS W/m K (µm m-1 K-1)

2.70 615-655 52 201 23.5 350-400 69,500

Typical Alumeco products with this alloy

• Bars in various dimensions and form

• Angle profiles

• Tubes

• Profiles

• Customized profiles

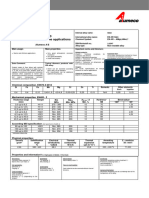

Properties and information (3 high/good; 2 medium; 1 poor/bad)

Resistance Weldability Machinability Anodizing

Corrosion index, general: 3 TIG welding: 2 Machinability index: 1 Decorative anodizing surface

Marine atm. corr. index: 3 MIG welding: 2 treatment: 3

Protective anodizing index: 3

Hot workability Hard anodizing: 3

Extrusion: 3 Solderability Color anodizing: 3

Forging: 3 2

Cold formability

Cold formability general: 2

Deep drawing: 1

Bending: 2 – 3 (Depending on the

temper)

You might also like

- Girder TrussDocument0 pagesGirder Truss74747474No ratings yet

- Hot Works SafetyDocument33 pagesHot Works Safetypammu18No ratings yet

- ASCE7 & API Load Combinations PDFDocument2 pagesASCE7 & API Load Combinations PDFTharach JanesuapasaereeNo ratings yet

- G+12 Raft Foundation ReportDocument13 pagesG+12 Raft Foundation ReportvinujohnpanickerNo ratings yet

- KS3 TestDocument6 pagesKS3 TestVytheeshwaran Vedagiri80% (5)

- Decking (Composite & 2 Layers Reinf)Document41 pagesDecking (Composite & 2 Layers Reinf)Than Than SoeNo ratings yet

- 3 Quarterly Exam: Eim 7 ExploratoryDocument3 pages3 Quarterly Exam: Eim 7 ExploratoryJulcon Avanceña Araiz100% (1)

- Low Cost Housing Report 3 GateDocument71 pagesLow Cost Housing Report 3 GateS.K. Recruiting100% (1)

- 6005 ProfilesDocument1 page6005 ProfilesBPP-Tech PythonNo ratings yet

- 1050a Rolled ProductsDocument1 page1050a Rolled ProductsBPP-Tech PythonNo ratings yet

- Nedal Alloy DataDocument1 pageNedal Alloy DataMurali KrishnaNo ratings yet

- CHP 1 ProjectDocument11 pagesCHP 1 ProjectDhyey KalariyaNo ratings yet

- Flux Cored Arc Welding for Low Carbon 18%Cr-12%Ni-2%Mo Stainless SteelDocument1 pageFlux Cored Arc Welding for Low Carbon 18%Cr-12%Ni-2%Mo Stainless Steelmohamed AdelNo ratings yet

- Cu Zn 15 alloy properties and applicationsDocument2 pagesCu Zn 15 alloy properties and applicationsPetrus UngureanuNo ratings yet

- Data Sheet: Oxygen-Free Copper Cu-OF - Luvata Alloy OF-OKDocument2 pagesData Sheet: Oxygen-Free Copper Cu-OF - Luvata Alloy OF-OKMuhammad Asif IqbalNo ratings yet

- Manganese Bronze Data SheetDocument10 pagesManganese Bronze Data SheetKapil HarchekarNo ratings yet

- 29102015000000B - Boehler DCMS-IG - SWDocument1 page29102015000000B - Boehler DCMS-IG - SWErdinc BayatNo ratings yet

- 29102015000000B - Boehler DCMS-IG - SWDocument1 page29102015000000B - Boehler DCMS-IG - SWErdinc BayatNo ratings yet

- Copper Cu-Dhp / Sf-Cu: Page 1/2Document2 pagesCopper Cu-Dhp / Sf-Cu: Page 1/2gemilanglpNo ratings yet

- 17 4 PHDocument2 pages17 4 PHParag NaikNo ratings yet

- Steel X20Cr13: EN 10250-4:1999, Number: 1.4021Document4 pagesSteel X20Cr13: EN 10250-4:1999, Number: 1.4021AdamNo ratings yet

- Phoenix 7018 Phoenix 6013Document1 pagePhoenix 7018 Phoenix 6013Pedro SilvaNo ratings yet

- LFBCW510L ST enDocument4 pagesLFBCW510L ST endrgilleNo ratings yet

- Data Sheet: Oxygen-Free Copper Cu-OF Standard Grade - Luvata Alloy Cu-OFDocument2 pagesData Sheet: Oxygen-Free Copper Cu-OF Standard Grade - Luvata Alloy Cu-OFMuhammad Asif IqbalNo ratings yet

- Aalco Metals LTD Aluminium Alloy 6082 T6 Extrusions 338Document3 pagesAalco Metals LTD Aluminium Alloy 6082 T6 Extrusions 338minhyen88No ratings yet

- Aalco Metals LTD Aluminium Alloy 6082 T6 Extrusions 338Document3 pagesAalco Metals LTD Aluminium Alloy 6082 T6 Extrusions 338Karan NanwaniNo ratings yet

- S-8018 B2Document5 pagesS-8018 B2Abhishek AnandNo ratings yet

- Cw008a Cu-Of Version1Document1 pageCw008a Cu-Of Version1Gaka RtaNo ratings yet

- BronzeLG2LeadedGunmetalBronze PDFDocument2 pagesBronzeLG2LeadedGunmetalBronze PDFAnthonyNo ratings yet

- Union TG 55 M: Classifications EN ISO 17632-A EN ISO 17632-B AWS A5.20Document2 pagesUnion TG 55 M: Classifications EN ISO 17632-A EN ISO 17632-B AWS A5.20brunizzaNo ratings yet

- Aalco Metals LTD Aluminium Alloy 2011 T3 Rod and Bar 3Document2 pagesAalco Metals LTD Aluminium Alloy 2011 T3 Rod and Bar 3Agung SulisNo ratings yet

- Alloy Data Sheet En-Aw 7020 (Alzn4.5Mg1) : Type: High Strength Structural Alloy)Document1 pageAlloy Data Sheet En-Aw 7020 (Alzn4.5Mg1) : Type: High Strength Structural Alloy)rahul vermaNo ratings yet

- PBT GF30 - Vampter 3026 V0 DFDocument1 pagePBT GF30 - Vampter 3026 V0 DFarmandoNo ratings yet

- 11042016000000T - Thermanit 22 - 09 - Tig RodDocument1 page11042016000000T - Thermanit 22 - 09 - Tig RodKonrad MatuszkiewiczNo ratings yet

- Aluminium Alloy 5083H116 Data SheetDocument1 pageAluminium Alloy 5083H116 Data SheetTarek MassimoNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Martin DuarteNo ratings yet

- AH MergedDocument6 pagesAH MergedReginaldo SantosNo ratings yet

- Aircraft MaterialsDocument71 pagesAircraft MaterialsArif AdjaNo ratings yet

- 2024 Aluminium SheetDocument1 page2024 Aluminium SheetGeorge ChachlakisNo ratings yet

- LINCOLN Nicromo 60-16Document2 pagesLINCOLN Nicromo 60-16AbdülHak ÖZkaraNo ratings yet

- Thermanit Nimo C 24 (ERNiCrMo3) GTAWDocument1 pageThermanit Nimo C 24 (ERNiCrMo3) GTAWNiranjan Fakirchand YadavNo ratings yet

- Bohler-Welding-Germany 26Document1 pageBohler-Welding-Germany 26misthahNo ratings yet

- Robofil M 700Document1 pageRobofil M 700Martin DunneNo ratings yet

- Nedal Alloy Datasheet EN AW 7003 PDFDocument1 pageNedal Alloy Datasheet EN AW 7003 PDFSinan YıldızNo ratings yet

- item22-LNT 502Document1 pageitem22-LNT 502VVan TanNo ratings yet

- 20Mncr5: Steel GradeDocument4 pages20Mncr5: Steel GradeAhmad ShujaNo ratings yet

- Böhler CM 2-Ig: Solid Wire, Low-Alloyed, Creep ResistanceDocument1 pageBöhler CM 2-Ig: Solid Wire, Low-Alloyed, Creep ResistancecocoNo ratings yet

- BS1400 HTB1Document2 pagesBS1400 HTB1Atul KulkarniNo ratings yet

- 02.CARBO - RC 3 Blau eDocument1 page02.CARBO - RC 3 Blau eMario CastilloNo ratings yet

- Sandvik 2RE69: Austenitic Stainless SteelDocument4 pagesSandvik 2RE69: Austenitic Stainless SteelalexmontellNo ratings yet

- 5083 en MarineDocument1 page5083 en MarineBPP-Tech PythonNo ratings yet

- Technical Delivery Condition For: Hot Rolled Carbon (Micro Alloy) SteelDocument2 pagesTechnical Delivery Condition For: Hot Rolled Carbon (Micro Alloy) SteelManjunath UNo ratings yet

- International Material Grade Comparison TableDocument2 pagesInternational Material Grade Comparison TableS.Hasan MirasadiNo ratings yet

- SF-1 Flux-cored wire for mild steel and 490N/mm2 steelDocument1 pageSF-1 Flux-cored wire for mild steel and 490N/mm2 steelHoque AnamulNo ratings yet

- Sandvik SAF 2507: Duplex Stainless SteelDocument8 pagesSandvik SAF 2507: Duplex Stainless SteelmattiaNo ratings yet

- Standards Approvals & Certificates: Rmrs Ce DNV-GL LR Classnk Tuv BV Abs Rina TL DBDocument2 pagesStandards Approvals & Certificates: Rmrs Ce DNV-GL LR Classnk Tuv BV Abs Rina TL DBKhaled GamalNo ratings yet

- 05042016000000A - Avesta 904L - CeDocument1 page05042016000000A - Avesta 904L - CeJorge Uribe RochaNo ratings yet

- Chromecore-430-G Er430Document1 pageChromecore-430-G Er430peymanNo ratings yet

- CSF-71T en 2014Document1 pageCSF-71T en 2014Yousab CreatorNo ratings yet

- Al 99.5 AW 10-50 Aluminium A 1050 Technical Data Sheet RLSADocument2 pagesAl 99.5 AW 10-50 Aluminium A 1050 Technical Data Sheet RLSAAlex GăuruşNo ratings yet

- CSF-71T en 2014Document1 pageCSF-71T en 2014HoangNo ratings yet

- 17 4 PHDocument2 pages17 4 PHzaranrajputNo ratings yet

- Matmatch Is Trusted by 2 Million+ Engineers and Product Developers Each YearDocument3 pagesMatmatch Is Trusted by 2 Million+ Engineers and Product Developers Each Yearhardeep SinghNo ratings yet

- Metallic Material Specification: SUBJECT: AISI 8630 (UNS G86300), Modified Chemistry, 85 Ksi Minimum Yield StrengthDocument5 pagesMetallic Material Specification: SUBJECT: AISI 8630 (UNS G86300), Modified Chemistry, 85 Ksi Minimum Yield StrengthReginaldo SantosNo ratings yet

- Utp 34 NDocument1 pageUtp 34 NbrayanNo ratings yet

- Elerep® 310: ClassificationDocument2 pagesElerep® 310: ClassificationSerhii MishchenkoNo ratings yet

- TECHNOLOGICAL UNIVERSITY OF THE PHILIPPINES LAB REPORTDocument24 pagesTECHNOLOGICAL UNIVERSITY OF THE PHILIPPINES LAB REPORTJeshua LloreraNo ratings yet

- Detailed Plan: Scale 1: 50 @A3 (Foyer Ground Block C)Document1 pageDetailed Plan: Scale 1: 50 @A3 (Foyer Ground Block C)Richard LeongNo ratings yet

- Bypass Thermostats: Installation InstructionsDocument1 pageBypass Thermostats: Installation InstructionsBassieNo ratings yet

- Is.8042.1989 White Cement SpecificationsDocument18 pagesIs.8042.1989 White Cement SpecificationsLucky KhanNo ratings yet

- Manual Montaj Gerard enDocument52 pagesManual Montaj Gerard enrazvan voicuNo ratings yet

- Tds Az 1500 SeriesDocument7 pagesTds Az 1500 SeriesIgor_uhuNo ratings yet

- Numerical Simulation of A Deep Excavation Near A Shield TunnelDocument9 pagesNumerical Simulation of A Deep Excavation Near A Shield TunnelEfi GusfianaNo ratings yet

- 2018 Deco Foil LeafletDocument2 pages2018 Deco Foil LeafletMahmood MolaeiNo ratings yet

- Viking Series 90 Operating & Maintenance Instructions: FiltersDocument15 pagesViking Series 90 Operating & Maintenance Instructions: FiltersninatenaNo ratings yet

- Code of Pactice For Dead and Imposed Loads 2011Document30 pagesCode of Pactice For Dead and Imposed Loads 2011iyhkNo ratings yet

- Tutorial ProblemsDocument3 pagesTutorial ProblemsJoel CurryNo ratings yet

- Tiginox 308H: Classification: ApprovalsDocument1 pageTiginox 308H: Classification: ApprovalsJagannath SahuNo ratings yet

- Pipeline Stress Analysis With Caesar IIDocument16 pagesPipeline Stress Analysis With Caesar IISathish KumarNo ratings yet

- Spojnice ArmatureDocument10 pagesSpojnice ArmatureMilan UljarevicNo ratings yet

- Structural Calculation of Box Culvert Type: B2.00m X H0.50m Class I Road Soil Cover Depth: 1.0 M 1 Dimensions and ParametersDocument3 pagesStructural Calculation of Box Culvert Type: B2.00m X H0.50m Class I Road Soil Cover Depth: 1.0 M 1 Dimensions and ParametersBoby CuliusNo ratings yet

- Equivalent Circulating DensityDocument7 pagesEquivalent Circulating DensityFlorina PrisacaruNo ratings yet

- Shear Force Diagram - Bending Moment DiagramDocument2 pagesShear Force Diagram - Bending Moment Diagrammoondonoo7No ratings yet

- Corrosion-Guide 1 Stainless Steel CategoriesDocument8 pagesCorrosion-Guide 1 Stainless Steel CategoriesMarc L'abbéNo ratings yet

- Weller LT-series PDFDocument13 pagesWeller LT-series PDFsandrorrrNo ratings yet

- Micro Project MRSDocument13 pagesMicro Project MRS너사랑No ratings yet

- Asphalt DistressesDocument31 pagesAsphalt DistressesWillard Apeng100% (1)

- 12.0 Moment and Shear Coefficient For Solid Slab: L Effective Span F Total Ultimate Load 1.35gDocument1 page12.0 Moment and Shear Coefficient For Solid Slab: L Effective Span F Total Ultimate Load 1.35gKumaresvaranNo ratings yet