Professional Documents

Culture Documents

Metso Unveils Plant Predictive

Uploaded by

Juliana AguiarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Metso Unveils Plant Predictive

Uploaded by

Juliana AguiarCopyright:

Available Formats

PROCESSING SOLUTIONS

Metso Unveils Plant Predictive

Maintenance Solution

“Mining companies need more visi-

bility to their processes, equipment

performance, and supply chain to im-

prove safety and efficiency, reduce ener-

gy usage, and, ultimately, inform better

business decisions,” said Blake Moret,

chairman and CEO, Rockwell Automa-

tion. “This connected mine solution al-

lows mining companies to derive measur-

able business value from their operations,

allowing for better collaboration and in-

creased productivity.”

The new offering covers Metso’s pri-

mary gyratory crushers, cone crushers

and vibrating screens. In the future, other

types of minerals processing equipment,

such as mills, will be addressed, accord-

ing to the company. The first generation

of Metso Metrics tools, focused on help-

ing aggregate and quarry producers, were

introduced in 2017.

Modular Trommel Line Offers

Long Life, Easier Maintenance

FLSmidth recently introduced a com-

pletely re-engineered trommel chassis

and associated screen media package.

The new trommel designs, said the com-

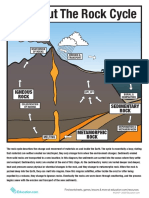

The latest version of Metso’s expanded Metrics service covers its primary gyratory crushers, cone crushers and

vibration screens, with other types of equipment to be included in future releases. pany, have been developed using Finite

Element Analysis (FEA) design calcula-

Metso has expanded its digital Metso ductivity at mine sites. This is where tions to ensure they are structurally sound

Metrics offering with the launch of a new digitalization coupled with expert sup- and can offer excellent service life.

predictive maintenance solution for min- port really comes into play — connect- The re-engineered trommel frames

ing equipment, aimed to help maximize ing the right data with the right people,” utilize modular design and standardized

the uptime and performance of comminu- said Jani Puroranta, chief digital officer, construction principles that provides a

tion circuits. The service was introduced Metso. “With innovative digital tools frame with less mass while maintaining

at the recent Automation Fair conference like Metso Metrics, minerals process- maximum structural integrity. The new

hosted by Rockwell Automation in Phila- ing plants can shift from reactive-mode design employs screen media that is cus-

delphia, Pennsylvania, USA. to being proactive and focused on con- tom designed to be easy and safe to in-

Metso said its Metrics solution is de- tinuous improvement.” stall and service.

signed to provide global mining custom- The Industrial Internet of Things (IIoT) The screening media weigh less than

ers improved visibility and new insights solution is built on the Rockwell Automa- 25 kg each and are fitted to the trommel

into their equipment and processes with tion FactoryTalk Cloud platform, powered using friction grip rails that don’t require

analytics, condition monitoring and pre- by Microsoft Azure. It securely collects bolts or pins. Panel fitting and main-

dictive maintenance, backed by expert data from hundreds of sensors within tenance activities can be carried out

support from Metso. The company said Metso equipment to assess process per- quickly and safely using simple tools,

the combination of advanced technology formance, as well as predict component reducing the time it takes to perform

and expertise will bring Metso services wear and failure. Metso performance routine maintenance activities, according

closer to customers by improving collabo- teams analyze the data with the support to the company.

ration, asset reliability and optimization. of advanced machine learning algorithms, Discrete Element Analysis (DEM) soft-

“Optimization of existing assets and to help customers optimize equipment ware, available to customers through FLS-

processes is now the key to drive pro- operations and processes. midth, simulates trommel operation and

100 E&MJ • DECEMBER 2018 www.e-mj.com

PROCESSING SOLUTIONS

Designed by FLSmidth with the aid of Finite Element Analysis techiques, the company’s new trommels are said to offer superior service life coupled with maintenance features

that enable quicker, easier service and media replacement.

allows an analysis of pulp flow through performance. The Timken Co. recently method in which a solid is vaporized pro-

the unit. The company said its engineers noted that even though it uses special ducing atoms or molecules that are trans-

can advise on how to optimize pulp flow heat-treating processes to produce highly ported in a vacuum to be deposited on

through the trommel to improve both durable bearings, some applications re- the object as a thin film. These coatings

throughput and wear life of the screens. quire a superior degree of wear resistance typically provide the highest level of wear

The trommel chassis can be custom and corrosion protection. resistance and friction reduction. Timken

made to suit specific requirements. The Timken said it has more than 20 years has validated bearing-life improvements

company said global sourcing plans are applied surface engineering technologies up to six times over the standard where

already in place and, in combination with to bearing rolling elements (balls and roll- PVD coatings are used in laboratory studies

the modular features incorporated in the ers) to limit component damage in harsh while in oil-out conditions. These bearings

new designs, that allows trommel chas- operating conditions where standard bear- have been observed to last approximately

sis to be fabricated closer to customers’ ings tend to fall short of customer expec- 10 times longer than those with uncoated

sites, providing faster delivery. tations for long, trouble-free life. rollers. Timken said PVD is a rigorous coat-

“We are excited to deliver this inno- When rolling elements with specific ing process that must be controlled within

vative solution to the market because we coatings and engineered surfaces are in- world-class production facilities and with

believe it will be a key component for in- corporated into a bearing, the assembly stringent design and quality specifications.

creased capacity for our customers. We may be described as a “wear-resistant Electrodeposited Coatings: Electrode-

recognized the customer’s need for a sim- bearing” by Timken. Decades of intensive posited coatings provide outstanding cor-

ple to use and dependable trommel solu- research and development have resulted rosion-resistance protection for a wide

tion and we responded. These are suit- in a range of coating options that enhance range of applications. This type of coat-

able to any mining operation across the the performance of bearings in mining and ing is typically applied on bearings expe-

globe and will deliver on our promise of many other types of industrial equipment. riencing lighter loads and nonacidic solu-

sustainable productivity enhancement,” Timken said it solves complex friction- tions. The degree of corrosion protection

said Brent Stokes, head of Wear Parts & management problems in a variety of ways, depends on the type of coating and the

Consumables, FLSmidth. including fundamental innovations in tri- application. Some coatings also increase

bology, lubrication, surface engineering and bearing wear life because they harden the

Coatings Cater to Bearings’ materials science. Understanding friction contact surfaces.

Special Needs and wear at the atomic level helps Timken Surface Conversions: Conversion coat-

Heavy industry demands stronger bear- engineer custom coatings for bearing com- ings combine excellent wear and corrosion

ings that can withstand greater loads, ponents that greatly improve the bearing’s resistance with an ability to withstand false

faster speeds, higher temperatures and ability to resist corrosion and wear. brinelling (fretting wear caused by oscilla-

the constant threat of contamination. The Timken coatings portfolio includes: tions or vibrations). While not as durable

Bearings in critical equipment are of- PVD Coatings: Physical vapor deposi- as PVD coatings, they offer another way

ten pushed to the limits of reliable tion (PVD) describes a vacuum-deposition to improve bearing performance and tend

www.e-mj.com DECEMBER 2018 • E&MJ 101

PROCESSING SOLUTIONS

to cost less than premium options. Black producer PT Amman Mineral Nusa Teng- 61850, making it possible to digitalize

oxide coatings, for instance, are processed gara. The contract, valued at approximate- existing brownfield sites.”

in an alkaline bath to convert the bearing ly €10 million, has been booked in Ou- The Power Control Library is part of

surface to an oxide layer. This helps retain totec’s 2018 fourth-quarter order intake. the ABB Ability MineOptimize digital

lubricant on the steel surfaces and mini- Outotec’s scope of engineering covers portfolio. It works with ABB Ability Sys-

mize wear in applications where bearing the design of the entire copper smelter. The tem 800xA, which is a platform for moni-

rollers are prone to slip or skid on the rings. engineering will be based on Outotec Flash toring and controlling a wide range of au-

Spray Coatings: Spray coatings such as Smelting and Flash Converting technology, tomated industrial processes. The library

powder coat and dielectric coat are main- and the facility includes an electrolytic re- is based on the International Electrotech-

ly applied to housed bearings, ancillary finery, slag concentrator, precious metals nical Commission’s (IEC) 61850 stan-

components and backing rings to resist refinery, wet gas cleaning, and Lurec sulfu- dard, which creates a common language

corrosion. Dielectric coatings also inhib- ric acid plant as well as effluent treatment for automated substations and power dis-

it electric arcing by providing insulation plant and its associated infrastructure. tribution systems so that technologically

where current passage through the bear- Outotec’s design work will take place advanced mines around the world are

ing is a damage risk. The housed bearing in the next nine months and is a continu- able to take advantage of its capabilities.

units commonly found on conveyors and ation of the feasibility study conducted in The updated version supports non-IEC

other material-handling applications are 2017. Once completed, the new smelter 61850 substations through the PLC Con-

good candidates for spray coatings that is planned to primarily process Indone- nect functionality of System 800xA, to com-

can deliver excellent corrosion resistance. sian copper concentrate. municate with and control a broader range

The company warned that coatings of intelligent electronic devices (IEDs).

cannot improve the performance of bear- ABB Updates Plant Power The Power Control Library provides en-

ings made of substandard steel or having Control Software Library gineers that operate automated mines with

poor dimensional control. An effective ABB has modified its ABB Ability System the ability to rapidly troubleshoot electri-

bearing solution starts with properly de- 800xA Power Control Library (formerly cal system issues through an enhanced

signed component geometry and met- MIDAS Library) software to include more substation control and monitoring envi-

allurgy for meeting clear application re- options to communicate with and control ronment in one control room. It allows a

quirements, and it must be manufactured electrical devices throughout the power broader range of electrical and substation

using appropriate methods and quality infrastructure for mining and mineral pro- equipment to be monitored and managed

processes. Only then will advanced treat- cessing operations. The digital solution remotely, so that potential issues can be

ments on functional surfaces deliver the now supports the PLC (Programmable resolved quickly and safely. This remote

specific benefits a customer is looking for. Logical Controller) Connect functionality monitoring allows the plant team to solve

Coatings, according to Timken, can to extend power automation beyond IEC problems safely, away from the electrical

deliver benefits anywhere load, speed and 61850 devices and infrastructure. substation, thus reducing the time for elec-

temperature requirements tax the capa- Martin Knabenhans, head of product trical fault diagnosis and problem solving.

bilities of conventional bearings. For ex- management for ABB’s Process Indus- ABB said that since its introduction in

ample, a customer will change from one tries business unit, said, “With the addi- 2014, the Power Control Library has been

type of lubricant to another and discover tion of PLC Connect support, this Power implemented in more than 20 projects

they’ve become susceptible to new sur- Control release also enables digitalization worldwide and has integrated more than

face wear as a result. Or a customer may for substations that were built without 4,000 IEDs.

want to run with a lower-viscosity lubri-

cant to improve the energy efficiency of

their equipment, but this can damage the

bearing. In such cases, a special coating

can be a cost-effective solution. Ulti-

mately, the goal for all customers is to ex-

tend the life of the bearing and eliminate

maintenance intervals.

More advice for extending bearing life

and reducing equipment downtime is

available online at timken.com/coatings.

Outotec to Design a Copper

Smelter in Indonesia

Outotec has signed a contract for the

Front-End Engineering Design (FEED)

of a new copper smelter to be located at

Benete Bay in Sumbawa, Indonesia. The

contract partner is PT Amman Mineral ABB’s Power Control Library software now offers a wider range of communication options for plant and mine

Industri, a subsidiary of copper and gold electrical systems, allowing them to be monitored and managed remotely.

102 E&MJ • DECEMBER 2018 www.e-mj.com

Copyright of Engineering & Mining Journal (00958948) is the property of Mining Media Inc.

and its content may not be copied or emailed to multiple sites or posted to a listserv without

the copyright holder's express written permission. However, users may print, download, or

email articles for individual use.

You might also like

- Dancing on a Cloud: A Framework for Increasing Business AgilityFrom EverandDancing on a Cloud: A Framework for Increasing Business AgilityNo ratings yet

- Longwall BrochureDocument9 pagesLongwall Brochurediky putraNo ratings yet

- Longwall Systems - Product Overview - English - EN-FA01Document9 pagesLongwall Systems - Product Overview - English - EN-FA01Freddie FosterNo ratings yet

- En 12cms01 12cm SeriesDocument5 pagesEn 12cms01 12cm SeriesAmit NagNo ratings yet

- Journal 02 10 eDocument88 pagesJournal 02 10 eWasif KhanNo ratings yet

- Cuerpos Moledores - DuomaxDocument2 pagesCuerpos Moledores - Duomaxmechanic78No ratings yet

- Accenture Report 2010Document12 pagesAccenture Report 2010PepeLeTvorNo ratings yet

- Handbook Wear Lining Sheeting 2976 en Lowres PDFDocument88 pagesHandbook Wear Lining Sheeting 2976 en Lowres PDFEngineering Office ShahrakNo ratings yet

- Solutions For Metal Forming: Innovative CarbideDocument2 pagesSolutions For Metal Forming: Innovative CarbideSa RaNo ratings yet

- Customer Story - TexmoDocument2 pagesCustomer Story - TexmoKirupa SankarNo ratings yet

- Kuettner Processing TechnologyDocument6 pagesKuettner Processing TechnologyalgobozkurtNo ratings yet

- FRIMO Technology Pressing Forming USDocument17 pagesFRIMO Technology Pressing Forming USAnonymous r3MoX2ZMTNo ratings yet

- Memiontec Holdings LTD.: Corporate ProfileDocument503 pagesMemiontec Holdings LTD.: Corporate ProfileJason RiadyNo ratings yet

- ALISSON - Metal-Matrix Composites in The Automative Industry - Opportunities and ChallengesDocument6 pagesALISSON - Metal-Matrix Composites in The Automative Industry - Opportunities and ChallengesJuliana Marotta RodriguesNo ratings yet

- Mapper - Lithography in Nature BusinessDocument1 pageMapper - Lithography in Nature BusinessdewilibiawatiNo ratings yet

- Industry Suite Automotive PDFDocument2 pagesIndustry Suite Automotive PDFUmesh SNo ratings yet

- Paper 2Document15 pagesPaper 2sashankknjsNo ratings yet

- European Technology Report.5dcecb4a25432Document26 pagesEuropean Technology Report.5dcecb4a25432Baptiste BetatNo ratings yet

- Syl201802 enDocument8 pagesSyl201802 enVictor alfonso vargasNo ratings yet

- 14cm-Brochure Joy GlobalDocument5 pages14cm-Brochure Joy GlobalbikamlnclNo ratings yet

- Jose Antonio Moreno - Danobat ScoopDocument6 pagesJose Antonio Moreno - Danobat ScoopÂrbaoui MedNo ratings yet

- 20 Most Promising Utilities Technology Solution ProviderDocument2 pages20 Most Promising Utilities Technology Solution ProviderlololeoNo ratings yet

- Aluminium Additive Manufacturing Applications in AviationDocument9 pagesAluminium Additive Manufacturing Applications in AviationtinaNo ratings yet

- Set-Up Reduction in An Interconnection Axle Manufacturing Cell Using SMEDDocument10 pagesSet-Up Reduction in An Interconnection Axle Manufacturing Cell Using SMEDVõ Hồng HạnhNo ratings yet

- 1707207969towards Circular Economy in Manufacturing Industries Based On Industry 4.0 TechnologiesDocument5 pages1707207969towards Circular Economy in Manufacturing Industries Based On Industry 4.0 TechnologiesRuhaniayth EvanNo ratings yet

- Welding and Cutting Issue 2 2014 LowresDocument64 pagesWelding and Cutting Issue 2 2014 LowresScott TrainorNo ratings yet

- HydMiningExcavators Brochure English EN HMEXBR01 0723 V1Document12 pagesHydMiningExcavators Brochure English EN HMEXBR01 0723 V1Alam Jaya KusumaNo ratings yet

- Underground Drilling Advances Improve Productivity, Safety While Cutting CostsDocument6 pagesUnderground Drilling Advances Improve Productivity, Safety While Cutting CostsHamilton Rubio BastidasNo ratings yet

- Sinterformteile MIM EnglDocument12 pagesSinterformteile MIM EnglMatija BušićNo ratings yet

- Brochure Talk2MDocument7 pagesBrochure Talk2MJorge Tamayo MancillaNo ratings yet

- Bending & Cutting Technologies Collection 2013Document35 pagesBending & Cutting Technologies Collection 2013Dragisa DjukicNo ratings yet

- Component Replacement Labor: For Crushing EquipmentDocument2 pagesComponent Replacement Labor: For Crushing EquipmentKarin AndersonNo ratings yet

- Conversion Kit For Komatsu PC2000-8 Hydraulic Excavator: Simulation Delivering Safety & ProductivityDocument4 pagesConversion Kit For Komatsu PC2000-8 Hydraulic Excavator: Simulation Delivering Safety & ProductivitysughieantoNo ratings yet

- Multicon Ic Amce2024 - 88Document15 pagesMulticon Ic Amce2024 - 88Pankaj ShelarNo ratings yet

- BRE Modern Methods of ConstructionDocument10 pagesBRE Modern Methods of ConstructionJack McLoughlinNo ratings yet

- Sistema de Trituracion y Cinta Transportadora.Document11 pagesSistema de Trituracion y Cinta Transportadora.Enso E Rosales FNo ratings yet

- Simulators and Demonstrators - Efficient Tools - Version 21-08-09Document21 pagesSimulators and Demonstrators - Efficient Tools - Version 21-08-09Khanh QuocNo ratings yet

- Casting Brochure 0Document12 pagesCasting Brochure 0makdangNo ratings yet

- Casting Brochure 1 PDFDocument12 pagesCasting Brochure 1 PDFAkshayNo ratings yet

- Amdocs Ms360 Appledore SolutionDocument22 pagesAmdocs Ms360 Appledore SolutionHesam SolhiNo ratings yet

- Editorial - EXPLOSIVES AND BLASTING - International MiningDocument7 pagesEditorial - EXPLOSIVES AND BLASTING - International MiningMoise EtsoraNo ratings yet

- Mid-Range Focused Activities: Analyzing Running Costs of Construction and Mining EquipmentDocument3 pagesMid-Range Focused Activities: Analyzing Running Costs of Construction and Mining EquipmentAshokNo ratings yet

- Catalog Modicon M241 Programmable Logic Controller For Performance Demanding Applications - October 2023Document21 pagesCatalog Modicon M241 Programmable Logic Controller For Performance Demanding Applications - October 2023control.divisionNo ratings yet

- International Journal of Computer Integrated ManufacturingDocument16 pagesInternational Journal of Computer Integrated ManufacturingHassan SalviNo ratings yet

- WmsDocument6 pagesWmsStevoIlicNo ratings yet

- Valust Sa011f en PDocument8 pagesValust Sa011f en PSandeep KulkarniNo ratings yet

- Batching Plant PDFDocument2 pagesBatching Plant PDFvinay rode50% (2)

- Flexible Cutting SystemDocument1 pageFlexible Cutting SystemTran AnhNo ratings yet

- Ecostruxure Architecture: Apps, Analytics & ServicesDocument1 pageEcostruxure Architecture: Apps, Analytics & ServicesS DNo ratings yet

- Cable Chains Catalogue 2019.01 enDocument123 pagesCable Chains Catalogue 2019.01 enJose Ramon Florez OrdizNo ratings yet

- Plastics in Automotive Engineering: Technical Solutions and TrendsDocument2 pagesPlastics in Automotive Engineering: Technical Solutions and TrendsMoHaN RaMaNaNo ratings yet

- Ecostruxure Machine Expert - Basic: Programming Software For Modicon M221 Logic ControllerDocument12 pagesEcostruxure Machine Expert - Basic: Programming Software For Modicon M221 Logic ControllerGoran PantelicNo ratings yet

- Trbonet Plus BrochureDocument5 pagesTrbonet Plus BrochureZilicoNo ratings yet

- Motorola TETRA CEP400 Brochure EN PDFDocument6 pagesMotorola TETRA CEP400 Brochure EN PDFVarlan DragosNo ratings yet

- Modeling and Simulation of Wear in A Pin On Disc TribometerDocument10 pagesModeling and Simulation of Wear in A Pin On Disc Tribometergoldy243usNo ratings yet

- Catalog Modicon M221 Programmable Logic Controller - February 2023Document27 pagesCatalog Modicon M221 Programmable Logic Controller - February 2023Edgardo RivasNo ratings yet

- Modicon M251 Logic Controllers: Catalog JuneDocument20 pagesModicon M251 Logic Controllers: Catalog JuneПавелNo ratings yet

- OilfieldTechnology October 2017 PreviewDocument17 pagesOilfieldTechnology October 2017 PreviewIgnacio MarínNo ratings yet

- Leaflet PC200 8M0Document22 pagesLeaflet PC200 8M0Egy KelokNo ratings yet

- Industry 4.0 Potential in Textile Production (Dyeing and Finishing)Document3 pagesIndustry 4.0 Potential in Textile Production (Dyeing and Finishing)DineshKumar VermaNo ratings yet

- G Ctec90Document105 pagesG Ctec90Manish IyerNo ratings yet

- 014 - Design and Structure Optimization of A Reconfigurable Vibrating ScreenDocument21 pages014 - Design and Structure Optimization of A Reconfigurable Vibrating ScreenJuliana AguiarNo ratings yet

- 024 - An Exact Modal Analysis Approach To VibrationDocument51 pages024 - An Exact Modal Analysis Approach To VibrationJuliana AguiarNo ratings yet

- 001 - A Dynamic Optimization Theoretical Method For Heavy LoadedDocument19 pages001 - A Dynamic Optimization Theoretical Method For Heavy LoadedJuliana AguiarNo ratings yet

- Parte2 InglesDocument15 pagesParte2 Inglesguillermo zubietaNo ratings yet

- Development and Verification of The Diagnostic Mod PDFDocument14 pagesDevelopment and Verification of The Diagnostic Mod PDFguillermo zubietaNo ratings yet

- Natural Frequency Vibrating ScreenDocument7 pagesNatural Frequency Vibrating ScreenJuliana AguiarNo ratings yet

- FatigaDocument9 pagesFatigajhon ortizNo ratings yet

- Natural Frequency Vibrating ScreenDocument7 pagesNatural Frequency Vibrating ScreenJuliana AguiarNo ratings yet

- DEM Technical Manual PDFDocument89 pagesDEM Technical Manual PDFJuliana AguiarNo ratings yet

- Powder TechnologyDocument12 pagesPowder TechnologyJuliana AguiarNo ratings yet

- Engineering Failure Analysis: F. Rumiche, A. Noriega, P. Lean, C. Fosca TDocument9 pagesEngineering Failure Analysis: F. Rumiche, A. Noriega, P. Lean, C. Fosca TJuliana AguiarNo ratings yet

- ContentServer PDFDocument15 pagesContentServer PDFLUIS ISAAC LEON PARONo ratings yet

- Dynamic Design Theory and Application of Large Vibrating ScreenDocument9 pagesDynamic Design Theory and Application of Large Vibrating ScreenAbhileshWaradeNo ratings yet

- 008 - Vibration Characteristics of An Inclined Flip-Flow Screen PanelDocument21 pages008 - Vibration Characteristics of An Inclined Flip-Flow Screen PanelJuliana AguiarNo ratings yet

- 001 - A Dynamic Optimization Theoretical Method For Heavy LoadedDocument19 pages001 - A Dynamic Optimization Theoretical Method For Heavy LoadedJuliana AguiarNo ratings yet

- Failure and Sensitivity Analysis of A Reconfigurable Vibrating Screen Using Finite Element AnalysisDocument12 pagesFailure and Sensitivity Analysis of A Reconfigurable Vibrating Screen Using Finite Element Analysisالمشري بدوNo ratings yet

- Caldera AcutubularDocument12 pagesCaldera AcutubularZhalom Chiclayo CuzcoNo ratings yet

- Journal of Sound and Vibration: S. Abolfazl Zahedi, Vladimir BabitskyDocument12 pagesJournal of Sound and Vibration: S. Abolfazl Zahedi, Vladimir BabitskyJuliana AguiarNo ratings yet

- 003 - Dynamic Analysis of A Chaotic Vibrating Screen PDFDocument7 pages003 - Dynamic Analysis of A Chaotic Vibrating Screen PDFJuliana AguiarNo ratings yet

- DEM Technical Manual PDFDocument89 pagesDEM Technical Manual PDFJuliana AguiarNo ratings yet

- DEM Technical Manual PDFDocument89 pagesDEM Technical Manual PDFJuliana AguiarNo ratings yet

- AltuglasDocument4 pagesAltuglasBhanuNo ratings yet

- SOLAR PV TechnologiesDocument33 pagesSOLAR PV TechnologiesMuraryspottyNo ratings yet

- Analisa Harga SatuanDocument8 pagesAnalisa Harga SatuanMbeda NayNo ratings yet

- HT Practice QuestionsDocument3 pagesHT Practice QuestionsVivek SharmaNo ratings yet

- Rock Cycle QuizDocument2 pagesRock Cycle QuizKizzi Kye Edelweiss BalmoresNo ratings yet

- Structure of SnO2 Nanoparticles by Sol-Gel MethodDocument3 pagesStructure of SnO2 Nanoparticles by Sol-Gel Methodivan benayaNo ratings yet

- Cleaning Pig Designs and ApplicationsDocument24 pagesCleaning Pig Designs and ApplicationsChristopher BrownNo ratings yet

- Reactivity Series QPDocument5 pagesReactivity Series QPSalman Farsi TaharatNo ratings yet

- 2 2 3 Aa RecyclingFactsDocument5 pages2 2 3 Aa RecyclingFactsRyan CedergrenNo ratings yet

- Demoulding of Concrete Cubes From Plastic MDocument4 pagesDemoulding of Concrete Cubes From Plastic MangelinemiuNo ratings yet

- IRC 58 (Plain Jointed Rigid Pavements Design Highways)Document61 pagesIRC 58 (Plain Jointed Rigid Pavements Design Highways)herculesbhai73% (11)

- Iec60599 (Ed3 0) BDocument82 pagesIec60599 (Ed3 0) Bnamsaigon316No ratings yet

- Safety Data Sheet: 1. IdentificationDocument6 pagesSafety Data Sheet: 1. IdentificationJessie O.BechaydaNo ratings yet

- SAE J429 - Portland BoltDocument2 pagesSAE J429 - Portland BoltDileepa WarnakulasooriyaNo ratings yet

- Blocks & M Sand RegisterDocument2 pagesBlocks & M Sand Registersurendra kumarNo ratings yet

- Hysys PrintDocument1 pageHysys Printlebiatan89No ratings yet

- Young's Modulus, Tangent Modulus, and Chord Modulus: Standard Test Method ForDocument7 pagesYoung's Modulus, Tangent Modulus, and Chord Modulus: Standard Test Method Forruben carcamoNo ratings yet

- Box Culvert - ISDocument14 pagesBox Culvert - ISShyamontika Choudhury ChakrabartiNo ratings yet

- Scale InhibitorDocument17 pagesScale InhibitorNihad S ZainNo ratings yet

- Eum 20230918Document31 pagesEum 20230918Govend BarNo ratings yet

- Conveyor BeltsDocument12 pagesConveyor BeltsEGS_1977No ratings yet

- Hempel Paint Manual 2019Document98 pagesHempel Paint Manual 2019copperratt7228No ratings yet

- Lecture # 4Document28 pagesLecture # 4Usama ShahidNo ratings yet

- Project Sherazi 12april2010Document159 pagesProject Sherazi 12april2010Carlos MarquezNo ratings yet

- Zipper Pull Strength 80 N: Test Results Buyer RequirementDocument1 pageZipper Pull Strength 80 N: Test Results Buyer Requirementyogesh123789No ratings yet

- Performance Evaluation of Water Hyacinth PDFDocument78 pagesPerformance Evaluation of Water Hyacinth PDFcarlooooNo ratings yet

- Catalyst Support Effects: Gas-Phase Hydrogenation of Phenol Over PalladiumDocument12 pagesCatalyst Support Effects: Gas-Phase Hydrogenation of Phenol Over PalladiumRungrawin NgamkhumNo ratings yet

- Thermochemistry - Chapter 6Document45 pagesThermochemistry - Chapter 6Gokul MukundaNo ratings yet

- 7 Marking Scheme: Worksheet (AS) : A F P A Decreases, Therefore The Pressure Exerted On The Floor Will IncreaseDocument2 pages7 Marking Scheme: Worksheet (AS) : A F P A Decreases, Therefore The Pressure Exerted On The Floor Will IncreaseRuby Chong100% (1)

- SPE 76-002 (2006) Flange MaterialsDocument6 pagesSPE 76-002 (2006) Flange Materials김창배No ratings yet

- RV Living Collection: RV living for beginners, RV travel for the whole family, RV repair and RV mobile solar power: Experience Freedom on the roads alone or with your family with this collection. Learn how to repair your motorhome while using renewable energy!From EverandRV Living Collection: RV living for beginners, RV travel for the whole family, RV repair and RV mobile solar power: Experience Freedom on the roads alone or with your family with this collection. Learn how to repair your motorhome while using renewable energy!No ratings yet

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesFrom EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesRating: 4.5 out of 5 stars4.5/5 (21)

- Shorting the Grid: The Hidden Fragility of Our Electric GridFrom EverandShorting the Grid: The Hidden Fragility of Our Electric GridRating: 4.5 out of 5 stars4.5/5 (2)

- The Permaculture City: Regenerative Design for Urban, Suburban, and Town ResilienceFrom EverandThe Permaculture City: Regenerative Design for Urban, Suburban, and Town ResilienceNo ratings yet

- A Pathway to Decarbonise the Shipping Sector by 2050From EverandA Pathway to Decarbonise the Shipping Sector by 2050No ratings yet

- Carbon Capture, Utilization, and Storage Game Changers in Asia: 2020 Compendium of Technologies and EnablersFrom EverandCarbon Capture, Utilization, and Storage Game Changers in Asia: 2020 Compendium of Technologies and EnablersRating: 4.5 out of 5 stars4.5/5 (2)

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- Solar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsFrom EverandSolar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsRating: 4.5 out of 5 stars4.5/5 (2)

- Renewable Energy: A Very Short IntroductionFrom EverandRenewable Energy: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (12)

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsFrom EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsNo ratings yet

- ISO 50001: A strategic guide to establishing an energy management systemFrom EverandISO 50001: A strategic guide to establishing an energy management systemNo ratings yet

- Fundamentals of Hydrogen Production and Utilization in Fuel Cell SystemsFrom EverandFundamentals of Hydrogen Production and Utilization in Fuel Cell SystemsNo ratings yet

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNo ratings yet

- Live Off Grid: Escape The City, Learn How To Travel Intelligently Using Solar PowerFrom EverandLive Off Grid: Escape The City, Learn How To Travel Intelligently Using Solar PowerNo ratings yet

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successFrom EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successRating: 4.5 out of 5 stars4.5/5 (3)

- Global Landscape of Renewable Energy FinanceFrom EverandGlobal Landscape of Renewable Energy FinanceNo ratings yet

- Practical Reservoir Engineering and CharacterizationFrom EverandPractical Reservoir Engineering and CharacterizationRating: 4.5 out of 5 stars4.5/5 (3)

- Electrical Load-Curve Coverage: Proceedings of the Symposium on Load-Curve Coverage in Future Electric Power Generating Systems, Organized by the Committee on Electric Power, United Nations Economic Commission for Europe, Rome, Italy, 24 – 28 October 1977From EverandElectrical Load-Curve Coverage: Proceedings of the Symposium on Load-Curve Coverage in Future Electric Power Generating Systems, Organized by the Committee on Electric Power, United Nations Economic Commission for Europe, Rome, Italy, 24 – 28 October 1977No ratings yet

- The Way Home: Tales from a life without technologyFrom EverandThe Way Home: Tales from a life without technologyRating: 4 out of 5 stars4/5 (45)

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetFrom EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetRating: 2 out of 5 stars2/5 (1)

- Industrial Waste Treatment HandbookFrom EverandIndustrial Waste Treatment HandbookRating: 5 out of 5 stars5/5 (1)

- Grid-Scale Energy Storage Systems and ApplicationsFrom EverandGrid-Scale Energy Storage Systems and ApplicationsFu-Bao WuNo ratings yet

- Practical Methods for Analysis and Design of HV Installation Grounding SystemsFrom EverandPractical Methods for Analysis and Design of HV Installation Grounding SystemsRating: 4.5 out of 5 stars4.5/5 (2)