Professional Documents

Culture Documents

Building Sciences

Uploaded by

giwneioOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Building Sciences

Uploaded by

giwneioCopyright:

Available Formats

The following article was published in ASHRAE Journal,

July 2007. ©Copyright 2007 American Society of Heating,

Refrigerating and Air-Conditioning Engineers, Inc. It is

presented for educational purposes only. This article may not

be copied and/or distributed electronically or in paper form

without permission of ASHRAE.

Capillary Suction

Small Sacrifices

By Joseph W. Lstiburek, Ph.D., P.Eng., Fellow ASHRAE ported by capillarity in solution through porous soils. When

porous building materials are in direct contact with porous

W

ater causes enough trouble by itself, but when we soils, the building materials also wick the water inwards

add salt, we go to another level, especially where and upwards. Concrete footings are typically placed directly

porous materials are concerned. What is the deal onto soil without any intervening capillary break, and water

with porous materials? Porous materials are capable of wick- wicks upward into the structure. The Brits call this “rising

ing water large distances due to capil- damp.” This rising damp, or capillary

lary suction.1 And, when water can groundwater, can cause serious dam-

move large distances, only bad things age in buildings. In new structures, the

can happen. problem is easy to avoid by installing

Some of the tiniest pores can be a capillary break on the top of foot-

found in wood, concrete, mortar and ings. We already provide capillary

brick. And, guess what we use as build- Capillary Break breaks under slabs—stones or sheet

On Exterior

ing materials? Yes, wood, concrete, Foundation Wall

membranes such a polyethylene—and

mortar and brick. The theoretical limit Capillary Break on the exterior of foundation walls

Under Slab

of capillary rise in concrete is about 10 by coating them with bitumen (damp

km (6 miles)—and that is not a typo. proofing). Adding capillary breaks

Concrete sucks big time. In wood it is over the top of footings makes the pro-

about 400 ft (122 m). The height that Capillary Break on Top of Footing tection continuous and avoids mois-

trees can grow is limited by the size of ture problems when below-grade inte-

the capillary pores in wood. Ever won- Figure 1: Capillary Break Over Footing. It’s not rior spaces are insulated and finished

der how leaves get water? When you go a common practice, but it should be because (Figure 1). But, how do we deal with

into a forest and listen carefully, you of the likelihood of finishing and insulating existing structures, especially the old

don’t hear any pumps pumping water interior below-grade spaces. ones? We need to figure this out be-

upwards to a couple of hundred feet do cause we have a lot of old buildings to

you? Capillary suction is powerful stuff. When you add salt to retrofit if we are serious about dealing with climate change

the water, the power becomes explosive, as we shall see. and energy security.

It is common for groundwater to dissolve mineral salts The best way to understand old buildings is to talk to old

found in the earth. These dissolved mineral salts are trans- people. Unfortunately, the old people we need to talk to are so

Evaporation

“Spalling”

Water with salt in solution travels in Salt is left behind as water Water rushes to dilute concentration Surface breaks apart and flakes when

porous material via capillary flow to evaporates; process leads to an of salt, leading to potentially huge hydrostatic pressure due to osmosis

surface where evaporation occurs. ever-increasing concentration of salt hydrostatic pressures. exceeds cohesive

as evaporation continues. strength of material.

Figure 2: Spalling of Porous Materials. Without salt present, evaporation of water from porous surfaces often can be easily managed.

With salt present, significant damage can occur.

58 ASHRAE Journal ashrae.org July 2007

old they have been dead for a long time. Hence, we must use

a tool practically unknown in the Internet age—books—and

really old ones that are typically written in a language other

than English by some long dead European.

First a little “engineering physics”* to help us understand

salt and water in porous materials. Figure 2 shows water with

salt in solution traveling through a porous material by capil-

lary flow to a surface where evaporation occurs. As the capil-

lary water evaporates from the surface, the salt is left behind.

As water continues to evaporate from the surface, this leads Photograph 1: Efflorescence on brick foundation.

to an ever-increasing concentration of salt in the material.

This increasing concentration of salt disturbs matters, and to

reestablish equilibrium, water rushes towards the salt to di-

lute the concentration of salt. This can lead to huge hydro-

static pressures within the porous material. Aficionados (aka

“geeks”) will recognize this as osmosis. Mortar “Eaten” Away as

The forces are not trivial (see below).2 The osmosis pres- Drying Happens From Within

The Mortar Matrix

sures can exceed the cohesive strength of most porous materi- Salts Left Behind on Surface

als, and they literally blow apart. In the Form of Crystals

(Efflorescence)

Diffusion Vapor Pressure 0.3 to 0.5 psi (2.1 to 3.5 kPa)

Capillary Pressure 300 to 500 psi (2.1 to 3.5 MPa) Evaporation From Surface

Osmotic Pressure 3,000 to 5,000 psi (21 to 35 MPa) Film of Water

Photograph 1 shows salt on the above-grade exposed sur-

face of a brick foundation. Water carries salt in solution to

the surface of the brick where the water evaporates, leaving

behind the salt on the surface of the brick in the form of salt

crystals. The white deposits of mineral salts are called efflo- Capillary Flow of Salts in Solution

rescence.When the crystallization of salts happen beneath the

surface of the brick-mortar matrix, the phenomenon is called Figure 3: Efflorescence and Spalling Brick in Foundations. Dam-

subsurface efflorescence or subflorescence. If the subflores- age is limited to lower portions of foundation—closest to the source

cence leads to sufficiently strong osmotic pressures—greater of capillary water and salt.

than the strength of the brick—and the brick flakes apart, the

damage is called spalling.

Figure 3 illustrates the common situation at the base of

a brick foundation in an old building. The mortar fails near

the base of the wall due to subflorescence. The damage is

localized near the base of the wall as the capillary water

does not travel upward very far as it is easier for it to evapo- Lime Mortar “Eaten” Away

Over Time, “Sacrificing”

rate inwards rather than travel upwards. If it is prevented Itself to Protect Brick and

from evaporating inwards, the capillary water will travel Masonry Units

upwards.

Evaporation From Thick

One thing you notice when you read old books written Lime-Based Mortar

by old people is that they noticed things—seemingly little Rendering

things that most of us would overlook, but that actually turn

out to be big things. Old master masons in the Old World

noticed that the mortar in the joints of brick assemblies

would get “eaten” away at a much faster rate than the brick

itself, if the mortar had a lot of lime in it. The lime made the

mortar weaker, and more liquid-water-permeable and more Capillary Flow of Salts in Solution

*Not true physics—but close enough—engineers deal with approximations and fudge factors (i.e., coefficients) so Figure 4: Sacrificial Layers. Old World technology at its best. If you

engineering physics are approximately correct. If we engineers waited for physicists to solve things, nothing would

can’t stop the damage function, at least direct it to a location where

ever get done. We’re still waiting for physicists to explain friction from first principles. Until they do, we will use our

coefficient of friction, and the trains will run and the planes will fly. you can deal with it and within a material you can replace.

July 2007 ASHRAE Journal 59

Photograph 2 (left): Spalling of sacrificial layer in Siena, Italy. Photograph 3 (center): Sacrificial layer being applied in Prague, Czech

Republic. Photograph 4 (right): New sacrificial layer in Florence, Italy.

vapor-permeable than the brick. It made the mortar a

“preferential” matrix for salt-laden capillary water.

They noticed that capillary water with dissolved salt Spray-Applied Foam Insulation

(Closed Cell, High Density)

preferred the mortar matrix to the brick.

Uninsulated Steel Stud Assembly

This observation led to the old practice, and good

Gypsum Board

practice, of wanting mortar to be weaker and softer 4 Wythe Masonry

Wall Subfloor Held Away From Wall

than brick—both above grade and below grade. Pres- Plywood Subfloor

Embedded Wood

ervationists go through a lot of brain damage analyz- Timber Floor Timber Decking

ing mortar chemistry to make sure this is the case Structure

when they replace old mortar using a process called Spray-Applied Foam

Stainless Steel Cap

re-pointing. You do not want the mortar to be stron- Flashing Regletted Insulation (Closed Cell,

Into Exterior Wythe High Density)

ger than the brick, because then the brick “sacrifices”

itself to protect the mortar, not the other way around. Uninsulated Steel Stud

Note to structural engineers: stronger is not better 3/4 in. Masonry Assembly

Mortar Rendering

where mortar is concerned. Listen to the preservation- (Sacrificial Coating) Paperless Gypsum Board

ists on this one.

Figure 4 illustrates the elegant solution to the Membrane Sheet

(Waterproofing)

problem of efflorescence, subflorescence and spall-

ing courtesy of a long-dead Old World mason. The

re-pointing of brick with weak lime-based mortar pro-

tects the brick from damage. The mortar “sacrifices” 4 Wythe Masonry

Foundation

itself to protect the brick. The re-pointing of the brick New Concrete “Patch”

with “sacrificial” lime mortar, over time, evolved into Extruded Polystyrene Rigid

applying sacrificial coatings over the entire brick sur- Insulation

face. The lime-mortar rendering (or parge coat) pref- Plywood Subfloor on

erentially attracts the capillary saltwater solution and “Sleepers”

evaporation happens in this layer, not in the brick-ma-

sonry assembly. The spalling and damage is limited to

Existing Concrete

the sacrificial layer. The lime-mortar layer acts like a Slab

poultice sucking the “salt poison” out of the assembly. Epoxy Paint

Coarse Gravel

As expected, the sacrificial layer eventually fails and (No Fines)

Geotextile (Filter Fabric)

falls off and needs to be replaced three or four times Perforated

a century. Drain Pipe

Photograph 2 shows a sacrificial layer failing on

the exterior of a foundation wall at grade in Siena,

Italy, letting the owners know that it is time to reapply Figure 5: Retrofitting Existing Brick Foundations. Damage function is con-

a new sacrificial layer. Photograph 3 shows a new sac- centrated on outside surface of foundation at grade in a material designed

rificial layer being applied on a building in the author’s to be replaced three or four times a century. Interior membrane sheet water-

ancestral home of Prague in the Czech Republic. Pho- proofing is designed to prevent inward drying of capillary water—water is

tograph 4 shows a recently applied sacrificial layer on directed upwards and outwards.

60 ASHRAE Journal ashrae.org July 2007

At the end of the day, in order to deal with old build-

ings that need to be retrofitted to meet the challenges

of climate change and energy security, it appears that

we will have to dust off some Old World technology.

one side of a doorway, but not yet applied on the other, on a embedded timbers in masonry foundations when directing

building in Florence, Italy. capillary water upward and outward.

Figure 5 illustrates an approach to address osmosis problems At the end of the day, to deal with old buildings that need

when retrofitting existing brick foundations. A sacrificial layer to be retrofitted to meet the challenges of climate change

of lime-based mortar is applied to the exterior of the founda- and energy security, it appears that we will have to dust off

tion at grade. An interior liquid-water-impermeable and va- some Old World technology. It is not too big of a sacrifice

por-impermeable layer is applied to the masonry foundation, to ask.

preventing the capillary water from evaporating to the interior.

The capillary water is directed upwards and outwards to the ex- References

terior sacrificial layer. The salt accumulates in this layer, rather 1. Hutcheon, N.B. and G.O. Handegord. 1983. Building Science for

than causing damage to the interior of the foundation. This al- a Cold Climate. Ottawa, ON, Canada: National Research Council

lows the interior of the masonry foundation to be insulated full of Canada.

2. Straube, J.F. and E.F.P. Burnett. 2005. Building Science for Build-

height from the slab to the underside of the floor assembly. ing Enclosures. Westford, Mass.: Building Science Press. www.

Here is where things get tricky. We want to direct the cap- buildingsciencepress.com.

illary water upward and outward—but not too far upward

into the structure where it can damage timbers and interior Joseph W. Lstiburek, Ph.D., P.Eng., is a principal of Building

finishes. Figure 6 provides guidance for the protection of Science Consulting in Westford, Mass.

Wood Floor Fram- Wood Floor Fram-

ing Embedded Into ing Embedded Into

Masonry Wall Masonry Wall

Stainless Steel Stainless Steel

Cap Flashing Cap Flashing

Regletted Into Regletted Into

Exterior Wythe Exterior Wythe

Stainless Steel Capillary

Break Regletted 1/3 of

Vapor Impermeable Layer Wall Thickness

To Prevent Evaporation or Vapor Impermeable Layer

Drying Inward To Prevent Evaporation or

Drying Inward

Sacrificial

Layer

Sacrificial

Layer

Figure 6: Rules of Thumb. Physicists hate this type of information—experienced-based recommendations, without formal equations de-

rived from first principles. I will come clean here—this is a “best guess” on my part. However, I have been around and have been pretty

good at guessing like this.

July 2007 ASHRAE Journal 61

Advertisement formerly in this space.

You might also like

- Rebels - in - Frills - A - Literature - Review - On 4Document93 pagesRebels - in - Frills - A - Literature - Review - On 4mariobogarinNo ratings yet

- 2022-02-03 Adidas Global Supplier ListDocument179 pages2022-02-03 Adidas Global Supplier ListTrần Đức Dũng100% (1)

- Plattischemic Stroke Lesson PlanDocument18 pagesPlattischemic Stroke Lesson Planapi-216258123100% (3)

- Efflorescence Water Damage - Building Science Podcast: Posted On Mar 29 byDocument2 pagesEfflorescence Water Damage - Building Science Podcast: Posted On Mar 29 byhulpeNo ratings yet

- Foundation Retrofit & Rehabilitation: Alaska Building Research Series Hcm-01555Document12 pagesFoundation Retrofit & Rehabilitation: Alaska Building Research Series Hcm-01555Rishika DixitNo ratings yet

- What Is The Difference Between Bleeding and Segregation in ConcreteDocument13 pagesWhat Is The Difference Between Bleeding and Segregation in ConcreteArif IrawanNo ratings yet

- Earth Science LT 2 ReviewerDocument2 pagesEarth Science LT 2 ReviewerG01 - Alba Danielle Faye Y.No ratings yet

- Collins On 2Document10 pagesCollins On 2José Matías GóngoraNo ratings yet

- FAQ7Document3 pagesFAQ7abualamalNo ratings yet

- Buildingsciences 012008Document5 pagesBuildingsciences 012008giwneioNo ratings yet

- Remediating Salt Attack in AdobeDocument8 pagesRemediating Salt Attack in AdobeDavid RockstrawNo ratings yet

- Bad Benchmarks: Workmanship Issues in Swimming Pool Dry-Mix ConstructionDocument6 pagesBad Benchmarks: Workmanship Issues in Swimming Pool Dry-Mix ConstructionmtNo ratings yet

- Time Dependent Deformation 1Document8 pagesTime Dependent Deformation 1Neil Myco Duterte SarsalejoNo ratings yet

- Foundations of Historic StructuresDocument2 pagesFoundations of Historic Structureshimabindugvsd71No ratings yet

- Dispersive SoilsDocument11 pagesDispersive Soilskundayi shava100% (1)

- Aggregate Pop OutDocument0 pagesAggregate Pop Outتوان امتياس سامسدينNo ratings yet

- Weathering, Erosion, and DepositionDocument56 pagesWeathering, Erosion, and DepositionSophiaNo ratings yet

- DRRRR ModukeDocument5 pagesDRRRR ModukeRyan BersaminNo ratings yet

- Activity 1Document4 pagesActivity 1Gerald MontanoNo ratings yet

- BB Efflorescence Prevention and ControlDocument2 pagesBB Efflorescence Prevention and ControlIndra Jeet YadavNo ratings yet

- Soils For Road: SheetDocument8 pagesSoils For Road: SheetUMA AKANDU UCHENo ratings yet

- Weathering, Erosion, and Deposition: Broken Down Moved Deposited, or DroppedDocument10 pagesWeathering, Erosion, and Deposition: Broken Down Moved Deposited, or DroppedbrbarnesNo ratings yet

- Concrete ChemicalsDocument5 pagesConcrete ChemicalsSTRUC CIVILNo ratings yet

- Cracks Phenomenonon HousesDocument22 pagesCracks Phenomenonon HousesSarah MendezNo ratings yet

- Salt breaks rock through crystal growthDocument3 pagesSalt breaks rock through crystal growthZhe VenturozoNo ratings yet

- Arc 223 Clay MaterialDocument14 pagesArc 223 Clay MaterialAgoyiNo ratings yet

- Building Technology ReviewerDocument117 pagesBuilding Technology ReviewerJess AndanNo ratings yet

- Foundation Remidial MesuresDocument12 pagesFoundation Remidial Mesuresapi-3869476No ratings yet

- Attach To PG 5 CellularDocument5 pagesAttach To PG 5 CellularDavid MattNo ratings yet

- FoundationDocument6 pagesFoundationAnonymous dK9Qi2XjNo ratings yet

- Types of Mechanical WeatheringDocument2 pagesTypes of Mechanical WeatheringPerly PeterNo ratings yet

- Rock weathering and soil erosion projectDocument7 pagesRock weathering and soil erosion projectLena JohnperNo ratings yet

- Module 4 GEODocument23 pagesModule 4 GEOJhon Mark Nelmida LubongNo ratings yet

- Document (3) WPS OfficeDocument5 pagesDocument (3) WPS Officejenelynarias4No ratings yet

- 20020203a PDFDocument4 pages20020203a PDFtalk2sumantaNo ratings yet

- A Study of Efflorescence in Clay BricksDocument26 pagesA Study of Efflorescence in Clay Bricksvincent.claudeNo ratings yet

- Science 5 Q4W1 6 PDFDocument20 pagesScience 5 Q4W1 6 PDFKatrina SalasNo ratings yet

- Module 1 ReviewerDocument5 pagesModule 1 ReviewerMikyla DulinNo ratings yet

- Weathering 2023Document26 pagesWeathering 2023jefrillevaldezNo ratings yet

- Slow Changes On Earth: What Causes Earth's Surface To Change Slowly?Document44 pagesSlow Changes On Earth: What Causes Earth's Surface To Change Slowly?Noroña S.R.No ratings yet

- Enggao AllDocument8 pagesEnggao AllAngeLo Ryan AmparoNo ratings yet

- Repair brickwork safely and effectivelyDocument8 pagesRepair brickwork safely and effectivelymoni_john_1No ratings yet

- Fig. 4. Image of A Fine-Grained Polycrystalline Diamond Die Surface, Displaying Sharp Grain Boundaries. Photo Courtesy of Fort Wayne Wire DieDocument1 pageFig. 4. Image of A Fine-Grained Polycrystalline Diamond Die Surface, Displaying Sharp Grain Boundaries. Photo Courtesy of Fort Wayne Wire DieDiego PinoNo ratings yet

- Earth ScienceDocument14 pagesEarth ScienceSan Vicente West Calapan CityNo ratings yet

- Weathering Meaning and EffectsDocument30 pagesWeathering Meaning and EffectsLeon FouroneNo ratings yet

- How moisture enters and impacts brick wallsDocument8 pagesHow moisture enters and impacts brick wallsaliNo ratings yet

- Green Sand Casting Defect!: NameDocument8 pagesGreen Sand Casting Defect!: Namekarthick rajaNo ratings yet

- Categories of Problems in MasonryDocument6 pagesCategories of Problems in Masonryamin tariqNo ratings yet

- Geology CH 4 1bjya3yDocument13 pagesGeology CH 4 1bjya3yGervie Dhevea Ganawed DianoNo ratings yet

- Soil Formation ProcessesDocument66 pagesSoil Formation ProcessesMaddyNo ratings yet

- Tech Note L7 - Removal of Efflorescence From Hardscape ProductsDocument8 pagesTech Note L7 - Removal of Efflorescence From Hardscape ProductsgineteNo ratings yet

- Gypsum ProductsDocument8 pagesGypsum Productsمحمد الخزرجيNo ratings yet

- Lesson 8 Weathering Types and ProcessesDocument5 pagesLesson 8 Weathering Types and ProcessesSharlaine TandinganNo ratings yet

- Chapter 2-Concrete EvaluationDocument28 pagesChapter 2-Concrete Evaluationziad almnaseerNo ratings yet

- Chapter 5-Foundation and Embankment Dam: Figure 84.-An Embankment Dam in Mississippi Constructed of DispersiveDocument61 pagesChapter 5-Foundation and Embankment Dam: Figure 84.-An Embankment Dam in Mississippi Constructed of DispersiveSoenarto SoendjajaNo ratings yet

- Restoration and Conservation of Works of Art Made of StoneDocument68 pagesRestoration and Conservation of Works of Art Made of StoneCrisencio M. PanerNo ratings yet

- Q2-W1 WeatheringDocument60 pagesQ2-W1 Weatheringlacaron.kurtalexanderNo ratings yet

- Rising Damp Information Sheet PDFDocument6 pagesRising Damp Information Sheet PDFKristin MunozNo ratings yet

- EfflorescenceDocument37 pagesEfflorescencecricket reviewNo ratings yet

- Weathering and Erosion: An Exogenic Processes GuideDocument2 pagesWeathering and Erosion: An Exogenic Processes GuideMesshael JonsonNo ratings yet

- Earth and Life Science Lesson 3Document11 pagesEarth and Life Science Lesson 3glyzzjohaneNo ratings yet

- Six Common Types of Cracks in Your ConcreteDocument5 pagesSix Common Types of Cracks in Your Concretemohannad eliassNo ratings yet

- Buildingsciences 012008Document5 pagesBuildingsciences 012008giwneioNo ratings yet

- Buildingsciences 0308Document6 pagesBuildingsciences 0308giwneioNo ratings yet

- Business 122007Document2 pagesBusiness 122007giwneioNo ratings yet

- RhinoboardDocument16 pagesRhinoboardraditanka aobakweNo ratings yet

- SGT Vacancy ListDocument196 pagesSGT Vacancy ListSusheelabaiNo ratings yet

- Charles Mwanza's ResumeDocument3 pagesCharles Mwanza's ResumeYash MalemuNo ratings yet

- Lcasean PaperDocument6 pagesLcasean Paperkean ebeoNo ratings yet

- BSNL Cda RulesDocument3 pagesBSNL Cda RulesAlexander MccormickNo ratings yet

- Impact of MusicDocument15 pagesImpact of MusicSterling GrayNo ratings yet

- Download 3000+ Books by Acharya Pt. Shriram SharmaDocument89 pagesDownload 3000+ Books by Acharya Pt. Shriram SharmaAllWorld GaayatreeParivaar SaharunpurNo ratings yet

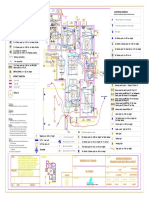

- Varun Valanjeri Electrical Layout-3Document1 pageVarun Valanjeri Electrical Layout-3ANOOP R NAIRNo ratings yet

- EM Complete NotesDocument191 pagesEM Complete NoteswsbwaqhpwpvcwuhajkNo ratings yet

- Neco Catlog 4 FoldDocument2 pagesNeco Catlog 4 FoldSanket PhatangareNo ratings yet

- Effects of The Sugar RevolutionDocument9 pagesEffects of The Sugar RevolutionSusan BarriotNo ratings yet

- IEC 61850 Configuration of A Phoenix Contact IED: User ManualDocument68 pagesIEC 61850 Configuration of A Phoenix Contact IED: User ManualHarold PuinNo ratings yet

- Aluminum Extrusions (HFS6 Series) Aluminum Extrusions (HFS6 Series)Document1 pageAluminum Extrusions (HFS6 Series) Aluminum Extrusions (HFS6 Series)Jesus ValenciaNo ratings yet

- StudenttextDocument29 pagesStudenttextapi-195130729No ratings yet

- Catalogue of Turkic Language BooksDocument26 pagesCatalogue of Turkic Language BooksBerhiv Şilan BiliciNo ratings yet

- The Residents of The British East India Company at Indian Royal Courts, C. 1798-1818Document224 pagesThe Residents of The British East India Company at Indian Royal Courts, C. 1798-1818Ajay_Ramesh_Dh_6124No ratings yet

- Call For Applications To JASTIP-Net 2021 Guidelines For ApplicantsDocument6 pagesCall For Applications To JASTIP-Net 2021 Guidelines For ApplicantsNadya IrsalinaNo ratings yet

- Manual - Nokia - AirScale - System Module - Presentation NokiaDocument29 pagesManual - Nokia - AirScale - System Module - Presentation NokiaAndres Obando100% (1)

- Valvula ContraincendioDocument6 pagesValvula ContraincendiowidNo ratings yet

- EN Sample Paper 19 UnsolvedDocument12 pagesEN Sample Paper 19 UnsolvedRashvandhNo ratings yet

- MEM05 Header R8.1Document388 pagesMEM05 Header R8.1andysupaNo ratings yet

- FVNL"'" - TT - ..: MycotaDocument8 pagesFVNL"'" - TT - ..: MycotaAmbesh JhaNo ratings yet

- Housing Inequality Causes and SolutionsDocument5 pagesHousing Inequality Causes and SolutionsFredrickNo ratings yet

- 18 MN216 Fluid Mechanics IDocument2 pages18 MN216 Fluid Mechanics Ijorge luisNo ratings yet

- 285519-35126-30-case-studyDocument12 pages285519-35126-30-case-studyapi-737834018No ratings yet

- Lesson 10 - Classfying Food and Drink OperationsDocument25 pagesLesson 10 - Classfying Food and Drink OperationsRyl SorianoNo ratings yet

- Revised SCOPE OF WORK and SCCDocument363 pagesRevised SCOPE OF WORK and SCCZia KhanNo ratings yet