Professional Documents

Culture Documents

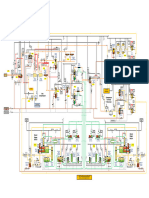

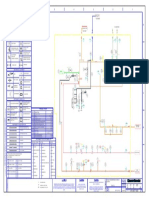

PID 674798 Rev02

Uploaded by

Daria PawłowiczOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PID 674798 Rev02

Uploaded by

Daria PawłowiczCopyright:

Available Formats

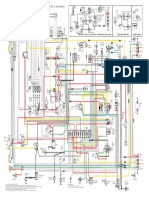

8 7 6 5 4 3 2 1

Local conveying system Ventil, allgemein

White Pigments Valve, general

~120 kg/min Vanne, général

Kugelhahn

Ball valve

Vanne à boule

H H

Dust Scheibenventil

Extraction, Butterfly valve

approx. Vanne papillon

1500 m³/h Druckminderer

Pressure reducer

Réducteur de pression

Kolbensitzventil

C Piston valve

Y DN250 DN150

Vanne à piston

Stellantrieb handbetätigt

Bag discharge station Manually operated actuator

B100.01 Commande manuelle

Stellantrieb pneumatisch

G Pneumatic drive G

Actionneur pneumatique

Armatur schließt bei

Hilfsenergieausfall

GOS - Valve closed at auxiliary energy

100.02 failure

B100.01 Vanne normallement fermée en

cas de coupure de courant

Leitstrahlmischer

„Airchoc“ PI guiding jetstream mixer

grid empty sack 360.01

Mélangeur à jet dirigé

disposal X360.50 Zahnradpumpe

DN300 Gear pump

B 360. 01 Pompe à engrenages

LS + Flanschverbindung allg.

110.05 WI C Flange connection, general

F Hopper scale F

A Raccord à bride, général

110.25 is supplied

Powder Hopper B110.01 locally X Y Schlauch

Volume: Hose

total approx. 1800 L 64.1 Tuyau

Pressure rating: atmospheric A Product from

Wägezelle

X Y Flushing with process tank

Load cell

solvent Product to - liquid level

Peson

10 m³/h max 5 bar process tank monitored

Elektromotor

LS- 8x Aerator M Electric motor

Y360.40 Moteur électrique

compressed air from 110.03 1x El. vibrator

ystral pneumatic C

Y Liefergrenze Y = Ystra l; C = Kunde

cabinet PC2 M110.61 Clamp Flange

M el. vibrator Y C Limit of supply Y = Ystra l; C = Client

DN15 DN100 Frontière de livraison

LS-

Y110.81 DIN 32676 V001.46 DIN EN1092-1 PN16

110.02 Y110.80

E E

compressed air from

Aerator ystral pneumatic

cabinet PC2 compressed air

manhole from ystral

Y110.79

DN300 pneumatic GOS -

Clamp Pneumatic

cabinet PC1 DN15 001.27

Cabinet PC1

DIN 32676 GOS +

Powder fluidising GOS - GOS + GOS -

system FSA-5 001.27 P S+

360.10 001.23 001.23

GOS -

V001.27

V001.23

Female threads 001.50

Compressed air

Aerator G½“ Clamp 001.40

GOS + approx. 20 Nm³/h

360.10

DN15 (peak value) @

Y070.45 GOS +

DIN 32676 V001.53 5.5...6bar

Flange

V360.10

001.40

LS- DN100

V001.40

GOS - GOS -

M 070.10 DIN EN1092-1 PN16

C

Y

360.20 001.20

D Conti TDS-5 Ex D

M070.02 GOS + Female threads GOS + C90.000S

360.20

G½“ 001.20

Clamp

compressed air from DN50 DN15

Ventilation M001.02

ystral pneumatic V070.23 DIN 32676

X070.30 Pumpenaggregat PA100

cabinet PC2 Flange Flange TS A+ S IC+/-

Lubrication pump unit

Flange V360.20 DN50 V001.20 DN50

M 001.03 001.04

C Y

DN50 R001.01 Systêm de Lubrification

DIN EN1092-1 PN16 DIN EN1092-1 PN16 DIN EN1092-1 PN16

Clamp

S DA + S DA +

DN40

DIN 32676 001.07 001.08

TS A+

LS A++

Pneumatic 001.11

V005.15 V005.21

V001.26

Cabinet PC2 FS A- PI 005.04

005.08 005.22

C Sperrmittelb. LS A- C

P S+ vessel 005.06

001.51

Compressed air

GOS + P005.02 rèservoir

approx. 65 Nm³/h 001.26 Vol. 30L TS A+

(peak value) @ B005.01

GOS - 005.09

V001.52 5.5...6bar V005.14

001.26

M M005.03

C

Y

Base frame

02 09.10.2019 MSH

B 01 08.05.2019 MSH B

00 25.04.2019 MSH

Index Datum / Date Name / Nom

Änderungsstand / change status

Etat des modifications

Maßstab / Scale

Format R + I Schema / P&I Diagram

Datum / Date Name / Nom

Erstellt 03.04.2019 MSH

674798 based on PID_566241_rev02

A A

zul. bearbeitet 09.10.2019 0 Zeichnungsnummer / Drawing-No Blatt / Page

ystral gmbh

Urheberschutzrechte nach DIN ISO 16016

werden beansprucht

maschinenbau + processtechnik PID_674798 1/1

D- 79282 Ballrechten- Dottingen

"Copyright reserved“

Tel. +49 (0) 7634 5603 - Fax 5603 - 99 Dateiname / Data file PID_674798_Rev02.vsd

8 7 6 5 4 3 2 1

You might also like

- Hydraulic SchematicDocument2 pagesHydraulic Schematicluis echevarria quispeNo ratings yet

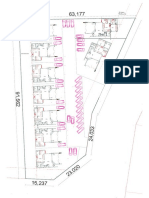

- Shivalik PlanDocument1 pageShivalik PlanGarNo ratings yet

- Line Pipe TCUDocument1 pageLine Pipe TCUI Made Candra IrawanNo ratings yet

- Dr. Suresh DrawingsDocument1 pageDr. Suresh DrawingsMohammed AliNo ratings yet

- Midnight BellsDocument5 pagesMidnight BellskendekoolytNo ratings yet

- TA2899-Progress Design 20220131Document3 pagesTA2899-Progress Design 20220131Back To SumateraNo ratings yet

- Alt Rokugon Map PosterDocument1 pageAlt Rokugon Map PosterTill Wer SonstNo ratings yet

- Cold Storage Shed, JAIPUR, (RAJ.) 07-12-2018Document1 pageCold Storage Shed, JAIPUR, (RAJ.) 07-12-2018designsolutionsallNo ratings yet

- Bach Minuet and BadinerieDocument4 pagesBach Minuet and Badinerietudorfurdui8No ratings yet

- Septic Tank Section Section of Ug Sump Column Foundation: 12' Feet Street RoadDocument1 pageSeptic Tank Section Section of Ug Sump Column Foundation: 12' Feet Street RoadPavithra.GNo ratings yet

- USE-IT TbilisiDocument2 pagesUSE-IT TbilisiLela Agnieszka BernatovaNo ratings yet

- Pozo de Luz 2 Reserva Jefe Ducha Apoyo Salones: Baños Hombres Baños Mujeres MontacargaDocument1 pagePozo de Luz 2 Reserva Jefe Ducha Apoyo Salones: Baños Hombres Baños Mujeres MontacargaNey Mendoza GómezNo ratings yet

- Zone Froide - 20°C 24 CAISSES (Une Palette)Document1 pageZone Froide - 20°C 24 CAISSES (Une Palette)Daniela DuşaNo ratings yet

- Logistic Warehouse - Drainage Schematic ServiceDocument1 pageLogistic Warehouse - Drainage Schematic ServiceWuillNo ratings yet

- 5-5-2023 SRIC Orientation-ModelDocument1 page5-5-2023 SRIC Orientation-ModelPavan Kumar YallaNo ratings yet

- Rakh Agf Set Ren Tube ModelDocument1 pageRakh Agf Set Ren Tube Modelbenaya prasetyaNo ratings yet

- Symphonic OvertureDocument29 pagesSymphonic OvertureEmilio EscaleraNo ratings yet

- The Entertainer: A Ragtime Two StepDocument12 pagesThe Entertainer: A Ragtime Two StepWalter RoccaroNo ratings yet

- Genshin Impact - Ganyu Radiant Dreams Qilins PranceDocument8 pagesGenshin Impact - Ganyu Radiant Dreams Qilins PranceEelis VihermaaNo ratings yet

- Btech. Sa2 B Garcia Miguel Antonio C.Document2 pagesBtech. Sa2 B Garcia Miguel Antonio C.Cristine ClarinNo ratings yet

- Iré y Haré. INTR PDFDocument2 pagesIré y Haré. INTR PDFCarolinaNo ratings yet

- RD-FF-with PR - New PRDocument1 pageRD-FF-with PR - New PRsassy girlNo ratings yet

- 33 File 20210813-135348 PRODUCT CATALOGUE 2021 PDFDocument20 pages33 File 20210813-135348 PRODUCT CATALOGUE 2021 PDFInsan AzizNo ratings yet

- Hisaishi Therain PianoCelloDocument3 pagesHisaishi Therain PianoCelloOlivier GaillyNo ratings yet

- 1800ES 73 WiringDiagram Colour V2.4Document1 page1800ES 73 WiringDiagram Colour V2.4niets2No ratings yet

- GRADE - Black and PinkDocument15 pagesGRADE - Black and PinkArruda Vinicius BorgesNo ratings yet

- Artist 1Document1 pageArtist 1C24Sakshi TakawaleNo ratings yet

- Lon Street MapDocument1 pageLon Street MapIvan LagatorNo ratings yet

- GTF Gas Compression Rev5Document1 pageGTF Gas Compression Rev5aqeel.sammiNo ratings yet

- O Mensch, Bewein Dein' Sünde Gross: Jean-Sebastien Bach (1685-1750) BWV 622Document4 pagesO Mensch, Bewein Dein' Sünde Gross: Jean-Sebastien Bach (1685-1750) BWV 622infobitsNo ratings yet

- A-120 - BLVD - 1 - Roof Floor PlanDocument1 pageA-120 - BLVD - 1 - Roof Floor PlanRaghu supertechNo ratings yet

- DescansoDocument2 pagesDescansofranciscojrg5No ratings yet

- Ig N e D: WMV Ral VSM Acp Ags Ral Cle WMV JCF FCM CleDocument1 pageIg N e D: WMV Ral VSM Acp Ags Ral Cle WMV JCF FCM Clenestor159357No ratings yet

- Chassis TV TRC LB5ADocument1 pageChassis TV TRC LB5Aroto44No ratings yet

- FL Ob CL Suite in D AirDocument2 pagesFL Ob CL Suite in D AirАлександра ПолетаеваNo ratings yet

- HALLELUJAH - PH C - HƯNG - F-DurDocument2 pagesHALLELUJAH - PH C - HƯNG - F-DurDiệu QuangNo ratings yet

- Accessory 02Document1 pageAccessory 02Rotich KiplangatNo ratings yet

- Dios Es Más PDFDocument2 pagesDios Es Más PDFLuis Enrique AzuajeNo ratings yet

- Hospital - Nivel 3Document1 pageHospital - Nivel 3jorge lucasNo ratings yet

- Modern March: Composta Da Paolo Di BartoloDocument45 pagesModern March: Composta Da Paolo Di BartoloPaolo Di Bartolo ComposerNo ratings yet

- MX-8637 PidDocument1 pageMX-8637 PidSaigon Esp GlerNo ratings yet

- KBZ in Otak ZZ RD XX Se RD 001Document1 pageKBZ in Otak ZZ RD XX Se RD 001Abdul LatheefNo ratings yet

- Lavington Elms 190401 - Site PlanDocument1 pageLavington Elms 190401 - Site PlanBonnie Maguathi MwauraNo ratings yet

- Dumb QuartetDocument2 pagesDumb QuartetLogan PurcellNo ratings yet

- VivaceDocument18 pagesVivaceYESOKWHYNOTNo ratings yet

- KT Instructions General Elbow PainDocument1 pageKT Instructions General Elbow PainDanni CoffeeNo ratings yet

- FHE Layout PDFDocument1 pageFHE Layout PDFArjun VinayakumarNo ratings yet

- Vellore DivisionDocument1 pageVellore DivisionDilesh KumarNo ratings yet

- IMSLP564646-PMLP909459-SonataII Breval GeneralDocument9 pagesIMSLP564646-PMLP909459-SonataII Breval GeneralRaquel RibeiroNo ratings yet

- 5.ThirdFloor SMS 105Document1 page5.ThirdFloor SMS 105MohammedNo ratings yet

- Wd11y021s10Document28 pagesWd11y021s10cages48160No ratings yet

- 1m2 Flying To The Island Fortnite Collision EventDocument9 pages1m2 Flying To The Island Fortnite Collision EventAchille SanseveroNo ratings yet

- 1800ES 72 WiringDiagram Colour V2.4Document1 page1800ES 72 WiringDiagram Colour V2.4niets2No ratings yet

- Bolero para Saxofon y BandaDocument66 pagesBolero para Saxofon y BandaBrayan TafurNo ratings yet

- 3.1 Plant LayoutDocument1 page3.1 Plant LayoutSatyaprakash SharadNo ratings yet

- Yoga Center TVM BALARAMAPURAM Final (2) - ModelDocument1 pageYoga Center TVM BALARAMAPURAM Final (2) - ModelJisniNo ratings yet

- Love Duet-Score and PartsDocument12 pagesLove Duet-Score and Partskirsten.merrillNo ratings yet

- Happy Duck Waltz: Tempo Di ValseDocument2 pagesHappy Duck Waltz: Tempo Di ValsesandroNo ratings yet

- IMSLP566553-PMLP912538-Sonate III Breval-Violonchelo PianoDocument13 pagesIMSLP566553-PMLP912538-Sonate III Breval-Violonchelo PianoNacho DelgadoNo ratings yet

- 904 Drilling Machine: Sizes: 1/2-To 4-InchesDocument4 pages904 Drilling Machine: Sizes: 1/2-To 4-InchesjasamaNo ratings yet

- Design & Manufacturing of Automated Gauging Unit For Injector BodyDocument34 pagesDesign & Manufacturing of Automated Gauging Unit For Injector BodyNiraj ChordiyaNo ratings yet

- Compressed Air Best Practice Guide For IndustryDocument22 pagesCompressed Air Best Practice Guide For IndustrySharon LambertNo ratings yet

- FOX Ejectors For Vapor RecoveryDocument4 pagesFOX Ejectors For Vapor RecoveryMuhammad ImranNo ratings yet

- Leaflet S24 - Cavagna RegulatorDocument8 pagesLeaflet S24 - Cavagna RegulatorWND PRTMNo ratings yet

- Types of Manual ValvesDocument12 pagesTypes of Manual ValvesDuy Nguyen DucNo ratings yet

- Axial Flow Compressor.Document3 pagesAxial Flow Compressor.Mohit MinzNo ratings yet

- 3239F592TDocument2 pages3239F592TAnderson London67% (3)

- Vp-15-109-001-A01-P-237-004abc-C-010 Performance Curve For PumpDocument3 pagesVp-15-109-001-A01-P-237-004abc-C-010 Performance Curve For PumpRicardo NapitupuluNo ratings yet

- Chiller Types and ApplicationsDocument73 pagesChiller Types and Applicationsvickers100% (3)

- Effects of Blade Manufacturing Deviations On Turbine PerformanceDocument10 pagesEffects of Blade Manufacturing Deviations On Turbine PerformanceBiswajit JenaNo ratings yet

- Lecture.6. Агрегаты продувки и наддуваDocument49 pagesLecture.6. Агрегаты продувки и наддуваSea Man MktNo ratings yet

- Acpump Fire Serie8100Document2 pagesAcpump Fire Serie8100Anonymous YmXY1bcNo ratings yet

- Eaton Gas-Liquid Separator CatalogDocument35 pagesEaton Gas-Liquid Separator CatalogEaton FiltrationNo ratings yet

- Hydraulics Part List March2013 Rexroth LineDocument5 pagesHydraulics Part List March2013 Rexroth LineDaniela SouzaNo ratings yet

- Manual XV Gig - enDocument32 pagesManual XV Gig - enWendel Soares CorreiaNo ratings yet

- Flowhead Ps PDFDocument2 pagesFlowhead Ps PDFaliffakmar019No ratings yet

- Reynolds Experiment FinalDocument4 pagesReynolds Experiment FinalArindam MandalNo ratings yet

- Pumps PDFDocument22 pagesPumps PDFNewNo ratings yet

- Testing ESVDocument2 pagesTesting ESVArun Prakash100% (1)

- 191M Oxygen Regulator Service PartsDocument2 pages191M Oxygen Regulator Service PartsSteve LimNo ratings yet

- 944 Ignition SystemDocument14 pages944 Ignition SystemDanno NNo ratings yet

- Boom Hydraulic System CAT 330Document17 pagesBoom Hydraulic System CAT 330hector100% (1)

- Fluid Mechanics and Hydraulics Laboratory: A Manual For TheDocument66 pagesFluid Mechanics and Hydraulics Laboratory: A Manual For TheMohammad AL-HajNo ratings yet

- New Ninja Ball Regulator System Owner'S Manual: 1.877.NINJAUSA (1.877.646.5287)Document2 pagesNew Ninja Ball Regulator System Owner'S Manual: 1.877.NINJAUSA (1.877.646.5287)SébastienKishiNo ratings yet

- Question Papers 2011Document9 pagesQuestion Papers 2011Ebenaza GodsonNo ratings yet

- Nozzle Performance Test Unit PDFDocument10 pagesNozzle Performance Test Unit PDFNaveen Rao50% (2)

- 08-Pressure - Blowers 1Document58 pages08-Pressure - Blowers 1Pedro SchiaviNo ratings yet

- 10 Subsurface Safety Equipment PDFDocument42 pages10 Subsurface Safety Equipment PDFMohamed AoudiNo ratings yet

- (BMPS) : Bapco Modernization Program SpecificationsDocument24 pages(BMPS) : Bapco Modernization Program Specificationschaitanya100% (1)