Professional Documents

Culture Documents

Suntech Quality Controll Suntech

Uploaded by

ARKA technocorpOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Suntech Quality Controll Suntech

Uploaded by

ARKA technocorpCopyright:

Available Formats

www.suntechbearings.

com

?

Right Questions

!

Quality Insight

X

Integrated Solution Value Multipliers

HYDRO DYNAMIC FLUID FILM BEARING

And

Quality Requirements

SUNTECH ENGINEERING CORPORATION

www.suntechbearings.com

Quality Policy:

“Suntech Engineering Corporation is Committed to total

satisfaction of customer by value addition with our prime

product “Hydro Dynamic Fluid Film Bearings”

SUNTECH ENGINEERING CORPORATION

www.suntechbearings.com

Our TQM model:

Customer Focus

Controlled Process Planning

environment

Process Process

Improvement Management

SUNTECH ENGINEERING CORPORATION

www.suntechbearings.com

Road Map for Customer Focus:

Customization Easy Accessibility Customer Feed

Back

Collaboration Scheduled Delivery Conversion of

information into action

SUNTECH ENGINEERING CORPORATION

www.suntechbearings.com

Our Quality Process Planning :

Communication Team Work Fact Base Analysis Customer Obsession with

Understanding Quality

1 2 3 4 5

Productivity

Customer Loyalty

Outcomes

Customer Satisfaction

Initiative

SUNTECH ENGINEERING CORPORATION

www.suntechbearings.com

Principle and certification:

We try to maintain all TQM

1 principles

We are an ISO 9001:2015 certified

2 Company.

SUNTECH ENGINEERING CORPORATION

Process flow diagram of our Quality check:

Our “Quality Process Flow Diagram” enable us to identify significant roll of our QC team members and a pathway to

improve our Quality

UT of Base Chemical &

Raw Material Metal Physical

If reject

Pre proof Dimension Other NDT

Machining Checking if required

If reject

Proof Dimension

Machining Checking

UT of

Cladding Cladding

Process surface

If reject

Final Turning & DP &

Milling Dimension

If reject

Final Dispatch Customer Feed Back

SUNTECH ENGINEERING CORPORATION

www.suntechbearings.com

Customer Feed Back from “INDAR Electric”- Spain

SUNTECH ENGINEERING CORPORATION

www.suntechbearings.com

Customer Feed Back form “Bharat Heavy Electric Limited”

SUNTECH ENGINEERING CORPORATION

www.suntechbearings.com

Some basic Data & Analysis tools for QA:

NCP & CAPA

NCP helps us to identify the products with nonconformity & CAPA help us to prevent the future problem

Why Why Analysis

For deep penetration to understand the actual reason of failure

Machine Maintenance

To minimise the machine breakdown time and cycle

Instruments Calibration

To achieve the Job accuracy

Time line Analysis

To complete the QC activity on time

All SOP and standards

SUNTECH ENGINEERING CORPORATION

www.suntechbearings.com

NCP & CAPA:

SUNTECH ENGINEERING CORPORAION

AN ISO 9001 : 2015 CERTIFIRD COMPANY

NCP DETAILS DOC NO: SEC/F/09

PO NO:

DRAWING NO : RECTIFICATION NOT

1 3rd TIME UT FAILURE ON FACE AREA JOURNAL BEARING

770.0404.27

NA ZZ22140P-F568

POSSIBLE

RE-CASTING 09.04.2022

PO DATE:01.03.2022

CLARIFICATION

OD LOCKING HOLE DIAMETER DID NOT SLEEVE BEARING DRAWING NO : PO NO:F621A00035 RECTIFICATION NOT

2 MATCH THE REQUIRED DIMENSIONS CUP SIDE 11804515373 REV 04 PO DATE:25.10.2021 POSSIBLE

REQUIRED FROM 25.04.2022

BHEL

BEARING FACE SLOT (5 MM BECOME 5.2 PO NO: CLARIFICATION

DRAWING NO : RECTIFICATION NOT

3 MM) BIGGER THAN REQUIRED JOURNAL BEARING

770.0404.27

NA ZZ22140P-F568

REQUIRED

REQUIRED FROM 03.05.2022

DIMENSIONS PO DATE:01.03.2022 ARTECH

PO NO:

The material falls out from the RECTIFICATION

4 machine,And very deep scarch in ID

JOURNAL BEARING DRAWING NO : NA

REQUIRED REPEARING DEEP 18.05.2022

PO DATE: SCARTCH MARK

POINTS AND TURNING

SUNTECH ENGINEERING CORPORATION

www.suntechbearings.com

Why why analysis:

SUNTECH ENGINEERING CORPORATION

www.suntechbearings.com

Machine Maintenance:

SUNTECH ENGINEERING CORPORATION

www.suntechbearings.com

List of Calibrated Instruments:

SUNTECH ENGINEERING CORPORATION 50 to 300

0.01 mm.

SIW/CR-

22.10.2021 22.10.2022

INSTRUMENTS CALIBRATION STATUS SEC/F/04 mm. 5185/SEC/21-22

SL NO. DESCRIPTION RANGE L.C TC.NO. DATE OF ISSUE VALIDE UP TO 6 inside micrometer

50 to 1000 SIW/CR-

0.01 mm 11.08.2021 11.08.2021

1 Digital thermometer Gun -50⁰ C to 550⁰ C 0.1⁰C YEA(C)/200728A/S2483/001 28.07.2020 28.07.2021 mm 3233/SEC/21-22

2

Digital Niddle

SIW/CR-3230/SEC/21-22 11.08.2021 11.08.2022 SIW/CR-

Temparature Monitor -200⁰C to 1372C 0.1⁰ C

0 to 300 1 mm 11.08.2021 11.08.2022

3234/SEC/21-22

Vernier Caliper 0 to 150 mm 0.02 mm SIW/CR-3235/SEC/21-22 11.08.2021 11.08.2022 0 to 600 SIW/CR-

7 Steel scale 1 MM 11.08.2021 11.08.2022

mm 3229/SEC/21-22

Vernier Caliper 0 to 150 mm 0.02 mm SIW/CR-5189/SEC/21-22 22.10.2021 22.10.2022 SIW/CR-

0 to 1000 1 mm 22.10.2021 22.10.2022

5193/SEC/20-21

DIGITAL VERNIER CALIPER 0 to 150 mm 0.02 mm SIW/CR-2273/SEC/21-22 21.07.2021 21.07.2022 SIW/CR-

8 Bivel protector 360° 1° 26.08.2021 26.08.2022

1486/SEC/21-2

3

Vernier Caliper 0 to 300 mm 0.02 mm SIW/CR-5188/SEC/21-22 22.10.20214 22.10.20215

9 Bore Dial 25 to 150 0.02 mm In Process In Process In Process

Vernier Caliper 0 to 300 mm 0.02 mm SIW/CR-2274/SEC/21-22 21.07.2021 21.07.2022 0 to 300 SIW/CR-381/SEC/22-

10 Height Gauge 0.02 mm 13.04.2022 13.04.2022

mm 23

DIGITAL VERNIER CALIPER 0 to 300 mm 0.02 mm SIW/CR-379/SEC/22-23 13.04.2022 13.04.2023 CAST IRON SURFACE

11 36" X 36" 06.50 MICRON 68611 27.02.2019 27.02.2020

PLATE

Vernier Caliper 0 to 600 mm 0.02 mm SIW/CR-2275/SEC/21-22 21.07.2021 21.07.2022

0 to 150 SIW/CR-

12 DEPTH METER 0.01 mm 11.08.2021 11.08.2022

4 Vernier Dial Caliper 0 tom 300 mm 0.02 SIW/CR-5190/SEC21-22 22.10.2021 22.10.2022

mm 3232/SEC/21-22

SIW/CR-

13 MASUREING TAPE 0-5 m 1 mm 11.08.2021 11.08.2022

0 to 25 mm 0.01 mm SIW/CR-5186/SEC21-22 22.10.2021 22.10.2022 3231/SEC/21-22

SIW/CR-

14 DIAL INDICATOR 0-5 mm 0.01 mm 22.10.2021 22.10.2022

0 to 50 mm 0.01 mm SIW/CR-5183/SEC/21-22 22.10.2021 22.10.2022 5191/SEC/21-22

LEVER TYPE DIAL SIW/CR-

15 0-1 mm 0.001 mm 22.10.2021 22.10.2022

25 to 50 mm 0.01 mm SIW/CR-5182/SEC/21-22 22.10.2021 22.10.2022 INDICATOR 5192/SEC/21-22

SIW/CR-380/SEC/22-

16 DIAL INDICATOR 0-10 mm 0.01 mm 13.04.2022 13.04.2023

50 to 75 mm 0.01 mm SIW/CR-5184/SEC/21-22 22.10.2021 22.10.2022 23

SIW/CR-377/SEC/22-

17 DIAL INDICATOR 0-1 MM 0.001 micron 13.04.2022 13.04.2023

75 to 100 mm 0.01 mm SIW/CR-5187/SEC/21-22 22.10.2021 22.10.2022 23

DIAL INDICATOR SIW/CR-378/SEC/22-

18 0-1 MM 0.001 Um 13.04.2022 13.04.2023

DIGITAL 23

5 Out side micrimeter 100 To 200 mm 0.01 mm. SIW/CR-5194/SEC/21-22 22.10.2021 22.10.2022

200 to 300 mm 0.01 mm. SIW/CR-5195/SEC/20-21 22.10.2021 22.10.2022

300 to 400 mm 0.01 mm SIW/CR-328/SEC/22-23 13.04.2022 13.04.2023

500 to 600 mm 0.01 mm. SIW/CR-7249/SEC/21-22 02.12.2021 02.12.2022

600 to 700 mm 0.01 mm SIW/CR-2276/SEC/21-22 21.07.2021 21.07.2022

700 to 800 mm 0.01 mm SIW/CR-2277/SEC/21-22 21.07.2021 21.07.2022

800 to 900 mm 0.01 mm SIW/CR-2278/SEC/21-22 21.07.2021 21.07.2022

SUNTECH ENGINEERING CORPORATION

www.suntechbearings.com

List OF procedure :

As per ISO norms we implemented most common and effective procedures & formats .

List Of Procedures.

SL.NO. TITLE PROCEDURE NO.

1. IDENTIFICATION & TRACEABILITY SEC/P/01

2. PRESERVATION OF PRODUCTS SEC /P/02

3. PACKING SEC /P/03

4. SAFETY SEC /P/04

5. CONTROL OF NON-CONFORMING PRODUCT SEC /P/05

6. CORRECTIVE ACTION SEC /P/06

7. PREVENTIVE ACTION SEC /P/07

8. PAINTING SEC /P/08

9. CUSTOMER COMPLAINTS HANDLING PROCESS SEC /P/09

10. CALIBRAITON OF INSTRUMENTS SEC /P/10

11. TRAINING SEC /P/11

12. INTERNAL AUDIT SEC /P/12

13 MANAGEMENT REVIEW MEETING SEC /P/13

14. CONTROL OF EXTERNAL PROVIDERS (PURCHASE) SEC /P/14

15. RISK ASSESSMENT SEC /P/15

16 CONTROL OF DOCUMENTED INFORMATION SEC /P/16

SUNTECH ENGINEERING CORPORATION

www.suntechbearings.com

Time line Analysis for NCP:

After introduction of ISO 9001:2015 gradually decreased of NCP is shown and our target is to make it ZERO value.

Time Line analysis

35

30

25

20

15

10

5

0

2019-2020 2020-2021 2021-2022

SUNTECH ENGINEERING CORPORATION

www.suntechbearings.com

Some special practice we are doing:

UT Testing of Babbitt surface – without Back wall echo method

Bond strength test as per ISO 4386

Implementation of Shock detector in Packing Box.

SUNTECH ENGINEERING CORPORATION

www.suntechbearings.com

Dehydrogenation Process:

Dehydrogenation has a important roll in I improvisation of bearing performance

.

It reduce trapped Hydrogen

Improve Bearing fatigue strength

Improve Bonding Capacity

SUNTECH ENGINEERING CORPORATION

www.suntechbearings.com

UT testing on Babbitt Surface Without Back wall Echo:

11.1 If the preconditions of standard procedure are not fulfilled, testing without back wall echo becomes necessary.

11.2 Use a reference piece with good bond between similar backing material and similar bearing metal lining as the

tested bearing. Adjust the reference bond echo to 80% of full screen height; see figure 3.

SUNTECH ENGINEERING CORPORATION

www.suntechbearings.com

UT testing on Babbitt Surface Without Back wall Echo:

11.3 Bond is given when the echo signal of the tested plain bearing is similar to the adjusted reference bond echo; see

figure 4.

11.4 Defective bond is given when the bond echo on the plain bearing is significant above the reference bond height;

see figure 5.

SUNTECH ENGINEERING CORPORATION

www.suntechbearings.com

Special destructive test to assure Bond strength Between Base metal and Babbitt Metal:

Bond strength test as per: ISO : 4386.

SUNTECH ENGINEERING CORPORATION

www.suntechbearings.com

Implementation of Shock Detector in Packing Box:

Implementation of Shock Detector helps us to identify and prevent the mishandling during transportation which

enable us to supply the materials hassle-free up to Customer door step.

Before Shock After Shock

SUNTECH ENGINEERING CORPORATION

www.suntechbearings.com

SUNTECH ENGINEERING CORPORATION

KOLKATA – PUNE – KARNATAKA

THANK YOU

SUNTECH ENGINEERING CORPORATION

You might also like

- Sonu Auto PPT 2018.ppsxDocument50 pagesSonu Auto PPT 2018.ppsxSoni Verma SwatiNo ratings yet

- DYPNF Presendation For Biomass PDFDocument33 pagesDYPNF Presendation For Biomass PDFJaeyoung LeeNo ratings yet

- TEF - Awareness - Mining ForumDocument18 pagesTEF - Awareness - Mining ForumTC BengalonNo ratings yet

- APQPDocument3 pagesAPQPapi-3742290100% (10)

- Smart SignalingDocument35 pagesSmart SignalingManish PatelNo ratings yet

- Curriculum - Vitae - Luis - Antonio - Nuñez - English 2019Document2 pagesCurriculum - Vitae - Luis - Antonio - Nuñez - English 2019luis nunezNo ratings yet

- CV 2023100310065768Document3 pagesCV 2023100310065768savisavitas244No ratings yet

- EDGE Quality Inspection Services (EQUIS) - Cbe-Company Profile.Document4 pagesEDGE Quality Inspection Services (EQUIS) - Cbe-Company Profile.Krishnamoorthi VenkatesanNo ratings yet

- Development Procedure 16-08-2021Document6 pagesDevelopment Procedure 16-08-2021CompdevpNo ratings yet

- NLQM-Ereformerand Tibur Full IntroDocument25 pagesNLQM-Ereformerand Tibur Full IntroShailesh JoshiNo ratings yet

- Subrat Prajapati ResumeDocument2 pagesSubrat Prajapati ResumeMNR SolutionsNo ratings yet

- MS 2100 Session-1 Mechanical Engineering in Manufacturing IndustryDocument28 pagesMS 2100 Session-1 Mechanical Engineering in Manufacturing IndustryEnrico MichaelNo ratings yet

- CH 1 Introduction - ME F316Document19 pagesCH 1 Introduction - ME F316Vinayak SNo ratings yet

- AMSC2013 Hu Jianping DONGFENG NISSAN EnglishDocument15 pagesAMSC2013 Hu Jianping DONGFENG NISSAN EnglishBuzon PciNo ratings yet

- Dan Craciun - CE VEDocument6 pagesDan Craciun - CE VEdkxNo ratings yet

- Mechanical Engineer Krishna Arora's ResumeDocument2 pagesMechanical Engineer Krishna Arora's ResumeBaljeetNo ratings yet

- Company Profile (ADESPL)Document16 pagesCompany Profile (ADESPL)Amit GaragNo ratings yet

- Computer Integrated Management: Advanced Manufacturing TechnologyDocument27 pagesComputer Integrated Management: Advanced Manufacturing TechnologyMuhammad Atif Qaim KhaniNo ratings yet

- CNC, PLC, Automation ProfessionalDocument2 pagesCNC, PLC, Automation Professionalatif jabbarNo ratings yet

- Quality Assurance - Quality Control: Afd/Gok Roads 2000 Central Phases 2 ProjectDocument23 pagesQuality Assurance - Quality Control: Afd/Gok Roads 2000 Central Phases 2 ProjectWambugu MaInaNo ratings yet

- Corporate Profile FFCDocument17 pagesCorporate Profile FFCFaisal MusaNo ratings yet

- Company Profile Global Twin StarDocument6 pagesCompany Profile Global Twin StarJane Junita WorangNo ratings yet

- Mis Assignment 1 by Daniel AwokeDocument9 pagesMis Assignment 1 by Daniel AwokeDani Azmi Awoke100% (4)

- Company Profile 2022 - MasterDocument23 pagesCompany Profile 2022 - MasterSekretaris BPPNo ratings yet

- Industrial Engineer Quality LEAN MES 1564069816Document1 pageIndustrial Engineer Quality LEAN MES 1564069816Sondos EuchiNo ratings yet

- Nuga Sigma Potenzia PDFDocument30 pagesNuga Sigma Potenzia PDFTriyonoNo ratings yet

- AAPL - Consulting Services For EngineeringDocument14 pagesAAPL - Consulting Services For EngineeringsalithNo ratings yet

- Quality Management System ManualDocument46 pagesQuality Management System ManualFaisal JamshedNo ratings yet

- Flutura Specialty Chemicals - BrochureDocument2 pagesFlutura Specialty Chemicals - BrochureJigar DoshiNo ratings yet

- YEC Broucher - Final - Compressed-1Document16 pagesYEC Broucher - Final - Compressed-1ynr clusterNo ratings yet

- Tamal Sengupta CV PDFDocument2 pagesTamal Sengupta CV PDFVinodhkanna GandhiNo ratings yet

- 3S Company ProfileDocument34 pages3S Company ProfileDanny P. UtomoNo ratings yet

- Problem Definition & Need Identification: N. Sinha Mechanical Engineering Department IIT KanpurDocument49 pagesProblem Definition & Need Identification: N. Sinha Mechanical Engineering Department IIT KanpurMoloy SarkarNo ratings yet

- Mechanical Transmissions Expert Over 50 Years ExperienceDocument14 pagesMechanical Transmissions Expert Over 50 Years ExperienceGioVanni LorizioNo ratings yet

- Chronological Resume - tcm1045 131480Document1 pageChronological Resume - tcm1045 131480Sita kumarNo ratings yet

- Sayantrik Engineers Profile & CapabilitiesDocument32 pagesSayantrik Engineers Profile & CapabilitiesAbhishek GuptaNo ratings yet

- GLOCOM - Introduction & Presentation CompressedDocument34 pagesGLOCOM - Introduction & Presentation CompressedthanhluanvtNo ratings yet

- Composite Division QA Projects and ChallengesDocument2 pagesComposite Division QA Projects and ChallengesSleepingKnightNo ratings yet

- TeamUp Profile Rev.04 PDFDocument22 pagesTeamUp Profile Rev.04 PDFwalid jawadiNo ratings yet

- Salamuddin: QA/QC EngineerDocument3 pagesSalamuddin: QA/QC Engineercrm 2No ratings yet

- Company IntroduceDocument33 pagesCompany IntroduceWen ChenNo ratings yet

- APQP WhitePaperDocument14 pagesAPQP WhitePaperJagdish Madhavji MataniNo ratings yet

- Overview of SBG Services' Quality & Reliability, Utility, and Construction Tech PortfoliosDocument3 pagesOverview of SBG Services' Quality & Reliability, Utility, and Construction Tech PortfoliosChirag sharmaNo ratings yet

- Value Engineering WhitepaperDocument3 pagesValue Engineering WhitepaperPaulanthonyGeorgeNo ratings yet

- Machineries for Metal to Rubber Bonded Components AutomationDocument8 pagesMachineries for Metal to Rubber Bonded Components AutomationVimal AathithanNo ratings yet

- Baldota Group Company ProfileDocument40 pagesBaldota Group Company ProfileankitNo ratings yet

- Over View of Six SigmaDocument40 pagesOver View of Six SigmaMohammed ImranNo ratings yet

- CpiDocument45 pagesCpiapi-3754041No ratings yet

- CV - Kushal B CDocument3 pagesCV - Kushal B Ckushal B CNo ratings yet

- Case Study BSNLDocument3 pagesCase Study BSNLchetan guptaNo ratings yet

- Simar Infrastructures Limited: (Commitment To Excellence)Document19 pagesSimar Infrastructures Limited: (Commitment To Excellence)Pawan Kumar AgrawalNo ratings yet

- Statement of Association - DYC and MR Avinash SomanDocument3 pagesStatement of Association - DYC and MR Avinash SomanParag WadekarNo ratings yet

- Qiddr Khan CVDocument2 pagesQiddr Khan CVQais AliNo ratings yet

- Mechanical Engineering: HCL Engineering and R&D ServicesDocument4 pagesMechanical Engineering: HCL Engineering and R&D Servicesasdqwerty123No ratings yet

- Quality Training - Audit PreparationDocument40 pagesQuality Training - Audit PreparationHans PunterNo ratings yet

- Optimal Control System Company Profile PDFDocument9 pagesOptimal Control System Company Profile PDFkarna patelNo ratings yet

- Afc-Qsm-09 Process Interaction ChartDocument1 pageAfc-Qsm-09 Process Interaction ChartSharif KhanNo ratings yet

- WBSIDCL Industrial Estates Lease ModelsDocument6 pagesWBSIDCL Industrial Estates Lease ModelsARKA technocorpNo ratings yet

- New Doc 2020-03-10 12.05.59Document2 pagesNew Doc 2020-03-10 12.05.59ARKA technocorpNo ratings yet

- Tilting-Pad Journal BearingsDocument2 pagesTilting-Pad Journal BearingsNguyễn Thanh SơnNo ratings yet

- Chimnee FactoryDocument1 pageChimnee FactoryARKA technocorpNo ratings yet

- BPG Catalog PDFDocument12 pagesBPG Catalog PDFes9857No ratings yet

- 3L NITIN JI ModelDocument1 page3L NITIN JI ModelARKA technocorpNo ratings yet

- RTD Purchase RequisitionDocument1 pageRTD Purchase RequisitionARKA technocorpNo ratings yet

- CatalogDocument24 pagesCatalogmuthuswamyNo ratings yet

- Chimnee FactoryDocument1 pageChimnee FactoryARKA technocorpNo ratings yet

- 4L NITIN JI ModelDocument1 page4L NITIN JI ModelARKA technocorpNo ratings yet

- Analyzing Fluid Film Bearings and Rotordynamics With ANSYS - PresentationDocument34 pagesAnalyzing Fluid Film Bearings and Rotordynamics With ANSYS - PresentationARKA technocorpNo ratings yet

- Babbitt Bearing Manufacturer Product GuideDocument7 pagesBabbitt Bearing Manufacturer Product GuideARKA technocorpNo ratings yet

- The World Around Us: Solar System, Seasons, LandformsDocument11 pagesThe World Around Us: Solar System, Seasons, LandformsARKA technocorpNo ratings yet

- 2LNITIN JI ModelDocument1 page2LNITIN JI ModelARKA technocorpNo ratings yet

- (E-Module) ALT - Math-2 (Skip Counting)Document13 pages(E-Module) ALT - Math-2 (Skip Counting)ARKA technocorpNo ratings yet

- BPG Catalog PDFDocument12 pagesBPG Catalog PDFes9857No ratings yet

- CatalogDocument24 pagesCatalogmuthuswamyNo ratings yet

- Din Suntech 20 21Document20 pagesDin Suntech 20 21ARKA technocorpNo ratings yet

- Suntech Thrust Pad Cata 18-19Document16 pagesSuntech Thrust Pad Cata 18-19ARKA technocorpNo ratings yet

- Amphenol PCD Terminal Junction Module Milt81714 PDFDocument18 pagesAmphenol PCD Terminal Junction Module Milt81714 PDFramalingamNo ratings yet

- Yawopay Pitch Desk v1Document15 pagesYawopay Pitch Desk v1Profil BasNo ratings yet

- Submarine Escape Survivability and Rescue MohundroDocument14 pagesSubmarine Escape Survivability and Rescue Mohundroali alvandiNo ratings yet

- 001 - Understanding Convergence in An Autodesk Nastran In-CAD Nonlinear Analysis - Nastran - Autodesk Knowledge NetworkDocument12 pages001 - Understanding Convergence in An Autodesk Nastran In-CAD Nonlinear Analysis - Nastran - Autodesk Knowledge NetworkEquitus EngNo ratings yet

- N600X SystemServiceManual EN 10030881b001Document210 pagesN600X SystemServiceManual EN 10030881b001Electrónica BiomédicaNo ratings yet

- Cat 151Document113 pagesCat 151bachandeepNo ratings yet

- Tech and Human DignityDocument7 pagesTech and Human Dignityrosemariegalindo70No ratings yet

- RRU3229 Technical Specifications(V100R016C10_01)(PDF)-ENDocument13 pagesRRU3229 Technical Specifications(V100R016C10_01)(PDF)-ENMohammed ShakilNo ratings yet

- Strategic Management at Infosys (Business Strategy)Document19 pagesStrategic Management at Infosys (Business Strategy)Madhusudan22No ratings yet

- Ts440s Repair FaqDocument17 pagesTs440s Repair FaqboardstNo ratings yet

- 4MDocument1 page4MTania MenesesNo ratings yet

- ICT Changes Business ModelsDocument43 pagesICT Changes Business Modelsrizki dwi astutiNo ratings yet

- Remote Monitoring & Control of RACON BeaconDocument2 pagesRemote Monitoring & Control of RACON Beacon송현호No ratings yet

- Customizing HCM HeadersDocument7 pagesCustomizing HCM Headersvemulapalli1100% (1)

- TS0010 - Trench Details R04Document1 pageTS0010 - Trench Details R04Juan Carlos CastroNo ratings yet

- Recipe Recommendation by Ingredients DetectionDocument10 pagesRecipe Recommendation by Ingredients DetectionIJRASETPublicationsNo ratings yet

- PIM2 Fuel Injection Controller KitDocument4 pagesPIM2 Fuel Injection Controller KitmondorolaNo ratings yet

- Baja Sae Fox Racing ProgramDocument8 pagesBaja Sae Fox Racing ProgramChristian MavarezNo ratings yet

- 11-07-2019 211346 PM 7 INTRODUCTION COST MANAGEMENTDocument4 pages11-07-2019 211346 PM 7 INTRODUCTION COST MANAGEMENTEddyRamirezNo ratings yet

- Application Note #4424: Programming MATLAB With Galil ControllersDocument12 pagesApplication Note #4424: Programming MATLAB With Galil ControllerssamanNo ratings yet

- Satu Atap by Citra Novy PDFDocument402 pagesSatu Atap by Citra Novy PDFSsNo ratings yet

- FCI 08-ProductBrochureDocument16 pagesFCI 08-ProductBrochurepardan aksaniNo ratings yet

- SC 092540Document700 pagesSC 092540Shashikant MauryaNo ratings yet

- Pawan Patidar HIS AssignDocument21 pagesPawan Patidar HIS Assignpawan2005patidarNo ratings yet

- UT-2506 User ManualDocument22 pagesUT-2506 User ManualBayanaka TehnikNo ratings yet

- 5800 Instructions Pour Le Remplacement de L'element Chauffant Du Réservoir D'alimentationDocument12 pages5800 Instructions Pour Le Remplacement de L'element Chauffant Du Réservoir D'alimentationKirelbysNo ratings yet

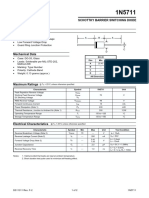

- Schottky Barrier Switching Diode FeaturesDocument2 pagesSchottky Barrier Switching Diode FeaturesОлег КлиновойNo ratings yet

- Siemens Energy Company Presentation en 2022 PDF Original FileDocument29 pagesSiemens Energy Company Presentation en 2022 PDF Original FileSunil DashoraNo ratings yet

- IVMS 8600 Platform Software IntroductionDocument37 pagesIVMS 8600 Platform Software Introductionbob felarcaNo ratings yet

- Oilcon Mark 6M: Technical ManualDocument177 pagesOilcon Mark 6M: Technical ManualParminder singh parmar100% (1)