Professional Documents

Culture Documents

LAB 4 - PSD-WET SIEVING (Level 0) - HYDROMETER (Level 0)

Uploaded by

Doris AsmaniOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LAB 4 - PSD-WET SIEVING (Level 0) - HYDROMETER (Level 0)

Uploaded by

Doris AsmaniCopyright:

Available Formats

FAKULTI KEJURUTERAAN AWAM

UNIVERSITI TEKNOLOGI MARA

PASIR GU DANG LABORATORY MANUAL

COURSE SOIL ENGINEERING LABORATORY

COURSE CODE ECG263

LEVEL OF OPENNESS 0

CATEGORY PARTIALLY OPEN

DEGREE OF OPEN-ENDED (%) 0

PERIOD OF ACTIVITY 1 WEEK (WEEK 5)

TITLE Particle Size Distribution (PSD) – Wet Sieving

1.1 Introduction

Level 1 laboratory activity refers to condition where the problem and ways & means are

guided and given to the students. However the answers to the assignment are left to the

students to solve using the group creativity and innovativeness. The activity is hope to

slowly introduced and inculcate independent learning amongst students and prepare them

for a much harder task of open ended laboratory activities.

In this laboratory activity students will be exposed to the usage of wet sieving tests to

determine the particle size distribution of fine-grained soil.

PREAMBLE

1.2 Objective

This test is performed to determine the particle size distribution in an essentially

cohesionless soil, down to the fine sand size.

1.3 Learning Outcomes

At the end of the laboratory activity, students would be able to:

1. conduct the particle size distribution (psd) – wet sieving

2. Analyse data correctly and present in typical format

3. Work in a group to produce technical report.

©FKA, UiTM PASIR GUDANG MARCH – AUG22

1.4 Theoretical Background

A basic element of the soil classification system is by determining the particle size of the

soil. The distribution of the particle sizes larger than 0.0075 mm is determine by sieving,

while smaller than 0.0075 mm is determine by sedimentation process (hydrometer analysis).

Below is the list of the particle size from largest to smaller:

Boulders : rocks that have an average diameter greater than 300 mm.

Cobbles : rocks that are smaller than 300 mm and retained on the 75 mm.

Gravel size particle : rock fragment or soil particles that will pass a 75 mm

sieve and be retained on a 4.75 mm.

FAKULTI KEJURUTERAAN AWAM

UNIVERSITI TEKNOLOGI MARA

PASIR GU DANG LABORATORY MANUAL

Sand size particle : soil particle that will pass a 4.75 mm sieve and be retained

on a 0.075 mm.

Silt size particle : fine soil particles that pass the 0.0075 mm sieve and are larger

than 0.002 mm.

Clay size particles : fine soil particles that are smaller than 0.002 mm.

Two method of sieving are specified:

i) Wet sieving is the definition method applicable to essentially cohesionless soils.

ii) Dry sieving is suitable only for soil containing insignificant quantities of silt and clay.

The procedure given involves preparation of the sample by wet sieving to remove silt and

clay-sized particles, which are rejected, followed by dry sieving of the remaining coarser

material.

Wet sieving is usually performed with one of two purposes. Either it is performed to

determine a fraction retained on a sieve or sieves, or it is a method of sample preparation

that allows a later particle size analysis to be performed more easily or accurately. The

procedures are often similar, but the one you choose should be based on your end goal.

2.0 Problem Statement

A soil consists of an assemblage of discrete particles of various shapes and sizes. The

object of a particle size analysis is to group these particles into separate ranges of sizes

PROBLEM and so determine the relative proportions, by dry mass of each size range. As a group you

STATEME are given

NT

a set of samples to determine the soil classifications.

The group must carry out the test following the procedures outline and subsequently analyse

the data and present it in a proper technical format.

©FKA, UiTM PASIR GUDANG MARCH – AUG22

3.1 Apparatus

i. Weighing Balance ii. Set of sieves

(20 mm & 0.063 mm) iii. Cleaning

brush & a scoop iv. Mechanical

sieve shaker (optional) v. Lid

and receiver (pan) vi. Drying Oven

vii. Large plastic container (60-80l) viii.

Sodium hexametaphosphate

WAYS

AND 3.2 Procedures & Data Acquisition

MEANS

1. Wet sieving is carried out to remove fine-grained particles and to determine the

combined clay/silt fraction percentage

2. A sub sample is first oven dried and sieved to separate the coarsest particle (>20 mm).

3. The sub sample is then immersed in water containing dispersing agent of sodium

hexametaphosphate of about 2 g/litre solution and is allowed to stand before being

washed away (store it in large container) in a 63 m mesh sieve.

4. The slurry that pass on 63 m mesh sieve and allow to settle for 1 week or until all fine

particle settle at the bottom of the container.

5. The wet sample (soil sediment) must be oven dried for hydrometer test sample

preparation if any.

FAKULTI KEJURUTERAAN AWAM

UNIVERSITI TEKNOLOGI MARA

PASIR GU DANG LABORATORY MANUAL

6. The retained fraction is again oven dried and passed into a nest of sieves(dry sieving,

LAB 3) if any.

7. The cumulative percentage passing is calculated and the combined clay/silt fraction is

determined from the weight difference expressed as a percentage of the total sub

sample from hydrometer test (LAB 4(B)).

8. The coarsest fraction (>20 mm) is sieved and the result is combined to complete the

grading curve.

4 Results, Analysis and Conclusion

Result

All result can be use on LAB 1 and LAB 2(B)

RESULTS

The group is required to submit the technical report of the laboratory results highlighting the

data acquisition process, analysis carried out and the relevancy of the set-out output to

achieve the objective.

The report must be submitted 7 days after the completion of the test.

©FKA, UiTM PASIR GUDANG MARCH – AUG22

FAKULTI KEJURUTERAAN AWAM

UNIVERSITI TEKNOLOGI MARA

PASIR GU DANG LABORATORY MANUAL

TITLE Particle size distribution of fine soil (Hydrometer test)

1.1 Introduction

Level 1 laboratory activity refers to condition where the problem and ways &

means are guided and given to the students. However the answers to the

assignment are left to the students to solve using the group creativity and

innovativeness. The activity is hope to slowly introduced and inculcate

independent learning amongst students and prepare them for a much harder

task of open ended laboratory activities.

In this laboratory activity students will be exposed to the usage of hydrometer

test to determine the particle size distribution of a given soil sample. For soil

samples containing fine-grained particles, a wet sieving procedure is first

carried out and test is conducted to determine the combined clay/silt fraction

percentage. The combined clay/silt fraction is determined from the weight

PREAMBLE difference and expressed as a percentage of the total sub-sample weight. The

test is in accordance to BS 1377-2:1990 test 9.2.

1.2 Objective

The objective of the test is:

To determine the grain size distribution of a soil sample (fine soil).

1.3 Learning Outcomes

At the end of the laboratory activity, students would be able to:

1. Identify the correct apparatus to carry out hydrometer

test. 2. Analyse data correctly and present in typical format

3. Work in a group to produce technical report.

©FKA, UiTM PASIR GUDANG MARCH – AUG22

1.4 Theoretical Background

Distribution of grain sizes affects the engineering properties of soil such as

permeability, strength, expansivity etc. It is also required in the classifying

the soil. Measurement of grain size distribution depends on the size of the

grains i.e. larger than 0.075 mm or in the range of 0.075 mm > D > 0.5 µm.

2.0 Problem Statement

To measure the grain size distribution, hydrometer test is normally used for fine

particle where the grain size is in the range of 0.075 mm > D > 0.5 µm. As a

group you are given a set of samples to test to determine its grain size

distribution.

PROBLEM A wet sieving test was conducted on 1kg of the air-dried soil sample to

STATEMENT determine the particle size distribution of the coarse materials. The results of

the wet sieving test were given in form PS1. The hydrometer sedimentation

test was then conducted in the laboratory to obtain the particle size distribution

of the fine portion of the soil sample.

FAKULTI KEJURUTERAAN AWAM

UNIVERSITI TEKNOLOGI MARA

PASIR GU DANG LABORATORY MANUAL

The group must carry out the test following the procedures outline and

subsequently analyse the data and present it in a proper technical format.

©FKA, UiTM PASIR GUDANG MARCH – AUG22

3.1 Apparatus

• Balance

• Set of sieves

• Cleaning brush

• Sieve shaker

• Mixer (blender)

• Hydrometer

• Sedimentation cylinder

• Control cylinder

• Thermometer

• Beaker

• Timing device.

• and other accessories which include evaporating dish, corrosion

resistant tray, calgon (33g of sodium hexametaphosphate and

7g of sodium carbonate in distilled water to make 1 Litre).

3.2 Procedures

1. Take the fine soil from the bottom pan of the sieve set, place it into a

beaker, and add 125 mL of the dispersing agent (sodium

hexametaphosphate (40 g/L)) solution. Stir the mixture until the soil is

WAYS & MEANS

thoroughly wet. Let the soil soak for at least ten minutes.

2. While the soil is soaking, add 125mL of dispersing agent into the

control cylinder and fill it with distilled water to the mark. Take the

reading at the top of the meniscus formed by the hydrometer stem

and the control solution. A reading less than zero is recorded as a

negative (-) correction and a reading between zero and sixty is

recorded as a positive (+) correction. This reading is called the zero

correction. The meniscus correction is the difference between the top

of the meniscus and the level of the solution in the control jar (Usually

about +1). Shake the control cylinder in such a way that the contents

are mixed thoroughly. Insert the hydrometer and thermometer into the

control cylinder and note the zero correction and temperature

respectively.

3. Transfer the soil slurry into a mixer by adding more distilled water, if

necessary, until mixing cup is at least half full. Then mix the solution

for a period of two minutes.

4. Immediately transfer the soil slurry into the empty sedimentation

cylinder. Add distilled water up to the mark.

5. Cover the open end of the cylinder with a stopper and secure it with

the palm of your hand. Then turn the cylinder upside down and back

upright for a period of one minute. (The cylinder should be inverted

approximately 30 times during the minute.)

FAKULTI KEJURUTERAAN AWAM

UNIVERSITI TEKNOLOGI MARA

PASIR GU DANG LABORATORY MANUAL

©FKA, UiTM PASIR GUDANG MARCH – AUG22

6. Set the cylinder down and record the time. Remove the stopper from

the cylinder. After an elapsed time of one minute and forty seconds,

very slowly and carefully insert the hydrometer for the first reading.

(Note: It should take about ten seconds to insert or remove the

hydrometer to minimize any disturbance, and the release of the

hydrometer should be made as close to the reading depth as possible

to avoid excessive bobbing).

The reading is taken by observing the top of the meniscus formed by

the suspension and the hydrometer stem. The hydrometer is removed

slowly and placed back into the control cylinder. Very gently spin it in

control cylinder to remove any particles that may have adhered.

8. Take hydrometer readings after elapsed time of 2 and 5, 8, 15, 30, 60

minutes and 24 hours.

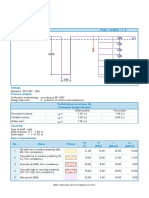

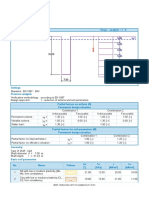

3.3 Data Results and Calculations

1. Apply meniscus correction to the actual hydrometer reading.

2. From calibration equation, obtain the effective hydrometer depth, Hr in

mm (for hydrometer corrected reading).

3. For known Gs of the soil (if not known, assume 2.65 for this lab

purpose), obtain the value of K1 from Table 2.

4. Calculate the equivalent particle diameter by using

the following formula:

D = 0.005531

(𝜌𝑠−1)

5. Where t is in minutes, and D is given in mm.

6. Calculate modified hydrometer reading as follows:

7. Rd = R’h–R’o

8. Where R’o= hydrometer reading in the dispersant solution

9. Calculate percent finer as follows:

100ρ

𝐾= s

𝑅𝑑 (%)

m(ρs−1)

10. Where m is the weight of the soil sample in grams.

11. Calculate the adjusted percentage passing and plot the grain size curve

D versus the adjusted percent finer on the semi logarithmic sheet.

©FKA, UiTM PASIR GUDANG MARCH – AUG22

FAKULTI KEJURUTERAAN AWAM

UNIVERSITI TEKNOLOGI MARA

PASIR GUDANG LABORATORY MANUAL

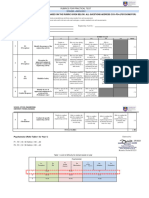

3.4 Data Acquisition

©FKA, UiTM PASIR GUDANG MARCH – AUG22

FAKULTI KEJURUTERAAN AWAM

UNIVERSITI TEKNOLOGI MARA

PASIR GU

DANG LABORATORY MANUAL

4 Results, Analysis and Conclusion

Result

1. Attach the table of the result.

2. Show the details calculation in determining each of the item needed in the

RESULTS table.

3. Plot a grain

-size distribution graph on -semi

log paper. (Adjusted percentage

passingvs.Particle diameter)

©FKA, UiTM PASIR GUDANG MARCH – AUG22

FAKULTI KEJURUTERAAN AWAM

UNIVERSITI TEKNOLOGI MARA

PASIR GU DANG LABORATORY MANUAL

The group is required to submit the technical report of the laboratory results

highlighting the data acquisition process, analysis carried out and the relevancy

of the set-out output to achieve the objective.

The report must be submitted 7 days after the completion of the test.

©FKA, UiTM PASIR GUDANG MARCH – AUG22

FAKULTI KEJURUTERAAN AWAM

UNIVERSITI TEKNOLOGI MARA

PASIR GUDANG LABORATORY MANUAL

©FKA, UiTM PASIR GUDANG MARCH – AUG22

You might also like

- The Science of Superhydrophobicity: Enhancing Outdoor Electrical InsulatorsFrom EverandThe Science of Superhydrophobicity: Enhancing Outdoor Electrical InsulatorsNo ratings yet

- Advances in Multi-Physics and Multi-Scale Couplings in Geo-Environmental MechanicsFrom EverandAdvances in Multi-Physics and Multi-Scale Couplings in Geo-Environmental MechanicsNo ratings yet

- LAB 3 - PSD - DRY SIEVING (Level 1)Document9 pagesLAB 3 - PSD - DRY SIEVING (Level 1)Doris AsmaniNo ratings yet

- Hydrometer Test Ecg 428Document6 pagesHydrometer Test Ecg 428Aiman SyafiqNo ratings yet

- LEVEL 0 - Week 3 - Sedimentation TestDocument4 pagesLEVEL 0 - Week 3 - Sedimentation TestNoradila RoslanNo ratings yet

- Exp2 1Document7 pagesExp2 1Alexis Joshua LaceNo ratings yet

- Full Report - Exp 1Document29 pagesFull Report - Exp 1Chiu FongNo ratings yet

- Mapua University: Experiment No. 3ADocument10 pagesMapua University: Experiment No. 3AGeojanni PangibitanNo ratings yet

- Dry Sieve Analysis - 006Document10 pagesDry Sieve Analysis - 006Nabil RahimiNo ratings yet

- Mapua University: Experiment No. 4ADocument7 pagesMapua University: Experiment No. 4ADenver John TejadaNo ratings yet

- Di Pa FinalllllllllDocument62 pagesDi Pa FinallllllllllouryNo ratings yet

- Full Report Exp 1Document26 pagesFull Report Exp 1drami94No ratings yet

- Dry Sieve AnalysisDocument3 pagesDry Sieve AnalysisHuda Fauzi0% (1)

- Applications of Quartering Method - 2017Document5 pagesApplications of Quartering Method - 2017Ionela HoteaNo ratings yet

- Cone Penetration Ecg428Document9 pagesCone Penetration Ecg428Aiman SyafiqNo ratings yet

- LAB 5 Permeability TestDocument9 pagesLAB 5 Permeability TestHanis RahamanNo ratings yet

- Dry Sieve ReportDocument11 pagesDry Sieve ReportNoor Shahirah Md Ruba'i93% (15)

- LAB 7 - Vane Shear - LEVEL 3Document5 pagesLAB 7 - Vane Shear - LEVEL 3Ainur Nasuha100% (1)

- Mapua University: Experiment No. 3.A Seive Analysis of SoilDocument8 pagesMapua University: Experiment No. 3.A Seive Analysis of SoilMike SyNo ratings yet

- Fakulti Kejuruteraan Awam Universiti Teknologi Mara EC110 Laboratory ManualDocument3 pagesFakulti Kejuruteraan Awam Universiti Teknologi Mara EC110 Laboratory ManualRichie BobbyNo ratings yet

- Me136p Exp5 Sieve Analysis of AggregatesDocument9 pagesMe136p Exp5 Sieve Analysis of AggregatesJohn Henry SalvadoNo ratings yet

- LAB 11 - Sand Patch Method OEL 1Document3 pagesLAB 11 - Sand Patch Method OEL 1ZULFAQAR BIN MOHAMMAD NIZAMNo ratings yet

- Sieve Analysis ReportDocument15 pagesSieve Analysis ReportTjia Tjie100% (1)

- Week 3 (2) - HYDROMETER (Level 0)Document5 pagesWeek 3 (2) - HYDROMETER (Level 0)Mohd YusriNo ratings yet

- LAB 9 - Bitumen Penetration OEL 1Document3 pagesLAB 9 - Bitumen Penetration OEL 12020890244No ratings yet

- Fakulti Kejuruteraan Awam Universiti Teknologi Mara Pasir Gudang Laboratory ManualDocument5 pagesFakulti Kejuruteraan Awam Universiti Teknologi Mara Pasir Gudang Laboratory ManualZaffira RahmanNo ratings yet

- Ecg 303Document2 pagesEcg 303Ain SyahiraNo ratings yet

- Student Code of Ethic (SCE) : Department of Infrastructure and Geomatic EngineeringDocument29 pagesStudent Code of Ethic (SCE) : Department of Infrastructure and Geomatic EngineeringLaraNo ratings yet

- Candelaria Experiment1 SoilMechLabDocument12 pagesCandelaria Experiment1 SoilMechLabHarley O. CandelariaNo ratings yet

- LAB 8 Bitumen Penetration OEL1Document3 pagesLAB 8 Bitumen Penetration OEL1Ali MifdzalNo ratings yet

- ElsieDocument12 pagesElsieEiyra NadiaNo ratings yet

- Derrick Screen ProjectDocument15 pagesDerrick Screen ProjectPortia ShilengeNo ratings yet

- Mapua University: Experiment No. 1Document8 pagesMapua University: Experiment No. 1Denver John TejadaNo ratings yet

- Analysis of Grain SizeDocument12 pagesAnalysis of Grain SizecortellaptopNo ratings yet

- Soil Mechanics Lab Manual Rev 2016Document24 pagesSoil Mechanics Lab Manual Rev 2016Karl Daniel VencerNo ratings yet

- Worksheet 1.4Document9 pagesWorksheet 1.4JeffersonTalanNo ratings yet

- LAB 5 & 6 Finenes Modulus and Particle Size DistributionDocument4 pagesLAB 5 & 6 Finenes Modulus and Particle Size DistributionWHfamily0% (1)

- LAB 1 - PARTICLE DENSITY - MOISTURE CONTENT (Level 0)Document7 pagesLAB 1 - PARTICLE DENSITY - MOISTURE CONTENT (Level 0)Doris AsmaniNo ratings yet

- LEVEL 1 - Sand Patch TestDocument3 pagesLEVEL 1 - Sand Patch TestAnonymous KpLy2NeNo ratings yet

- Wet and Dry Sieve Analysis Lab ManualDocument2 pagesWet and Dry Sieve Analysis Lab Manualmm100% (2)

- ScreeningDocument16 pagesScreeninganthony ijigaNo ratings yet

- Experiment No.1 Preparation of Samples For TestDocument5 pagesExperiment No.1 Preparation of Samples For TestRochelleMirandaNo ratings yet

- Mapua University: Experiment No. 1Document11 pagesMapua University: Experiment No. 1Geojanni PangibitanNo ratings yet

- Course NameDocument5 pagesCourse NameAiman SyafiqNo ratings yet

- E3Document4 pagesE3royNo ratings yet

- Republic of Iraq Ministry of Higher Education and Scientific Research College of Engineering Department of Chemical EngineeringDocument6 pagesRepublic of Iraq Ministry of Higher Education and Scientific Research College of Engineering Department of Chemical Engineeringعبد اللهNo ratings yet

- Properti Material Modul C 1-5Document10 pagesProperti Material Modul C 1-5Jhonny WankyNo ratings yet

- Sieve Analysis - An ExperimentDocument7 pagesSieve Analysis - An ExperimentamjadakramNo ratings yet

- CE322 - Final Lab 2Document39 pagesCE322 - Final Lab 2Vios, Allen Rafael M.No ratings yet

- GeoTech Lab Report TwoDocument15 pagesGeoTech Lab Report TwoSara Keranakis100% (1)

- Wet Preparation of Disturbed Soil SamplesDocument6 pagesWet Preparation of Disturbed Soil SamplesKEN KEN100% (1)

- Ceramics Lab 2Document9 pagesCeramics Lab 2Muhammad AbtaheeNo ratings yet

- LAB 8 - Compaction - LEVEL 2 - AINUR NASUHA BINTI MOHAMMAD RODZI-2019892466Document8 pagesLAB 8 - Compaction - LEVEL 2 - AINUR NASUHA BINTI MOHAMMAD RODZI-2019892466Ainur NasuhaNo ratings yet

- Exp 2 Preparation of Disturbed Soil Sample For TestDocument4 pagesExp 2 Preparation of Disturbed Soil Sample For TestMark Lester PonteNo ratings yet

- Fakulti Kejuruteraan Awam Universiti Teknologi Mara Shah Alam Laboratory ManualDocument5 pagesFakulti Kejuruteraan Awam Universiti Teknologi Mara Shah Alam Laboratory ManualhamiddinkomaNo ratings yet

- Lab 4 - Hydrometer Testnvxjkcvbcxckvbckjvjkvknvck.Document6 pagesLab 4 - Hydrometer Testnvxjkcvbcxckvbckjvjkvknvck.Amirah ShafeeraNo ratings yet

- Soil Mechanics Laboratory ReportDocument11 pagesSoil Mechanics Laboratory ReportSalman AlmajidNo ratings yet

- La Abrasion TestDocument3 pagesLa Abrasion TestHahahahahahahahahahaNo ratings yet

- Constitutive Modeling of Soils and RocksFrom EverandConstitutive Modeling of Soils and RocksPierre-Yves HicherRating: 5 out of 5 stars5/5 (1)

- LAB 7 - STANDARD PROCTOR (Level 1)Document5 pagesLAB 7 - STANDARD PROCTOR (Level 1)Doris AsmaniNo ratings yet

- ECG253 (Psychomotor) - RUBRIC PT 2 - MAC 23Document2 pagesECG253 (Psychomotor) - RUBRIC PT 2 - MAC 23Doris AsmaniNo ratings yet

- LAB 10 - SHEAR BOX TEST (Level 1)Document5 pagesLAB 10 - SHEAR BOX TEST (Level 1)Doris AsmaniNo ratings yet

- ElsivierDocument11 pagesElsivierDoris AsmaniNo ratings yet

- UthmDocument9 pagesUthmDoris AsmaniNo ratings yet

- Training Handwriting Grid & Lines-2 (1) - 8Document1 pageTraining Handwriting Grid & Lines-2 (1) - 8Doris AsmaniNo ratings yet

- Training Handwriting Grid & Lines-2 (1) - 11Document1 pageTraining Handwriting Grid & Lines-2 (1) - 11Doris AsmaniNo ratings yet

- APPENDIXDocument1 pageAPPENDIXDoris AsmaniNo ratings yet

- Training Handwriting Grid & Lines-2 (1) - 14Document1 pageTraining Handwriting Grid & Lines-2 (1) - 14Doris AsmaniNo ratings yet

- 4 Effect of Drying Methods and Sand Additiveon Shrinkage Cracks of An Expansive Soil PDFDocument13 pages4 Effect of Drying Methods and Sand Additiveon Shrinkage Cracks of An Expansive Soil PDFYousif MawloodNo ratings yet

- Part 1Document16 pagesPart 1Bagkermaix Anak ChundiNo ratings yet

- Attenuation of Vibration - Amick-SPIE99Document9 pagesAttenuation of Vibration - Amick-SPIE99Sen HuNo ratings yet

- CE5 ReviewerDocument12 pagesCE5 ReviewerKIM ANDREI MATELANo ratings yet

- Soil Properties GuidlineDocument27 pagesSoil Properties GuidlineJulfikar KhanNo ratings yet

- Site Investigation ReportDocument45 pagesSite Investigation ReportSamuel YekoNo ratings yet

- Shaft DA2Document8 pagesShaft DA2Anonymous koR9VtfNo ratings yet

- Musgrave (1955) - How Much of The Rain Enters The SoilDocument10 pagesMusgrave (1955) - How Much of The Rain Enters The SoilFrancisco Thibério Pinheiro LeitãoNo ratings yet

- Bryant RedHawk's Epic Soil Series ThreadsDocument94 pagesBryant RedHawk's Epic Soil Series ThreadsjeslynNo ratings yet

- Geotechnical Engineering For InfrastructureDocument370 pagesGeotechnical Engineering For InfrastructureMohamed Kamal100% (2)

- Geotechnical Parameters Study Using Seismic Refraction TomographyDocument6 pagesGeotechnical Parameters Study Using Seismic Refraction TomographyAdly Al-SaafinNo ratings yet

- Sieve Analysis: - Wet Sieve - Dry Sieve - Hydrometer TestDocument20 pagesSieve Analysis: - Wet Sieve - Dry Sieve - Hydrometer TestfarahaidasabriNo ratings yet

- MRDTM 210Document7 pagesMRDTM 210Tahir Mubeen100% (1)

- GTQ Lab 2 VM ID Examination Protocols Sept 2017Document2 pagesGTQ Lab 2 VM ID Examination Protocols Sept 2017晓春王No ratings yet

- En-37 Cuaresma Lab-8Document4 pagesEn-37 Cuaresma Lab-8Vincent LeguesNo ratings yet

- Landslide ReportDocument44 pagesLandslide ReportMahmuddin AminNo ratings yet

- Borehole Log: DescriptionDocument5 pagesBorehole Log: DescriptionAnonymous ilWXWxgNo ratings yet

- BS 812-1 - 1975Document12 pagesBS 812-1 - 1975realitepeace75% (8)

- Classification of Soil IDocument11 pagesClassification of Soil IMohit Suri0% (1)

- Chapter 3 Soil Science Physical PropertiesDocument220 pagesChapter 3 Soil Science Physical PropertiesJulieto ZubradoNo ratings yet

- Unconfined Compression TestDocument4 pagesUnconfined Compression TestAshfaq AhmadNo ratings yet

- Site Classification AS2870-2011 Residential Slabs and FootingsDocument16 pagesSite Classification AS2870-2011 Residential Slabs and FootingsMark TimkangNo ratings yet

- shaftDA1 PCDocument8 pagesshaftDA1 PCAnonymous koR9VtfNo ratings yet

- Presentation On GIBR-20May2020Document49 pagesPresentation On GIBR-20May2020Jasmine ENo ratings yet

- Aldeias Et Al-2016-Geoarchaeology PDFDocument20 pagesAldeias Et Al-2016-Geoarchaeology PDFJorge Alonso Rodriguez MoralesNo ratings yet

- ASTM D2487 Unified Soil Classification SystemDocument2 pagesASTM D2487 Unified Soil Classification SystemOsama FaekNo ratings yet

- Appc Soil Properties 718Document5 pagesAppc Soil Properties 718pinkuru100% (1)

- Particle Distribution of SoilDocument4 pagesParticle Distribution of SoilPatrick ValdezNo ratings yet

- Geotechnics - C1-C12 PDFDocument500 pagesGeotechnics - C1-C12 PDFSimi NagyNo ratings yet

- Recitation 1 Stress Distribution-Field Tests: P1) Load Under A Rectangular AreaDocument11 pagesRecitation 1 Stress Distribution-Field Tests: P1) Load Under A Rectangular AreaCemre CaglarNo ratings yet