Professional Documents

Culture Documents

Chapt 710

Uploaded by

cleberOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chapt 710

Uploaded by

cleberCopyright:

Available Formats

MAINTENANCE MANUAL MBB -- BK117

710 STICK POSITION AUGMENTATION SYSTEM (SPAS)

Table of Contents

Paragraph Title Page

710 -- 1 DESCRIPTION -- SPAS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

710 -- 2 TROUBLESHOTING -- SPAS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

710 -- 3 INSPECTION FOR CONDITION -- SPAS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

710 -- 4 FUNCTIONAL TEST -- SPAS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

710 -- 5 Removal -- Actuator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

710 -- 6 Installation -- Actuator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

710 -- 7 Removal -- Collective Transducer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

710 -- 8 Installation -- Collective Transducer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

710 -- 9 Removal -- SPAS Computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

710 -- 10 Installation -- SPAS Computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

710 -- 11 Removal -- Differential Pressure Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

710 -- 12 Installation -- Differential Pressure Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Revision 21 CHAPTER 710

Code C Page 1

MAINTENANCE MANUAL MBB -- BK117

BLANK PAGE

CHAPTER 710 Code C

Page 2

Revision 21

MAINTENANCE MANUAL MBB -- BK117

710 - 10 Installation - SPAS-- Computer

1. Open nose door.

2. Hold SPAS computer (12, figure 710--6) against mounting frame (10) and fasten with three screws (14) and

washers (15).

3. Use remaining screw (14) with washers (15, 17) to reinstall bonding jumper (16) at same time.

CAUTION USE SPECIAL CARE WHEN INSERTING ELECTRIC PLUG INTO SOCKET OF

SPAS COMPUTER -- IMPROPER INSERTION WILL DAMAGE PC BOARD.

4. Reconnect electrical cable (13) to socket.

5. Carry out a functional test in accordance with paragraph 710--4.

710 -- 11 Removal -- Differential Pressure Sensor (pre SB--MBB--BK117--80--160)

1. Open nose door.

2. Disconnect electrical cable (1, figure 710--6).

3. Sperate end of bonding jumper (9) by removing attaching hardware (2, 6, 7, 8).

4. Detach pneumatic connectors (5, 27).

5. To dismantle differential pressure sensor (4) from mounting frame (10), remove screws (25), washers (26)

and threaded plates (11) from clamps (3). Lift out sensor.

710 -- 11A Removal -- Differential Pressure Sensor (post SB--MBB--BK117--80--160)

1. Open nose door.

2. Disconnect electrical cable (39, figure 710--6).

3. Sperate end of bonding jumper (38) by removing attaching hardware (2, 6, 7, 8).

4. Detach pneumatic connectors (5, 27).

5. To dismantle differential pressure sensor (28) from adapter plate (31) remove screws (34), washers (35)

from clamps (33). Lift out sensor.

Revision 21 CHAPTER 710

Code C Page 23

MAINTENANCE MANUAL MBB -- BK117

710 -- 12 Installation - Differential Pressure Sensor (pre SB--MBB--BK117--80--160)

1. Open nose door.

2. Hold differential pressure sensor (4, figure 710--6) with both clamps (3) against mounting frame (10) and

fasten with screws (25), washers (26) and threaded plates (11).

3. Rejoin pneumatic connectors (5, 27).

4. Mount bonding jumper (9) to frame clamp using attaching hardware (2, 6, 7, 8).

5. Reconnect electrical cable (1).

6. Carry out a functional test in accordance with paragraph 710--4.

710 -- 12AInstallation - Differential Pressure Sensor (post SB--MBB--BK117--80--160)

1. Open nose door.

2. Hold differential pressure sensor (28, figure 710--6) with both clamps (33) against adapter plate (31) and

fasten with screws (34) and washers (35).

3. Rejoin pneumatic connectors (5, 27).

4. Mount bonding jumper (38) to frame clamp (37) using attaching hardware (2, 6, 7, 8).

5. Reconnect electrical cable (39).

6. Carry out a functional test in accordance with paragraph 710--4.

CHAPTER 710 Code C Revision 21

Page 24

MAINTENANCE MANUAL MBB -- BK117

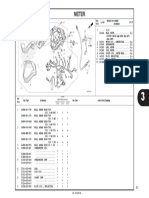

Differential pressure

transmitter pre

SB--MBB--BK117--80--160

Differntial pressure

39 transmitter post

SB--MBB--BK117--80--160

34, 35

37

28

29, 30 31

38

33

36 2

34, 35

2

32

31 32

28 Pressure transmitter PDCR340-4509 34 Screw Remove insulating surface protection layer from contact surface. Protect bare metal surfaces with PU--lacquer (CM

29 Screw LN9038-04010 35 Washer 478, CM 479, CM 480) after installation has been accomplished.

30 Washer LN9016-04K 36 Bracket If installed pitot--static lines are too short, they must be replaced with new piot--static lines.

2

31 Adapter plate 117-888202 37 Clamp for grounding point

32 Adapter SS-6M0-A-4ANF 38 Grounding strip

33 Clamp 39 Elt. connection Figure 710--6 SPAS--Computer and Differential Pressure Transmitter

Revision 21 CHAPTER 710

Page 29/30

You might also like

- GE 1.5 Service Manual PDFDocument148 pagesGE 1.5 Service Manual PDFMuhammad Ahmad100% (3)

- Practical Power System and Protective Relays CommissioningFrom EverandPractical Power System and Protective Relays CommissioningRating: 4.5 out of 5 stars4.5/5 (10)

- Mitsubishi Lancer EVO X Engine Overhaul PDFDocument74 pagesMitsubishi Lancer EVO X Engine Overhaul PDFStephen JordanNo ratings yet

- Midas Price List & Options2Document1 pageMidas Price List & Options2Marko Šimić100% (2)

- Site Engineers Manual PDFDocument3 pagesSite Engineers Manual PDFFahadNo ratings yet

- NTM 51-10-01Document21 pagesNTM 51-10-01kien Duy PhanNo ratings yet

- Transmission TC-SST Mitsubishi Ralliart, EvolutionDocument350 pagesTransmission TC-SST Mitsubishi Ralliart, EvolutionBogdan StefanNo ratings yet

- Manual de Taller ABS Mitsubishi Montero 2006Document136 pagesManual de Taller ABS Mitsubishi Montero 2006skppp100% (1)

- Scope of Works, Technical Specifications AND Bill of MaterialsDocument16 pagesScope of Works, Technical Specifications AND Bill of MaterialsRoi KimssiNo ratings yet

- Data Sheets Cba 300 Series Pneumatic Actuators Bettis en en 6000680Document18 pagesData Sheets Cba 300 Series Pneumatic Actuators Bettis en en 6000680Anak Agung YuniarthaNo ratings yet

- Scanned Manual: Cooper Nuclear Station Vendor Manual Mfr. Byron Jackson Pump DivisionDocument77 pagesScanned Manual: Cooper Nuclear Station Vendor Manual Mfr. Byron Jackson Pump DivisionEdison Marin MuñozNo ratings yet

- GR00003400 32Document10 pagesGR00003400 32dudurezNo ratings yet

- Manuel 1 Mi30dDocument48 pagesManuel 1 Mi30dChachou MohamedNo ratings yet

- Lennox EvenHeat ECB29EH 11 2007Document15 pagesLennox EvenHeat ECB29EH 11 2007ghaitmaNo ratings yet

- Engine Overhaul : Group 11BDocument96 pagesEngine Overhaul : Group 11Bopa952ya.ruNo ratings yet

- C 7 ENGINE APU (ATA 49,71,72,73,74,75,76,77,79,80) MumbaiDocument2 pagesC 7 ENGINE APU (ATA 49,71,72,73,74,75,76,77,79,80) Mumbaiarun RajannaNo ratings yet

- Manitou Y48130X Y43160X Y8140X Y48150X Repair Manual - 647119ENDocument6 pagesManitou Y48130X Y43160X Y8140X Y48150X Repair Manual - 647119ENbekirmakramNo ratings yet

- SB190-24-0001 - Electrical Power PC Outlet InstallationDocument48 pagesSB190-24-0001 - Electrical Power PC Outlet InstallationKevin AnguloNo ratings yet

- Telwin Superior240 CE PDFDocument24 pagesTelwin Superior240 CE PDFCune IonutNo ratings yet

- Engine Overhaul : Group 11BDocument58 pagesEngine Overhaul : Group 11BJeffrey WattsNo ratings yet

- GR00008300 27B PDFDocument50 pagesGR00008300 27B PDFToponari MedveNo ratings yet

- Manual Servicio Sony TRINITRON® COLOR TELEVISION Kv21fe13Document108 pagesManual Servicio Sony TRINITRON® COLOR TELEVISION Kv21fe13ARGENIS VALERONo ratings yet

- Engine Overhaul: Group 11BDocument74 pagesEngine Overhaul: Group 11BToponari MedveNo ratings yet

- 412 MM CH71 PDFDocument152 pages412 MM CH71 PDFFelie Alejandro LopezNo ratings yet

- Service Manual: KLV-32L500ADocument58 pagesService Manual: KLV-32L500ASaul Sabath Sandoval Delgado0% (1)

- 4G15M Dohc Engine Manual PDFDocument51 pages4G15M Dohc Engine Manual PDFPeter James Bruce Clark100% (1)

- Sect 2 Overhaul 1fs Engine Ce303Document45 pagesSect 2 Overhaul 1fs Engine Ce303laura Mt100% (1)

- Engine Mechanical: Group 11CDocument30 pagesEngine Mechanical: Group 11CAndy A.S.No ratings yet

- ASB - BK117 D2 67 007 Rev1 ENDocument13 pagesASB - BK117 D2 67 007 Rev1 ENDejan ZlatanovicNo ratings yet

- Sony Klv-26l500a 32l500a 37l500a Chassis Ex2t Rev.1 SMDocument87 pagesSony Klv-26l500a 32l500a 37l500a Chassis Ex2t Rev.1 SMDodi Gak DodolNo ratings yet

- Service Manual FE-2: KV-14LT1B KV-14LT1E KV-14LT1K KV-14LT1U KV-14LM1B KV-14LM1E KV-14LM1K KV-14LM1UDocument42 pagesService Manual FE-2: KV-14LT1B KV-14LT1E KV-14LT1K KV-14LT1U KV-14LM1B KV-14LM1E KV-14LM1K KV-14LM1Ukn_21No ratings yet

- SelectricDocument153 pagesSelectricLuissmrmix ER DjTraxNo ratings yet

- Siemens Price List (Low Voltage Power Distribution Products) PDFDocument23 pagesSiemens Price List (Low Voltage Power Distribution Products) PDFMd. Nazmul Karim100% (1)

- Case Cx240b Crawler Excavator Shop ManualDocument20 pagesCase Cx240b Crawler Excavator Shop Manualphyliss100% (51)

- 210 m2 Jet ElectricalDocument47 pages210 m2 Jet ElectricalДмитрий ЗолотковNo ratings yet

- Tech Manual 1222B: Booster Cylinder Assembly EH34-BC03Document21 pagesTech Manual 1222B: Booster Cylinder Assembly EH34-BC03jose perozoNo ratings yet

- KUMKANG LOAD CAL - 1500KVA - 19.03.26 (3차)Document70 pagesKUMKANG LOAD CAL - 1500KVA - 19.03.26 (3차)Phạm Đức HoằngNo ratings yet

- Meter F-2: No. Ref. L.O.N. (Nomor Ref. Relatif) Deskripsi F.R.TDocument1 pageMeter F-2: No. Ref. L.O.N. (Nomor Ref. Relatif) Deskripsi F.R.TIan GoNo ratings yet

- ColorlinerM PDFDocument82 pagesColorlinerM PDFCarlos AravenaNo ratings yet

- CX7P9 Calefaccion PDFDocument92 pagesCX7P9 Calefaccion PDFJuan IdrovoNo ratings yet

- CX7P9 Calefaccion PDFDocument92 pagesCX7P9 Calefaccion PDFJuan IdrovoNo ratings yet

- SONY KV-21FT1K Service Manual PDFDocument42 pagesSONY KV-21FT1K Service Manual PDFClaudiu MorarNo ratings yet

- TL Manual PDFDocument1,260 pagesTL Manual PDFdenizinakNo ratings yet

- GR00000600-11E 4G69 Engine MechanicalDocument56 pagesGR00000600-11E 4G69 Engine MechanicalHarold SarmientoNo ratings yet

- Section 2C: General SpecificationsDocument36 pagesSection 2C: General SpecificationsJarry PotterNo ratings yet

- Engine Mechanical : Group 11CDocument56 pagesEngine Mechanical : Group 11CNoob StalkerNo ratings yet

- Sony Klv-26l500a 32l500a 37l500a Chassis Ex2t Rev.2 SM PDFDocument87 pagesSony Klv-26l500a 32l500a 37l500a Chassis Ex2t Rev.2 SM PDFivan navarro tapiaNo ratings yet

- Abs DTCDocument118 pagesAbs DTCDenCom DzNo ratings yet

- LG GC260WwDocument122 pagesLG GC260WwLesNo ratings yet

- Mazda Protege 5 Control SystemDocument14 pagesMazda Protege 5 Control SystemJGAR2009No ratings yet

- Tracción ControlDocument212 pagesTracción Controltallermae100% (1)

- Series BBV-2 5-Valve Block and Bleed Manifold: Specifications - Installation and Operating InstructionsDocument4 pagesSeries BBV-2 5-Valve Block and Bleed Manifold: Specifications - Installation and Operating InstructionsGuillermo de la Fuente SantiagoNo ratings yet

- Sony KV 29cl11k SM PDFDocument52 pagesSony KV 29cl11k SM PDFViorellNo ratings yet

- GR00000400 70Document20 pagesGR00000400 70Sergio EspinozaNo ratings yet

- 70DS-01FP: Service ManualDocument33 pages70DS-01FP: Service ManualmendermanNo ratings yet

- 66mm Busbar System Data SheetDocument9 pages66mm Busbar System Data SheetOzhen SelexboysNo ratings yet

- Job Card: 27-51-00-710-803-A - Operational Check of Interconnecting Strut and Proximity SensorsDocument11 pagesJob Card: 27-51-00-710-803-A - Operational Check of Interconnecting Strut and Proximity Sensorsatony357No ratings yet

- Modern Borehole Analytics: Annular Flow, Hole Cleaning, and Pressure ControlFrom EverandModern Borehole Analytics: Annular Flow, Hole Cleaning, and Pressure ControlNo ratings yet

- Next Generation SDH/SONET: Evolution or Revolution?From EverandNext Generation SDH/SONET: Evolution or Revolution?Rating: 2.5 out of 5 stars2.5/5 (2)

- 841Document14 pages841cleberNo ratings yet

- 840Document6 pages840cleberNo ratings yet

- Chapt 808Document8 pagesChapt 808cleberNo ratings yet

- Chapt 802Document11 pagesChapt 802cleberNo ratings yet

- Chapt 806Document5 pagesChapt 806cleberNo ratings yet

- Chapt 800Document2 pagesChapt 800cleberNo ratings yet

- Chapt 701Document8 pagesChapt 701cleberNo ratings yet

- Chapt 703Document9 pagesChapt 703cleberNo ratings yet

- Chapt 704ADocument31 pagesChapt 704AcleberNo ratings yet

- 14 - Aircraft Weighing KitDocument204 pages14 - Aircraft Weighing KitcleberNo ratings yet

- 13 - Balancer 8500CDocument12 pages13 - Balancer 8500CcleberNo ratings yet

- 12 - Rads SatDocument277 pages12 - Rads Satcleber100% (1)

- 04 - Hpu Skydrol 5431Document255 pages04 - Hpu Skydrol 5431cleberNo ratings yet

- 03 - Pitot Static 6600 NGDocument103 pages03 - Pitot Static 6600 NGcleberNo ratings yet

- 3119lecture PDFDocument298 pages3119lecture PDFChoi TomNo ratings yet

- Hazen William FormulaDocument4 pagesHazen William FormulaShahbaz Manzoor100% (1)

- Membina Dan Menyiapkan Sebuah Bangunan Klinik Satu Tingkat Bagi Jabatan Otorinolaringologi Di Hospital Tuanku Ampuan Najihah, Kuala PilahDocument5 pagesMembina Dan Menyiapkan Sebuah Bangunan Klinik Satu Tingkat Bagi Jabatan Otorinolaringologi Di Hospital Tuanku Ampuan Najihah, Kuala PilahNor_Hisham_2241No ratings yet

- Ductwork RequirementsDocument1 pageDuctwork RequirementsBaha Abdulhaleem AlsaliebyNo ratings yet

- Navtec Stretch CalculationFormula PDFDocument1 pageNavtec Stretch CalculationFormula PDFJon LawheadNo ratings yet

- 17 StairDocument2 pages17 StairNiranjan ShresthaNo ratings yet

- CATALOG - Valves and Actuators (EN) PDFDocument64 pagesCATALOG - Valves and Actuators (EN) PDFflorentinNo ratings yet

- Al SiC MMCDocument16 pagesAl SiC MMCVinu VikkyNo ratings yet

- MS - 9 Shaft SinkingDocument9 pagesMS - 9 Shaft SinkingSyed Umair HashmiNo ratings yet

- SP - SM Limit Switch Box Series: Linking The Process With The Control RoomDocument4 pagesSP - SM Limit Switch Box Series: Linking The Process With The Control Roomsaeed_393512703No ratings yet

- ARCH 1173: RSW: 01 Title: Wood Stairs Date Given: February 19, 2021 Due Date: February 25, 2021 ReferencesDocument7 pagesARCH 1173: RSW: 01 Title: Wood Stairs Date Given: February 19, 2021 Due Date: February 25, 2021 ReferencesJohn Nichole Hernandez DacanayNo ratings yet

- Lecture 07 - CUPOLA AND CHARGE ESTIMATION FOR CUPOLADocument9 pagesLecture 07 - CUPOLA AND CHARGE ESTIMATION FOR CUPOLAManan GuptaNo ratings yet

- Timber Design Review PDFDocument4 pagesTimber Design Review PDFJunar AmaroNo ratings yet

- Specification FOR Electrical Insulation Coating: EDMS 29-300-1Document12 pagesSpecification FOR Electrical Insulation Coating: EDMS 29-300-1Mina RemonNo ratings yet

- Seismic Evaluation and Retrofit of DeterDocument195 pagesSeismic Evaluation and Retrofit of DeternoijpNo ratings yet

- TWJO-1-TCD-ST1-0004-Rev E-A3Document30 pagesTWJO-1-TCD-ST1-0004-Rev E-A3Anang AprizalNo ratings yet

- Numerical Investigation of The Turbulent Cross Flow and Heat Transfer in A Wall Bounded Tube Bundles - LiDocument13 pagesNumerical Investigation of The Turbulent Cross Flow and Heat Transfer in A Wall Bounded Tube Bundles - LiMeshal Al-mutairiNo ratings yet

- Steel Standards - Equivalence - MP MétalDocument2 pagesSteel Standards - Equivalence - MP MétalIr AyenNo ratings yet

- Structural Steel Design: DR - Mu'taz K.M Ass - Prof. in Civil EngineeringDocument12 pagesStructural Steel Design: DR - Mu'taz K.M Ass - Prof. in Civil EngineeringAhmed Pshtiwan AhmedNo ratings yet

- Is 15622-2017Document17 pagesIs 15622-2017Rohil Julaniya50% (6)

- Models: 1284, 1285, 1286 and 1287 Forma Class II, A2 Biological Safety CabinetsDocument44 pagesModels: 1284, 1285, 1286 and 1287 Forma Class II, A2 Biological Safety CabinetsAtrocitus RedNo ratings yet

- Premature Failure of Linear Guides and Ball ScrewsDocument15 pagesPremature Failure of Linear Guides and Ball ScrewsamgunaNo ratings yet

- Most Important Topics On Material ScienceDocument122 pagesMost Important Topics On Material ScienceAjesh kumarNo ratings yet

- Cold Storage System: Pfir PferDocument2 pagesCold Storage System: Pfir PferUcok DedyNo ratings yet

- (TDB) SINGLE Multi-Position AHU For Latin America (R410A, 60Hz, HP) - Ver.1.0 - 160322Document22 pages(TDB) SINGLE Multi-Position AHU For Latin America (R410A, 60Hz, HP) - Ver.1.0 - 160322Jean Carlos SanchezNo ratings yet

- Carbon and Low Alloy SteelsDocument3 pagesCarbon and Low Alloy Steelspratapkumar333No ratings yet

- Epa CertificationDocument124 pagesEpa Certificationplumbguru100% (5)