Professional Documents

Culture Documents

SV and Fans Comparison

Uploaded by

Afsal JhOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SV and Fans Comparison

Uploaded by

Afsal JhCopyright:

Available Formats

COMPARISON BETWEEN NATURAL SMOKE VENT AND SMOKE EXTRACT FANS

Powered Ducted smoke extract (Tube Axial Fan)

Features Natural Smoke vent

Fail safe operation Failsafe operation can be enabled by use of Fusible links or battery back up Operation depends on reliable power supplies

Noise during operation Silent operation as no high-speed rotating components are involved Too noisy when run under fire conditions due to higher speed operation

Self-compensating Can accommodate bigger than design fires as they cause higher buoyancy and higher extract rates The airflow rate is fixed and cannot accommodate any additional requirements than design

No time limit to operation as once opened they will remain active. Will be operational for days without

No Time limit of operation Can operate only till rated operation limits eg- 2 hrs for F400 or F300 rating

external power (Minimum 72 hrs as standard)

Comparatively much heavier and dynamic loading during operation mandates the need for separate

Weight of unit Light weight and does not need separate supporting structures

support structures

Operation costs/energy consumption No operational cost and nominal power consumption (24-48W) with minimal cabling High energy consumption and costlier cabling

Maintenance requirements Maintenance free operation Requires periodic maintenance

Ducted applications Not suited for complex ducting. Suitable for complex and branched ducting

Since fans are the inline ducted type locating at the roof installing directly above the concrete slab, there will not be any water leakage issue. Smoke ventilators are installing above the soaker panel at the roof

Water Leakage

with water proofing, there is possibility of leakage in the system due to poor workmanship

Consultant's Reccomendation Our reccomendation is to use Smoke Ventilators instead of Smoke Fan Due to Cost impact and more reliable operations

You might also like

- Tube Axial Fan and Ventilators Technical ComparisonDocument1 pageTube Axial Fan and Ventilators Technical ComparisonAfsal JhNo ratings yet

- Pill AeratorDocument20 pagesPill AeratorAhmed NahrawyNo ratings yet

- Leaflet Vent Eng RGBDocument2 pagesLeaflet Vent Eng RGBEmrah MertyürekNo ratings yet

- Suntech 250 DatasheetDocument2 pagesSuntech 250 DatasheetKrishna ManandharNo ratings yet

- Ficha TXB PDFDocument23 pagesFicha TXB PDFJohas Ogando RNo ratings yet

- PM PeraturanDocument2 pagesPM Peraturanyan energiaNo ratings yet

- WCVS0905Document4 pagesWCVS0905Quynh NguyenNo ratings yet

- AF-6 Catalogue Ed02 (En)Document64 pagesAF-6 Catalogue Ed02 (En)NateshNo ratings yet

- En Ultra V Stp550s c72 PMH+Document2 pagesEn Ultra V Stp550s c72 PMH+Luis Mauro Rivera FloresNo ratings yet

- Distributed Generation AttachmentsDocument10 pagesDistributed Generation AttachmentsMg76No ratings yet

- Distributed - Generation AttachmentsDocument10 pagesDistributed - Generation AttachmentsM UsmanNo ratings yet

- TAD760VE: Volvo Penta Industrial DieselDocument2 pagesTAD760VE: Volvo Penta Industrial DieselAntónio AbrunhosaNo ratings yet

- 48VL-03PD CarrierDocument32 pages48VL-03PD CarrierNaomi SandovalNo ratings yet

- FN 3410 Open FrameDocument6 pagesFN 3410 Open FrameVarun GuptaNo ratings yet

- Brochure Solar Module - Suntech - EN - Ultra - S - STP455S - B72 - VNH (MC4 - 455 - 435) - 4G - S3Document2 pagesBrochure Solar Module - Suntech - EN - Ultra - S - STP455S - B72 - VNH (MC4 - 455 - 435) - 4G - S3Yudha Trias RusmanaNo ratings yet

- Engine Power: SAE J1349, Net 345kw (463 HP) @1,800 RPM Operational Weight: 70,100kg - STD. Bucket Capacity (SAE) : 3.0 4.5 MDocument20 pagesEngine Power: SAE J1349, Net 345kw (463 HP) @1,800 RPM Operational Weight: 70,100kg - STD. Bucket Capacity (SAE) : 3.0 4.5 MSusy Cruz VegaNo ratings yet

- Big Fan Submittal-ID (New Update 12 Des 2022)Document16 pagesBig Fan Submittal-ID (New Update 12 Des 2022)Wijaya GultomNo ratings yet

- Injection Moulding: Dedicated Products and Solutions ForDocument4 pagesInjection Moulding: Dedicated Products and Solutions ForArun NatoNo ratings yet

- CarepolebrochureDocument4 pagesCarepolebrochurenivya machadoNo ratings yet

- Technical Guide: ListedDocument30 pagesTechnical Guide: ListedJhon DiazNo ratings yet

- Static Blower: FDN-H Series FGN-H SeriesDocument7 pagesStatic Blower: FDN-H Series FGN-H SeriesAung Thiha SoeNo ratings yet

- Industrial FansDocument15 pagesIndustrial FansMoch SolichinNo ratings yet

- Powerline: Rg15/Ug15Document4 pagesPowerline: Rg15/Ug15pedro perezNo ratings yet

- AnsaldoEnergia SYNCHRONOUSCONDENSERS 20220622Document6 pagesAnsaldoEnergia SYNCHRONOUSCONDENSERS 20220622rotimi olalekan fataiNo ratings yet

- Product Data: 50HJQ Single-Package Rooftop High Efficiency Heat Pump UnitsDocument52 pagesProduct Data: 50HJQ Single-Package Rooftop High Efficiency Heat Pump UnitsfjeroNo ratings yet

- Fan Filter UnitDocument3 pagesFan Filter UnitPads PrietoNo ratings yet

- ACS 2000 Medium Voltage Drives: Technical DataDocument24 pagesACS 2000 Medium Voltage Drives: Technical DataDaigo CfNo ratings yet

- 2 FT Climate Wizard (CW-P15)Document16 pages2 FT Climate Wizard (CW-P15)Paulo CruzNo ratings yet

- Hospital Operating Theatre PDFDocument56 pagesHospital Operating Theatre PDFfisplNo ratings yet

- Zhuowei Catalog 2016 - Fan Filter Units SeriesDocument3 pagesZhuowei Catalog 2016 - Fan Filter Units Seriesinnovameq.ingenieriaNo ratings yet

- Axial Piston Variable Motor A10VER Series 52 Reversible Fan Motor in Open CircuitDocument2 pagesAxial Piston Variable Motor A10VER Series 52 Reversible Fan Motor in Open CircuitJorge CabreraNo ratings yet

- Impulse VentilationDocument12 pagesImpulse VentilationYe Myat ThuNo ratings yet

- 435-450watt: 144 Cell Half Cut Mono Perc Solar ModuleDocument2 pages435-450watt: 144 Cell Half Cut Mono Perc Solar ModuleGandharv Kumar ThakurNo ratings yet

- Split Type Air Conditioners: DC Inverter Control 50 HZDocument4 pagesSplit Type Air Conditioners: DC Inverter Control 50 HZlucio ruiz jrNo ratings yet

- 201511ERACS.C Air-Cooled ChillerDocument16 pages201511ERACS.C Air-Cooled ChillerZaw Moe KhineNo ratings yet

- ATS - Com VSD - TEC-manual-ATS PDFDocument76 pagesATS - Com VSD - TEC-manual-ATS PDFg3qwsfNo ratings yet

- Hertz Hgs HSC Brochure en 2Document4 pagesHertz Hgs HSC Brochure en 2Percy Santiago felixNo ratings yet

- Suntech HyPro STP385S 72 VFH MC4 385 380 375 2GDocument2 pagesSuntech HyPro STP385S 72 VFH MC4 385 380 375 2GRaul SantosNo ratings yet

- VACUTAP® Technology New Standard For Users of Regulating TransformersDocument8 pagesVACUTAP® Technology New Standard For Users of Regulating TransformerskotaNo ratings yet

- Centrifugal Blowers: Assured Safety Through Gas-Tight and Pressure-Resistant CasingsDocument7 pagesCentrifugal Blowers: Assured Safety Through Gas-Tight and Pressure-Resistant CasingspedpixNo ratings yet

- EN Ultra V Mini STP410S C54 UmhDocument2 pagesEN Ultra V Mini STP410S C54 Umhjabt4568No ratings yet

- Miller Welding Generator-Big Blue 500x Eco ProDocument8 pagesMiller Welding Generator-Big Blue 500x Eco Progroshan20No ratings yet

- Improving Boiler Feedwater Pump ReliabilityDocument2 pagesImproving Boiler Feedwater Pump ReliabilityP.g. SunilkumarNo ratings yet

- Fisa Tehnica Vents Vko1Document2 pagesFisa Tehnica Vents Vko1Irimiea VirgilNo ratings yet

- UntitledDocument32 pagesUntitledAjay NishadNo ratings yet

- Xylem Guide To BlowersDocument11 pagesXylem Guide To BlowersAmal KaNo ratings yet

- Vacuum Circuit Breakers: For Generator Switching ApplicationsDocument12 pagesVacuum Circuit Breakers: For Generator Switching Applicationsabut tirtaNo ratings yet

- Wind Power: What Is It? How Does It Work? Types Applications Advantages DisadvantagesDocument30 pagesWind Power: What Is It? How Does It Work? Types Applications Advantages DisadvantagesEric Cook0% (1)

- Pegasus: Medium Voltage AC Induction MotorsDocument6 pagesPegasus: Medium Voltage AC Induction MotorsSergio aldoNo ratings yet

- ERV Ceiling MountDocument8 pagesERV Ceiling MountTMVR's TVNo ratings yet

- Synchronous Alternators: G Plus Line AG10 Line 60 HZDocument48 pagesSynchronous Alternators: G Plus Line AG10 Line 60 HZSeitec AssistenciaNo ratings yet

- Engine Power: SAE J1349, Net 345kw (463 HP) @1,800 RPM Operational Weight: 70,100kg - STD. Bucket Capacity (SAE) : 3.0 4.5 MDocument20 pagesEngine Power: SAE J1349, Net 345kw (463 HP) @1,800 RPM Operational Weight: 70,100kg - STD. Bucket Capacity (SAE) : 3.0 4.5 Mpoeloe nagaNo ratings yet

- Brochure HTW HTWD enDocument5 pagesBrochure HTW HTWD enRaul GallardoNo ratings yet

- Minetek - Air Brochure - USA-digitalDocument7 pagesMinetek - Air Brochure - USA-digitalMarcelo PachecoNo ratings yet

- Fiche de Specifications Dx300 LcaDocument20 pagesFiche de Specifications Dx300 LcaFedorNo ratings yet

- Jet Fan 1Document5 pagesJet Fan 1nghialuNo ratings yet

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Rfi - 29.01.2023Document12 pagesRfi - 29.01.2023Afsal JhNo ratings yet

- Water Consumption Calculation-AhizDocument3 pagesWater Consumption Calculation-AhizAfsal JhNo ratings yet

- ADDC - Musaffah Region Sector M-33Document89 pagesADDC - Musaffah Region Sector M-33Afsal JhNo ratings yet

- VRF & DX Unit Comparison-Labour Accomodation - RakezDocument1 pageVRF & DX Unit Comparison-Labour Accomodation - RakezAfsal JhNo ratings yet

- Amazon MeetingDocument2 pagesAmazon MeetingAfsal JhNo ratings yet

- Pump - LIUDocument1 pagePump - LIUAfsal JhNo ratings yet

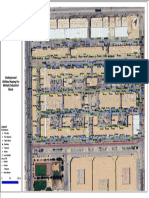

- Underground Utilities Maping For Alkhalij Industrial Block: LegendDocument1 pageUnderground Utilities Maping For Alkhalij Industrial Block: LegendAfsal JhNo ratings yet

- Ac Equipment ScheduleDocument1 pageAc Equipment ScheduleAfsal JhNo ratings yet

- Annex Ix.3 - Mech'l SpecsDocument202 pagesAnnex Ix.3 - Mech'l SpecsAfsal JhNo ratings yet

- Jack Portal ConnectionDocument24 pagesJack Portal ConnectionAfsal JhNo ratings yet

- Rack Sprinkler Arrangement - TypicalDocument1 pageRack Sprinkler Arrangement - TypicalAfsal JhNo ratings yet

- 2 - Table 2 - Discharge Units (DU)Document1 page2 - Table 2 - Discharge Units (DU)Afsal JhNo ratings yet

- Neb CHW - Pipe Sizing ChartDocument1 pageNeb CHW - Pipe Sizing ChartAfsal JhNo ratings yet

- Louver Calculation & ScheduleDocument2 pagesLouver Calculation & ScheduleAfsal JhNo ratings yet

- Ventilation SchematicDocument4 pagesVentilation SchematicAfsal JhNo ratings yet

- Systemair DVV 1000D4-6-XP F400 Smoke ExtDocument8 pagesSystemair DVV 1000D4-6-XP F400 Smoke ExtAfsal JhNo ratings yet

- PRC 14222 Ventilationoffirepumproomsv 1Document3 pagesPRC 14222 Ventilationoffirepumproomsv 1Afsal JhNo ratings yet

- Quick Guide On Water Demand Calculations - 221208 - 163015Document2 pagesQuick Guide On Water Demand Calculations - 221208 - 163015Afsal JhNo ratings yet

- Inserting Images - ShareLaTeX, Online LaTeX EditorDocument11 pagesInserting Images - ShareLaTeX, Online LaTeX EditorAviraj3892No ratings yet

- Physics XIDocument13 pagesPhysics XIArokiaraj RajNo ratings yet

- FB-150 FQ-150 Basket StrainerDocument1 pageFB-150 FQ-150 Basket Strainerklich77No ratings yet

- Vogue 201602 Japan PDFDocument254 pagesVogue 201602 Japan PDFJack Douglas YooNo ratings yet

- Laser in ProsthodonticsDocument84 pagesLaser in ProsthodonticsmarwaNo ratings yet

- Adjectives 4Document34 pagesAdjectives 4Delia Bolasoc100% (1)

- Chapter 3 Ni ChupaghettiDocument2 pagesChapter 3 Ni ChupaghettiRodemar RosarioNo ratings yet

- Yohimbine InjectionDocument1 pageYohimbine InjectionKasidit SornchaiNo ratings yet

- Fire InvestigationDocument126 pagesFire InvestigationAbcede IloiloNo ratings yet

- Imageformula Dr-m260 SM Rev0!1!200128Document144 pagesImageformula Dr-m260 SM Rev0!1!200128Ernesto De la TorreNo ratings yet

- Science 3 PDFDocument12 pagesScience 3 PDFJelyn CandoNo ratings yet

- Lecture 4: Expert Systems: What Is An Expert System?Document5 pagesLecture 4: Expert Systems: What Is An Expert System?Zerihun BekeleNo ratings yet

- CNS - Types of CiphersDocument47 pagesCNS - Types of Ciphersmahesh palemNo ratings yet

- An Isogeometric Analysis Approach For The Study of Structural VibrationsDocument59 pagesAn Isogeometric Analysis Approach For The Study of Structural VibrationsBharti SinghNo ratings yet

- Forces Revision Questions 1. Resistive Force.: Island School 1Document13 pagesForces Revision Questions 1. Resistive Force.: Island School 1Deepal PrasankaNo ratings yet

- Ece R13Document36 pagesEce R13DilipReddiarNo ratings yet

- Diagnosis and Testing: Four Wheel Drive (4WD) Systems - Electronic ShiftDocument38 pagesDiagnosis and Testing: Four Wheel Drive (4WD) Systems - Electronic ShiftLojan Coronel José Humberto100% (1)

- AssignmentDocument9 pagesAssignmentRazi BaigNo ratings yet

- Computer Networks: Introduction (Chapter 1)Document92 pagesComputer Networks: Introduction (Chapter 1)Speed PianoNo ratings yet

- Evaluation of Yogurt Production Line Simulation Using Arena SoftwareDocument8 pagesEvaluation of Yogurt Production Line Simulation Using Arena Softwareg defNo ratings yet

- Sheet Pile Analysis Sheet v1.07-18.1Document2 pagesSheet Pile Analysis Sheet v1.07-18.1SES DESIGN100% (1)

- QE and Complex Numbers DPPDocument9 pagesQE and Complex Numbers DPPsatishmhbdNo ratings yet

- Simulation of Congestion Control Algorithm AimDocument4 pagesSimulation of Congestion Control Algorithm AimHaru HarshuNo ratings yet

- ITTC Surface TreatmentDocument63 pagesITTC Surface Treatments_brizzolaraNo ratings yet

- Theories and Methods of Two Way Slab Design-5-8-2017Document3 pagesTheories and Methods of Two Way Slab Design-5-8-2017amerta 4320No ratings yet

- 2015-NBLUCK LK260 Engine Part ListDocument16 pages2015-NBLUCK LK260 Engine Part ListPedroNo ratings yet

- Ec2203-Unit IV Memory Devices Digital ElectronicsDocument38 pagesEc2203-Unit IV Memory Devices Digital ElectronicsKarthikeyan_Go_952567% (6)

- Unit 10 Lesson 3 Activity Guide - Unreasonable TimeDocument2 pagesUnit 10 Lesson 3 Activity Guide - Unreasonable Timetrivediom427No ratings yet

- Water Cooled Chiller Operation & Maintenance ManualDocument13 pagesWater Cooled Chiller Operation & Maintenance ManualPaul KwongNo ratings yet

- NMEADocument38 pagesNMEADavidNo ratings yet