Professional Documents

Culture Documents

Original

Original

Uploaded by

Jason toralde0 ratings0% found this document useful (0 votes)

8 views18 pagesOriginal Title

original

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views18 pagesOriginal

Original

Uploaded by

Jason toraldeCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 18

BALUSTRADE — GLASS

AZUMA

Design

CLIENT — CR LAURENCE AUSTRALIA P/L

PRODUCT — GRS Gass RAILING DRY GLAZE TAPER-LOC® SysTEM

TESTED By

AZUMA DEsIGN Pry LTp

AZT0362.18A,

NATA ACCREDITED LABORATORY NO. 15147

‘This document shall not be reprotuced, except in full

Th rele of trae

Vor measurements el

Added the 1500 N/m result to Section 3, updated requirements on

“Amendment 1 — | etformauce at end of table

05/03/2021 Removed C5 rating from conch

on replaced with C1/C2 and C3 rating

Added note to Section 5.2.1 on performance

1 Aim

‘To test the sample as per loads specified in “Clause 3.6, Table 3.3 of AS1170.1- 2002’ and

combination factors as specified in Clause 4.2 of AS/NZS 1170.0:2002 by the test methods

specified in “Appendix B & C of AS1657-2018

2 Referenced Standards

‘* AS/NZS 1170.0:2002 Structural design actions - General principles (Clause 4.2 and

Appendix B - Table B1)

* AS/NZS1170.1:2002 Structural design actions- Permanent, imposed and other actions

(Clause 3.6, Table 3.3)

© AS1657-2018 Fixed platforms, walkways, stairways and ladders- Design, construction

and installation (Appendix B & C)

«AS1288-2006 Glass in buildings Set - Section 7 Balustrades

3 Result Summary

Load Type Deflection | Permanent | Breakage

Deflection

Concentrated Loads

Serviceability (600 N) Outwards Timm mm

Serviceability (600 N) Downwards 1mm 1mm

Ultimate (1080 N) Outwards

Ultimate (1080 N) Downwards

Uniformly Distributed Loads

Serviceability Vertical (750 N/m) 0mm Omm

Serviceability Horizontal (1500 N/m) 28 mm

Serviceability Horizontal (3000 N/m) 97 mm*

Ultimate Vertical (750 N/m)

Ultimate Horizontal (1500 N/m)

Ultimate Horizontal (3000 N/m)

Infill Loads

Pressure Load (4500 Pa)

Serviceability Requirements ~ Maximum allowable deflection for this test specimen is 30 mm ax per AST238,

Ultimate Requirements ~ No structural damage to the tost specimen. Deflection is measured for reference only.

Aza Design Pey Le

{5 Resins Store Wetbil Park. NSW. 2168 Atala +61(0) SH08 0255

Acctaten Nee 4? Nata

AZT 0362.18 “Sanlu il pe ese al at

Page 1 of 17

4 Test Sample Description

4.1 General

Mode! No./Name

GRS glass railing dry glaze TAPER-LOG® system

Customer CR Laurence Australia P/L

Address 9 Shale Place, Eastern Creek, NSW 2766

Azuma Testing Number | AZT0362.184

Date of Test 22/08/2018

Date of Amendment 05/03/2021

Overall Size

‘Test Sample Description

AS1288 Classification

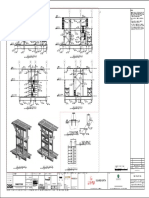

4.2 Barrier

1130 mm (H) x 1500 mm (W)

Toughened Laminate glass wedged into Aluminium Channel

Cantilevered - Structural

Glass Material

Glass Grade

Glass Thickness

Glass Panel Size

Gap between bottom of barrier

and ground level

Complies with AS 2208

Toughened Laminate

Not Specified

21.52 mm

1100 mm (H) x 1490 mm (W)

Nil

See Attached

Naum Design Pry Led

{8 Rosen Stee Woe Park, NSW. 2164 Acro +6102) 908 6235 A

Accnliatna Numi: 18147 NATA

Arve i compliance wile BO/IEC 1708 - TESTING, Vv

AZT 0362.18A,

Thin doaren sll ob ep apt fl

Page 2 of 17

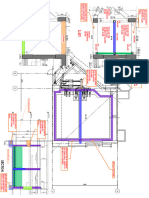

4.3 Base Channel

Product No./Name Hole Pattern “D’

Material Aluminium

Overall Dimensions 81. mm (W) x 120 mm (H) x 1500 mm (1)

Base Plate (if applicable) | N/A

Drawing Supplied See Attached

EBA335 - Hilti® M12 156 mm Long HSL-3 Expansion

Anchor at 300 mm spacing

ing Method

4.4 Handrail

Handrail Not part of tested sample

Figure 1: Profile of tested system

I Pak, NSW. 2164 Ansa 03 1 02

oul

AZT 0362.184, “This sent sl nt bo

4 Barrier Loads

4.1 Procedure

From A$1657-2013 Fixed platform

and installation:

. walkways, stairways and ladders- Design, construction

L. Set the hydraulic ram to push on the handrail at the centreline between the two fixed

points.

Record a datum from the centre of the push area to a fixed point,

Smoothly increase the force acting on the side of the rail or top edge until the test

force is

equal to desired load.

Hold the test force for 90 seconds,

Record the deflection.

Remove the test force and after 2 minutes record the permanent deflection reading

‘The forces applied to this sample are taken from Table 3.3 from AS 1170.1-2002 - Section 3.6

Barriers, a combination factor for permanent, and imposed actions is applied to these figures

determined from Table B1 of AS1170.0

102 as well as a variation factor.

4.2 Testing Parameters for Ultimate Loads

4.2.1 Multipliers

Combination Factor, Ea, (AS/NZS 1170.0 Section 4) 15

Variation Factor, k., (AS/NZS 1170.0 Appendix B, Table B1) | 1.2

4.2.2 Calculations

4.2.2.1 Serviceability Deflection Criteria

‘The following maximum deflection limits apply to this produet:

Height _ 1100

30. 30

36.67mm

This value is only applicable while it remains less than 30 mm, otherwise 30 mm is maximum.

allowable deflection,

4.2.2.2. Concentrated Strength Calculation

The required concentrated load for the glass panel is:

Force (N) = Imposed Action (N) + Combination Factor + Variation Factor

‘eentin Smber: 1S Wata

Aetna br oan BOTEC M25 TESTING

AZT 362.184 “isi aon etc x

Page 4 of 17

4

Uniform Strength Calculation

‘The required uniformly distributed load for the glass panel is:

Force (N) = Imposed Action (N/m) * Width (m) * Combination Factor + Variation Factor

4.2.2.4 Wind Load Strength Calculation (Infill Barrier Only)

‘The required wind load for the glass panel is:

Force (W)

= Pressure (Pa) + Area (m?) * Combination Factor » Variation Factor

5 Results

5.1 Concentrated Load

5.1.1 Serviceability

Direction |oad Applied | Datum | Reading During, | Permanent

Outwards 600 N 494 mm 50] mm 495 mm

Notes: Nil

Downwards 600 N 273 mm 274 mm 274 mm

Notes: Nil

5.1.2 Ultimate

Direct Load Applied from | Any damage, signs of breakage or

meene® | Section 4.2.2.1 fracture observed

Outwards 1080 N No Damage

Downwards 1080 N No Damage

AZT 0362.18A,

‘Azuma Design Dry Li

‘8 Resen Serer Wool Pack, NSW, 211 Asean +602) 04 0255

Accel fo mpl wis SOIEC 1

i- TESTING

This ott sal ot be ec eso fl

Page 5 of 17

»

|

5.2 Uniform Load

5.2.1 Serviceability

Uniformly .

Direction [Distbuted |20% [datum | Reaing | Permanent

Loud pplied uring Load | Deflection

350 N/m ~ a ~ -

Vertical

750N/m | 175N | 274 mm 274 mm 274 mm

Notes: Nil

350 N/m ~ ~ ~ -

750 N/m ~ - - ~

Horizontal

1500 N/m | 2235N | 565 mm 593 mm, 565 mm

3000N/m | 4470N | 565 mm 662 mm 570 mm

Notes: 3000 N/m exceeds allowable deflection of 30 mm

5.2.2 Ultimate

Direction | L084 Applied from | Any damage, signs of breakage or

Section 4.2.2.1 fracture observed

Outwards 8046 D 2 mm lift of channel, no damage observed

Downwards 2011.5 N No Damage

‘Azuma Dosen Pry Li

{5 Rec Stee Worl Pack, NSW, 168 Austin +63(0) 96040255

Arerwrion Number {5147

Act fo omplson with ISO/IEC 17025 - TESTING.

18A This document shall 9 be pectic excep in Fal.

Page 6 of 17

i>

5.3 Infill Load

5.3.1 Point Load

Testing not required for Structural Balustrade

5.3.2. Pressure Load

‘Testing completed at customers request using new test sample.

‘Any damage, signs of breakage

Test Pressure | Test Area | Load Applied (ne ne ee eee

1500 Pa 1.497 mi? 4043 N Nil

3000 Pa 1.497 m2 8086 N Nil

4500 Pa 1.497 m2 12129 N Nil

Ultimate Load

5201 Pa 1.497 m? 14020 N Glass unit collapsed

AZT 0362.18A,

{4 Rolo Stowe Wot Park, NSW, 2168 Attala +01(0) 9605 0255

Anco ompsnon wih ISO/IEC 1725 - TESTING

A.

NATA

<

This dace ll we be ert ese nfl x

Page 7 of 17

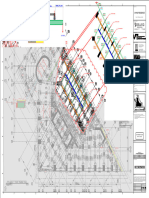

6 Pictures

re 2: Concentrated Load Stability

Figure 3: Concentrated Load Strength

- Assit Nile GT NATA

Arr nae 19a See bd hI 75 - TES Vv

Page 8 of 17

Figure 5: Uniform Load - Stability

Aus Design ry it

58 Ren St Weer Pak, NSW. 24 Axara 40102 960 9855 “A

Aecation Sun: 114 : NATA

AZT 0362.18A “Sheu sae ea ea

Page 9 of 17

Figure 7: Uniform Load - Stability

3 Ree Sree Wesel Pork. XS

Ace fr compas with ISO/IEC 1705 - TESTING

AZT 0362.18 Tides ll ot be sa

Page 10 of 17

NATA

Figure 8: Uniform Load - Strength 1500 N/m

Figure 9: Uniform Load - Strength 3000 N/m

NATA

AZT 0362.18A “ee

Figure 10: Wind Load

Figure 11; Wind Load - 1500 Pa

Som Den Li

Sw oe NaTA

AZT 0362.18A Thins all beep ace i a

Page 12 of 17

Figure 12: Wind Load - 3000 Pa.

Figure 13: Wind Load - 4500 Pa

AZT 312.284 Thee laa een an

Page 13 of 17

Figure 14: Ultimate Load - Load Reading

Figure 15: Ultimate Load - Sample

Aura Design Py Lt

28 Rasen Stew Worl Park NSW. 2164 Austral 46102) 9604 025

Accmtaren Nut: 113

AZT 0362.18 «Rhema ale bere el

Page 14 of 17

7 Conclusion and Signatories

7.1

Conclusion

From the results achieved the sample is deemed to satisfy the loading requirements as per table

3.3 of AS1170.1- 2002 for the following classification(s):

for a Category 'A' Domestic and residential activities - Other Residential (See C3);

for a Category ‘B, E' Offices and work areas not included elsewhere including storage

areas - Fixed platforms, walkways, stairways and ladders for access (see NOTE 2).

for a Category 'C1/C2' Areas with tables or fixed seating ~ Areas with fixed seating

adjacent to a balustrade, restaurants, bars, ete

for a Category ‘C3’ Areas without obstacles for moving people and not susceptible to

over-crowding ~ Stairs, landings, external balconies, edges of roofs, ete.

for a Category ‘D’ Retail Areas ~ All retail areas including public areas of banks/building

societies, (see C5 for areas where overcrowding may occur)

for a Category ‘F/G’ Vehicular ~ Pedestrian areas in car parks including stairs, landings,

ramps, edges of internal floors, footways, edges of roofs.

NOTE: All classifications with equal or lower load specifications may be applied to this sample.

For more information as to their specific use please see table 3.3 of AS1170.1 - 2002.

NOTE 2: This usage (under B,E) is for access to and safe working places normally used by

operating, inspection, maintenance and servicing personnel.

7.2

Signatories

tested By Ash Hovne

sme

9 Glass Compliance Statement

G.JAMES

AZT 0362.18

tee &Facary mat nares

2st Set Poaenan?

Sais SW 2164 ‘tart Pak NSW 266

pier

Fane 29702798

CERTIFICATE OF COMPLIANCE

(R Laurence Aus PTY Led

9 Shale Poco

astern Creek NSW 2766

2 August 2018

‘tention The Manager

Dear ir;

We hereby caruy thatthe 2 pleces of 21.52mun thick Clear Toughened Laminated

dass we supped to you on our invoke number 100196147 have been supplied a spciied in

‘the Australien Standards 1288 and 2208

‘Tis glass has boon manufacured under Quality Assurance Systems based onthe Australian

‘Standard 3902. As caquettad there have been no stamps paced on the any ofthe panels,

though there areno visible stamps the gass does comply withthe xbove standards.

‘We wil be pleased to provide any further Information you may requires ook forward 0

susisting you with fare projects.

e-

Michael Pascoe

Ganeral Manages (NSW)

Defining

Spaces.

Rein Set Wet ark SM 2108 Aue $00 065 “A.

‘eeitton Sie 1th Nata

Page 17 of 17

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- SOLN-MS-ELV-IIC-BB605-0005 - Method Statement For The Scaffolding Erecting & Dismantling 0Document22 pagesSOLN-MS-ELV-IIC-BB605-0005 - Method Statement For The Scaffolding Erecting & Dismantling 0Jason toraldeNo ratings yet

- Midas Standalone PasswordDocument1 pageMidas Standalone PasswordJason toraldeNo ratings yet

- S SHR1 534Document1 pageS SHR1 534Jason toraldeNo ratings yet

- Comparison of Girder Dimensions (42F) - Girders That Exceed ColumnDocument3 pagesComparison of Girder Dimensions (42F) - Girders That Exceed ColumnJason toraldeNo ratings yet

- Comparison of Girder Dimensions (64F Upper) - Girders That Exceed ColumnDocument3 pagesComparison of Girder Dimensions (64F Upper) - Girders That Exceed ColumnJason toraldeNo ratings yet

- Comparison of Girder Dimensions (Rdeck) - Girders That Exceed ColumnDocument3 pagesComparison of Girder Dimensions (Rdeck) - Girders That Exceed ColumnJason toraldeNo ratings yet

- Lay L41 Tank Framing-StudyDocument1 pageLay L41 Tank Framing-StudyJason toraldeNo ratings yet

- Comparison of Girder Dimensions (55F-59F) - Girders That Exceed ColumnDocument3 pagesComparison of Girder Dimensions (55F-59F) - Girders That Exceed ColumnJason toraldeNo ratings yet

- Comparison of Girder Dimensions (43F-49F) - Girders That Exceed ColumnDocument3 pagesComparison of Girder Dimensions (43F-49F) - Girders That Exceed ColumnJason toraldeNo ratings yet

- S3-41 - Tower 2 Shear Wall SectionsDocument1 pageS3-41 - Tower 2 Shear Wall SectionsJason toraldeNo ratings yet

- Soms Detail g2Document1 pageSoms Detail g2Jason toraldeNo ratings yet

- s3-11 - Tower 1 Shear Wall ElevationDocument1 pages3-11 - Tower 1 Shear Wall ElevationJason toraldeNo ratings yet

- Comparison of Girder Dimensions (40f) - Girders That Exceed ColumnDocument3 pagesComparison of Girder Dimensions (40f) - Girders That Exceed ColumnJason toraldeNo ratings yet

- L2 Framing - Hoisting Beam Study - Revised 2Document1 pageL2 Framing - Hoisting Beam Study - Revised 2Jason toraldeNo ratings yet

- S5-03 - Concrete Sections and DetailsDocument1 pageS5-03 - Concrete Sections and DetailsJason toraldeNo ratings yet

- S3-06 - Tower 1 Shear Wall ElevationDocument1 pageS3-06 - Tower 1 Shear Wall ElevationJason toraldeNo ratings yet

- Soln CD ST Sy2 HP 30825Document1 pageSoln CD ST Sy2 HP 30825Jason toraldeNo ratings yet

- S5-02 - Concrete Sections and DetailsDocument1 pageS5-02 - Concrete Sections and DetailsJason toraldeNo ratings yet

- s3-10 - Tower 1 Shear Wall ElevationDocument1 pages3-10 - Tower 1 Shear Wall ElevationJason toraldeNo ratings yet

- S1-03 - Load MapsDocument1 pageS1-03 - Load MapsJason toraldeNo ratings yet

- LOT1, 6 Floor Framing: 5 Flooor Framing Rook Deck GardenDocument1 pageLOT1, 6 Floor Framing: 5 Flooor Framing Rook Deck GardenJason toraldeNo ratings yet

- S2-01C - Framing Plan Level 01 - Sector CDocument1 pageS2-01C - Framing Plan Level 01 - Sector CJason toraldeNo ratings yet

- SID-CPD-05 Rev 02 Completion ReportDocument2 pagesSID-CPD-05 Rev 02 Completion ReportJason toraldeNo ratings yet