Professional Documents

Culture Documents

Wap-7 Izn-Ner

Uploaded by

Shrish Shankhdhar0 ratings0% found this document useful (0 votes)

15 views50 pagesLoco Shed Izatnagar

Original Title

39216 WAP-7 IZN-NER

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentLoco Shed Izatnagar

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

15 views50 pagesWap-7 Izn-Ner

Uploaded by

Shrish ShankhdharLoco Shed Izatnagar

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 50

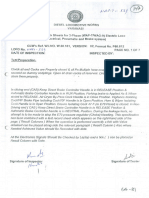

LOCO TESTING & DISPATCH REPORT OF IGBT

BASED 3 PHASE ELECTRIC LOCOMOT WE

LOCO NO. : 39216

TYPE: WAP-7

RAILWAY SHED: NER/GD(D)

PROPULSION SYSTEM: BTIL

HOTEL LOAD: SIEMENS

DATE OF DISPATCH: 21.12.2022

Se

Sudian Railways

Patiala Locomotive Works, Patiala

aie Prater Pears

LOCO NO. - 39246

RAILWAY/SHED: NER/GD(D)

DOD: DECEMBER 2022

INDEX

Patiala Locomotive Works, Patiala

[SN] PARA | ACTIVITIES

Testing & Commissioning (TRS)

|_PAGE NO.

ra 70 | Continuity Test of the cables

| 18 | Continuity Test of Traction Cirut Cables

42. | Continuty Test of Auxiliary Crcut Cables 14

| 13 | continuity Test of Battery Circut Cables

|_| 14 | comity test Seraned Coto ev Cablos

2 | 20 | Low Tension fest

Ft | iMoasuremont of resistor in OHMS (0) aa

| 22 | Check Points

3e pe Tension Test Batery Cirouks (without control eloctronies)

30 | Downloading of Software

31 | Check Points

| | 32 | Download Software 740

35 | Analogue Signal Checking

3.4 | Functional test in simulation mode

7 | —a0 | Sensor test & convertor test

| 49 | “Test wining Transformer Circuits — Polarity Tost

| 4a | Test uring auxiliary transformer 1000V/815V-110V (pos. 67)

43 | Primary Voltage Transformer

| $4 | Minimum vottage relay (Pos. 86)

|| 45 | Maximum curentrty (Pos 70) 116 |

| 4.6 | Test cunent sensors

45 | Test BG Link Vortage Sensors (Pos 16.67)

| 47 | Testication of Converter Protection Circuits (Hardware limits)

49 ‘Sequence of BUR contactors

| e-}-50 Commissioning with High Vortage

31 | Check List

3.2 _ | Safoty test main circuit breaker

5.3 _ | Auxiliary Converter Commissioning

831 | Running test of 3 ph, auxilary equipments

33.2 | Performance of Auxilary Converters

23.3 | performance of BURs when one BUR goes out 16-25

54 | Auxiliary circu 415/110

85 | Hotel Load Circut

5.6 Traction Converter Commissioning

| 5.7 Test protective shutdown SR

| 58 Test Harmonic Filter

|__| 55 _| est mportant components ofthe locometive

(&_[-6.0 | Running Trial of the locomotive 25-26

$ | oo —| Final Check List fo be verified al the time of Loco dispatch 27

& [66 [Annexure HEC 26-35

91 1-10 | Pneumatic Test Parameters 34-37

[70-| Toco Check Sheet(LRS) 38

T= Component History RS.TRS ABS) 30H

tt. — Gomponent History & Testing Parameter (Bogie Shop) 243 |

T Warranty Conditions as per Tenders 44-46

Issue No.03 Doc.No.F/ECS/01

Effective Date: Feb 2022 (Ref: WUECS/10)

PATIALA LOCOMOTIVE WORKS, PATIALA.

Testing & Commissioning Format For 3-Phase Locomotive fitted with

cet fraction Gonverter, Auxiliary Converter and TGN based VCU

Locomotive No: 92/6 ‘Type of Locomotive: WAP-7IWAG-9HC

1.0 Continuity Test of the cables Page: 1 of 27

4.1 Continuity Test of Traction Circuit Cables

a per cable list given in Para 1.3 of document no. 3 EHX 410 124, check the continuity with

ee Rinuity tester and megger each cable to be connected between following equipment with

500V megeer.

From To Continuity | Prescribed Measured

(OK/Not OK) | Megger Value (min)] Megger Value

Filter Cubicle Transformer OK 100 M2 goo

0 Ma

Filter Cubicle muro ct eK 100 M gn

Resistor (Roof)

Filter Cubicle Earthing Choke ok 100 MO. Boo

Earthing Choke Earth Return OK 100 M2 igo

Brushes

Transformer power Converter | 7% roma | oy

Transformer Power Converter2 | 8 100 Ma Boo

Power Converter 1 | TM1, TM2, TM3 eK 100 MQ. qa

Power Converter 2 | TM4, TMS, TM6 eK 100 MO. jer

Earth Power Converter | 7% 100 MO Foor

Earth Power Converter2 | 100 MQ ee

1.2 Continuity Test of Auxiliary Circuit Cables

[As per cable lst given in Para 1.4 of document no. 3 EHX 410 124, check the continuity with

continuity meter and megger each cable to be connected between following equipment with the

help of SOOV megger. ‘Z

Signature of face oes Testing

Issue No.03 Doc.No.FIECS/0T

Effective Date: Feb 2022 (Ref: WWECS/10)

PATIALA LOCOMOTIVE WORKS, PATIALA

‘Testing & Commissioning Format For 3-Phase Locomotive fitted with

Festa § Fraction Converter, Auxiliary Converter and TEN based VCU

Locomotive No: 3 92/6 Type of Locomotive: WAP-7IWAG-SHC

Page: 20f 27

From | To Continuity(OK/] _ Prescribed ‘Measured

Not OK) | Megger Value) Megger Value

(min) NS

Transformer | BURL on 100 MO OF

Transformer | BUR2 eK wooma | Fe

Transformer | BUR3 eK 400MQ__| Sew

garth | BURL OK Tooma | 7?

Earth _ | BUR2 oK yooma | eww

Earth | BUR3 ok 100 MO qa“

BURL | HB2 ok T0oMQ | ow

puR2 | HB2 OK Tooma | jew

te1__| HB2 OR 700 MO oF.

He1 | TM Blower oR yooma | ex

HBL TM Scavenge Blower 1 OK jooma | eS.

1HB1__| Oil Cooling Unit 1 ow 100 MO Qo

HB1 __ | Compressor 1 eK TOMO | 2s

HB1__| TEP Oil Pump 1 oK 7100 MQ Wa

He1 | Converter Coolant eK 100 MQ Imo I

Pump 1 |

He1_| MR Blower 1 oK 100 MO Qe"

FiBL | MR Scavenge Blower 1 eK 100 MO Qo

Hei | Cabt on 100 MO oF

Cabl__| CabHeater 1 OK 100 MO 202

W52 | TM Blower 2 ok 100 MQ. 3 se

TB2_| TM Scavenge Blower 2 o® 100 MQ Sua

HB2__ | Oil Cooling Unit 2 OK 100 MQ Zoe

HB2__ | Compressor 2 oR 100 M2. ass

HB2__| TEP Oil Pump 2 OR 100 MQ. 1g

182 __| Converter Coolant Pump 2 oR 700 MQ wo

HB2 MR Blower 2 ek 100 MQ. Row |

HB2 | MR Scavenge Blower 2 OR 100 MQ Roo

HB2 | Cab2 OK 100 MQ RO

Cab2 Cab Heater 2 OR 100 MQ 2o7 |

Signature of meats Testing

Issue No.03

Effective Date: Feb 2022

Doc.No.FIECoI""

(Ref: WWECS/10)

PATIALA LOCOMOTIVE WORKS, PATIALA

Testing & Com

missioning Format For

3.Phase Locomotive fit

with,

\GBT based Traction Converter, Auxillary “Converter and TCN based VCU

a52le

of Battery Circuit Cables

Locomotive No.:

1.3. Continuity Test

Type of

Locomotive: WAP-7WAG-SHC

Page : 3 of 27

heck continuity of following cables as per Para 2.3 of document no. 3 EHX 610 299

From To Condition Continuity |

(OK/Not OK)

Fattery (wire no 2093) | Circut breakers 110° By opening and

2, 112.1-4, 3104-1 closing MCB 112 ok

MCB 10 Connector SOXT-L By opening and &

closing MCB 110

pattery (Wire no. 2052) | Connector 50.%7-2 - ok

Sar Wire no 2050) | Connector SOX7-3 ig

Close the MCB 112, 110, 112.1, and 310.4 and Prescribed value Measured

measure the resistance of battery wires 2093, >0.5MQ Value

3052, 2050 with respect to the loco earth. é mo

‘Wieasure the resistance between 2093 & 2052, Prescribed value: Weasured

2093 & 2050, 2052 &

2050 >50MQ value

és MO

Commission the indoor lighting of the lo

1.4 Continuity

Check the continuity and isolati

help of sheet no. mentioned against each as per document no.

on of the sereen cable of the following circuits with the

3 EHX 610 299.

comotive as per Sheet No 7A & 7B.

Test of Screened Control Circuit Cables

[Screened control circuit cables for Corresponding | Continuity &

Sheet Nos. Isolation (OK/Not OK)

Battery voltage measurement 048 we

Meinotel circuit of cab1 &2 110A Ok

‘Memotel speed sensor 10A ok

Primary voltage detection OIA, 128 Ob.

Brake controller cab-1 & 2 O6F, 066 OK

a

Signature of the JEIS:

SELoco Testing

Issue No.03 Doc.No.FIEvon

Effective Date: Feb 2022 (Ref: WWECS/10)

PATIALA LOCOMOTIVE WORKS, PATIALA

Testing & Commissioning Format For S-0aS% Locomotive fitted with

1@BT based Traction Converter, Auxili Converter and TCN based VCU

P-TIWAG-SHC

Locomotive No: 29 2b ‘Type of Locomotive: WAI

Page : 4 0f 27

Master controller cab-1 &2 ‘08, 08D ey ob

TE/BE meter bogie-T &2 08E, O8F ob

Terminal fault indication cab-l & 2 09F ee

Brake pipe pressure actual BE electric 6H ca

Primary current sensors 126, 12 ae

Fiarmonie filter current sensors 128, 12F ck

Runiliary current sensors 126, 12F OK.

Giraireut wansformer bogie T Tae, 121 ah

‘Magnetization current T2C, 126 OB

“Traction motor speed sensors (2 NOs) i

‘and temperature sensors (1 no.) of TM-L &

Fraction motor speed sensors (2n0s) 120 ke

and temperature sensors (1 no.) of TM-2 e

Traction motor speed sensors (2n0s) 120 me

and temperature sensors (1 no.) of TM-3

Fraction motor speed sensors (2 n0s.) TH ob

and temperature sensors (1.n0.) of TM,

Traction motor speed sensors (210s) 12H ak

and temperature sensors (1.n0.) of TM:5

“Traction motor speed sensors (2n0s) 12H ok

and temperature sensors (1.n0.] of TM-6

Train Bus cab 1&2

(Wire U13A& U138 to earthing BA of

resistance=

10Kat+ 10%)

UiC line 13B OR

Connection FLGI-Box TB TA OR

Signature of the aos Testing

Issue No.03 ee

Effective Date: Feb 2022 (Ref: WVECS/10)

PATIALA LOCOMOTIVE WORKS, PATIALA

Testing & Commissioning Format For 3-Phase Locomotive fitted with

\Ggu babed Traction Converter, Auxiliary Gonverter ind TCN based VCU

Locomotive No: 92/4 Type of Locomotive: WAP-7WAG-SHC

2.0 Low Tension test Page: Sof 27

a1 Measurement of resistor in OHMS (0)

a rhasure the resistances of the load resistors for primary voltage transformer, load resistor

for primary current transformer and Resistor hormone fiter as per Para 3.2 of the document

no. 3 EHX 610 279.

Name of the resistor Prescribed value Weasured value

[oad resistor for primary voltage 3.9K0 + 10% BIER

transformer (Pos. 74.2),

Resister to maximum current relay. 1M + 10% st

Load resistor for primary current 3.3.04 10% 3-3

transformer (Pos. 6.11)

Resistance harmonic fiter (Pos 8.3). Variation WARY war

| towed £10%

[Between wires &6 020 eae

| Between wire 6 &7 0.20 oot

t

Between wire 5&7 04a ones

For train bus, line UIA to earthing. 0 ks 10% g 97K

For train bus, line U13B to earthing. 10 kM + 10% 70-0)

insulation resistance of High Voltage Cable 200M Boren

from the top of the roof to the earth

{by1000 V megger).

Resistance measurement earth return 30.30 oe

brushes Pos. 10/1.

Resistance measurement earth return 30.30 ODER

brushes Pos. 10/2.

Resistance measurement earth return 030 o Zest

brushes Pos. 10/3.

Resistance measurement earth return $0.30 ost

brushes Pos. 10/4.

aesereg resistance (earth fault detection) | 22KOS 10% sea

Harmonic Filter ~I; Pos. 8.61

TerFing resistance (earth fault detection) | 2.7 KO 10% ages

Harmonic Filter Il; Pos 8.62.

Farthing resistance (earth fauit detection) | 39K0% 10% BIL

‘Aux, Converter; Pos. 90.3.

Farthing resistance (earth fault detection) | 18KOs 10% 7 er

415/110V; Pos. 90.41.

Tarthing resistance (earth fault detection) +3900 + 10% BPH

control circuit; Pos. $0.7

Farthing resistance (earth fault detection) | 33K0# 10% nA

Hotel load; Pos. 37.1(in case of WAPS).

Tesistance for headlight dimmer; Pos. 3323. | 100% 10% eS

Signature of the ae Testing

Issue No.03 Doc.No.F/E@s/0T

Effective Date: Feb 2022 (Ref: WUECS/10)

PATIALA LOCOMOTIVE WORKS, PATIALA

esting &. commissioning Format For 3-Phase Locomotive ited with

GBT based Traction ‘Converter, Auxiliary Converter and TCN based VCU

Locomotive No: B92/6 ‘Type of Locomotive: \WAP-7IWAG-SHC

Note: Page : 6 of 27

Make sure that the earthing brush device don’t make direct contact with the axle housing,

earth connection must go by brushes.

2.2 Check Points

Ttems to be checked Remarks

Greckwhether all he earthing connection in roof and machine

caeeas mentioned in sheet no. 22A is done properly or not. cheokod ah

These earthing connections must be flexible and should be

marked yellow & green

Check whether all the ‘earthing connection between Toco body

ce og is done property or not, These cables must be flexible checked

having correct length and cross section

2.3 Low Tension Test Battery Circuits (without control electronics)

‘These tests are done with the help of the special type test loop Boxes 25 PE procedure given in

Para 3.6 of the document no. 3 EHX 610 279

Name of the test ‘Schematic used. Remarks

Test 24V supply Sheet O4F and other linked in h 4 ak

sheets

Fest 48V supply Sheet O4F & sheets of group 09] Fan supply to be checked,

Test traction control Sheets of Group 08. ae

-aaipower supply bus stations. | Sheets of Group 09 Fan supply to be checked.

Test control main apparatus ‘Sheets of Group 05. OR

Test earth fault detection battery ‘Sheet 04C

circuit by making artificial earth fault wh

to test the earth fault detection

Searzontrol Preumaticdevices __| Sheets of Group 06 ok

Fest lighting control Sheets of Group 07 oh

Pretest speedometer ‘Sheets of Group 10 ok

Pretest vigilance control ‘and fire Sheets of Group 11 ok

system

| Power supply train bus sheets of Group 13 ok |

Signature of the JEISSE/Loco Testing

Issue No.03 Doc.No.FiEVoi"

Effective Date: Feb 2022 (Ref: WUECS/10)

PATIALA LOCOMOTIVE WORKS, PATIALA

Testing & Commissioning Format For 3-Phass. Locomotive fitted with

\GBT based Traction Converter, Auxiliary Converter a id TCN based VCU

Locomotive No: 292-/6 ‘Type of Locomotive: WAP-7/WAG-9HC

3,0 Downloading of Software Page:7 of 27

SL Check Points. Yes/No

heck that al the cards are physically present in the bus stations ‘andall the plugsare| yes

connected.

| cpaak That allthe TGTE optic cables ave correctly connected t0 The Bus stations. ay

Take sure that control electronics off relay isnot energized i.e disconnect Sub-D yes

JALLG and loco is set up in simulation mode.

| opeck nar bawtery power ison and all the WCBS (Pos. 127-*)n SBI ESB are on ya |

3,2 Download Software

The software of Traction converter, Auxiliary converter and VCU should be done by

Commissioning engineer of the firm in presence of supervisor Correct software version of the

propulsion equipment to be ensured and noted!

Traction converter-1 software versio\ rer ys a

| Treetion converter-2 software version (8087. al

| Auxiliary converter-1 software version: Le29

[Aunliry converter-2 software version: DEF

| Auxiliary converter-3 software version: Be 2G

‘Vehicle control unit -1 software version: pede 2s

[Wehicle control unit -2 software version: Le ess ]

3.3. Analogue Signal Checking

Check for the following analogue signals with the help of diagnostic tool connected with loco.

Description Signal name Prescribed value ‘Measured

Value

arava pipe pressure’ | FLGZ01=OlMnrAUNTs 700% [= 5 Ke/em2) wm

cmc PO ee Spe | 10V) wk

Fijece T poakton | ET: ANE GK Hee Tes Beween 9% and 11% jaye

from both cab FLG2; AMSB_0101- Xang Trans

efaE gt TE meadroa’| FCG: AMON OT: Kine Fes cameenD% and TOI% | popy,

position from both cab| pLG2; AMSB_0101- Xang Trans

Tea ar TE minimal | FLGT; AMSB_O1OT- Xang Trans pees. BO% wd 75 % 7

position from both cab| FLG2; AMSB_0101- Xang Trans ( J

HK

signature of the JE/SSEILoco Testing

Issue No.03

Effective Date: Feb 2022

Testing & Commissioning Format For 3-Phase Li fi

\GgT boned Traction Converter, Auxiliary Converter and TCN based VC

Locomotive No: 39216

Doc.No.FIEC SI"

(Ref: WVECS/10)

PATIALA LOCOMOTIVE WORKS, PATIALA

ocomotive fitted with

Type of Locomotive: WAP-7\WAG-9HC

Page: 8 of 27

TE/BE at ‘BE maximal’) FLG1; "AMSB_0101-

position from both cab| XangTrans Between 99% and 101% looy-

FLG2; AMSB_0101-

‘XangTrans

TEBE at ‘BE Minimal | FLGT: AMSB_OTOI-

position from both cab| XangTrans Between 20% and 25% 2”,

FLG2; AMSB_0101-

XangTrans

TE/BE at 1/3’position| HBBT; AMS OTO1- 4

WrEand BE mode in | LT/BDEM>1/3 Between 42 and 44% ay

ath cab: HBB2; AMS_0101-

LT/BDEM>1/3

TE/BE at 1/3’position| #BB1; AMS_0101- Thy

in TE and BE mode in} L'T/BDEM>2/3 Between 72 and 74%

both cab. HBB2; AMS_0101-

LI/BDEM>2/3

Both temperature SLGI, AMSB_0106- Between 10% to 11.7% depending, 1390

Sensor GEIL XAtmp!Mot upon ambient temperature

0°C to 40°C

Between 10% to 11.7% depending} rus

2 upon ambient temperature 0'C to| S

Both temperature | SLG1; AMSB_0106- | 40°c

sensor of TM2 Xatmp2Mot

Between 10% to 11.7% depenging|

u 1426

Both temperature | SLGI; AMSB_0106- are ambienttemperstureo Cte]

sensor of TM3 ‘Xatmp3Mot

Between 10% to 11.7% depending, on

upon ambient temperature 0'C to} ae

Both temperature

sensor of TM4

SLG2; AMSB_0106-

XAtmp|Mot

40°C

Between 10% to 11.7% depending

ibient te itt (2S

pothtemperature | SL.G2; AMSB_0106- | SoC lent tenner |

sensor of TMS: Xatmp2Mot

Goth temperature BUGD; AMSB_0106- _ Petween toto 11.7% dependig a

sensor of TMG atmp3Mot pon ambient temperature 0°C 13

10 40°C

Signature of the JEISSE/Loco Testing

Issue No.03 Doc.No.FIEC SINT

Effective Date: Feb 2022 (Ref: WUECS/10)

PATIALA LOCOMOTIVE WORKS, PATIALA

Testing & Commissioning Format For 3-Phase. Locomotive fitted with

\apT based Traction Converter, Auxiliary Converter a id TCN based VCU

Locomotive No: 392/6 ‘Type of Locomotiv WAP-7IWAG-9HC

Page : 9 of 27

3.4 Functional test in simulation mode

Conduct the following functional tests in simulation mode as Per para 5.5 of document no.3EHX

610 281. through the Diagnostic tool/laptop :

"Test Function Result desired in sequence Result

obtained

‘Emergency shutdown through VER must open.

emergency stop switch 244 Panto must lower. cachel ok

Shatbown through cab activation | VCB must open.

ok

switch to OFF position Panto must lower. ouch)

Tonverter and filter contactor FB contactor 8.41 is closed.

operation with both Power By moving reverser handle:

Converters during Start UP. |* Converter pre-charging contactor

12.3 must close after few seconds.

1s Converter contactor 12.4 must close. checked ok

+ Converter re-charging contactor

12.3 must opens.

By increasing TE/BE throttle:

|» FB contactor 8.41 must open.

|» FB contactor 8.2 must close.

J £8 contactor 8.1 must close.

Tomerter and filter contactor] Bring TE/BE to O -

Gpoction ‘with both Power ring tesa ae tetian ey t0 “o”

Converters during Shut Down, _* VCB must open.

|» Panto must lower:

|» Converter contactor 12.4 must open. chechad ak

|» FB contactor 8.1 must open.

= FB contactors 8.41 must close.

«FB contactor 8.2 must remain closed.

Signature of the ae Testing

Issue No.03

Effective Date: Feb 2022

Testing & Commissionin

IGBT based Traction Converter, Auxi

aqeit

Locomotive No:

Baines a

(Ref: WWECS/10)

PATIALA LOCOMOTIVE WORKS, PATIALA

or 3-Phase Locomotive fitted with,

trary Converter and TCN based VCU

Format

WAP-7AVAG-SHC

‘Type of Locomotive:

Page: 10 of 27

Tontactor filter adaptation by

isolating any bogie

Golate any oné bogie through bogie

cut out switch. Wait for self-test of

the loco.

'e Check that FB contactor 8.1 is open.

'e Check that FB contactor 8.2 is open

‘after raising panto, closing VCB, and

setting TE/BE

|» FB contactor 8.1 closes.

.« FB contactor 8.2 remains open.

Cheobed 0&

Test earth fault detection battery

circuit positive & negative

By connecting wire 2050 to

earth, create earth fault

negative potential.

message for earth fault

# By connecting wire 2095

to earth, create earth

fault positive potential.

message for earth fault

checbelok

Test tire system. Create a smoke in

the machine room near the FDU.

Watch for activation of alarm.

‘When smoke sensor-1 gets

activated then

«Alarm triggers and fault

message priority 2

appears on screen

When both smoke sensor

1142 gets activated then

A fault message priority

‘appears on screen and

Jamp LSF1 glow.

«# Start/Running interlock occurs and

TE/BE becomes to 0.

rime, date & loco number

sure correct date time and Loco

umber

Signature of the eis Testing

Issue No.03

Effective Date: Fob 2022

PATIALA LOCOMOTIVE WORKS, PATIALA

Testing & Commissioning Format For 3-Phase Locomotive fitted wit!

\Gby based Traction Converter, Auxiliary G: vavertor and TCN based VCU

Locomotive No.:

ag2lb

4,0 Sensor Test and Converter Test

4A. Test wiring main Transformer Circuits

‘Apply 198Vp/140Vs to the primary ‘vinding of the transformer (at 2u; wire no. * 28 surge

Mi eno. 100 at earthing choke). Measure the ‘output voltage and compare

arrestor and at Iv;

Type

eet rt

(Ref: WIECS/10)

‘of Locomotive: WAP-7WAG-9HC

Page : 11 of 27

the phase of the following of the transformers.

[Output Description of Prescribed Measured | Measured

Winding nos. Output Voltage output | polarity

& Polarity with

input supply.

20; &2V1 Forineconverter bogie1 | 20.05V, and Teosve | oK

between cable 801A- same polarity

8048

204 & Na Fortine converter bogie | 20.05Vp and 10050 me

between cable 811A- same polarity

814A

207 & V2 Forline converter bogie 2 | 10.05Vp and 70 Ov? oK

between cable 801B- same polarity

8048

2U3 823 Forline converterbogie2 | 10.05V, and 70:0 me

between cable 811B- same polarity

8148

2p & V6 For aux. converter 1 TiVe56Vams | 7 OVE

between cable 1103- and same feline OS

1117 (in HB1) polarity. ease

For Aux converter 2

between cable 1103-

1117 (in HB2)

20; & 2Ve For harmonic filter 912 qe aCe

between cable 4-12 (in 6.45Vamsand | 6" overs!

FB) same polarity.

44.2 Test wiring auxiliary transformer 1000V/415V-110¥ (pos. 67)

Apply 141Vp / 100Vams to input

measure the output at

tof the auxiliary transformer at cable no 1203 -1117 and

[ Description of wire no.

with input supply.

Prescribed Output Voltage & Polarity Measured | Measured

output polarity

Cable no. 1218-

7200 | S8.7Vp. 41-5Vams an

opposite polarity | SeSVE | J OK

4iuyens

Cable no. 1218= 6500

[5.5Vp, 11.0Vaus and opposite polarity Te-sve qh

D3 Vas7t

Signature of the JE/SSE/Loco Testing

eee

(Ref: WWECS/10)

Issue No.03

Effective Date: Fob 2022

PATIALA LOCOMOTIVE WORKS, PATIALA

Testing & Commissioning Format For S-£0as*- Locomotive fitted with

(Hee Sa Traction Converter, Auxillary Converter ‘and TCN based VCU

Locomotive No 39214 “Type of Locomotive: WAP-7WAG 951°

Page: 12 of 27

4.3. Primary Voltage Transformer

Apply 250Ver/350Vp by vatiac to roof wire ‘and any wire 0 and measure the magnitude and

polarity of the output of the primary voltage in Former for both bogies as per the procedare

Specified and suggested by the traction converter manufacturer. Primary voltage ‘measurement

spe tors (Pos. 224.1/*) & catenary voltmeter (Pos 74/*)

‘This testis to be done for each converter.

activate cab in driving mode and Supply 200VaMs through variac to wire no 1501 and 1502-

Acta the following parameters through Diagnostic ‘tool and in catenary voltmeter.

Signal name Prescribed value in ‘Monitored Monitored |

catenary voltmeter value in value in SR

catenary diagnostic tool

voltmeter

SEGLG eFxUPrIm | 25K. 350% ee BOT”

[sic2_¢ 87-xuPrim 25 kV 250% as kv (eee aN

pecrease the supply voltage below 140 Vans: VCB must open at this voltage. n this case the

pectrags in Diagnostic Tool and catenary voltmeter will be as follows.

Signal name Prescribed value in preserbed [Monitored | Monitored mal

catenary voltmeter valuein \valuein | value in SR

Mieview | catenary | diagnostic tool

voltmeter

Soe evUram | T7KV 110% Ti Tel”

SLG2_G 87-XUPrim 17K 170% Tk Tol”

peactivate VCB to on by increasing this voltage 19 175% (17.5 kV).

Increase the supply to 240 Vinus through varie cB must open at this voltage, In this case

the readings in diagnostic tool and catenary voltmeter will be as follows:

Signal name precibed value [Prescribed [Monitored ‘Monitored

in catenary valuein | value in value in SR

voltmeter Micview | catenary | diagnostic

voltmeter__| tool

‘SLGT_G S7-XUPrim 3OKV 300% DORV 3a”

SLG2_G 87-XUPrim 30KV 300% De raphy Wis

reactivate VCB to on by decreasing this voltage t0 290% (29 KV).

signature of the JEISSE/Loco Testing

(Ref; WVECS/10)

Issue No.03

Effective Date: Feb 2022

PATIALA LOCOMOTIVE WORKS, PATIALA

“esting & Commissioning Format For SFOS ‘ocomotive fitted with

\GBr based Traction Gonvestor, Aux PSonverter and TCN based VCU

‘Type of Locomotive: WaAP-7WWAG-9HC

Locomotive No: 292!6

2 Page: 13 of 27

4,4 Minimum voltage relay (Pes. 86)

Functionality test

“mum voltage relay (Pos. SOL must be adjusted to approx 68% ]

Retivate loco in cooling mode. check Power ‘supply of 48V to it (Yes/No)

Activmum voltage relay. Disconnect BANAT voltage

minirtormer (wire no. 1511 and 1512) fom load resistor (Pos:

74.9) and connect variac to wire No ‘1501 and 1502. Supply

2O0Vaqys through variac. In this case; ‘Minimum voltage relay

(Pos. 86) picks UP

Try to activate the cab in driving mode: i)

Contactor 218 do not close; the contro!

electronics is not be working.

Turn off the variac (AINo}

Contactor 218 closes; the control electronics '§ be

working

Test Under Voltage Protection;

AeiNate The cab 1h cooling mode; Raise panto; Pres/No

Supply 200Vans through variac to wire 1501

2. 15025 Close the VCB; Interrupt the supply

voltage

| the vcB goes off after 2 second time delay.

‘Again supply 200Vems through variac to wire NO. Yes/No)

#851 & 1502; Decrease the supply voltage below

140Vans £ 4Vi

Fine tune the minimum vottage relay SO that VCB opens.

4.5. Maximum current relay (Pos: 78)

Disconneet wire 1521 & 1522 of primary cuivent Wansformer; Connect varlac to wire 1521.

1522 (including the resistor at POs. 6.11); Put loco in simulation for driving mode; Open R3—Ra

ton contact 136.3; Close VCB; supply & Anns at the open wire 1524) Tune ‘the drum of the

on coum current relay Pos. 78 for correct Over current value;

(eSINO}

VéB opens with Priority 1 fault message on

display.

Keep contact Rs— Ry oF 136.3 closed Goce VB; Tune the resistor 78.2 for the current of 7.0Aans

/9.9hp at the open wire 1524;

VGB opens with Priority Tfault message on %5/No)

display.

eo il

fe ee

signature of the ee Testing

Issue No.03

Effective Date: Fob 2022

PATIALA

ommissi

Testing & C

\GBy based Traction Converter, Auxila Gonverter and TCN based VU.

wi

LOCOMOTIVE WORKS, PATIAI

ioning Format For 3-Phase Loc

gers, «

(Ref: WECS/10)

A

motive fitted with

Locomotive No: 392! Type of Locomotive: IAP-7IWAG-SHC

Page : 14 of 27

4.6 Test current sensors ne 33

Ae Tere the sensor Deseription of the test — prescribed value |Set/Measured

value

pores Ce amd

pamary return current | Activate cab in aang mode supply | (Variation allowed] —

sensor (Test-1,P0s.6.2/1 | 10A. Measure the current through | is

& 6.2/2) diagnostic tool or measuring print. | + 10%) |

Aus Supply 90mAgc to the Test winding of ame ES ae

aarp or through connector 415.AA/20" =

2 pin no. 7+) & 8)

Primary return current

sensor (Test-2, Pos.6.2/2 | pinno. 718) &8U)

‘supply 333mApc to the test winding of a

‘sensor through connector 415.AC/1, 3E md

or2 pin no. 71+) & 80)

——

Harmonic filter ‘Supply 9OmMAgc to the test winding of aa

current sensors sensor through connector 415.Ak/10r

(P0s.8.5/1 88:5/2) 2 pin no. 7(4) & 80) cay

[Supply 342mApc to the test winding of

| coksor through connector 415.AE/10r _ 34 émn

2 pin no. 7(4) 80)

‘witch on hotel load. Supply 90mApc ae oT

to the test winding of sensor through

| Hotel load current connector 415.AG/1or 2 pin no. 14)

sensors (Pos. 33/1 & 8)

33/2) Supply 1242MAgc to the test winding

of sensor through connector 12-4 7mm

| 415.AG/1or 2 pin no. 7(+) & 8)

signature of the JEISSEiLoco Testing

Issue No.03

Effective Date: Feb 2022

ATIALA LOCOMOTIVE WORKS. PATIALA

od with,

p

‘Testing & Commissioning Format FFt 3-Phase Locomotive fitted

sry Converter and TCN based VC

\Gpt based Traction Converter, Aw

Locomotive No: 292 ib

47. Test DC Link Voltage Sensors (Pos 15.6/*)

This testis to be done by the commissioning

4.8. Verification of Converter Prot

This test is to be done as

Protection circuits

section Circuits (Haraware

« per para 6.17 of the document

Type of Locomotive: WAP-7:

engineer of the firm f requires.

limits) ~

Timit on which shutdown

should take place

Page

(Ref: WVECS/10)

IWAG-SHC

115 of 27

no. BEHX 610 282 for both the converters.

‘Measured limit al

Currant Sensors (Pos 18.2/1, 18.2/2,

18.2/3, 18.4/4, 18.5/1, 18.5/2,

18.5/3)

for Power Converter 1

increase the current quickly in

the test winding of the current

sensors, VCB will off at 2.524

swith priority 2 fault for each

ok

Tarrant sensors (Pos 18.2/1, 18.2/2,

18.2/3, 18.4/4, 18.5/1, 18:5/2,

18.5/3)

for Power Converter 2

sensor. For 18.5/1=

For 18.5/2>

For 18.5/3=

increase the current quicklyin | For T8.2/1=

For 8.2/2

the test winding of the current

sensors, VCB will off at 2.524

with priority 1 fault for each

sensor.

ok

For 18.5/3=

Fibre optic fallure In Power Femove one of the orange

Converter fibre optic plugs on traction k

lconverter. VCB should trip ie

Fibre optic failure In Power Remove one of the orange

Converter2 fibre optic plugs on traction

converter. VCB should trip ok

2S eee

4.9 Sequence of BUR contactors

‘The sequence of operation of BUR conte

pe Verified by putting the Loco in

condition has to

ctors for ‘ALL BUR OK’ BUR 1 out BUR & out and BUR 3 out

Aftving mode (VCB should not be ‘closed) and

‘ctlowing will be the contactor sequence:

coneting the BURs one by one. In these condition

‘Status S21 | safe _| 52/3 [52/4 Says [Sala | 52.872 | 525/2 52.5/2|

ATBUR OK | Close | Open | Close pen | Close | Open_| Close Close _| Open

BURA off __|[ Close [Open | Close Glose [Open | Close | Open_| Open Close

BURZ off —[ Open | Open | Close | Close Ziese | Close Open [Open _| Close

‘BUR3 off _ [Open | Close | Open Zose [Close [close [Open | Open Close

signature of the JEISSE/Loco

Testing

(Ref: WWECS/10)

Issue No.03

Effective Date: Feb 2022

PATIALA LOCOMOTIVE. WORKS. PATIALA

Testing & Commissioning Format For 3-Phase Locomotive fitted with

By based Traction Converter For converter and TCN based vel

Locomotive No.: 3qals ‘Type of Locomotive: IAP-TINAG-9HC-

Page : 16 of 27

Monitored contactor sequence

Status Saft | 52l2 | 52/3 saya | Sais | 52.4/1) rapa] 5251] 52-5/2|

aOR [eles [oben | olen | en “Tae | open [edo [Lae |

URI off [cles | oh» ‘char \eles | obo ellos | Obey | eves lo.

Bl

aor wpa hey _| oboe [eles | eles. Bs | 41

BURS off {oben | lest ‘open rn Leles ie Fe ieee lowe

5.0 Commissioning with High voltage

5.1 Check List

Tkems to be checked Yesno |

Fibre optic cables connected correct. nee |

so Tubbish In machine room, on the Zoot, under the loco. ys =

Ailthe electronic Sub-D and connectors connected yes

“Arthe MCBs of the MBI & HB2 open yes

ITane Tree Fuses AOT™ OF the AUNTY converters 3

he Tuse oF the 415/T10V auxiliary Gault (in HBA) open. ya

Aaor to Toor earthing and FOOkTO cA earthing done 3} eal

Fang, connection and earthing in the SURE arrestor done correctly. Ws

eee rT He VATOR TOTES HEE Sie eye

sarihe bose body connection and Saahian connection done correct ys a

pulse Generator (Pos. 94.17 connection Gone correctly ys

FITERE oI cocks OF the pate walve oF the raneformerin open condition. yes

Al everson Rx & Power converter = Filter block, HBA, HB: med | ys

[KABA key interlocking 5 stem. Lye

5.2 Safety test main circuit breaker

prepare to switch off the catenary supply during the first charBing Of the locomotive in case of any

rinexpected behavior of the electrical apponent of the 1co. Charge the oco for the first time by closing

uty ewiteh The VB wil tip after certain time Mr no ol/eootant pumps are runing Yo

perform the following safety test of main circuit breaker through both the cabs fof the locomotive.

signature of the yersenoco Testing

Issue No.03

Effective Date: Feb 2022

PATIALA LOCOMOTIVE WORKS: PATIALA

(Ref: WWECS/10)

Testing & Commissioning Format For 3-Phase Locomotive fitted with

Converter and TON.

Locomotive Ni

[Name of the test

a92lb

Description of the test

1Ggr based Traction Converter, Auxiliary al based VOU

wal

Type of Locomotive: p-TINWAG-SHC

Page : 17 of 27

Expected result Monitored result]

Emergency stop

in cooling mode

aise panto in cooling mode. Put

the brake controller into RUN

position. Close the VCB.

Push emergency stop button 244.

| brake will be ‘applied. aod ok

VGB must open. Panto

must lower. Emergency

protection in

driving mode

Emergency stop | Ralse panto in driving ‘VeB must open.

indriving mode | mode in. Put the brake Panto must

controller into RUN lower.

Lroelhed ok

position. Close the VCB- Emergency a

Push emergency stop brake will be

button 244 applied.

‘Under voltage Raise panto in cooling VCB must open.

protection in mode. Close the VCB- \

cooling mode switch off the supply of cece ok

catenary by isolator

Under voltage Raise panto in driving ‘VCB must open with

mode. Close the VCB.

switch off the supply of

catenary by isolator

diagnostic message that

catenary voltage out of

limits Cheol) ak

Shut down in False panto in cooling mode. WCB must open.

cooling mode. Close the VCB. Bring the Bl- Panto must choebad ok

key in O position lower.

‘Shutdown in Fae panto Tr arWving mode, Close] VCB must pen:

the VOB. Bring the BL-key IO | Panto must

driving mode position. lower. cpached ok

Interlocking, Raise panto in cooling VEB must open.

pantograph- mode. Close the VCB. hk

shed o!

vce in cooling Lower the pantograph ce

mode by ZPT

interlocking auise panto driving mode. Close] VCB must opens

pantograph ues ‘CB. Lower the pantograph by crate ve

VcB in driving

| mode

J

signature of the JEISSEILoco Testing

Issue No.03

Effective Date: Feb 2022

PATIALA LOCOMOTIVE WORKS. PATIALA

Testing & Commissioning Format For 3-phase Locomotive fitted with

\GBT based Traction Converter nat ary Converter and TCN based vcU

Type of Locomotive: WAP-7WAG-9HC

Page: 18 of 27

(Ref: WIECS/10)

Locomotive No: 92'6

5.3. Auxiliary Converter Commissioning

switeh on the high voltage supply and Se° ot the 1oco In driving mode. Raise the panto Close the YB.

Check that there is no earth fault in the ary circuit, Switch off the VCB. Lowe ‘the panto. Create the

earth fault in auxiliary circuit by making vvanection between wire no 21171" HE? cubicle) and earth

‘after 3 minutes a diagnostic message ‘wil come that “Earth fault auxiliary circu

5.3.4 Running test of 3 ph. auxiliary ‘equipments

Sitch on the 3 ph. auxiliary equipment ‘py one. Check the direction of retaven of each

SMnxiliary machine and measure the ner jnyous current and starting current drawn by them.

Name of the auxiliary Typical phase Measured Measured al

machine current continuous phase starting phase

current current

Dil pump transformer 1 38 amps qf Tae

Dir pump transformer 2 TB amps FF me

Coolant pump [9.6 amps eso ah

converter t

Coolant pump 19.6 amps os“ geo

converter 2

Dir cooling blower unit 1 40.0.amps Gao se

Dil cooling blower unit 2 40.0 amps yre /es-*

Fraction motor blower 1 34.0 amps ae 793°

Traction motor blower 2 34.0 amps 324 79e 8

Se. Blower to Traction 6.0 amps 2 ¢ 73-2

motor blower 1

Se, Blower to Traction ed amps ang Ze

motor blower 1

Compressor L 75 amps at 0

kg/cm" 27° Show

40 amps at 10

kg/cm*

Compressor 2 5 amps at

pI 2 mee ato 263 1482

40 amps at 10

kg/cm”

Signature of the es Testing

Issue No.03 OPE ah a

Effective Date: Feb 2022 (Ref; WVECS/10)

PATIALA LOCOMOTIVE WORKS, PATIALA

Testing & Commissioning Format Er ‘3-phase Locomotive fitted with

unilfary Converter and TCN

\GBT based Traction Converter. A ry Col based VCU

Locomotive No: B92 16 ‘Type of Locomotive: WAP-7IWAG-9HC

Page :19 of 27

5.3.2 Performance of Auxiliary Converters

Faeasure the performance of the aurdicny converters through software and record it

buRZ (Condition: Switch off all the oad of BUR 1)- to be filled by ‘commissioning engineer

of the firm.

[Signal name

Monitored | Value under

value __| timit (Yes/No]

Description of the signal Prescribed

fa ane value ___

[Ri 7508 KUUN | Input voltage to BURT 75% (10%=125V)

Burr 7303 XUUZI| DC link voltage of BURT_| 60 mt esew | Ye

Loar Taos MUIZT | DC Tink current of BI BURT | 7 Beth ey

GuRE (Condition: Switch off all the Toad of BUR 2, Battery Charger ‘on) to be

filled by commissioning engineer ‘of the firm.

Signal name Description of the Fraccribed value | Monitored | Value under

signal by the firm value Limit (Yes/No)

AGRE TS0S-KUUN | Input voltage to BUR2 75% (LOVeT2SV) | Te/sv Yey |

URE THE XUUAT | DC TINK voltage of BURT] ETO) | 6 37V arial

BORE TOS RUE | DC nk current of BUR? TUS | 7 Boh Yon

| er TarERUITG | Carver battery SCOT] a7

charger of BUR2 ar 2

SORE THERUIBT | Curvent battery oF BUR2| | FaVAIOOAY | /)P ep Yes

FORT Ts TUB VoTRage battery of BURT] _NOAION=IOV) ToT S

+ Readings are dependent upon charging Condition of the battery.

uR3 (Condition: Switch off all the load of BUR 3, Battery Charger on) £0 be filled by

commissioning engineer of the fm.

‘Signal name Description of | Prescribed set Monitored | Value under

the signal value by the firm _| value limit (Ves/No)

URS THOSRUUN [Taput voltage to 75% (OMRTISV Jor 7¥ oT

BUR3,

BURS 7303- DC link voltage 0% (1O%=100V) oty yey

XUUZL of BUR3

BURT THOSNUIZ1 | DC Tink current Te OMESOAY® Spey Yoo

of BUR3 ans

FURS THOS-KUILG | Current battery 3 (LOW TO0A)®

charger of BUR 3 22 .

FURS THE-KUIBY | Current battery Fra loe=100A)* 5

er TamorRt00A)” | />-Bryh Yes

URS T505-KUUB | Voltage battery Tova IO%=10V) TT8 on

\B of BUR3

Readings ave dependent upon charging Zondition of the battery.

Signature of the oo Testing

Issue No.03

22

Effective Date: Feb 20:

PATIALA LOCOMOTIVE WORKS: PATIALA

(Ref: WWECS/10)

Testing & Commissionina Format Et ‘-phaso Locomotive fitted with

cuniliary Converter and TCN bas

agi paved Traction Converter, Auxiliary SO ised VOU

Locomotive No; 92I6 ‘Type of Locomotive: WAP-TIWAG-9H1C

Page : 20 of 27

5.3.3. Performance of BURs when one BUR goes out

hen any one BUR goes out then rest ‘of the two BURs should take the oad of all the

Wlfgries at ventilation level 3 of the locomotive.

[condition of | Loads on BURL Toads in BUR2 Toads in BUR3

BURS,

AITBURS OK _ | Oil Cooling unit =i bloweri&2, TEP ot | Compressor Taz, Battery

182 pump 182, SReoolant | Chaves ‘and TM Scavenger

pump 182. blower 182

BUR Tout Dir Cooling unit 182, TM Compressor ET ot

blower&2,™ pump 182, SR coolant oh

scavenger blower 182 pump 182 and Battery

charger.

BURTout | OW Cooling unit 182, Compressor 182, TFP oll

7M blower 182, TM pump 182, SR coolant

Scavenger blower 182 pump 1&2 and Battery

charger.

BUR Tout | Ou Cooling writ 182, Compressor 182, TFP oll

einslowert&2,TM | pump 182, SR coolant

veavenger blower 182) pump 182 and Battery

Ne charger.

5.4 Auxiliary circuit 415/110

or checking earth fault detection, make > connection between wire no- 2228 and ‘vehicle body. On

witching on VCB, Earth fault relay 89.

Diagnostic display that Earth Fau

witch on the 1 ph. auxiliary ead

aust pick up and after 3 minutes

it 415/110V Circuit

pment one by one

Check the direct

J message will come in the

tion of rotation of each

Swett machine and measure the continuous one Feand starting current drawn by ther

Name of the auxiliary Typical ‘Measured phase | Measured

machine phase current starting current

current

| Machine room blower 1 sage ae

sams"

Machine room blower 2 epee

Blower to MR blower 1 Ts amps

Se. Blower to MR blower 2 ie

Ventilator cab heater 2 | Seer

| ventilator cab heater 2_ ug

Cab heater 1 eee

Cab heater 2

4.8 amps

¥ For indigenous MR blowers.

signature of the JEISSE/Loco Testing

Issue No.03

Effective Date: Feb 2022

ATIALA LOCO!

\OTIVE WORKS, PATIALA

ee es ee

(Ref: W/ECS/10)

P

‘esting & Commissioning Format For 3.Phase Locomotive fitted with

sre ilfary Converter and TCN based VCU

Locomotive No.:

35216

5.5 Hotel load circuit (Not applicable for WAG-9HC)

For WAP-7 locomotive with Hotel lo

5,6 Traction Converter Commissioning

‘This testis carried out in associ

yn with Firm.

Te

\GBT based Traction Converter ry Gonvel

‘Type of Locomotive: WAP-7WAG-SHC

Page: 21 of 27

ad converter refer to Annexure-HLC

‘Traction converter commissioning is being Gone Ts ata time. For testing Converter 1, switch

Wit the traction converter 2 by switch bogie cut out sw!

off the traction converter 2 by switch bogie ‘cut out switch 154. Isolate the

the loco by one converter. Follow

‘by switch 160. Start uP

For Converter 1

itch 154. For testing

Converter 2, switch

harmonic filter also

the functionality tests.

[est Function Results desired Result obtained al

Measurement of Traction converter manufacturer to

charging and pre- declare the successful operation checheelok

charging and charging land demonstrate ‘the same to the

‘of DC Link of Converter 1 PLW supervisor.

‘Measurement of [Fraction converter manuracturer to

Weasuring of clink declare the successful operation

of Converter 1

and demonstrate the same to the

PLW supervisor.

Checlacdot

Earth fault detection on

positive potential of DC

Link of Converter 1

Fraction converter manufacturer to

declare the successful operation

‘and demonstrate the same to the

PLW supervisor.

Cheohed ok

Earth fault detection on

negative potential of DC

Link of Converter 1

rrraction converter manufacturer to

declare the successful operation

‘and demonstrate the same to the

PLW supervisor.

Cheched die

Zari fault detection on AC

part of the traction

circuit of Converter 1

Firaction converter manufacturer to

ldeclare the successful operation

land demonstrate the same to the

IPLW supervisor.

chee breol ok

Pulsing of line converter

7action converter manufacturer to

converter of Converter 1

pees

ldeclare the successful operation

land demonstrate the same to the

__ ively

IPLW supervisor.

of Converter 1 declare the successful operation

pe6 demonstrate the same to the Cheehed ok

IPLW supervisor.

Pulsing of drive Fraction converter Manufacturer to

chet red oR

Signature of the wae Testing

Issue No.03

Effective Date: Feb 2022

1ALA LOCOMO’

i

(Ref; WUECS/10)

sTIVE WORKS, PATIALA

pall

“Testing & Commissioning Format For 3-Phase Loco!

\@BT based Traction Converter na riliary Converter and TN based VOI

tive fitted with

Locomoiive No.: agut ‘Type of Locomot IAP-TIWAG-9HC

Page : 22 of 27

For Converter 2

eee Results desired in sequence Result obtained

Weasurement OF | action converter manufacturer to

Miiraing’ and pre- (oectare the successful operation and

Chargingand charging [demonstrate ‘the same to the PLW cheobelO&

St DC Link of Converter \supervisor-

2

a arement oF {fraction converte! manufacturer to

Mischarging of DC Link declare the uccessful operation and | 1p rod ob

of Converter 2 Vdemonstrate the same tothe PLW a

1 supervisor.

arth fault detection on fraction converter manufacturer tO

positive potential of DC

Link of Converter 2.

Meare the successful operation and

\demonstrate the same to the PLW

|supervisor.

chee bad oe

Farth fault detection on

negative potential of OC}

Link of Converter 2.

Farth fault detection on

‘AC part of the traction

circuit of Converter 2.

Fraction converter manufacturer to

Vaciare the successful operation and

‘ermonstrate the same to the

Isupervisor/V

+ cation converter manufacturer to

declare the successful operation and

Jdemonstrate the same to the PLW

|supervisor.

gueohdok

cheohod oh,

Pulsing of line converter

of Converter 2.

Fraction converter Tmanufacturer to

Mcelare the successful operation and

Jdemonstrate the same tothe PLW

supervisor.

Qnadhd ok

Pulsing of drive

converter of

Converter 2

F ction converter manufacturer tO

Idectare the successful operation

(orci demonstrate the same to the

PLW supervisor.

ee

creehgol o&

signature of the JEISSE/Loco Testing

Issue No.03 er

Effective Date: Feb 2022 (Ref: WHECS/10)

PATIALA LOCOMOTIVE WORKS. PATIALA

Testing & Commissioning Format For 3-Phase Locomotive fitted with,

\geT based Traction Converter reepiliary Converter and TN based VCU

ive: Wi

Locomotive No-: agrié Type of Locomoti IKP-TIWAG-9HC

Page : 23 of 27

5.7 Test protective shutdown SR

Fest Function Results desired in sequence Result obtained

‘Measurement of Sart up the Toco with both the

protective shutdown converter. Raise panto. Close VCB.

by Converter ‘Move Reverser handle to forward oF

electronics. reverse. Remove one of the orange

fibre optic feedback cable from

Converter 1check that converter 1 | ¢, poohasl ak

GIeetronies produces a protective shut

down.

VCB goes off

‘priority 1 fault mesg. on DDU

appears

| Disturbance in Converter 1

Weasurement of Sart up the Toco with both the

protective shutdown | converter Raise panto. Close VCB.

bby Converter 2 Move Reverser handle to forward OF

electronics. reverse. Remove one of the orange

fibre optic feedback cable from cle obred ok.

converter 2. Check that converter 2

electronics produces a protective shut|

down.

# cB goes off

«Priority 1 fault mes8. ‘on diagnostic

display appears

(es ‘Disturbance in Converter 2 )

5.8 Test. Harmonic Filter

switch on the filter by switch 160

Test Function Results desired in sequence Result obtained |

srcasurament OF fiter| Start up the 1oco wath both the

currents converter. Raise panto. Close VCB-

Move Reverser handle to forward choolasd okt

or reverse. Apply 2 small value of

“TE/BE by moving the throttle.

les FB contactor 8.41 must open: [e

signature of the a Tost

Issue No.03

Effective Date: Feb 2022

PATIALA LOCOMOTIVE WORKS. PATIALA

Locomotive No: 49216

Check the

diagnostic

switch off the VCB

must clos

FB contactor 8.2 must close.

| FB contactor 8.

Bring the TE/BE throttle to O

‘© FB contactor 8.1must open.

‘e FB discharging contactor 8.4%

Check the filter current in

diagnostic laptop,

ee rs

(Ref: WWECS/10)

‘Testing & Commissioning Format Et ‘3-Phase Locomotive fitted with

\Ggy based Traction Converter, Auxila FTonverter and TN based VCU

Type of Locomotive:

‘1 must close

filter current in

laptop

e

Wap-7IWAG-9HC

Page : 24 of 27

checked ok

Test earth fault ‘Wake a connection between wire

detection harmonic | no. 42 and vehicle body. Start up

filter circuit. the loco. Close vcB.

‘s Earth fault relay 89.6 must pick uP- Checled ok

‘* Diagnostic

Eorth fault

message comes that -

in harmonic filter circuit

Test traction motor

speed sensors for

Traction converter manufacturer

to declare the successful operation

dheched ok

forth bogle in both | and demonstrate the same tothe

cabs supervisor] PLW

5,9 Test important components of the locomotive

Tyremsto be tested _| Description of the test Monitored value/remarks|

VCU converter manufacturer to ‘declare the

speedometer suceessful operation and demonstrate the Cheolhad ok

same to the supervisor/ PLW

Time delay module

of MR blower hnbere

THE time after which the starting capacitor for

‘Should go off the circuit should be

set to 10-12 seconds

chooksel ok.

Ni-Cd battery Voitage| At full charge, the Dattery voltage should be

a0v DC. P Checlbed ok,

Flasher light From both cab flasher ignt should Blink at

ee least 65 times in one minute. Chachd ob

Head light Tiead light should glow from ‘oth cabs by

Operating ZLPRD. Dimmer operation of saaked ok

headlight should also occur by operating the

fa. switch ZLPRD. d

signature of the JESS

4

{E/Loco Testing

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Highlights of Loco Shed IzzatnagarDocument7 pagesHighlights of Loco Shed IzzatnagarShrish ShankhdharNo ratings yet

- Brake Binding Investigation by Loco Shed IZNDocument20 pagesBrake Binding Investigation by Loco Shed IZNShrish ShankhdharNo ratings yet

- WAP-7 NER GD/NER History BookDocument83 pagesWAP-7 NER GD/NER History BookShrish ShankhdharNo ratings yet

- WAP-7 NER GD/NER History BookDocument82 pagesWAP-7 NER GD/NER History BookShrish ShankhdharNo ratings yet

- WAP-7 NER GD/NER History BookDocument82 pagesWAP-7 NER GD/NER History BookShrish ShankhdharNo ratings yet

- Wag-9hc BLW Ner/iznDocument86 pagesWag-9hc BLW Ner/iznShrish ShankhdharNo ratings yet

- Wag9hc CLWDocument85 pagesWag9hc CLWShrish ShankhdharNo ratings yet

- Wag-9hc BLW Ner/iznDocument86 pagesWag-9hc BLW Ner/iznShrish ShankhdharNo ratings yet

- Wag-9hc BLW Ner/iznDocument85 pagesWag-9hc BLW Ner/iznShrish ShankhdharNo ratings yet

- Wag9hc BLW Ner Izn (D)Document86 pagesWag9hc BLW Ner Izn (D)Shrish ShankhdharNo ratings yet

- SLAM Implimentation PositonDocument6 pagesSLAM Implimentation PositonShrish ShankhdharNo ratings yet