Professional Documents

Culture Documents

STEALTH 22 Torque Conversion Chart

STEALTH 22 Torque Conversion Chart

Uploaded by

chinedu0 ratings0% found this document useful (0 votes)

7 views2 pagesOriginal Title

STEALTH-22-Torque-Conversion-Chart

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views2 pagesSTEALTH 22 Torque Conversion Chart

STEALTH 22 Torque Conversion Chart

Uploaded by

chineduCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

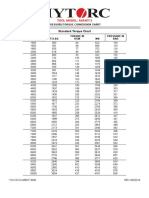

TOOL MODEL: STEALTH 22

PRESSURE/TORQUE CONVERSION CHART

Standard Torque Chart

PRESSURE IN TORQUE IN PRESSURE IN

PSI FT.LBS. KGM NM BAR

1500 3250 449 4406 104

1600 3472 480 4707 110

1800 3916 542 5309 124

2000 4360 603 5910 138

2200 4802 664 6510 152

2400 5244 725 7109 165

2600 5686 786 7708 179

2800 6128 848 8307 193

3000 6570 909 8906 207

3200 7000 968 9489 220

3400 7430 1028 10072 234

3600 7860 1087 10655 248

3800 8290 1147 11238 262

4000 8720 1206 11821 276

4200 9132 1263 12379 290

4400 9544 1320 12938 303

4600 9956 1377 13496 317

4800 10368 1434 14055 331

5000 10780 1491 14613 345

5200 11245 1555 15244 358

5400 11710 1619 15874 372

5600 12175 1684 16504 386

5800 12640 1748 17135 400

6000 13105 1812 17765 414

6200 13542 1873 18357 427

6400 13979 1933 18949 441

6600 14415 1994 19542 455

6800 14852 2054 20134 468

7000 15289 2114 20726 482

7200 15729 2175 21323 496

7400 16169 2236 21919 510

7600 16610 2297 22516 524

7800 17050 2358 23113 538

8000 17490 2419 23709 552

8200 17928 2479 24303 565

8400 18366 2540 24897 579

8600 18804 2601 25491 593

8800 19242 2661 26084 607

9000 19680 2722 26678 620

9200 20119 2782 27273 634

9400 20558 2843 27868 648

9600 20997 2904 28464 662

9800 21436 2965 29059 676

10000 21875 3025 29654 690

* ISO DOCUMENT 9000 REV. 12/04

IMPORTANT SAFETY INSTRUCTIONS

WARNING: Your HYTORC TORQUE MACHINE is a power tool, and as with any power tool, certain safety precautions

should be observed to avoid accidents or personal injury. The following tips will assist you.

READ ALL INSTUCTIONS.

KEEP WORK AREA CLEAN AND WELL LIT.

CONSIDER WORK AREA ENVIRONMENT.Electrical Pumps should never be used in an atmosphere which

can be considered potentially volatile. If there is any doubt, use an air pump. Also Note: metal to metal contact

can cause sparks, precautions should be taken.

AVOID PREMATURE TOOL STARTING. The Pump Remote Control is for the TOOL OPERATOR only.

STAY CLEAR DURING OPERATION. In most cases, the tool will allow “hands free” operation. If the tool must

be held or steadied during operation, use alternative means of securing the tool to the application

GUARD AGAINS ELECTRIC SHOCK. Ensure the pump is properly grounded and the proper voltage is being

used

STORE IDLE TOOLS. When not in use, tool sand accessories should be properly stored to avoid deterioration

USE RIGHT TOOL. Don’t force small tools or attachments to do the job of a larger tool. Don’t use a tool for

purposes not intended.

PROPER SAFETY ATTIRE. When handling/operating hydraulic equipment use work gloves, hard hats, safety

shoes and other applicable clothing.

USE SAFETY GLASSES.

MOVING EQUIPMENT. Do not use hydraulic hoses, uni-swivels, pump power or remote cords as means of

moving the equipment.

MAINTAIN TOOLS WITH CARE. For top performance, inspect tools, powerpack and accessories for visual

damage frequently and always prior to use. Always follow instruction for proper tool and pump maintenance.

Refer to the Operations Maintenance Section for further clarification

STAY ALERT. Watch what you are doing. Use Common sense. Do not use power equipment under the

influence of any mood altering substances.

PRIOR TO OPERATION

Ensure that all hydraulic connections are securely connected and there is no leakage

Verify that the Hydraulic hoses are not kinked or otherwise damaged.

Ensure the square drive and its retainer are fully and securely engaged.

Be certain that all connectors, elbows, fitting and swivels are not bent, loose or damaged.

PRIOR TO USE.

Check sockets for size, quality and flaws. (Do not use if questionable)

Cycle tool to ensure proper function.

Locate a solid, secure reaction point.

Be sure the reaction arm retaining clamp is fully engaged.

Be sure the hydraulic hoses are free of the reaction point.

Pressurize the system momentarily; if the tool tends to “ride up” or to “creep”, stop and re-adjust the

reaction arm to a more solid andsecure position.

NOTE: Remain clear of the reaction arm during operation and never put body parts between reaction arm and

reaction surfaces.

ALWAYS USE QUALITY ACCESSORIES. Always use top quality impact sockets in good condition which are

the correct size and fully engage the nut. Hidden flaws, however, remain a possibility which could cause

breakage, so stay clear of sockets during operation

DO NOR USE other equipment to enhance performance (Hammer on Socket/Tool)NOTE: Hytorc Pumps are

designed to operate Hytorc Tools only. Damage may occur to the pump or the product that is being operated

due to misuse.

SAVE THESE INSTRUCTIONS FOR FUTURE USE!

You might also like

- PDF Hino Wiring Diagram DDDocument129 pagesPDF Hino Wiring Diagram DDNathawat95% (21)

- FILE 20190926 173523 eS2008A 5008A SM EN VerB Mark PDFDocument1,016 pagesFILE 20190926 173523 eS2008A 5008A SM EN VerB Mark PDFPham Nguyen Hoang Minh71% (7)

- Standard Torque Chart: Tool Model: MXT 1Document2 pagesStandard Torque Chart: Tool Model: MXT 1Wahyu WidiyantoNo ratings yet

- AVANTI 3 Torque Conversion ChartDocument2 pagesAVANTI 3 Torque Conversion ChartJovani SecrettiNo ratings yet

- ICE 1 Torque Conversion ChartDocument2 pagesICE 1 Torque Conversion ChartDeivid BezerraNo ratings yet

- Captura de Pantalla 2022-03-30 A La(s) 20.30.14Document2 pagesCaptura de Pantalla 2022-03-30 A La(s) 20.30.14Manuel CaipoNo ratings yet

- Tabla STEALTH 14Document2 pagesTabla STEALTH 14luz_cuellar_15No ratings yet

- mxt10 PDFDocument2 pagesmxt10 PDFTaufikNo ratings yet

- Hytorc Avanti 3 Torque ChartDocument2 pagesHytorc Avanti 3 Torque ChartDarwin Tovar ZuriqueNo ratings yet

- Tool Model: HY-3MXT: Pressure/Torque Conversion ChartDocument2 pagesTool Model: HY-3MXT: Pressure/Torque Conversion ChartBhavin GamiNo ratings yet

- XLCT 14Document2 pagesXLCT 14carlosNo ratings yet

- Tool Model: Hy-5Xlt: Standard Torque ChartDocument2 pagesTool Model: Hy-5Xlt: Standard Torque ChartFabioNo ratings yet

- RT10 Torque ChartDocument2 pagesRT10 Torque ChartRoy Ramos100% (1)

- RTX04 Torque ChartDocument1 pageRTX04 Torque ChartYang Kyo OhNo ratings yet

- Datasheet LR 13000Document13 pagesDatasheet LR 13000RasoolKhadibi100% (1)

- Stealth Torque Pressure ChartDocument3 pagesStealth Torque Pressure Chartnarft narftNo ratings yet

- 1 May 2019 Avocab New LP New March W.E.F - May 1stDocument1 page1 May 2019 Avocab New LP New March W.E.F - May 1stKaushal JhaNo ratings yet

- Hazen-Williams Formula PDFDocument4 pagesHazen-Williams Formula PDFyehuoy100% (1)

- TableBookErrata PDFDocument4 pagesTableBookErrata PDFLutfi LailaNo ratings yet

- TableBookErrata PDFDocument4 pagesTableBookErrata PDFIbnuyusoff77No ratings yet

- Hazen William Formula PDFDocument4 pagesHazen William Formula PDFMac ShaikNo ratings yet

- EDGE 6 - Torque - Conversion - ChartDocument1 pageEDGE 6 - Torque - Conversion - ChartindunilNo ratings yet

- General Testing and Adjusting InformationDocument3 pagesGeneral Testing and Adjusting InformationmkNo ratings yet

- DIN 2215 V Belt SpecificationDocument1 pageDIN 2215 V Belt SpecificationumeshNo ratings yet

- XLCTTorqueDocument4 pagesXLCTTorqueSebastin DrignyNo ratings yet

- 3MXT Torque ConversionDocument2 pages3MXT Torque ConversionRodrigo SanzNo ratings yet

- Satuan GDocument1 pageSatuan GWoro IndrianiNo ratings yet

- Price List For LT Aluminium Cables: May - 2021Document5 pagesPrice List For LT Aluminium Cables: May - 2021Sandeep GMNo ratings yet

- Measurements For Anchor-Chain and AccessoriesDocument4 pagesMeasurements For Anchor-Chain and AccessoriesOzata TersanesiNo ratings yet

- HTL DS Series Torque Pressure ChartDocument1 pageHTL DS Series Torque Pressure ChartElmo JuiceNo ratings yet

- Pressure Versus Torque - S-Series Torque WrenchesDocument5 pagesPressure Versus Torque - S-Series Torque WrenchesManga MinNo ratings yet

- Marine Chain DataDocument7 pagesMarine Chain DataIrwan SyahNo ratings yet

- Catalogo Generadores SincronosDocument11 pagesCatalogo Generadores SincronosMirko Yanque TomasevichNo ratings yet

- Spinlock Conversion ChartDocument1 pageSpinlock Conversion ChartjmairadoNo ratings yet

- Flow, KV Values and Zeta Values For Gate Valves, Resilient Seated Appendix 6Document3 pagesFlow, KV Values and Zeta Values For Gate Valves, Resilient Seated Appendix 6Imtiyaz KhanNo ratings yet

- GC-3000 Torque ChartDocument1 pageGC-3000 Torque Chartgerryocnahron86No ratings yet

- WKT/WKTR/WKB 6 Design Data: 6.1 WeightsDocument6 pagesWKT/WKTR/WKB 6 Design Data: 6.1 WeightsWibowo ArieNo ratings yet

- KEI AEC Wires Cables Full Price List 28 February 2022Document6 pagesKEI AEC Wires Cables Full Price List 28 February 2022anirban 007No ratings yet

- RR KABEL Price List - LT HT Cables - 01st February 2023Document4 pagesRR KABEL Price List - LT HT Cables - 01st February 2023threephase electricNo ratings yet

- Atlas Copco TFX08 Torque ChartDocument1 pageAtlas Copco TFX08 Torque Chartgauthamac07No ratings yet

- Generator KVA KW Amp ChartDocument2 pagesGenerator KVA KW Amp ChartSajid MahmoodNo ratings yet

- Generator kVA-kW-Amp Chart PDFDocument2 pagesGenerator kVA-kW-Amp Chart PDFAEE MHCH Sub Div 1stNo ratings yet

- VF730 & VF733 - AGA ApprovedDocument8 pagesVF730 & VF733 - AGA ApprovedJamyansuren TseveendorjNo ratings yet

- Auditorium TX - Dimensions - and - Capacity - GuideDocument2 pagesAuditorium TX - Dimensions - and - Capacity - GuideChong Hong RuiNo ratings yet

- Load Inertia TablesDocument7 pagesLoad Inertia TablesgabrielaNo ratings yet

- FLOWTITE Handling and StorageDocument13 pagesFLOWTITE Handling and StorageMohammed khaleelNo ratings yet

- Br. Naziv Prostorije Gubici (W) Tip Radijatora Dužina (CM) Izaberi Tip 0 Temp (°C) Površina (m2) Po Radijatoru Protok Grijanje (KG/H)Document5 pagesBr. Naziv Prostorije Gubici (W) Tip Radijatora Dužina (CM) Izaberi Tip 0 Temp (°C) Površina (m2) Po Radijatoru Protok Grijanje (KG/H)Damir ĆavarNo ratings yet

- Powersoft TN005 PeakOutVoltage en v1.0Document2 pagesPowersoft TN005 PeakOutVoltage en v1.0victor mogajane100% (1)

- Rezistoare-Valori Standard de SerieDocument1 pageRezistoare-Valori Standard de SerieRobert ViorelNo ratings yet

- Hydraulic Torque Wrench Operation ManualDocument18 pagesHydraulic Torque Wrench Operation Manualahmad fahmeyNo ratings yet

- PH Hydraulic Torque Wrench Instruction ManualDocument23 pagesPH Hydraulic Torque Wrench Instruction ManualLikLiek WahahaNo ratings yet

- Duzina Kabla Na DobosimaDocument3 pagesDuzina Kabla Na DobosimaDe RNo ratings yet

- TFX02 Torque ChartDocument1 pageTFX02 Torque ChartArnulfo SánchezNo ratings yet

- Face-To-Face Valve Dimensions - EN-558-1: DN Basic SeriessDocument3 pagesFace-To-Face Valve Dimensions - EN-558-1: DN Basic Seriessdona_001No ratings yet

- Polycab22 3Document2 pagesPolycab22 3Velu SNo ratings yet

- Nozzle Load TableDocument27 pagesNozzle Load TableRamuAlagappanNo ratings yet

- Pressure Vs Torque Conversion Chart: Titan T Series ToolsDocument1 pagePressure Vs Torque Conversion Chart: Titan T Series ToolsHanselPerezAguirreNo ratings yet

- Ax Contactor Catalogue 1524473646Document40 pagesAx Contactor Catalogue 1524473646Sami SalmanNo ratings yet

- Stored Energy Solutions For A Demanding World: SpecificationsDocument2 pagesStored Energy Solutions For A Demanding World: SpecificationsALEX ALEXNo ratings yet

- United States Census Figures Back to 1630From EverandUnited States Census Figures Back to 1630No ratings yet

- RS Alligator Staple Ab FastenersDocument4 pagesRS Alligator Staple Ab FastenersAdelia RachmanNo ratings yet

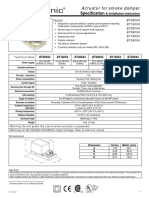

- Specification: Actuator For Smoke DamperDocument2 pagesSpecification: Actuator For Smoke Dampermartin saadNo ratings yet

- Galaxy M32 INDIa-SamsungDocument5 pagesGalaxy M32 INDIa-SamsungJuanNo ratings yet

- VANTAGE Mechanical Installation Manual 24022015 CT DOC12381V100Document46 pagesVANTAGE Mechanical Installation Manual 24022015 CT DOC12381V100Udo IheanachoNo ratings yet

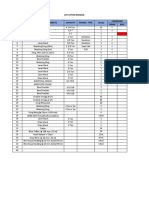

- Row Part of Designation Reference Material Description ManufacturerDocument1 pageRow Part of Designation Reference Material Description ManufacturerEdwinGomezNo ratings yet

- List Lifting RiggingDocument2 pagesList Lifting RiggingrezaNo ratings yet

- Wagner Hydraulic Cylinder Repair: SectionDocument4 pagesWagner Hydraulic Cylinder Repair: SectionLuis Silva NavarroNo ratings yet

- A7III-A7RIII Custom-Settings and Support Firmware 3Document245 pagesA7III-A7RIII Custom-Settings and Support Firmware 3Miguel SerenoNo ratings yet

- Curriculum Vitae: Personal DetailDocument4 pagesCurriculum Vitae: Personal DetailsafdarNo ratings yet

- Replacement Instructions Far2xx7Document12 pagesReplacement Instructions Far2xx7Nishant PandyaNo ratings yet

- CSSP Report 1. Project Informa On: 2.1equipment ListDocument7 pagesCSSP Report 1. Project Informa On: 2.1equipment ListIssam LaamiriNo ratings yet

- Nema Receptacles Wiring DiagramDocument5 pagesNema Receptacles Wiring DiagramBryan LlenaNo ratings yet

- 3D OCT-1 Maestro2 - RM - E - Ver.1.02 (R-OCT-1-1901-04) - PT - PARTE1Document200 pages3D OCT-1 Maestro2 - RM - E - Ver.1.02 (R-OCT-1-1901-04) - PT - PARTE1DFH Oftalmo ServiceNo ratings yet

- Tempro - BASIC PRIMUS C90 ENDocument66 pagesTempro - BASIC PRIMUS C90 ENradhoinezerellyNo ratings yet

- ADAS FCA - Quick Start Guide - EnglishDocument8 pagesADAS FCA - Quick Start Guide - EnglishkimsrosNo ratings yet

- Optical Coherence Tomography: Seminar OnDocument18 pagesOptical Coherence Tomography: Seminar OnSourabhNo ratings yet

- Quick Reference Guide: Important InformationDocument16 pagesQuick Reference Guide: Important InformationDanijela MravikNo ratings yet

- Plano Hidraulico Rodillo Vibratorio CS 663E PDFDocument2 pagesPlano Hidraulico Rodillo Vibratorio CS 663E PDFOSCAR LOSADANo ratings yet

- Normally Closed Solenoid Valve by DungsDocument6 pagesNormally Closed Solenoid Valve by DungsM.H.No ratings yet

- Float Shoe Single-Double ValveDocument1 pageFloat Shoe Single-Double ValveAdrian NegoiNo ratings yet

- (Sample) : Fire-Life Safety Survey ReportDocument3 pages(Sample) : Fire-Life Safety Survey ReportWaqasNo ratings yet

- Nycwy: Low Voltage Power Cable (0.6/1 KV)Document2 pagesNycwy: Low Voltage Power Cable (0.6/1 KV)Сергей КозловNo ratings yet

- Panel Testing Procedure 1Document9 pagesPanel Testing Procedure 1ArunkumarNo ratings yet

- Epl SyllabusDocument2 pagesEpl SyllabuskaviinfoenggNo ratings yet

- Epoxy Resin BushingDocument12 pagesEpoxy Resin BushingSURJIT SINGHNo ratings yet

- Daily Report: Privatisation of Sungai Besi - Ulu Kelang Elevated Expressway (Suke)Document1 pageDaily Report: Privatisation of Sungai Besi - Ulu Kelang Elevated Expressway (Suke)KumaResan SubramaniamNo ratings yet

- Parts List: (MX-GT90) (MX-GT80)Document27 pagesParts List: (MX-GT90) (MX-GT80)Ariel NiedoNo ratings yet

- Impcops Medicines Price List 01.03.2018 PDFDocument32 pagesImpcops Medicines Price List 01.03.2018 PDFVinothini0% (1)