Professional Documents

Culture Documents

Imerys Tableware Raw Materials Incl KaoPearl

Uploaded by

LOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Imerys Tableware Raw Materials Incl KaoPearl

Uploaded by

LCopyright:

Available Formats

Mineral Solutions for Tableware

Technical datasheets

Imerys, world leading supplier of mineral-based solutions for industry

From our mines and installations we have developed a comprehensive offering for the ceramic industries.

Under its Performance Minerals segment, Imerys is the European leading supplier of mineral solutions for the

tableware industry.

Customers worldwide include the most prestigious brands

Imerys’ tailor-made offering to tableware manufacturers include:

high quality products

laboratories dedicated to tableware formulation

state of the art technical service

on-site production support

BALL CLAYS

TYPICAL DATA Hywite Superb Hywite Magnum FMT

SiO2 49 49 Max. 59.4

Al2O3 33 31 Min. 27.0

Fe2O3 1.1 1.2 1.15 ± 0.20

TiO2 0.9 0.9 0.60 ± 0.10

CaO 0.2 0.2 0.60 ± 0.30

CHEMICAL ANALYSIS (mass %)

MgO 0.3 0.3 0.80 ± 0.30

K2 O 1.8 2 0.80 ± 0.20

Na2O 0.2 0.2 0.20 ± 0.10

L.O.I. 14 14.5 Max. 11.0

Carbon 2.5 3.2 Max. 0.35

> 125 m 1.5 1.5 -

> 53 m 2.5 2 5

<5 m 94 96 85

PARTICLE SIZE ANALYSIS (mass %)

<2 m 84 87 77

<1 m 75 79 60

< 0.5 m 63 66 48

SURFACE AREA M.B.I** (mg g-1) 26 34 65

Dried at 110°C (MN m-2) 5.5 7.5 2.4

MoR

Dried at 110°C (p.s.i) 780 1065 348

Casting concentration (mass %) 65 62.5 -

CASTING DATA Deflocculant demand for slips of* (0.7 Pa.s) 0.9 0.9 -

Deflocculant demand for slips of* (0.5 Pa.s) 1.3 1.3 -

Water absorption (mass %) 6.5 5.5 11.2

CERAMIC CHARACTERISTICS at

Brightness (%) 72 70 77-

1180°C

Contraction (%) 14 14 5.4

Water absorption (mass %) 4 3.5 10.6

CERAMIC CHARACTERISTICS at

Brightness (%) 68 65 76

1240°C

Contraction (%) 15 15 6.1

** M.B.I.: Methylene Blue Index - the amount of methylene blue dye required to saturate the surface of the clay.

FELDSPARS & PEGMATITES

TYPICAL DATA WhiteSpar XS100P XQ010P

SiO2 66.5 ± 1.0 82.5 83.5

Al2O3 18.2 ± 1.0 9.7 9.5

Fe2O3 Max. 0.10 0.1 0.12

TiO2 0.01 0.06 0.16

CHEMICAL ANALYSIS (mass %) CaO 0.25 0.02 0.03

MgO 0.03 0.07 0.06

K2O Min. 11.0 6.9 4.65

Na2O 2.50 ± 0.75 0.29 0.22

L.O.I < 0.3 0.6 1.55

> 80 m - - -

> 63 m - 1.5 -

PARTICLE SIZE ANALYSIS (mass

> 50 m - - 10

%)

> 40 m - - -

D50 m - 12 -

HALLOYSITE

TYPICAL DATA Filtercake Premium Premium Granules

SiO2 49.5 49.5 49.5

Al2O3 35.5 35.5 35.5

Fe2O3 0.29 0.29 0.29

TiO2 0.09 0.09 0.09

CHEMICAL ANALYSIS (mass %) K2 O 0.01 0.01 0.01

CaO 0.02 0.02 0.02

MgO 0.02 0.02 0.02

Na2O 0.04 0.04 0.04

L.O.I 13.8 13.8 13.8

PARTICLE SIZE ANALYSIS (%) #240 mesh < 0.1 < 0.1 < 0.1

Dried at 110°C (MN m-2) 3.4 2.9 2.9

MoR

Dried at 110°C (psi) 493 421 421

CERAMIC CHARACTERISTICS AT L* 98.7 98.7 98.7

1180°C

(%) Concentration 10.8 10.9 10.9

Specific gravity 2.55 2.55 2.55

PHYSICAL PROPERTIES

Moisture content (%) 37 3 5

SURFACE AREA (m2/gm) 25 25 25

DELIVERY FORM Extruded 25 kg blocks Hammer milled powder Granules

KAOLINS

KaoShine KaoPearl Standard

TYPICAL DATA Grolleg BIP

BB30 CNL30 Porcelain

SiO2 47.1 47.6 48 49 49.0

Al2O3 37.6 37.1 36.5 36 35.1 ± 1.5

Fe2O3 0.35 0.56 0.72 0.80 0.36 ± 0.05

TiO2 0.56 0.05 0.04 0.05 Max. < 0.10

CHEMICAL ANALYSIS

CaO 0.4 0.06 0.07 0.06 0.10

(mass %)

MgO <0.1 0.32 0.3 0.3 0.10

K2O 0.4 1.20 1.74 1.96 1.8 ± 0.4

Na2O <0.1 0.12 0.1 0.10 0.20

L.O.I 13.4 13.2 12.5 12 11.7 ± 1.2

Kaolinite / Halloysite 94 90 87 83 81

MINERALOGICAL Quartz 2 2 - - 4

ANALYSIS Feldspar 6 2 2 -

(mass %) Micaceous material 3 2 8 10 13

Other minerals 1 - 3 2 2

PARTICLE SIZE > 53 m 1 0.05 Max. 0.04 Max. 0.05 0.24

ANALYSIS >8 m 10 0.7 4 8 19

(mass %) <2 m 70 85 70 58 41

SURFACE AREA (m2g-1) 12 - 14.6 11.5 12.6

At 80% RH (MN m-2) 2.7 1.4 1 0.5

At 80% RH (p.s.i) - 200 140 78

MoR -2

Dried at 110°C (MN m ) - 3.2 2.6 2.0

Dried at 110°C (p.s.i) - 450 365 284

Casting concentration (mass %) 57 62 61 65.7

Deflocculant demand (mass %

CASTING DATA 1.7 0.55 0.5 0.20

P84)

Casting rate (mm2 min-1) 0.25 0.2 0.5 1.2

PRESSING BODIES

PP606B PP117B PP097B PP935B GP444B PP047B PP410B VP545B VP403B VP251B VP001B BP900B

TYPICAL DATA Bone

Porcelain Porcelain Porcelain Porcelain Stoneware Porcelain Porcelain Vitreous Vitreous Vitreous Vitreous

China

FIRING TEMPERATURE (°C) 1380-1400 1380-1400 1380-1400 1380-1420 1180-1200 1380-1400 1250-1300 1220-1280 1220-1280 1220-1250 1200-1230 1255-1265

ATMOSPHERE Reducing Reducing Reducing Reducing Oxidizing Reducing Reducing Oxidizing Oxidizing Oxidizing Oxidizing Oxidizing

SiO2 71.2 68.1 44.02 67.8 66.2 64.8 68.4 57.0 68.6 47.9 67.5 33

Al2O3 24.5 27.7 50.7 27 25.5 23.8 25.2 36.6 24 45.7 26 16.2

TiO2 0.06 0.07 0.11 0.1 0.35 0.08 0.06 0.08 0.22 0.07 0.09 0.05

CHEMICAL Fe2O3 0.25 0.49 0.41 0.54 0.72 0.31 0.48 0.23 0.59 0.39 0.31 0.32

ANALYSIS MgO 0.16 0.17 0.19 0.19 0.95 0.11 0.45 0.36 0.71 0.56 0.77 0.70

(mass %) CaO 0.17 0.13 0.22 0.10 1.17 0.12 0.4 0.59 0.84 1.02 1.13 26.4

Na2O 0.72 0.33 0.83 0.21 0.26 0.33 0.22 1.10 0.2 1.68 2.29 0.80

K2O 3.06 2.73 3.45 3.65 4.37 2.97 4.5 3.72 4.5 2.77 0.93 2.50

L.O.I 7.6 8.7 6.8 7.95 8.66 7.2 7.55 6.40 7.85 7.9 8.9 6.0

> 0.5 mm 2 2 1 7 6 1 7 7 9 2.5 1 8

0.4 - 0.5 mm 10 20 6.5 17 24 10 23 19 18 9 8 19

PARTICLE SIZE 0.315 - 0.4 mm 25 25 18 35 36 21 33 30 30 16 17 27

ANALYSIS

(mass %) 0.2 - 0.315 mm 40 35 46 30 26 42 26 31 30 45 44 33

0.1 - 0.2 mm 22 16 26 10 7 21 10 11 11 25 25 10

< 0.1 mm 2 4 5 1 1 2.5 1 2 2 2.5 2.5 1

MoR (MPa) Dried at 110°C 4.5 4 4.3 4.8 5 3.60 4.5 5.5 5 4 4.3 4.0

FIRED BENDING

MPa 75 75 110 64 40 70 65 75 65 90 75 75

STRENGTH

L* Lightness 91.7 88.5 90.4 87.0 87.3 87.34 87.8 92.7 84.5 91.1 87.8 95.6

CERAMIC a* + red /- green -1 -1 -0.4 -1.1 -0.8 -0.80 -1.1 -0.8 -1.2 -0.3 -0.8 -0.8

CHARACTERISTICS b* + yell. /- blue -0.6 -0.2 1.5 0.8 12.9 0.07 1.1 4.4 7.7 6.3 3.8 2.4

Shrinkage (%) 11 11.3 12 11 9.2 11.6 11 11.1 10.8 12 11.4 11.3

TRANSPARENT GLAZES

TYPICAL DATA ES185T ER204Z ER302T EP230T EN562T EN103T EK619T EH457T EH091T EE478T

1350-136 1230-125

FIRING TEMPERATURE (°C) 1400-1420 1380-1420 1380-1400 1360-1380 1340-1380 1280-1300 1220-1260 1160-1180

0 0

ATMOSPHERE Reducing Reducing Reducing Reducing Reducing Reducing Reducing Oxidizing Oxidizing Oxidizing

SiO2 76.2 72.9 73.8 73.1 73.4 73 71.7 65.9 61.98 58.26

Al2O3 13.8 14.3 12.48 13.3 12 12.3 10.4 12.5 9.25 0.13

TiO2 0.03 0.1 0.03 0.03 0.06 0.03 0.03 0.09 0.02 0.02

Fe2O3 0.24 0.18 0.1 0.12 0.13 0.11 0.08 0.15 0.13 0.1

MgO 1.79 1.9 2.51 2.44 2.3 2.59 0.88 1.5 2.02 1.01

CHEMICAL ANALYSIS

CaO 6 7.7 8.45 8.41 9.1 9.09 12.22 15.4 7.69 7.67

(mass %)

Na2O 0.83 0.5 0.34 0.25 0.3 0.29 1.36 0.6 0.62 0.45

K2O 1.7 2.1 2.27 2.28 2.5 2.56 3.32 2.6 4.29 4.8

BaO - - - - - - - - 6.7 7.14

ZnO - - - - - - - - 7.3 11.2

L.O.I 6.8 7.9 11.7 8.5 9.5 9.5 10 12.4 8.2 8

> 63 m < 0.02 - - < 0.02 - < 0.02 < 0.02 - < 0.02 < 0.02

PARTICLE SIZE ANALYSIS

> 20 m - < 0.2 - - < 1.5 - - < 1.5 - -

(mass %)

D50 m 3.8 3.6 4.1 3.8 3.8 3.8 4.2 3.8 5 -

DELIVERY FORM Powder Liquid Powder Powder Spray-dried Powder Powder Spray-dried Powder Powder

www.imerys.com

These values do not represent a specification. The data quoted are determined by the use of Imerys Standard Test Methods, copies of which will be supplied on request. Every precaution is taken

in production to ensure the products conform to our published data. Since the products are based on naturally occurring materials, we reserve the right to change these data should it become

necessary. Sales are in accordance with our “Conditions of Sale”, copies of which will be supplied on request.

You might also like

- Mix Design Concrete ExcelDocument7 pagesMix Design Concrete ExcelJoshua NdaloNo ratings yet

- TBR Bio2 OptDocument495 pagesTBR Bio2 OptTheodore Marghitu100% (1)

- Sinter PlantDocument12 pagesSinter PlantRajan Bhandari100% (1)

- 3-Cement Test ReportDocument2 pages3-Cement Test ReportAhsan Farid100% (1)

- Mixtures Worksheet KeyDocument1 pageMixtures Worksheet KeyNeen Naaz0% (1)

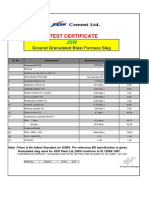

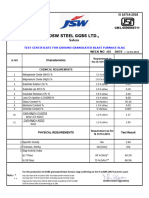

- JSW Ggbs 1 2015 PDFDocument1 pageJSW Ggbs 1 2015 PDFMohammed Javeed ahmedNo ratings yet

- TC of GGBS For Week No 1 28 Days - 2015Document1 pageTC of GGBS For Week No 1 28 Days - 2015Ramkumar KNo ratings yet

- Magnetic CircuitsDocument83 pagesMagnetic CircuitsVansh KhuranaNo ratings yet

- S C 7 1 - Mixtures Worksheet and KEYDocument4 pagesS C 7 1 - Mixtures Worksheet and KEYBrianMarBeltran33% (3)

- Extraction, Isolation, Purification and Identification CurcuminDocument16 pagesExtraction, Isolation, Purification and Identification CurcuminRaisyIkrimahNo ratings yet

- Biophotonics: Future - Horizons "Wishing Machine" Is Actually A Radionic Device and Is Now Available As ADocument50 pagesBiophotonics: Future - Horizons "Wishing Machine" Is Actually A Radionic Device and Is Now Available As AStellaEstelNo ratings yet

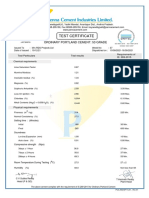

- Ground Granulated Blast Furnace Slag: Test CertificateDocument2 pagesGround Granulated Blast Furnace Slag: Test CertificatenoumanNo ratings yet

- BC Mix Design FinalDocument7 pagesBC Mix Design Finalraja MNo ratings yet

- MulcoaDocument2 pagesMulcoaRolando Cordova100% (1)

- 1-Mix Design UHPGC (W-B (0.35) (Ca 0.3) - Effect of MolarityDocument93 pages1-Mix Design UHPGC (W-B (0.35) (Ca 0.3) - Effect of MolaritySawa Zayia MichaelNo ratings yet

- Raw Mix Design SoftwareDocument6 pagesRaw Mix Design SoftwareIrfan Ahmed100% (1)

- Tosoh Silica Precipitated Silica BrochureDocument16 pagesTosoh Silica Precipitated Silica BrochureDewiNo ratings yet

- Lafarge Process Engg ManualsDocument132 pagesLafarge Process Engg ManualsYhane100% (1)

- Ball Mill SimulatorDocument4 pagesBall Mill SimulatorIrshad HussainNo ratings yet

- Cement Process Engineering Vade-Mecum: 3. QualityDocument22 pagesCement Process Engineering Vade-Mecum: 3. QualityRaúl Marcelo VelozNo ratings yet

- Analysis of Indian Coal (F Grade)Document3 pagesAnalysis of Indian Coal (F Grade)JKKNo ratings yet

- En Assets ANE4 18328 Analysis of Major and Minor Elements in Cement Pressed Powders Tcm50-55501Document2 pagesEn Assets ANE4 18328 Analysis of Major and Minor Elements in Cement Pressed Powders Tcm50-55501JGGNo ratings yet

- Certification of Slag Powder January 2022Document1 pageCertification of Slag Powder January 2022Kyaw KhineNo ratings yet

- Analysis of Washery RejectsDocument3 pagesAnalysis of Washery RejectsJKKNo ratings yet

- Yinka PowerDocument38 pagesYinka PowerAbdullahi MuhammadNo ratings yet

- Whatman Filtration Catalog PDFDocument68 pagesWhatman Filtration Catalog PDFJohn E. BeNo ratings yet

- Almatis Reactive Alumina Brochure PDFDocument2 pagesAlmatis Reactive Alumina Brochure PDFLuis OteroNo ratings yet

- Retaining WallDocument8 pagesRetaining WallethjetjetNo ratings yet

- Portland Clinker - Basic ChemistryDocument80 pagesPortland Clinker - Basic ChemistryAnil PatelNo ratings yet

- Cromax 280X: Hard Chrome BarDocument4 pagesCromax 280X: Hard Chrome BarpeterNo ratings yet

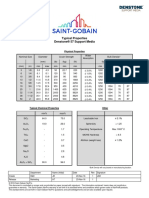

- Denstone® 57 Support Media Typical PropertiesDocument1 pageDenstone® 57 Support Media Typical PropertiesJuan Victor Sulvaran ArellanoNo ratings yet

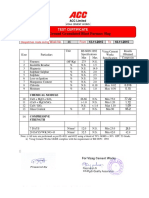

- TCS For Week39-2023 (28days) - OPC 53-ARYDocument1 pageTCS For Week39-2023 (28days) - OPC 53-ARYVmpsite RamalingamNo ratings yet

- Ecc SF 80Document1 pageEcc SF 80longyiequipmentNo ratings yet

- Chemical Composition of Silica Sand in Site 11Document3 pagesChemical Composition of Silica Sand in Site 11mohamed kassemNo ratings yet

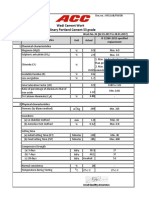

- Wadi Cement Work Ordinary Portland Cement 53 Grade: Chemical CharacteristicsDocument1 pageWadi Cement Work Ordinary Portland Cement 53 Grade: Chemical CharacteristicsAshish SontakkeNo ratings yet

- Attention Sample Data: Lube Oil Analysis ReportDocument1 pageAttention Sample Data: Lube Oil Analysis ReportnurdinzaiNo ratings yet

- Attention Sample Data: Lube Oil Analysis ReportDocument1 pageAttention Sample Data: Lube Oil Analysis ReportnurdinzaiNo ratings yet

- Technical Data: SilverbondDocument2 pagesTechnical Data: SilverbondI Love MusicNo ratings yet

- Plasma and HVOF - 1940hogDocument1 pagePlasma and HVOF - 1940hogStefanoNo ratings yet

- 3 Materials - 3Document13 pages3 Materials - 3Kesava KalepuNo ratings yet

- TDS - Mulcoa - 47 - Rev 1Document1 pageTDS - Mulcoa - 47 - Rev 1유유재하No ratings yet

- Cracking EvaluationDocument17 pagesCracking Evaluationهوا عجلون-المهندسNo ratings yet

- MABU - HCC 2022-SpecDocument2 pagesMABU - HCC 2022-SpecDUANJUNXINo ratings yet

- MCM - Final RoughDocument41 pagesMCM - Final RoughNaveen NatarajanNo ratings yet

- Concrete Moisture Correction SheetDocument7 pagesConcrete Moisture Correction SheetAmit MaityNo ratings yet

- Nes D2188Document6 pagesNes D2188prasannaNo ratings yet

- Trend Water AnalisisDocument3 pagesTrend Water AnalisisHayus MaulanaNo ratings yet

- Week No 40,43 GR, 3 Day'sDocument1 pageWeek No 40,43 GR, 3 Day'sshinde rushiNo ratings yet

- 25mm-Semi-Dense - Bituminous - Concrete (SDBC) - 19-01-2024Document3 pages25mm-Semi-Dense - Bituminous - Concrete (SDBC) - 19-01-2024Mithun RaulNo ratings yet

- PFL Slow Filter Sand: Chemical AnalysisDocument1 pagePFL Slow Filter Sand: Chemical AnalysisforuzzNo ratings yet

- Week No.05-28Days Updated - 1707204787769Document1 pageWeek No.05-28Days Updated - 1707204787769bineetmishra1990No ratings yet

- A.S.T.M. B584-09a: WWW - Okendo.mxDocument4 pagesA.S.T.M. B584-09a: WWW - Okendo.mxShariq KhanNo ratings yet

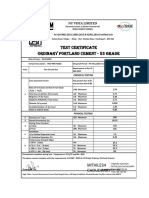

- Test Certificate: Ordinary Portland Cement: 53 GradeDocument1 pageTest Certificate: Ordinary Portland Cement: 53 GradeRDS KMRNo ratings yet

- TC-NVL - Infracem - Opc WK-19-2023-7DDocument1 pageTC-NVL - Infracem - Opc WK-19-2023-7DSirajul IslamNo ratings yet

- SilcoTek Coatings For High Purity ApplicationsDocument30 pagesSilcoTek Coatings For High Purity ApplicationsKommu RohithNo ratings yet

- Effect of Slag Basicity Adjusting On Inclusions in Tire Cord Steels During Ladle Furnace Re Fining ProcessDocument7 pagesEffect of Slag Basicity Adjusting On Inclusions in Tire Cord Steels During Ladle Furnace Re Fining ProcessBoujemaa DrifNo ratings yet

- TC OPC 53Gr Week 20Document1 pageTC OPC 53Gr Week 20divithNo ratings yet

- Ejemplos - Estructuras de ContenciónDocument4 pagesEjemplos - Estructuras de ContenciónAngii RomeroNo ratings yet

- Mix Design FormatDocument18 pagesMix Design FormatChandan MondalNo ratings yet

- Dry Magnetic Separation of Nepheline Syenite OresDocument11 pagesDry Magnetic Separation of Nepheline Syenite OresMo TahaNo ratings yet

- Timfold Product Page PDFDocument2 pagesTimfold Product Page PDFVlado KaucicNo ratings yet

- c70260 Cuni2si0.4 UsDocument2 pagesc70260 Cuni2si0.4 UsBeyzanur TepecikNo ratings yet

- Clinker: Astm C150 Type 1 No. Items Unit SpecificationsDocument1 pageClinker: Astm C150 Type 1 No. Items Unit Specificationsmylou casanovaNo ratings yet

- IsoplatonDocument1 pageIsoplatonikahashimNo ratings yet

- 316 LVMDocument1 page316 LVMMetehan AgacaNo ratings yet

- 5.2. Classification of FuelsDocument16 pages5.2. Classification of FuelsadiNo ratings yet

- Calendula DepilatoriaDocument1 pageCalendula DepilatoriaCesar Augusto Altahona RojasNo ratings yet

- PH Ysicsguide: Old Quantum TheoryDocument27 pagesPH Ysicsguide: Old Quantum TheoryRithish BarathNo ratings yet

- MeasurementDocument24 pagesMeasurementAnonymous P1iMibNo ratings yet

- Bio VentingDocument10 pagesBio VentingSeiton FernandezNo ratings yet

- A Numerical Model For Thermal-Hydraulic Design of A Shell and Single Pass Low Finned Tube Bundle Heat ExchangerDocument27 pagesA Numerical Model For Thermal-Hydraulic Design of A Shell and Single Pass Low Finned Tube Bundle Heat ExchangerSilvio PeluffoNo ratings yet

- Facilities Chemical SpareDocument73 pagesFacilities Chemical SparesamuelNo ratings yet

- CHE-504 Lecture 2 Basics of IR Spectroscopy by Dr. Charu C. PantDocument22 pagesCHE-504 Lecture 2 Basics of IR Spectroscopy by Dr. Charu C. Pantabdelfattah oufNo ratings yet

- Presentación 2 - Cinética PDFDocument7 pagesPresentación 2 - Cinética PDFDanny GarcíaNo ratings yet

- Agbo 2023 IOP Conf. Ser. Earth Environ. Sci. 1178 012019Document10 pagesAgbo 2023 IOP Conf. Ser. Earth Environ. Sci. 1178 012019Agbo sundayNo ratings yet

- 2012-05-11 Inorganic Chemistry PART 2Document40 pages2012-05-11 Inorganic Chemistry PART 2Shaina OrnopiaNo ratings yet

- PH, Ka, Pka and KW Exam Questions MarkschemeDocument3 pagesPH, Ka, Pka and KW Exam Questions Markscheme장채윤No ratings yet

- Silicone Conductor Cover, Overhead Line Cover IndiaDocument6 pagesSilicone Conductor Cover, Overhead Line Cover IndiaNikhil MathewNo ratings yet

- 3a Lattice Vibrations PDFDocument18 pages3a Lattice Vibrations PDFGanesh NegiNo ratings yet

- Shinko PCDocument128 pagesShinko PCThaitadashi CalNo ratings yet

- UNIT 1 Introduction To BiopharmaceuticsDocument208 pagesUNIT 1 Introduction To BiopharmaceuticsMamta Pant100% (5)

- M Alkalinity and P AlkalinityDocument4 pagesM Alkalinity and P AlkalinityiastraNo ratings yet

- Determination of Radionuclide Content in Agricultural Lands Using ResRad Off-Site Computer Model in Nasarawa State, NigeriaDocument10 pagesDetermination of Radionuclide Content in Agricultural Lands Using ResRad Off-Site Computer Model in Nasarawa State, NigeriaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- MEC126 - COMBUSTION - List 3 / Reactors: 1 Problem 6.12 (Turns, 2013) - Fixed Volume ReactorDocument17 pagesMEC126 - COMBUSTION - List 3 / Reactors: 1 Problem 6.12 (Turns, 2013) - Fixed Volume ReactorGiovanni AndradeNo ratings yet

- Leakfinder Wv622nvwkitDocument20 pagesLeakfinder Wv622nvwkitPaul ZiddyNo ratings yet

- 2.2.35. OsmolalityDocument1 page2.2.35. OsmolalitySpectre SpectreNo ratings yet

- Natsci5l Lecture2kinematicsDocument2 pagesNatsci5l Lecture2kinematicsjaneth waminalNo ratings yet

- Xii C Holiday HWDocument151 pagesXii C Holiday HWArnav SaksenaNo ratings yet