Professional Documents

Culture Documents

Figure Generator

Uploaded by

Tao Moustapha OumarouCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Figure Generator

Uploaded by

Tao Moustapha OumarouCopyright:

Available Formats

Specification sheet

Gaseous Fuel

Generator Set

GTA 855E Engine Series

250 kW 60 Hz

Description

The Cummins Inc. commercial Generator starting/stopping, precise voltage

Set (GenSet) is a fully integrated power regulation, alarm and status message

generation system providing optimum display, AmpSentry™ protective relay,

performance, reliability, and versatility for output metering, and auto-shutdown at

stationary standby power applications. fault detection.

Features Warranty and Service - Backed by a

Cummins Heavy-Duty Engine - Rugged comprehensive warranty and worldwide

4-cycle industrial spark-ignited engine distributor network.

delivers reliable power, low emissions, and

quick response to load changes. UL 2200 Certification - This Cummins

GenSet has been designed, tested, and

Alternator - Several alternator sizes offer certified to UL 2200 standards.

selectable motor-starting capability with

low reactance 2/3 pitch windings, low National Fire Protection Association

waveform distortion with non-linear loads, (NFPA) - The GenSet accepts full rated

fault-clearing short-circuit capability, and load in a single step in accordance with

class H insulation. NFPA 110 Type 10 (ten seconds) for Level

1 and Level 2 Emergency or Standby

Control System - The PowerCommand® Power Supply Systems (EPSSs).

electronic control is standard equipment

and provides total GenSet system

integration, including automatic remote

Standby rating* Emissions Compliance Data sheet

60 Hz 50 Hz

Model kW (kVa) kW (kVa) 60 Hz 50 Hz

C250N6 250 (312) EPA SI NSPS Stationary Emergency Certified FR 10792

* Tested at 0.8 power factor (PF) per NFPA 110.

© 2017 | Cummins Sales and Service www.power.cummins.com

Doc. A042J408 Rev. 1

GenSet Specifications

Voltage Regulation, No Load to Full Load ±1%

Random Voltage Variation ±1% (Three-phase only.)

Frequency Regulation Isochronous

Random Frequency Variation ±0.5%

Radio Frequency Interference Optional PMG excitation operates in compliance with BS800 and VDE

level G and N. Addition of RFI protection kit allows operation per

MIL-STD-461 and VDE level K.

Engine Specifications

Base Engine Cummins Model GTA855E

Displacement 14 L (854 in3)

Overspeed Limit 2100 rpm

Regenerative Power 30 kW

Cylinder Block Configuration Cast iron with replaceable wet cylinder liners

Cranking Current 900 amps at ambient temperature of 0 °C (32 °F)

Battery Charging Alternator 43 amps

Battery Type 8D (x2)

Starting Voltage 24-volt, negative ground

Standard Cooling System See derates on Engine Data Sheet

Lube Oil Filter Types One spin-on canister-combination full flow with bypass

Total System Back Pressure Allowed 51 mm Hg (2 in. Hg)

Catalyst Back Pressure 5.6 mm Hg (.22 in. Hg)

Silencer Back Pressure (Factory Enclosed Units Only) 22 mm Hg (.88 in. Hg)

Alternator Specifications

Design Brushless, 4-pole, drip-proof revolving field

Stator 2/3 pitch

Rotor Direct-coupled by flexible disc

Insulation System Class H per NEMA MG1-1.65 or better

Standard Temperature Rise * 120 °C

Exciter Type Permanent Magnet Generator (PMG)

Phase Rotation A (U), B (V), C (W)

Alternator Cooling Direct-drive centrifugal blower

* For UL 1004 ratings, refer to temperature rise at 120 °C or below, and ambient temperature up to 40 °C

Amp Rating at Full-load Voltage

Full Load Voltage 120/240 (1 Ph) 120/208 127/220 139/240 220/380 240/416 254/440 277/480 347/600

C250N6 Amps N/A 867 820 752 475 434 410 376 301

Fuel Consumption

Rated Load Fuel Consumption in Standard Cubic Feet per Hour (CFH)

Model Fuel Type 1/4 1/2 3/4 Full

C250N6 NG 950 1951 2692 3440

Fuel inlet pressure at GenSet connection: 381 to 508 mm WC (15 to 20 in. WC)

© 2017 | Cummins Sales and Service www.power.cummins.com

Doc. A042J408 Rev. 1 2

PowerCommand® 3.3 Control

Alternator Data

• Line-to-neutral and line-to-line AC volts.

System • Three-phase AC current.

• Frequency.

• kW, kVar, and power factor kVa (three-phase and total).

• Winding temperature (optional).

• Bearing temperature (optional).

An integrated microprocessor based generator set control Engine Data

system providing voltage regulation, engine protection, • DC voltage and engine speed.

alternator protection, operator interface and isochronous • Lube oil pressure and temperature.

governing. Refer to document S-1570 for more detailed • Coolant temperature.

information on the control. • Comprehensive FAE data.

AmpSentry™ - Includes integral AmpSentry™ protection,

which provides a full range of alternator protection functions that Other Display Data

are matched to the alternator provided. • GenSet model data.

Power management - Control function provides battery • Start attempts, starts, running hours, kW hours.

monitoring and testing features and smart starting control • Load profile (operating hours at % load in 5% increments).

system. • Fault history – up to 32 events.

• Data logging and fault simulation (requires InPower™).

Advanced control methodology -Three-phase sensing, full • Air cleaner restriction indication.

wave rectified voltage regulation, with a PWM output for stable • Exhaust temperature in each cylinder.

operation with all load types.

Standard Control Functions

Communications interface - Control comes standard with

PCCNet and Modbus® interface. Digital Governing

Regulation compliant - Prototype tested: UL, CSA and CE • Temperature dynamic governing.

compliant. • Integrated digital electronic isochronous governing.

Service - InPower™ PC-based service tool available for

detailed diagnostics, setup, data logging and fault simulation. Digital Voltage Regulation

• Configurable torque matching.

Easily upgradeable - PowerCommand® controls are designed

• 3-phase, 4 wire line-to-line sensing.

with common control interfaces.

• Integrated digital electronic voltage regulator.

Reliable design - The control system is designed for reliable

operation in harsh environment. AmpSentry™ AC Protection

Multi-language support - English, Spanish, French (standard); • AmpSentry™ protective relay.

other languages (optional). • Over current and short circuit shutdown.

• Over current warning.

Operator Panel Features

• Single and three-phase fault regulation.

Operator/Display Panel • Low oil pressure warning and shutdown.

• High coolant temperature warning and shutdown.

• Displays paralleling breaker status. • Low coolant level warning and shutdown.

• 320 x 240 pixels graphic LED backlight LCD.

• Low coolant temperature warning.

• Provides direct control of the paralleling breaker.

• Over and under voltage shutdown.

• Alphanumeric display with pushbuttons. • Over and under frequency shutdown.

• Auto, manual, start, stop, fault reset, and lamp test/panel

• Overload warning with alarm contact.

lamp switches.

• Reverse power and reverse var shutdown.

• LED lamps indicating GenSet running, remote start, not in • Field overload shutdown.

auto, common shutdown, common warning, manual run

• Fuel-in-rupture-basin warning or shutdown.

mode, auto mode and stop.

• Full authority electronic engine protection.

• AMM arc flash provision

Paralleling Control Functions

• First Start Sensor System selects first genset to close to Engine Protection

bus. • Cranking lockout; overspeed shutdown; and battleshort.

• Phase Lock Loop Synchronizer with voltage matching. • Sensor failure indication.

• Sync check relay. • Low fuel level warning or shutdown.

• Isochronous kW and kVar load sharing. • Fail to start (overcrank) and fail to crank shutdown.

• Load govern control for utility paralleling. • Full authority electronic engine protection.

• Extended Paralleling (baseload/peak shave) Mode. • Battery voltage monitoring, protection, and testing.

• Digital power transfer control, for use with a breaker pair to

provide open transition, closed transition, ramping closed Control Functions

transition, peaking and base load functions.

• Data logging and cycle cranking.

• Load shed.

Other Control Features • Remote emergency stop.

• 150 watt anti-condensation heater. • Time delay start and cooldown.

• DC distribution panel. • Configurable inputs and outputs (20).

• AC auxiliary distribution panel. • Real time clock for fault and event time stamping.

• Exerciser clock and time of day start/stop.

© 2017 | Cummins Sales and Service www.power.cummins.com

Doc. A042J408 Rev. 1 3

GenSet options and accessories

Engine

• 120 V, 2500 W coolant heaters

• 240/480 V, 4000 W coolant heaters

• 120/208/240 V, 300 W lube oil heater

Alternator

• 80 °C rise

• 105 °C rise

Fuel System

• Flexible fuel connector and fuel strainer

Exhaust System

• GenSet mounted muffler (enclosure models only)

Generator Set

• Batteries and battery charger

• Main line circuit breaker

• PowerCommand® Network Aux 101, 102 module

• Modbus® to BACnet™ Module

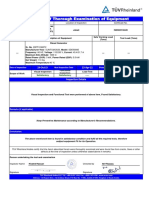

This outline drawing is for reference only.

• Weather protective enclosure (F001) with silencer

• Level I and Level II enclosure w/silencer Do not use for installation design.

• Audible alarm, remote drains, and oil maintainer Dim “A” Dim “B” Dim “C”

• Remote annunciator panel mm (in.) mm (in.) mm (in.)

• Spring isolators

C250N6 3734 (147) 1676 (66) 1997 (79)

• Two-year standby warranty

• Five-year basic power warranty NOTE: Consult drawings for applicable weights. Contact the factory for additional

information. See enclosure Specification Sheet for enclosure dimensions.

Codes and Standards

This product has been manufactured under the controls established

by a Bureau Veritas Certification approved management system that

conforms with ISO 9001:2015.

© 2017 | Cummins Sales and Service www.power.cummins.com

Doc. A042J408 Rev. 1 4

Ratings Definitions

Emergency Standby Power (ESP):

Applicable for supplying power to varying electrical load

for the duration of power interruption of a reliable utility

source. Emergency Standby Power (ESP) is in

accordance with ISO 8528. Fuel Stop power is in

accordance with ISO 3046, AS 2789, DIN 6271, and BS

5514.

Prime Power (PRP):

Applicable for supplying power to varying electrical load

for unlimited hours. Prime Power (PRP) is in accordance

with ISO 8528. Ten percent overload capability is

available in accordance with ISO 3046, AS 2789, DIN

6271, and BS 5514.

Base Load (Continuous) Power (COP):

Applicable for supplying power continuously to a

constant electrical load for unlimited hours. Continuous

Power (COP) is in accordance with ISO 8528, ISO 3046,

AS 2789, DIN 6271, and BS 5514.

Warning: Backfeed to a utility system can cause electrocution and/or property damage. Do not connect GenSets to

any building electrical system except through an approved device or after the building main disconnect is open. Neutral

connection must be bonded in accordance with National Electrical Code.

Specifications are subject to change without notice.

Cummins Sales and Service

875 Lawrence Drive

DePere, Wisconsin 54115

www.power.cummins.com

© 2017 | Cummins Sales and Service

Doc. A042J408 Rev. 1 5

You might also like

- C250N6CB A042j412Document5 pagesC250N6CB A042j412hareudangNo ratings yet

- C450N6 A042j403 G-01Document5 pagesC450N6 A042j403 G-01JoseLuisAramayoNo ratings yet

- A042j408 0Document5 pagesA042j408 0Anonymous 13AT3RUCNo ratings yet

- Gaseous Fuel Generator Set: GTA50 Engine SeriesDocument5 pagesGaseous Fuel Generator Set: GTA50 Engine SeriesEdwin Fernando Ariza QuirogaNo ratings yet

- Diesel Generator Set: QSB7 Series Engine 125-200 KW at 60 HZ EPA Tier 3 EmissionsDocument6 pagesDiesel Generator Set: QSB7 Series Engine 125-200 KW at 60 HZ EPA Tier 3 EmissionsAlan MtzNo ratings yet

- Cummins C1160 Specifications SheetDocument4 pagesCummins C1160 Specifications SheetMaximiliano SanchezNo ratings yet

- Diesel Generator Set QSX15 Series Engine: 364 kVA - 500 kVA 50 HZ Data Center ContinuousDocument4 pagesDiesel Generator Set QSX15 Series Engine: 364 kVA - 500 kVA 50 HZ Data Center ContinuousLwin PhyoNo ratings yet

- QSX15 DatasheetDocument4 pagesQSX15 DatasheetLuis Arturo Ramirez EstebanNo ratings yet

- Natural Gas Generator Set QSK60 Series Engine: 995 KW - 1540 KWDocument4 pagesNatural Gas Generator Set QSK60 Series Engine: 995 KW - 1540 KWJose Leandro Del ZarNo ratings yet

- Diesel Generator Set QSK95 Series Engine: 3125 kVA - 3350 kVA 50 HZ Data Center Continuous Emissions RegulatedDocument5 pagesDiesel Generator Set QSK95 Series Engine: 3125 kVA - 3350 kVA 50 HZ Data Center Continuous Emissions RegulatedthainarimeNo ratings yet

- Diesel Generator Set QSK23 Series Engine: 750 kVA - 820 kVA 50 HZ Data Center ContinuousDocument4 pagesDiesel Generator Set QSK23 Series Engine: 750 kVA - 820 kVA 50 HZ Data Center ContinuousTDH OfficialNo ratings yet

- SS12 CPGK DC50 PDFDocument4 pagesSS12 CPGK DC50 PDFTDH OfficialNo ratings yet

- Diesel Generator Set VTA28 Series Engine: 681 kVA 60 HZ Data Center ContinuousDocument4 pagesDiesel Generator Set VTA28 Series Engine: 681 kVA 60 HZ Data Center ContinuousRiverPlaceNo ratings yet

- SS27 CPGK DC50Document4 pagesSS27 CPGK DC50mnezamiNo ratings yet

- SDocument4 pagesSDenisNo ratings yet

- Gas Engine DataDocument10 pagesGas Engine Datarendy simanjuntakNo ratings yet

- Natural Gas Generator Set QSK60 Series Engine: 995 KW - 1540 KWDocument4 pagesNatural Gas Generator Set QSK60 Series Engine: 995 KW - 1540 KWJohn YangNo ratings yet

- Manual CVM c10 Itf 485 Ict2Document4 pagesManual CVM c10 Itf 485 Ict2Alejo MiraNo ratings yet

- A. Genset.2Document2 pagesA. Genset.2menggandakanNo ratings yet

- WCUMMINSONAN Diesel GeneratorDocument4 pagesWCUMMINSONAN Diesel GeneratorweldsaidiNo ratings yet

- Diesel Generator Set: QSB5 Series Engine 50-125 KW at 60 HZ EPA Tier 3 EmissionsDocument12 pagesDiesel Generator Set: QSB5 Series Engine 50-125 KW at 60 HZ EPA Tier 3 EmissionsٍJordan SportNo ratings yet

- Generator LogDocument4 pagesGenerator LogFELIXENGIPLASCOMNo ratings yet

- SS16 CPGK DC60Document4 pagesSS16 CPGK DC60Benjie CallantaNo ratings yet

- Diesel Generator Set Qsl9 Series Engine: 275 Kva - 330 Kva 50 HZ 250 Kwe - 300 Kwe 60 HZDocument5 pagesDiesel Generator Set Qsl9 Series Engine: 275 Kva - 330 Kva 50 HZ 250 Kwe - 300 Kwe 60 HZFarhad MalikNo ratings yet

- Diesel Generator Set QST30 Series Engine: 680 KW - 1000 KW 60 HZ Data Center ContinuousDocument5 pagesDiesel Generator Set QST30 Series Engine: 680 KW - 1000 KW 60 HZ Data Center ContinuousmnezamiNo ratings yet

- C400N5C - A042j404 Cummins Gta38Document5 pagesC400N5C - A042j404 Cummins Gta38Maximiliano SanchezNo ratings yet

- C400D6BDocument5 pagesC400D6BGestión del Talento Humano GEMRANo ratings yet

- Nas 5829 DC enDocument4 pagesNas 5829 DC enmnezamiNo ratings yet

- Planta de Luz 500 KWDocument4 pagesPlanta de Luz 500 KWikhtiyar ali khan ikhtiyarNo ratings yet

- GGKD 60 HZ Generator SetDocument8 pagesGGKD 60 HZ Generator SetDaniel RojasNo ratings yet

- Spec Sheet C600D6Document4 pagesSpec Sheet C600D6MIGUELNo ratings yet

- Cummins 175 DSGAD - QSB7Document4 pagesCummins 175 DSGAD - QSB7pank4r4No ratings yet

- Diesel Generator Set NT Series Engine: 360 Kwe - 400 Kwe 60 HZDocument5 pagesDiesel Generator Set NT Series Engine: 360 Kwe - 400 Kwe 60 HZLuis MejiaNo ratings yet

- Cummins GensetDocument4 pagesCummins GensetBenny S PutraNo ratings yet

- SS13 CPGKDocument4 pagesSS13 CPGKQuang Pham100% (3)

- c50 d6 Cummins 50kwDocument5 pagesc50 d6 Cummins 50kwRexelynNo ratings yet

- Cummins C25N6 Spec Sheet and DrawingsDocument15 pagesCummins C25N6 Spec Sheet and DrawingsjesseNo ratings yet

- s-1645DC Specification SheetDocument5 pagess-1645DC Specification SheetmnezamiNo ratings yet

- C800D6Document4 pagesC800D6Gestión del Talento Humano GEMRANo ratings yet

- Cummins C1000 Spec SheetDocument4 pagesCummins C1000 Spec SheetNimaNo ratings yet

- gEN C185D635 Ficha TecnicaDocument5 pagesgEN C185D635 Ficha TecnicaIldebrando Montaño MedinaNo ratings yet

- Cummins GTA19 G2spec SheetDocument8 pagesCummins GTA19 G2spec SheetEdwin PinzonNo ratings yet

- Diesel Generator Set QSK95 Series Engine: 2500 kW-3500 KW 60 HZ EPA Tier 2 Emissions RegulatedDocument5 pagesDiesel Generator Set QSK95 Series Engine: 2500 kW-3500 KW 60 HZ EPA Tier 2 Emissions RegulatedLuna DarkNo ratings yet

- S 1644DCDocument5 pagesS 1644DCAnh NguyenNo ratings yet

- C1000D6RGDocument4 pagesC1000D6RGDavid GomezNo ratings yet

- Diesel Generator Set Qsg12 Series Engine: 400 Kva - 450 Kva 50 HZ 320 Kwe-400 Kwe 60 HZDocument4 pagesDiesel Generator Set Qsg12 Series Engine: 400 Kva - 450 Kva 50 HZ 320 Kwe-400 Kwe 60 HZFabian David EspitiaNo ratings yet

- Spec Sheet C1000 D6Document4 pagesSpec Sheet C1000 D6jorge solanoNo ratings yet

- Rental Power 2000 KW: Specification SheetDocument4 pagesRental Power 2000 KW: Specification SheetPauline LunaNo ratings yet

- SS9 CPGKDocument4 pagesSS9 CPGKYahya SaifanNo ratings yet

- Nas 5872 enDocument5 pagesNas 5872 enjoseph mendezNo ratings yet

- Diesel Generator Set QSK23 Series Engine: 750 kVA - 900 kVA 50 HZ 680 KW - 800 KW 60 HZDocument4 pagesDiesel Generator Set QSK23 Series Engine: 750 kVA - 900 kVA 50 HZ 680 KW - 800 KW 60 HZJose VarelaNo ratings yet

- C2000D6Document4 pagesC2000D6Gestión del Talento Humano GEMRANo ratings yet

- SS22 CPGKDocument4 pagesSS22 CPGKArtemio Garcia BarrientosNo ratings yet

- C1500D6Document4 pagesC1500D6Gestión del Talento Humano GEMRANo ratings yet

- Nas 5829 enDocument4 pagesNas 5829 enmnezamiNo ratings yet

- Century Generator EspecificacionesDocument4 pagesCentury Generator EspecificacionesSebastianVargasNo ratings yet

- C600D6Document4 pagesC600D6Gestión del Talento Humano GEMRANo ratings yet

- Descripción Tecnica Del Generador C600 D6 PDFDocument4 pagesDescripción Tecnica Del Generador C600 D6 PDFMiguel Villavicencio100% (1)

- AQT 50 EditDocument3 pagesAQT 50 EditbassemNo ratings yet

- Eaton Xenergy Light Add On Distribution Board Product Catalog 2017 en UsDocument140 pagesEaton Xenergy Light Add On Distribution Board Product Catalog 2017 en UsOmar Yasser HarbNo ratings yet

- 313GC - Specalog APD - PEDJ0867-01 EmailDocument12 pages313GC - Specalog APD - PEDJ0867-01 EmailJoneil RanidoNo ratings yet

- RMU Test ReportDocument3 pagesRMU Test ReportGANESH K75% (4)

- Pascall - Catalogue - CAPCODocument28 pagesPascall - Catalogue - CAPCOBelialShaun0% (1)

- ME 346: Heat Transfer: Instructor: Ankit JainDocument29 pagesME 346: Heat Transfer: Instructor: Ankit JainDeepankar Sakya KusumaNo ratings yet

- TNB - NEM Customer Load Profile FormDocument1 pageTNB - NEM Customer Load Profile FormKian Keong YeeNo ratings yet

- DC motor speed control using chopper driveDocument6 pagesDC motor speed control using chopper driveTan Chuan ChetNo ratings yet

- Power Electronics Lecture NotesDocument12 pagesPower Electronics Lecture NotesFady KamilNo ratings yet

- ASTM D56-16a PDFDocument12 pagesASTM D56-16a PDFJOSENo ratings yet

- VOLVO EXCAVATOR EC330B LCDocument12 pagesVOLVO EXCAVATOR EC330B LCyansenbarus0% (1)

- Functional Testing of G60 A Test Results Engro PDFDocument14 pagesFunctional Testing of G60 A Test Results Engro PDFunab84No ratings yet

- 31 4 2 - ScienceDocument23 pages31 4 2 - SciencesubdirNo ratings yet

- Cooling Tower Exp 2 Students' ManualDocument23 pagesCooling Tower Exp 2 Students' ManualDAYANG NUR SYAZANA AG BUHTAMAMNo ratings yet

- Positively Innovative: Instructions For Use and HandlingDocument16 pagesPositively Innovative: Instructions For Use and HandlingNelson MartinsNo ratings yet

- NASA Surface Meteorology and Solar Energy - Available TablesDocument5 pagesNASA Surface Meteorology and Solar Energy - Available TablesShayan AhmedNo ratings yet

- Plastics SolutionsDocument20 pagesPlastics SolutionsGavazzi JuarezNo ratings yet

- IGNITING QUANG TRI WEEKS AHEAD OF SCHEDULEDocument2 pagesIGNITING QUANG TRI WEEKS AHEAD OF SCHEDULENguyen Khanh MinhNo ratings yet

- Clean Energy Trainer - ContentDocument3 pagesClean Energy Trainer - ContentPedro HenriqueNo ratings yet

- Boiler and Its TypesDocument11 pagesBoiler and Its TypesParas RaoNo ratings yet

- TUV Rheinland Arabia certificate generator inspectionDocument1 pageTUV Rheinland Arabia certificate generator inspectionShahid BhattiNo ratings yet

- Makerere University 72 Graduation List For May 2022Document160 pagesMakerere University 72 Graduation List For May 2022The Campus Times100% (2)

- Crude Test: by Khazar HayatDocument27 pagesCrude Test: by Khazar HayatkhayatNo ratings yet

- Student score and selection for practical competitionDocument3 pagesStudent score and selection for practical competitionJnanam62% (13)

- Kisembo Academy UrlsDocument26 pagesKisembo Academy UrlsKisembo RwangakuramyaNo ratings yet

- Mvrla 5s Ppt-SustenanceDocument185 pagesMvrla 5s Ppt-SustenanceChethan Nagaraju KumbarNo ratings yet

- Maintenance ScheduleDocument22 pagesMaintenance Scheduleghanbari.s60No ratings yet

- Green Technology ReportDocument5 pagesGreen Technology Reportdylyn jane gallegoNo ratings yet

- Pump & Pump Accessories Cross Reference Sheet: Beckett Description Suntec Danfoss NotesDocument1 pagePump & Pump Accessories Cross Reference Sheet: Beckett Description Suntec Danfoss NotesMubarak BaigNo ratings yet

- One Global Company - ENABL - ProfilesDocument7 pagesOne Global Company - ENABL - ProfilesDinesh Kumar pNo ratings yet