Professional Documents

Culture Documents

Page 4 of 22

Page 4 of 22

Uploaded by

mOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Page 4 of 22

Page 4 of 22

Uploaded by

mCopyright:

Available Formats

Draft Specification No.

TS/ED/2012/65

3.6. Preventive Maintenance

No maintenance including inspection of any type shall be required before 180 days. The

bidder shall specify the preventive maintenance schedule required. Care shall be taken by

the bidder to ensure that these schedules match the existing locomotive schedules, and

the least work content in these schedules shall be preferred.

3.7. Functional requirements

3.7.1. Application - The injector envelope is defined by the cylinder head for the EMD 710

engine. The envelope is also defined by the space available between exhaust valve

bridges. The injector will be held in the cylinder head with a crab.

3.7.2. The injector will be supplied with fuel using flexible fuel jumpers made of extruded

polytetrafluoroethylene with a continuous conductive path protected by stainless steel

braiding. The nominal I.D. of the jumper is 0.406 inches.

3.7.3. The fuel system is a through-system, not a dead-end system. Each injector has a fuel inlet

and outlet port.

3.7.4. Electronic Unit injector (EUI)

Adjustment Features

Free adjustment of begin of delivery should be possible within cam related

borders depending on engine demand (load and speed).

Individual control of fuel delivery for each cylinder should be possible.

Emergency Stop

Immediate stop of delivery by non-energizing of valve to prevent over-fuelling

in case of sudden load drop.

Injector Operating Parameters

The injector will operate in a two stroke cycle engine rated for 4500 BHP at

954 rpm maximum, and idle at 200 rpm.

The injectors are required to operate to the following parameters listed in

Table 1.

With the solenoid control valve closed, the injector must not lose more than

100 psi fuel pressure in twelve seconds at an initial fuel pressure of 550 psi.

Table 1: Injector performance parameters

PARAMETER 16-710 G3B

TURBOCHARGED

LOCOMOTIVE WDG4, WDP4

Page 4 of 22

You might also like

- VW Transporter T4 ( Diesel - 2000-2004) Workshop Manual: Owners Edition (Owners' Workshop Manuals)From EverandVW Transporter T4 ( Diesel - 2000-2004) Workshop Manual: Owners Edition (Owners' Workshop Manuals)Rating: 1 out of 5 stars1/5 (3)

- John Deere Riding Mower 120 Hydrostatic Tractor ManualDocument54 pagesJohn Deere Riding Mower 120 Hydrostatic Tractor Manualmalakas_123100% (1)

- 1300 EDi (Heui) Electronic EngineDocument38 pages1300 EDi (Heui) Electronic Engineاشرينكيل مسونكيل91% (33)

- Cameron BOP Control SystemsDocument38 pagesCameron BOP Control SystemsAshok Suresh100% (3)

- Paxman SpecsDocument9 pagesPaxman Specsbastech100% (2)

- Tr7-8fi ManualDocument82 pagesTr7-8fi ManualClint CooperNo ratings yet

- Audi - The 2.7-Litre V6 BiturboDocument72 pagesAudi - The 2.7-Litre V6 BiturboLola Selo100% (3)

- Pdm301320en 0419 V1 - 2Document134 pagesPdm301320en 0419 V1 - 2auasincNo ratings yet

- CT Ecn 71.0 - EngDocument29 pagesCT Ecn 71.0 - Englucian.voinicaNo ratings yet

- Specification For Motorized Gear Units (Mgus) IPSS:1-03-008-03Document8 pagesSpecification For Motorized Gear Units (Mgus) IPSS:1-03-008-03HEMANTKHERANo ratings yet

- 1221 - 1010KVA DG Set SpecificationDocument36 pages1221 - 1010KVA DG Set SpecificationKhiem Le100% (1)

- Installation Instructions - JW - C130637 - RevbDocument1 pageInstallation Instructions - JW - C130637 - Revbdavid80147179No ratings yet

- Lister EngineDocument2 pagesLister Enginedjordjes123No ratings yet

- CC Pump Manual-Full (Original)Document109 pagesCC Pump Manual-Full (Original)friendbce100% (1)

- PGM FiDocument36 pagesPGM FiJuan Sánchez LópezNo ratings yet

- 1300 EDi Heui Electronic EngineDocument38 pages1300 EDi Heui Electronic EngineYasirSwati100% (1)

- Oly 1300edi HeuiDocument39 pagesOly 1300edi HeuiTengri89 TengriNo ratings yet

- Overhaul (Top End) 3508Document7 pagesOverhaul (Top End) 3508Randy jr macielNo ratings yet

- Manual Motor CousterDocument69 pagesManual Motor CousterRenner Tabraj EspinozaNo ratings yet

- Alpha LPW2 G-Build Technical Data SheetDocument2 pagesAlpha LPW2 G-Build Technical Data SheetCristian S Cárdenas RiveraNo ratings yet

- Bosch General Injection TechnologiesDocument12 pagesBosch General Injection Technologiescinefil70No ratings yet

- Jeep 3.7l Fuel System PDFDocument85 pagesJeep 3.7l Fuel System PDFFabian MartinezNo ratings yet

- PGM Fi PDFDocument36 pagesPGM Fi PDFteja Mudhiraj raj100% (1)

- Technical Specification - Rev - 2 July14Document21 pagesTechnical Specification - Rev - 2 July14مراد احمدNo ratings yet

- IO-320 Operator Manual 60297-31Document5 pagesIO-320 Operator Manual 60297-31Josue Eleazar Guerrero DuranNo ratings yet

- Engineering Installation Bulletin: Cold Weather StartingDocument13 pagesEngineering Installation Bulletin: Cold Weather StartingmxnoxnNo ratings yet

- Transfluid Fluid Coupling CatalougeDocument32 pagesTransfluid Fluid Coupling CatalougeNaeem KhanNo ratings yet

- Solar 5.2MVADocument15 pagesSolar 5.2MVAsohaila7No ratings yet

- C210 WML 204Document10 pagesC210 WML 204Efrén SantínNo ratings yet

- TT CapriDocument12 pagesTT CapriLuis A. Rivera LópezNo ratings yet

- DROPSADocument27 pagesDROPSAcguillermosmNo ratings yet

- Mt700C/800C Series Tracked Tractors Secondary Steering Valve Rework - Rp6396 MandatoryDocument4 pagesMt700C/800C Series Tracked Tractors Secondary Steering Valve Rework - Rp6396 MandatoryMessi EmetievNo ratings yet

- The EA888 2.0L TSI Engine Gen III B: Self Study Program 820173Document21 pagesThe EA888 2.0L TSI Engine Gen III B: Self Study Program 820173MARIO100% (1)

- 1265 - 1010KVA DG Set SpecificationDocument35 pages1265 - 1010KVA DG Set SpecificationTien Nguyen100% (1)

- Fiche A4 4M11 2020Document2 pagesFiche A4 4M11 2020DHINAKARAN KumarNo ratings yet

- 3500 Governer Fuel Ratio ControlDocument32 pages3500 Governer Fuel Ratio ControlaliNo ratings yet

- Pda300832en 0317 V1 - 1Document128 pagesPda300832en 0317 V1 - 1auasincNo ratings yet

- 02-023E Rev.4 FO Injection Pump Rack Limit Values On Engine Starting. (Rev.4 Engines Complying With IMO Tier2 Regulation Added.)Document3 pages02-023E Rev.4 FO Injection Pump Rack Limit Values On Engine Starting. (Rev.4 Engines Complying With IMO Tier2 Regulation Added.)Bibi Bibilescu100% (2)

- Diesel EnginesDocument15 pagesDiesel EnginesDivyansh kaushalNo ratings yet

- DG SET-Technical Specs PDFDocument26 pagesDG SET-Technical Specs PDFankur yadavNo ratings yet

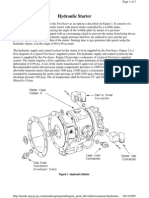

- Figure 1. Hydraulic StarterDocument3 pagesFigure 1. Hydraulic StarterDenis JimenezNo ratings yet

- DG SET-Technical Specs PDFDocument26 pagesDG SET-Technical Specs PDFankur yadavNo ratings yet

- Service Bulletin Mercarb 97 - 08Document6 pagesService Bulletin Mercarb 97 - 08hormiganegra431No ratings yet

- 8905-Exhibit B Technical SpecificationsDocument30 pages8905-Exhibit B Technical SpecificationsManuel GonzalezNo ratings yet

- N25242 - Technical Specifications Part B-III Revised 05.04.2015Document137 pagesN25242 - Technical Specifications Part B-III Revised 05.04.2015Bha BhaNo ratings yet

- Analysis of 4 Stroke 4 Cylinder Petrol EngineDocument36 pagesAnalysis of 4 Stroke 4 Cylinder Petrol Enginesuri surendraNo ratings yet

- Quickstart ManualDocument16 pagesQuickstart ManualotmanNo ratings yet

- Prueva PresionDocument7 pagesPrueva PresionAlonso PachecoNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- VW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004From EverandVW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004Rating: 3 out of 5 stars3/5 (1)

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SNo ratings yet

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualFrom EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualRating: 3.5 out of 5 stars3.5/5 (2)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- 899Document1 page899mNo ratings yet

- 18480Document1 page18480mNo ratings yet

- 895Document1 page895mNo ratings yet

- 891Document1 page891mNo ratings yet

- 898Document1 page898mNo ratings yet

- 894Document1 page894mNo ratings yet

- 893Document1 page893mNo ratings yet

- 1501Document1 page1501mNo ratings yet

- 1460Document1 page1460mNo ratings yet

- 1461Document1 page1461mNo ratings yet

- 1458Document1 page1458mNo ratings yet

- Page 9 of 22Document1 pagePage 9 of 22mNo ratings yet

- 6Document1 page6mNo ratings yet

- 4Document1 page4mNo ratings yet

- 5Document1 page5mNo ratings yet

- 7Document1 page7mNo ratings yet

![VW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004](https://imgv2-2-f.scribdassets.com/img/word_document/282876773/149x198/5fb74bd6e1/1675169638?v=1)