Professional Documents

Culture Documents

DD - 7 Transition Width Metric

DD - 7 Transition Width Metric

Uploaded by

Eyas hamadOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DD - 7 Transition Width Metric

DD - 7 Transition Width Metric

Uploaded by

Eyas hamadCopyright:

Available Formats

Design Data 7M

Transition Width

In the construction of sewer and culvert facilities The trench and positive projecting embankment

using round pipe, the two most common types of instal- conditions represent the limiting loading conditions with

lations are trench and positive projecting embankment. the trench being the most favorable and the embankment

the most severe. When pipe is installed in a relatively

TRENCH CONDITION narrow trench, the backfill load is a function of the trench

When concrete pipe is installed in a relatively narrow width. As the trench width is increased, for any given size

trench, settlement between the backfill material and the of pipe, type of in situ material and height of backfill,

undisturbed soil in which the trench is excavated gener- a limiting width is reached beyond which the frictional

ates upward frictional forces which effects a load transfer. forces does not help support the weight of the backfill

These frictional forces helps support the backfill material material. The trench width at which this condition occurs

within the trench and results in less load on the pipe than is defined as the TRANSITION WIDTH. At trench widths

the weight of the prism of backfill material over the pipe. greater than the transition width, the installation simulates

a positive projecting embankment condition with the load

POSITIVE PROJECTING EMBANKMENT transfer increasing the weight of the prism of backfill over

CONDITION the pipe. Once the transition width is realized, the backfill

When concrete pipe is installed on the original ground load is a maximum and remains constant regardless of

and fill material is placed around and over the pipe, rela- any further increase in the trench width. To illustrate the

tive settlements between the fill adjacent to the sides transition condition, and the relationship between trench

of the pipe and the fill directly over the pipe generates loads and embankment loads, the frictional forces and

downward frictional forces, also effecting load transfer. resultant load transfer can be depicted as columns of fill

However, this load transfer results in greater fill load on or backfill material.

the pipe than the weight of the prism of fill over the pipe. Figure 1 illustrates a positive projecting embankment

installation with the pipe installed on a firm, unyield-

TRANSITION CONDITION ing foundation. Since concrete pipe is relatively rigid

Figure 1 Positive Projecting Embankment Figure 2 Wide Trench Condition

Imtermediate Column

Imtermediate Column

Column

End Column

End Column

KBc KBc

Center

Before Settlement After Settlement

American Concrete Pipe Association • www.concrete-pipe.org • info@concrete-pipe.org 1

© 2012 American Concrete Pipe Association, all rights reserved. DD 7M (11/12)

compared to the semi-elastic soil surrounding the pipe, the KBc dimension and load on the pipe is the same as

the columns of fill adjacent to the sides of the pipe will the positive projecting embankment condition. The load

compress or settle more than the prism of fill directly over from the intermediate columns will be transmitted to the

the pipe. This relative settlement generates downward trench bottom and, because of compression, horizontal

frictional forces in the soil mass which transfers load forces will develop against the sides of the pipe.

onto the pipe so that the pipe carries a load in excess of Figure 3 is the same as Figure 2, except the trench

the weight of material directly above it. This increased is narrower and of such width that the intermediate col-

load can be represented by a column of fill of width KBc, umns have been eliminated. The two end columns are

where K is a load transfer coefficient and Bc is the outside now being supported by the trench walls and the pipe.

diameter of the pipe. When concrete pipe is installed in With the elimination of the intermediate columns (Figure

this manner, the coefficient K will always be greater than 2), the entire backfill load is being supported by the pipe

1.0 and can be as much as 1.45. In addition to the verti- and the trench walls. This is the TRANSITION WIDTH,

cal load on the pipe, compression of the fill material on with the load carried by the pipe being the same as for

either side of the pipe results in horizontal forces against the “positive projecting embankment installation” and the

the sides of the pipe (lateral support) which increase the “wide trench installation”. This load is constant for any

load carrying capacity of the pipe. trench width from the “transition width” to infinity.

The Figure 2 installation is the same as Figure 1, If the pipe is installed in a trench narrower than the

except the pipe is placed in a wide trench relative to the transition width, as illustrated in Figure 4, the trench walls

size of the pipe. When concrete pipe is installed in a wide support as much of the load as in the previous wide

trench, the backfill material can be considered as five trench and transition installations. However, the width of

separate but interacting columns; two end columns, two the remaining center column to be supported by the pipe

intermediate columns and a center column. The two end has decreased. The load carried by the pipe is no longer

columns adjacent to the trench walls will settle relative to a function of the pipe, but instead is controlled by the

the undisturbed soil in which the trench was excavated. width of the trench. Therefore, the narrower the trench,

This settlement generates upward frictional forces along the less the backfill load will be on the pipe. However the

the trench walls resulting in a load transfer as indicated. trench must be greater than the minimum trench width

This load transfer does not reduce the load on the pipe, based on appropriate specifications.

since the trench is of sufficient width that the intermediate Figures 5, 6, and 7 show the transition widths for

and center columns still simulate the positive projecting ACPA Standard Installations Type 1-4. An explanation of

condition illustrated in Figure 1. The intermediate columns Standard Installations can be found in the ACPA Concrete

of fill on either side of the pipe are not affected by the pipe Pipe Design Manual. For any given size of pipe and height

or trench walls. These columns will settle more than the of backfill, the transition width is dependent on the type

center column and transfer load onto the pipe such that of in situ material. However, variations in the transition

Figure 3 Transition Condition Figure 4 Trench Condition

Column

Center Column

End Column

End Column

End Column

End Column

KBc

Center

Before Settlement After Settlement

American Concrete Pipe Association • www.concrete-pipe.org • info@concrete-pipe.org 2

© 2012 American Concrete Pipe Association, all rights reserved. DD 7M (11/12)

Figure 5 Transition Widths for Type 1 Installations Using Sand and Gravel Backfill Material

40

144

132

35

120

108

138

114

126

102

96

72

30

84

27

90

54

66

78

60

33

48

24

21

Heigth of Backfill, H, Top of Pipe (Feet)

36

42

18

15

30

12

25 es

D in Inch

20

r

Diamete

15

10

0

0 2 4 6 8 10 12 14 16 18 20 22 24 26

Transition Width, Bd (Feet)

Figure 6 Transition Widths for Type 2 and 3 Installations Using Sand and Gravel Backfill Material

40

138

132

35

144

108

126

120

102

114

66

60

96

24

30

90

27

21

84

54

33

78

42

48

72

Heigth of Backfill, H, Top of Pipe (Feet)

15

36

18

12

30

25

hes

r D in Inc

20

Diamete

15

10

0

0 2 4 6 8 10 12 14 16 18 20 22 24 26

Transition Width, Bd (Feet)

American Concrete Pipe Association • www.concrete-pipe.org • info@concrete-pipe.org 3

© 2012 American Concrete Pipe Association, all rights reserved. DD 7M (11/12)

Figure 7 Transition Widths for Type 4 Installations Using Sand and Gravel Backfill Material

40

138

144

126

132

35

120

114

108

102

78

96

84

27

90

30

60

66

72

21

54

48

24

33

42

36

18

Heigth of Backfill, H, Top of Pipe (Feet)

15

30

12

es

25

D in Inch

20

r

Diamete

15

10

0

0 2 4 6 8 10 12 14 16 18 20 22 24 26

Transition Width, Bd (Feet)

Figure 8 Transition Loads on Circular Pipe (Type 1)

40

Diameter D in Inches

35

15 21 27 33

Heigth of Backfill, H, Above Top of Pipe (Feet)

12 18 24 30 36 42 48 54 60 66 72 78 84 90 96 102 108 114 120 126 132 138 144

30

25

20

15

Loads based on positive projection embankment

10

installations with 100 pounds per cubic foot backfill.

For fill weighing 110 pounds per cubic foot, increase

loads 10%; for 120 pounds, increase loads 20%; etc.

5

0

0 5000 10000 15000 20000 25000 30000 35000 40000 45000 50000 55000 60000 65000

Backfill Load, W(Pounds Per Linear Foot)

American Concrete Pipe Association • www.concrete-pipe.org • info@concrete-pipe.org 4

© 2012 American Concrete Pipe Association, all rights reserved. DD 7M (11/12)

Figure 9 Transition Loads on Circular Pipe (Type 2 & 3)

40

Diameter D in Inches

35

15 21 27 33

Heigth of Backfill, H, Above Top of Pipe (Feet)

12 18 24 30 36 42 48 54 60 66 72 78 84 90 96 102 108 114 120 126 132 138 144

30

25

20

15

Loads based on positive projection embankment

10

installations with 100 pounds per cubic foot backfill.

For fill weighing 110 pounds per cubic foot, increase

loads 10%; for 120 pounds, increase loads 20%; etc.

5

0

0 5000 10000 15000 20000 25000 30000 35000 40000 45000 50000 55000 60000 65000

Backfill Load, W(Pounds Per Linear Foot)

Figure 10 Transition Loads on Circular Pipe (Type 4)

40

35 Diameter D in Inches

Heigth of Backfill, H, Above Top of Pipe (Feet)

12 15 18 2124 27 3033 36 42 48 54 60 66 72 78 84 90 96 102 108 114 120 126 132 138 144

30

25

20

15

Loads based on positive projection embankment

10

installations with 100 pounds per cubic foot backfill.

For fill weighing 110 pounds per cubic foot, increase

loads 10%; for 120 pounds, increase loads 20%; etc.

5

0

0 5000 10000 15000 20000 25000 30000 35000 40000 45000 50000 55000 60000 65000

Backfill Load, W(Pounds Per Linear Foot)

American Concrete Pipe Association • www.concrete-pipe.org • info@concrete-pipe.org 5

© 2012 American Concrete Pipe Association, all rights reserved. DD 7M (11/12)

width for different types of backfill material is such that

in normal design work, it is sufficiently accurate to use

sand and gravel backfill material for the evaluation of

transition widths.

Figures 8, 9, and 10 present maximum backfill loads

for pipe installed in a trench where the trench width is

equal to or greater than the transition width loads based

on positive projection embankment installations with

15.7 kN per cubic meter backfill density. The maximum

backfill loads are based on the embankment loading

condition. For embankment installations the load transfer

coefficient, K, varies between 1.35 and 1.45 for Standard

Installation Types 1, 2, 3, and 4. The value of this coef-

ficient and resultant load increase is dependent on:

a. The type of foundation on which the pipe is

placed.

b. Compaction of the fill material adjacent to the

sides of the pipe.

c. The vertical height of the pipe projecting above

the original ground.

American Concrete Pipe Association • www.concrete-pipe.org • info@concrete-pipe.org 6

© 2012 American Concrete Pipe Association, all rights reserved. DD 7M (11/12)

Technical data herein is considered reliable, but no guarantee is made or liability assumed.

You might also like

- Design of Box CulvertDocument17 pagesDesign of Box CulvertSanket Diwate100% (13)

- Buried Piping Design PDFDocument34 pagesBuried Piping Design PDFAnonymous gr5Pr9AVNo ratings yet

- Culvert Design - WEEK 4 LECTURE NOTESDocument31 pagesCulvert Design - WEEK 4 LECTURE NOTESDammy Taiwo-AbdulNo ratings yet

- NFPA 14, 2019 Edition - Sprinkler AgeDocument6 pagesNFPA 14, 2019 Edition - Sprinkler AgeJhoNo ratings yet

- Buried Pipe Design PlexcoDocument34 pagesBuried Pipe Design PlexcoJuan Carlos Rivera100% (1)

- Railway Loads On Concrete PipeDocument4 pagesRailway Loads On Concrete PipeamokhtaNo ratings yet

- Audit Problem UzDocument7 pagesAudit Problem UzRaies JumawanNo ratings yet

- 32mmcabinet PDFDocument4 pages32mmcabinet PDFlordkyoriNo ratings yet

- BCA - RC Spreadsheet User Guide Version 3Document308 pagesBCA - RC Spreadsheet User Guide Version 3alex_3_1583% (6)

- DD-07M - Transition WidthDocument6 pagesDD-07M - Transition Widthilo88No ratings yet

- Cma Fill Heights Over Concrete PipeDocument8 pagesCma Fill Heights Over Concrete PipejessieNo ratings yet

- Double Composite Bridges The Main Concept and Examples of Its ImplementationDocument8 pagesDouble Composite Bridges The Main Concept and Examples of Its ImplementationDiego Cobo del ArcoNo ratings yet

- CHAPTER 8: Earth Loads On Steel Pipe Source: Journal (American Water Works Association), Vol. 53, No. 8 (AUGUST 1961), Pp. 1045-1080 Published By: Wiley Accessed: 12-06-2020 06:32 UTCDocument37 pagesCHAPTER 8: Earth Loads On Steel Pipe Source: Journal (American Water Works Association), Vol. 53, No. 8 (AUGUST 1961), Pp. 1045-1080 Published By: Wiley Accessed: 12-06-2020 06:32 UTCDesalegn TamirNo ratings yet

- External Loads On Buried Flexible PipesDocument5 pagesExternal Loads On Buried Flexible PipesAdelmo Filho100% (3)

- Ponding of Concrete Deck Floors PDFDocument4 pagesPonding of Concrete Deck Floors PDFdantranzNo ratings yet

- ACPPA TechSeries 12 JackingCPP FinalDocument6 pagesACPPA TechSeries 12 JackingCPP FinalWilliamray PabloNo ratings yet

- Handbook of PVC Pipe Chap6 PDFDocument44 pagesHandbook of PVC Pipe Chap6 PDFWolfnkom NkomNo ratings yet

- Columns: Combined Axial and BendingDocument23 pagesColumns: Combined Axial and Bendingرجاء صبرةNo ratings yet

- Module - 5 Construction of Sewers and BeddingDocument38 pagesModule - 5 Construction of Sewers and Beddingnaeem ullahNo ratings yet

- Literature Review - The Design of Buried Flexible PipesDocument47 pagesLiterature Review - The Design of Buried Flexible PipesxbeldaNo ratings yet

- Finite Element Analysis of Box Culvert: A. C. L, S. K. K, S. A. MDocument6 pagesFinite Element Analysis of Box Culvert: A. C. L, S. K. K, S. A. MAnonymousNo ratings yet

- Ponding of Concrete Floor DeckDocument4 pagesPonding of Concrete Floor DeckKrish DoodnauthNo ratings yet

- Construction and Beddings of SewersDocument35 pagesConstruction and Beddings of SewersShahbaz ManzoorNo ratings yet

- Unit 9 Canal Regulators: StructureDocument11 pagesUnit 9 Canal Regulators: StructureM.E.T EC CIVIL DEPARTMENTNo ratings yet

- Railway Loadings On Concrete PipeDocument4 pagesRailway Loadings On Concrete PipephatmatNo ratings yet

- Manual y GuíaDocument55 pagesManual y GuíaGabrielaNo ratings yet

- Concrete Pipe Design Manual 2012 (1) - RemovedDocument29 pagesConcrete Pipe Design Manual 2012 (1) - RemovedGabrielaNo ratings yet

- DD 20MDocument5 pagesDD 20Mlian9358No ratings yet

- 17Pt1 014Document5 pages17Pt1 014Jia Jie KohNo ratings yet

- Direct Design Method "DDM"Document95 pagesDirect Design Method "DDM"Nadir Khattak Jr.No ratings yet

- DD20 CircularPrecastConcreteManholes PDFDocument5 pagesDD20 CircularPrecastConcreteManholes PDFlian9358No ratings yet

- Seismic Performance of Plate Reinforced Composite Coupling BeamsDocument11 pagesSeismic Performance of Plate Reinforced Composite Coupling BeamsKhaled Abdel SalamNo ratings yet

- Chapter3 FoundationDocument62 pagesChapter3 FoundationChala Giduma WakjiraNo ratings yet

- Illustration 4.1 Essential Features of Types of InstallationsDocument10 pagesIllustration 4.1 Essential Features of Types of InstallationsSalomón GutiérrezNo ratings yet

- Pipeline Buckling Caused by Axial Loads PDFDocument9 pagesPipeline Buckling Caused by Axial Loads PDFWan Ah-LunNo ratings yet

- Is 103 Concrete Encasement of PipeDocument3 pagesIs 103 Concrete Encasement of Pipejhoe_15No ratings yet

- Aspect-96-155 Lateral Buckling PalmerDocument20 pagesAspect-96-155 Lateral Buckling PalmerJuan Roberto López Betanzos100% (2)

- Concrete DamsDocument144 pagesConcrete DamsspattiwarNo ratings yet

- Design For shear-LSDDocument11 pagesDesign For shear-LSDAmanuelNo ratings yet

- Soil Mechanics Ii CE 3509: Bearing CapacityDocument73 pagesSoil Mechanics Ii CE 3509: Bearing Capacityselda durmazNo ratings yet

- Unit 4: Well and Caisson FoundationDocument93 pagesUnit 4: Well and Caisson FoundationJagadeeswar ReddyNo ratings yet

- SPECIAL REPORT - New Method Assesses The Risk of Upheaval Buckling For Submerged Pipelines - Print This PageDocument7 pagesSPECIAL REPORT - New Method Assesses The Risk of Upheaval Buckling For Submerged Pipelines - Print This PageazamshafiqNo ratings yet

- Possible Solution To Past CM Examination Question: Question 3 - April 2011 Farm Access BridgeDocument13 pagesPossible Solution To Past CM Examination Question: Question 3 - April 2011 Farm Access BridgeWillNo ratings yet

- Sugar MummyDocument6 pagesSugar MummyFemi Richard Fakoya100% (1)

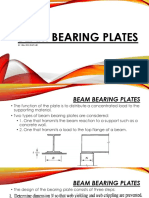

- 7-B. Beam Bearing PlatesDocument14 pages7-B. Beam Bearing PlatesMelchizedek EllNo ratings yet

- Group 7Document31 pagesGroup 7Baby John lystier NadayaoNo ratings yet

- Cen 308 - RCC BridgesDocument24 pagesCen 308 - RCC BridgesSanchit KumarNo ratings yet

- Introduction To Combined Footing.Document18 pagesIntroduction To Combined Footing.OmkarNo ratings yet

- Bridges PDF Part 2Document75 pagesBridges PDF Part 2Karmath budthapaNo ratings yet

- Seminar Report PDFDocument8 pagesSeminar Report PDFAbdul RafayNo ratings yet

- MyNotes CombinedFooting Rev1Document7 pagesMyNotes CombinedFooting Rev1engrnoreendelacruzNo ratings yet

- Settlement of Precast Culverts Under High Fills The Influence of Construction Sequence and Structural Effects of Longitudinal StrainsDocument9 pagesSettlement of Precast Culverts Under High Fills The Influence of Construction Sequence and Structural Effects of Longitudinal StrainsVarun VermaNo ratings yet

- Circular Precast Concrete ManholesDocument5 pagesCircular Precast Concrete ManholesAnthony Quintua PatinoNo ratings yet

- Handbook of PVC Pipe Chap7 PDFDocument57 pagesHandbook of PVC Pipe Chap7 PDFWolfnkom Nkom100% (1)

- Investigation of Load Transfer Characteristics of DowelsDocument5 pagesInvestigation of Load Transfer Characteristics of Dowelsnima sarNo ratings yet

- Canalcrossing 139Document3 pagesCanalcrossing 139Subuk NgaboNo ratings yet

- Desain Pondasi TapakDocument32 pagesDesain Pondasi TapakDaudNo ratings yet

- VariousFrpStrengtheningTechniquesForRetrofitting Hassan Dec2001 PDFDocument8 pagesVariousFrpStrengtheningTechniquesForRetrofitting Hassan Dec2001 PDFmr. oneNo ratings yet

- Computers and Geotechnics: Brian B. Sheil, Byron W. Byrne, Christopher M. MartinDocument12 pagesComputers and Geotechnics: Brian B. Sheil, Byron W. Byrne, Christopher M. Martinshuntao fanNo ratings yet

- DD-01M - Highway Live Loads On Concrete Pipe PDFDocument10 pagesDD-01M - Highway Live Loads On Concrete Pipe PDFilo88No ratings yet

- Instructions on Modern American Bridge BuildingFrom EverandInstructions on Modern American Bridge BuildingNo ratings yet

- Some Mooted Questions in Reinforced Concrete Design American Society of Civil Engineers, Transactions, Paper No. 1169, Volume LXX, Dec. 1910From EverandSome Mooted Questions in Reinforced Concrete Design American Society of Civil Engineers, Transactions, Paper No. 1169, Volume LXX, Dec. 1910No ratings yet

- Astm c1433Document25 pagesAstm c1433Eyas hamadNo ratings yet

- 33 4001 Astm C1577-14Document19 pages33 4001 Astm C1577-14Eyas hamadNo ratings yet

- DD - 5-Multiple Pipe Installations Trench ConditionDocument9 pagesDD - 5-Multiple Pipe Installations Trench ConditionEyas hamadNo ratings yet

- ACPA Fill Height Tables LFRD Concrete Pipe Rebrand CPDPGN029Document16 pagesACPA Fill Height Tables LFRD Concrete Pipe Rebrand CPDPGN029Eyas hamadNo ratings yet

- DD - 21 Curved Alignment MetricDocument4 pagesDD - 21 Curved Alignment MetricEyas hamadNo ratings yet

- Repair FutsalDocument4 pagesRepair FutsalAhmad Mustanir HadadakNo ratings yet

- CSPI - Handbook of Steel Drainage Highway Construction Products (215 320)Document106 pagesCSPI - Handbook of Steel Drainage Highway Construction Products (215 320)Ashly Bedregal GuevaraNo ratings yet

- LUSAS Bridge Full Brochure Email VersionDocument24 pagesLUSAS Bridge Full Brochure Email Versionavikshit yNo ratings yet

- Road Note Method No 4Document22 pagesRoad Note Method No 4ramya_an2411100% (1)

- Design DetailsDocument30 pagesDesign DetailsNikhil VamsiNo ratings yet

- ABS Guide For Application of Higher-Strength Hull Structural Thick Steel Plates in Container CarriersDocument72 pagesABS Guide For Application of Higher-Strength Hull Structural Thick Steel Plates in Container Carriersamin_corporationNo ratings yet

- Spec - 2017-02 - A00 - NON-METALLIC MATERIALS - SELECTION AND APPLICATIONDocument25 pagesSpec - 2017-02 - A00 - NON-METALLIC MATERIALS - SELECTION AND APPLICATIONAL Rajhi Zakaria100% (1)

- 4ce7: Concrete Technology Lab: Experiment No.:-5Document5 pages4ce7: Concrete Technology Lab: Experiment No.:-5sita ram JatNo ratings yet

- Greenheck Damper Selection - CatalogDocument24 pagesGreenheck Damper Selection - CatalogDhirendra Singh RathoreNo ratings yet

- Grundfosliterature 146012Document20 pagesGrundfosliterature 146012Si ThuNo ratings yet

- Construction 4112018Document7 pagesConstruction 4112018Rafique Sayed100% (1)

- 5.deflections of Beam PDFDocument10 pages5.deflections of Beam PDFharshdeepNo ratings yet

- Form Penawaran Harga Subcon Pekerjaan Gas Metering (18mei2022) - MNWDocument19 pagesForm Penawaran Harga Subcon Pekerjaan Gas Metering (18mei2022) - MNWFor AppsNo ratings yet

- Adair County Courthouse Ribbon Cutting Agenda 8.5x11 v2Document2 pagesAdair County Courthouse Ribbon Cutting Agenda 8.5x11 v2Matt GunnNo ratings yet

- Bottom ConstructionDocument8 pagesBottom ConstructionarmanimamsNo ratings yet

- 7.4 Tower Design: Bracing SystemsDocument49 pages7.4 Tower Design: Bracing SystemsBoisterous_Girl100% (1)

- Hse PlanDocument17 pagesHse PlanElchin IsmayilovNo ratings yet

- Materials Today: Proceedings: Chethan Kumar G, Sagar M. Baligidad, A.C. Maharudresh, Nishchay DayanandDocument6 pagesMaterials Today: Proceedings: Chethan Kumar G, Sagar M. Baligidad, A.C. Maharudresh, Nishchay DayanandNISHCHAY DAYANANDNo ratings yet

- Failure CriteriaDocument26 pagesFailure CriteriaSagarias AlbusNo ratings yet

- Building Bye Laws 1983Document153 pagesBuilding Bye Laws 1983Vivek MittalNo ratings yet

- The Power of Early Contractor Involvement Volume 12 Issue 2Document4 pagesThe Power of Early Contractor Involvement Volume 12 Issue 2Odilon KongoloNo ratings yet

- Pump (English) TemplateDocument1 pagePump (English) TemplateMichael HaiseNo ratings yet

- The Composite Steel Reinforced Concrete Column Under Axial and Seismic Loads: A ReviewDocument19 pagesThe Composite Steel Reinforced Concrete Column Under Axial and Seismic Loads: A ReviewPatel TosifNo ratings yet

- L&T SHE ProgramDocument42 pagesL&T SHE Programkanakarao150% (2)

- EXP: 2 Date: Manual Part Program For Radial Grooving, Threading and Axial Drilling Operation Using Canned CycleDocument9 pagesEXP: 2 Date: Manual Part Program For Radial Grooving, Threading and Axial Drilling Operation Using Canned CyclegowthamakNo ratings yet

- Outside Parties Development Handbook - JpaDocument39 pagesOutside Parties Development Handbook - JpaMegat AimanNo ratings yet