Professional Documents

Culture Documents

Slvu2 8

Uploaded by

hadiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Slvu2 8

Uploaded by

hadiCopyright:

Available Formats

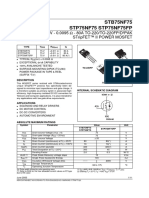

SLVU2.

8

Low Voltage EPD TVS Diode

For ESD and Latch-Up Protection

PROTECTION PRODUCTS

Description Features

The SLV series of transient voltage suppressors are 400 Watts peak pulse power (tp = 8/20μs)

designed to protect low voltage, state-of-the-art CMOS Transient protection for high speed data lines to

semiconductors from transients caused by electro- IEC 61000-4-2 (ESD) ±15kV (air), ±8kV (contact)

static discharge (ESD), cable discharge events (CDE), IEC 61000-4-4 (EFT) 40A (5/50ns)

lightning and other induced voltage surges. IEC 61000-4-5 (Lightning) 24A (8/20μs)

The devices are constructed using Semtech’s propri- One device protects one unidirectional line

etary EPD process technology. The EPD process pro- Two devices protect two high-speed line pairs

vides low standoff voltages with significant reductions Low capacitance

in leakage currents and capacitance over silicon- Low leakage current

avalanche diode processes. The SLVU2.8 features an Low operating and clamping voltages

integrated low capacitance compensation diode that Solid-state EPD TVS process technology

allows the device to be configured to protect one

unidirectional line or, when paired with a second Mechanical Characteristics

SLVU2.8, two high-speed line pairs. The low capaci-

tance design of the SLVU2.8 means signal integrity is

JEDEC SOT23 package

preserved in high-speed applications such as 10/100 Molding compound flammability rating: UL 94V-0

Ethernet. Marking : U2.8

Packaging : Tape and Reel per EIA 481

The SLVU2.8 is in an SOT23 package and has a low

2.8 volt working voltage. It is specifically designed to Applications

protect low voltage components such as Ethernet

transceivers, laser diodes, ASICs, and high-speed RAM. 10/100 Ethernet

The low clamping voltage of the SLVU2.8 minimizes the WAN/LAN Equipment

stress on the protected IC. Switching Systems

The SLV series TVS diodes will exceed the surge re- Desktops, Servers, Notebooks & Handhelds

quirements of IEC 61000-4-2, Level 4. Laser Diode Protection

Base Stations

Circuit Diagram Schematic & PIN Configuration

1 2

SOT23 (Top View)

Revision 06/25/2008 1 www.semtech.com

SLVU2.8

PROTECTION PRODUCTS

Absolute Maximum Rating

R ating Symbol Value Units

Peak Pulse Power (tp = 8/20μs) Pp k 400 Watts

Peak Pulse Current (tp = 8/20μs) IP P 24 A

Lead Soldering Temp erature TL 260 (10 seconds) o

C

Op erating Temp erature TJ -55 to +125 o

C

Storage Temp erature TSTG -55 to +150 o

C

Electrical Characteristics

SLVU2.8

Parameter Symbo l Conditions Minimum Typical Maximum Units

Reverse Stand-Off Voltage VRWM Pin 3 to 1 or Pin 2 to 1 2.8 V

Punch-Through Voltage V PT IPT = 2μA, Pin 3 to 1 3.0 V

Snap -Back Voltage VSB ISB = 50mA, Pin 3 to 1 2.8 V

Reverse Leakage Current IR VRWM = 2.8V, T=25°C 1 μA

Pin 3 to 1 or Pin 2 to 1

Clamp ing Voltage VC IPP = 2A, tp = 8/20μs 3.9 V

Pi n 3 to 1

Clamp ing Voltage VC IPP = 5A, tp = 8/20μs 7 V

Pi n 3 to 1

Clamp ing Voltage VC IPP = 24A, tp = 8/20μs 12.5 V

Pi n 3 to 1

Clamp ing Voltage VC IPP = 5A, tp = 8/20μs 8.5 V

Pi n 2 to 1

Clamp ing Voltage VC IPP = 24A, tp = 8/20μs 15 V

Pi n 2 to 1

Junction Cap acitance Cj Pin 3 to 1 and 2 70 100 pF

(Pin 1 and 2 tied

together)

VR = 0V, f = 1MHz

Junction Cap acitance Cj Pin 2 to 1 (p in 3 N .C.) 5 10 pF

VR = 0V, f = 1MHz

Steering Diode Characteristics

Reverse Breakdown Voltage V BR IT= 10μA, Pin 3 to 2 40 V

Reverse Leakage Current IR D VRWM = 2.8V, T=25°C 1 μA

Pi n 3 to 2

Forward Voltage VF IF= 1A, Pin 2 to 3 2 V

© 2008 Semtech Corp. 2 www.semtech.com

SLVU2.8

PROTECTION PRODUCTS

Typical Characteristics

Non-Repetitive Peak Pulse Power vs. Pulse Time Power Derating Curve

10 110

100

Peak Pulse Power - Ppk (kW)

90

% of Rated Power or IPP

80

1 70

60

50

40

0.1

30

20

10

0.01 0

0.1 1 10 100 1000 0 25 50 75 100 125 150

o

Pulse Duration - tp (µs) Ambient Temperature - TA ( C)

Pulse Waveform Clamping Voltage vs. Peak Pulse Current

110 18

W aveform

100 Parameters: 16

90 tr = 8µs

Clamping Voltage - VC (V)

td = 20µs 14

80

12

70

Percent of IPP

e -t

10

60

Pin 3 to 1

50 8

40 td = I PP /2 6

Waveform

30 4 Parameters:

20 tr = 8µs

2

10 td = 20µs

0

0

0 5 10 15 20 25 30 35

0 5 10 15 20 25 30

Peak Pulse Current - IPP (A)

T im e (µs)

Forward Voltage vs. Forward Current Normalized Capacitance vs. Reverse Voltage

16 2

f = 1MHz

1.8

14

1.6

Forward Voltage - VF (V)

12

1.4 Pin 3 to Pin 1 and 2

CJ(VR ) / C J(V R=0)

10

1.2

8 1

6 0.8

4 Waveform 0.6

Parameters: Pin 2 to Pin 1

0.4

2 tr = 8µs

td = 20µs 0.2

0

0

0 5 10 15 20 25 30 35 0 0.5 1 1.5 2 2.5 3

Forward Current - IF (A) Reverse Voltage - VR (V)

© 2008 Semtech Corp. 3 www.semtech.com

SLVU2.8

PROTECTION PRODUCTS

Typical Characteristics (Continued)

Insertion Loss S21

CH1 S21 LOG 10 dB /REF 0 dB

START . 030 MHz STOP 3000. 000000 MHz

© 2008 Semtech Corp. 4 www.semtech.com

SLVU2.8

PROTECTION PRODUCTS

Applications Information

Device Connection Options SLVU2.8 Circuit Diagram

Electronic equipment is susceptible to transient distur-

bances from a variety of sources including: ESD to an 1 3

open connector or interface, direct or nearby lightning

strikes to cables and wires, and charged cables “hot

plugged” into I/O ports. The SLVU2.8 is designed to

protect sensitive components from damage and latch-

up which may result from such transient events. The 2

SLVU2.8 can be configured to protect either one

unidirectional line or two (one line pair) high-speed data

lines. The options for connecting the devices are as Protection of one unidirectional line

follows:

1 . Protection of one unidirectional I/O line: Protec-

tion of one data line is achieved by connecting pin

3 to the protected line, and pins 1 and 2 to ground.

This connection option will allow the device to

operate on lines with positive polarity signal transi-

tions (during normal operation). In this configura-

tion, the device adds a maximum loading capaci-

tance of 100pF. During positive duration tran-

sients, the internal TVS diode will be reversed

biased and will act in the avalanche mode, con- Low capacitance protection of one high-speed line

ducting the transient current from pin 3 to 1. The pair

transient will be clamped at or below the rated

clamping voltage of the device. For negative

duration transients, the internal steering diode is

forward biased, conducting the transient current

from pin 2 to 3. The transient is clamped below

the rated forward voltage drop of the diode.

2. Low capacitance protection of one differential

line pair: Protection of a high-speed differential line

pair is achieved by connecting two devices in anti-

EPD TVS Characteristics

parallel. Pin 1 of the first device is connected to

line 1 and pin 2 is connected to line 2. Pin 2 of the The SLVU2.8 is constructed using Semtech’s propri-

second device is connected to line 1 and pin 1 is etary EPD technology. The structure of the EPD TVS is

connected to line 2 as shown. Pin 3 must be left vastly different from the traditional pn-junction devices.

open on both devices. During negative duration At voltages below 5V, high leakage current and junction

transients, the first device will conduct from pin 2 capacitance render conventional avalanche technology

to 1. The steering diode conducts in the forward impractical for most applications. However, by utilizing

direction while the TVS will avalanche and conduct the EPD technology, the SLVU2.8 can effectively

in the reverse direction. During positive transients, operate at 2.8V while maintaining excellent electrical

the second device will conduct in the same man- characteristics.

ner. In this configuration, the total loading capaci-

tance is the sum of the capacitance (between pins The EPD TVS employs a complex nppn structure in

1 and 2) of each device (typically <10pF) making contrast to the pn structure normally found in tradi-

this configuration suitable for high-speed interfaces tional silicon-avalanche TVS diodes. The EPD mecha-

such as 10/100 Ethernet (See application note nism is achieved by engineering the center region of

SI98-02). the device such that the reverse biased junction does

© 2008 Semtech Corp. 5 www.semtech.com

SLVU2.8

PROTECTION PRODUCTS

Applications Information (continued)

not avalanche, but will “punch-through” to a conduct-

ing state. This structure results in a device with supe-

rior dc electrical parameters at low voltages while

maintaining the capability to absorb high transient

currents.

The IV characteristic curve of the EPD device is shown

in Figure 1. The device represents a high impedance

to the circuit up to the working voltage (VRWM). During a

transient event, the device will begin to conduct as it is

biased in the reverse direction. When the punch- SLVU2.8

through voltage (VPT) is exceeded, the device enters a

low impedance state, diverting the transient current Laser Diode Protection

away from the protected circuit. When the device is

conducting current, it will exhibit a slight “snap-back” or

negative resistance characteristic due to its structure.

This must be considered when connecting the device Circuit Board Layout Recommendations for Suppres-

to a power supply rail. To return to a non-conducting sion of ESD.

state, the current through the device must fall below Good circuit board layout is critical for the suppression

the snap-back current (approximately < 50mA). of ESD induced transients. The following guidelines are

recommended:

IPP

z Place the SLVU2.8 near the input terminals or

connectors to restrict transient coupling.

z Minimize the path length between the TVS and the

protected line.

ISB z Minimize all conductive loops including power and

ground loops.

z The ESD transient return path to ground should be

IPT

kept as short as possible.

VBRR IR z Never run critical signals near board edges.

VRWM VSB VPT VC

z Use ground planes whenever possible.

IBRR

Matte Tin Lead Finish

Matte tin has become the industry standard lead-free

replacement for SnPb lead finishes. A matte tin finish

is composed of 100% tin solder with large grains.

Since the solder volume on the leads is small com-

pared to the solder paste volume that is placed on the

land pattern of the PCB, the reflow profile will be

EPD TVS IV Characteristic Curve determined by the requirements of the solder paste.

Therefore, these devices are compatible with both

lead-free and SnPb assembly techniques. In addition,

unlike other lead-free compositions, matte tin does not

have any added alloys that can cause degradation of

the solder joint.

© 2008 Semtech Corp. 6 www.semtech.com

SLVU2.8

PROTECTION PRODUCTS

Typical Applications

10/100 Ethernet Protection Circuit

(Reference Semtech Application Note SI98-02 for more information)

10/100 Ethernet “Enhanced” Lightning Protection Circuit

(Reference Semtech Application Note SI98-02 for more information)

© 2008 Semtech Corp. 7 www.semtech.com

SLVU2.8

PROTECTION PRODUCTS

Applications Information - SPICE Model

0.6 nH

SLVU2.8 Spice Model

SLVU2.8 Spice Parameters

Parameter Unit D1 (T VS) D2 (LCR D)

IS Amp 6.09E-14 8.57E-9

BV Volt 3.4 420

VJ Volt 13.8 0.62

RS Ohm 0.389 0.15

IB V A mp 10E-3 10E-3

CJO Farad 24.75E-12 3.15E-12

TT sec 2.541E-9 2.541E-9

M -- 0.145 0.113

N -- 1.1 1.1

EG eV 1.11 1.11

© 2008 Semtech Corp. 8 www.semtech.com

SLVU2.8

PROTECTION PRODUCTS

Outline Drawing - SOT23

D A DIMENSIONS

INCHES MILLIMETERS

e1 DIM

MIN NOM MAX MIN NOM MAX

A .035 - .044 0.89 - 1.12

H

3 A1 .000 - .004 0.01 - 0.10

B A2 .035 .037 .040 0.88 0.95 1.02

b .012 - .020 0.30 - 0.51

GAUGE 0 c c .003 - .007 0.08 - 0.18

SEATING PLANE D .110 .114 .120 2.80 2.90 3.04

E PLANE E .082 .093 .104 2.10 2.37 2.64

E1 0.25 E1 .047 .051 .055 1.20 1.30 1.40

C e .075 1.90 BSC

L e1 .037 0.95 BSC

L1 L .015 .020 .024 0.40 0.50 0.60

L1 .022 (0.55)

DETAIL A

N 3 3

1 2 0 0° - 8° 0° - 8°

aaa .004 0.10

bxN bbb .008 0.20

e bbb C A B

A A2 aaa C

3X SEE DETAIL A

SIDE VIEW

SEATING PLANE

A1 C

NOTES:

1. CONTROLLING DIMENSIONS ARE IN MILLIMETERS (ANGLES IN DEGREES).

2. DATUMS -A- AND -B- TO BE DETERMINED AT DATUM PLANE -H-

3. DIMENSIONS "E1" AND "D" DO NOT INCLUDE MOLD FLASH, PROTRUSIONS

OR GATE BURRS.

Land Pattern - SOT23

Y

DIMENSIONS

DIM INCHES MILLIMETERS

C (.087) (2.20)

Z C E .037 0.95

G

E1 .075 1.90

G .031 0.80

X .039 1.00

Y .055 1.40

Z .141 3.60

Y

E1

NOTES:

1. THIS LAND PATTERN IS FOR REFERENCE PURPOSES ONLY

CONSULT YOUR MANUFACTURING GROUP TO ENSURE YOUR

COMPANY'S MANUFACTURING GUIDELINES ARE MET.

2. REFERENCE IPC-SM-782A.

© 2008 Semtech Corp. 9 www.semtech.com

SLVU2.8

PROTECTION PRODUCTS

Marking

U2.8

Ordering Information

Part Number Lead Finish Qty per R eel R eel Size

SLVU2.8.TC SnPb 3,000 7 Inch

SLVU2.8.TCT Pb free 3,000 7 Inch

Contact Information

Semtech Corporation

Protection Products Division

200 Flynn Road, Camarillo, CA 93012

Phone: (805)498-2111 FAX (805)498-3804

© 2008 Semtech Corp. 10 www.semtech.com

You might also like

- Low Capacitance TVS For LVDS Interfaces: Protection Products - Railclamp Description FeaturesDocument8 pagesLow Capacitance TVS For LVDS Interfaces: Protection Products - Railclamp Description FeaturesAnibal Tantalean SarmientoNo ratings yet

- Low Voltage Clamp For ESD and CDE Protection: Protection Products Protection Products - Microclamp Description FeaturesDocument6 pagesLow Voltage Clamp For ESD and CDE Protection: Protection Products Protection Products - Microclamp Description FeaturesAmirNo ratings yet

- GT I9300 Galaxy S3 U713 PDFDocument10 pagesGT I9300 Galaxy S3 U713 PDFhernanNo ratings yet

- Azc199 02SDocument8 pagesAzc199 02SHamzaNo ratings yet

- Railclamp Low Capacitance Tvs Array: Protection Products - Railclamp Description FeaturesDocument8 pagesRailclamp Low Capacitance Tvs Array: Protection Products - Railclamp Description FeaturesHemantkumarNo ratings yet

- Low Capacitance 3.3 Volt TVS For High Speed Interfaces: Protection Products Protection Products Description FeaturesDocument7 pagesLow Capacitance 3.3 Volt TVS For High Speed Interfaces: Protection Products Protection Products Description FeaturesStuxnetNo ratings yet

- Tesdc24V: Taiwan SemiconductorDocument6 pagesTesdc24V: Taiwan Semiconductorn tanevarNo ratings yet

- Railclamp Low Capacitance Tvs Array: Protection Products - Railclamp Description FeaturesDocument10 pagesRailclamp Low Capacitance Tvs Array: Protection Products - Railclamp Description FeaturesEinson SepulvedaNo ratings yet

- Current Mode PWMDocument9 pagesCurrent Mode PWMluis albertoNo ratings yet

- Datasheet BTA41-600BDocument13 pagesDatasheet BTA41-600BCentral TempNo ratings yet

- Itr8307 S17 TR8Document10 pagesItr8307 S17 TR8cointoinNo ratings yet

- STMicroelectronics STP25NM50N DatasheetDocument16 pagesSTMicroelectronics STP25NM50N DatasheetAndre AnsyahNo ratings yet

- Semt Lcdaxxc 8Document6 pagesSemt Lcdaxxc 8Aditya SrivatsavNo ratings yet

- Dual Channel TVS Diode: ESD8V0L..Document6 pagesDual Channel TVS Diode: ESD8V0L..psujith_87No ratings yet

- For Operating Voltage of 5V and Below Ultra Low Capacitance: 0.5pF TypicalDocument10 pagesFor Operating Voltage of 5V and Below Ultra Low Capacitance: 0.5pF TypicalTri Nguyen Real EstateNo ratings yet

- K40T120 InfineonDocument16 pagesK40T120 InfineonSyed Danish ShahNo ratings yet

- 1.6mm X 1.0mm DFN Package Saves Board: Transient Voltage Suppressing Device For ESD and Surge ProtectionDocument7 pages1.6mm X 1.0mm DFN Package Saves Board: Transient Voltage Suppressing Device For ESD and Surge ProtectionxXMythicalRoseXNo ratings yet

- Bta41 800B 1846805 PDFDocument13 pagesBta41 800B 1846805 PDFAldo NalettoNo ratings yet

- Railclamp Low Capacitance Tvs Diode Array: Protection Products Description FeaturesDocument13 pagesRailclamp Low Capacitance Tvs Diode Array: Protection Products Description Featuresrishi sagarNo ratings yet

- Bta312x 600eDocument13 pagesBta312x 600eCesar JakobyNo ratings yet

- AC-DC LED Driver MT7930Document8 pagesAC-DC LED Driver MT7930Daniel GonzálezNo ratings yet

- MC78M12Document14 pagesMC78M12Radio AtelierNo ratings yet

- Datasheet 1 4Document5 pagesDatasheet 1 4HJavi MPNo ratings yet

- Bta440z 800BT 1846753Document14 pagesBta440z 800BT 1846753AndresNo ratings yet

- Ka78Mxx: 3-Terminal 0.5A Positive Voltage RegulatorDocument14 pagesKa78Mxx: 3-Terminal 0.5A Positive Voltage RegulatorTinwin HtutNo ratings yet

- Everlight Elec ITR8307 L24 TR8 - C181894Document11 pagesEverlight Elec ITR8307 L24 TR8 - C181894Влад ГорNo ratings yet

- ESD Protection AZC099-04S PDFDocument12 pagesESD Protection AZC099-04S PDFChrist TianNo ratings yet

- STB 75 NF 75Document11 pagesSTB 75 NF 75costas1182No ratings yet

- BTA330Y-800BT: 1. General DescriptionDocument14 pagesBTA330Y-800BT: 1. General DescriptionAntoxaNo ratings yet

- IRAMS10UP60B: Series 10A, 600VDocument17 pagesIRAMS10UP60B: Series 10A, 600VAngel VelasquezNo ratings yet

- Stp8Nk80Z - Stp8Nk80Zfp STW8NK80ZDocument11 pagesStp8Nk80Z - Stp8Nk80Zfp STW8NK80Zserrano.flia.coNo ratings yet

- Stp5Nc50 - Stp5Nc50Fp Stb5Nc50 - Stb5Nc50-1: N-Channel 500V - 1.3 - 5.5A To-220/Fp/D Pak/I Pak Powermesh Ii MosfetDocument12 pagesStp5Nc50 - Stp5Nc50Fp Stb5Nc50 - Stb5Nc50-1: N-Channel 500V - 1.3 - 5.5A To-220/Fp/D Pak/I Pak Powermesh Ii MosfetJavier55No ratings yet

- SM2LZ47: Ac Power Control ApplicationsDocument5 pagesSM2LZ47: Ac Power Control ApplicationsNelson VargasNo ratings yet

- ESD5302N WillSEMIDocument7 pagesESD5302N WillSEMIRenato Luiz TécnicoNo ratings yet

- 3N80Document6 pages3N80hectorsevillaNo ratings yet

- STP80NF12Document12 pagesSTP80NF12vanuzalopeslopes1No ratings yet

- TVL ST23 04 Ad0Document9 pagesTVL ST23 04 Ad0coulsonpfilNo ratings yet

- BT137Document7 pagesBT137Gabriel RacovskyNo ratings yet

- Act108w 600eDocument15 pagesAct108w 600eRogerioNo ratings yet

- Bta416y600c TriacDocument13 pagesBta416y600c Triacacodr83No ratings yet

- Stb35Nf10 Stp35Nf10: N-Channel 100V - 0.030 - 40A - D Pak/To-220 Low Gate Charge Stripfet™ Ii Power MosfetDocument14 pagesStb35Nf10 Stp35Nf10: N-Channel 100V - 0.030 - 40A - D Pak/To-220 Low Gate Charge Stripfet™ Ii Power MosfetRichardNo ratings yet

- SM10LZ47Document3 pagesSM10LZ47faraeinshirazi.1998No ratings yet

- WS1219PT W03010560aDocument6 pagesWS1219PT W03010560amimramesNo ratings yet

- Tde 3247Document15 pagesTde 3247Orlando HernandezNo ratings yet

- STP 10 NK 70 ZFPDocument13 pagesSTP 10 NK 70 ZFPOsama Bin AtaNo ratings yet

- Media 3323329Document6 pagesMedia 3323329Daniel MesiNo ratings yet

- Stp8Nc50 - Stp8Nc50Fp Stb8Nc50-1: N-Channel 500V - 0.7 - 8A To-220/To-220Fp/I2Pak Powermesh Ii MosfetDocument11 pagesStp8Nc50 - Stp8Nc50Fp Stb8Nc50-1: N-Channel 500V - 0.7 - 8A To-220/To-220Fp/I2Pak Powermesh Ii MosfetAbraham Esteban DominguezNo ratings yet

- IGBTDocument13 pagesIGBTEddy SanchezNo ratings yet

- WILLSEMI Will Semicon ESD5311N 2 TR - C153721 PDFDocument5 pagesWILLSEMI Will Semicon ESD5311N 2 TR - C153721 PDFPippoNo ratings yet

- BTA416Y-800BDocument12 pagesBTA416Y-800BmrgpaezNo ratings yet

- BT137 Series: 8A TriacDocument4 pagesBT137 Series: 8A TriacRenso RodriguezNo ratings yet

- Data SheetDocument10 pagesData SheetRaphael Silveira de SouzaNo ratings yet

- BTA204S-600E: 1. General DescriptionDocument13 pagesBTA204S-600E: 1. General DescriptionNoe SaantNo ratings yet

- Stp5Nk80Z Stp5Nk80Zfp: N-Channel 800V - 1.9 - 4.3A - To-220/To-220Fp Zener-Protected Supermesh™ Power MosfetDocument15 pagesStp5Nk80Z Stp5Nk80Zfp: N-Channel 800V - 1.9 - 4.3A - To-220/To-220Fp Zener-Protected Supermesh™ Power MosfetMarcilio AlmeidaNo ratings yet

- SGT40N60FD2PN enDocument9 pagesSGT40N60FD2PN enJeferson TarsoNo ratings yet

- Rectifier Diodes BYQ30E, BYQ30EB, BYQ30ED Series Ultrafast, RuggedDocument8 pagesRectifier Diodes BYQ30E, BYQ30EB, BYQ30ED Series Ultrafast, RuggedJose M PeresNo ratings yet

- Rectifier Diodes BYQ30E, BYQ30EB, BYQ30ED Series Ultrafast, RuggedDocument8 pagesRectifier Diodes BYQ30E, BYQ30EB, BYQ30ED Series Ultrafast, RuggedingucvNo ratings yet

- Standard TriacDocument4 pagesStandard TriacHector Alberto SanchezNo ratings yet

- Sic Power Module: Bsm300D12P2E001Document10 pagesSic Power Module: Bsm300D12P2E001doggaravi07No ratings yet

- A Dictionary of Electronics and Electrical Engineering 2018Document1,087 pagesA Dictionary of Electronics and Electrical Engineering 2018Prince Danda100% (1)

- Automated Low Voltage Differential Signaling LVDS App-Note-48W-61639-0Document9 pagesAutomated Low Voltage Differential Signaling LVDS App-Note-48W-61639-0hadiNo ratings yet

- Ex Certificate IECEXDEK120070X 001 00 PDFDocument11 pagesEx Certificate IECEXDEK120070X 001 00 PDFhadiNo ratings yet

- Topics 1 3 Family Education Work IELTS Speaking PDF PDFDocument51 pagesTopics 1 3 Family Education Work IELTS Speaking PDF PDFhannah faith100% (1)

- Handout Exercise Inter Usedtobe Usedto Getusedto PDFDocument3 pagesHandout Exercise Inter Usedtobe Usedto Getusedto PDFhadiNo ratings yet

- 26681p020 Navtex - Nav-5 PDFDocument2 pages26681p020 Navtex - Nav-5 PDFdityoz1288No ratings yet

- User Manual: Version 4.3 - June 2021Document146 pagesUser Manual: Version 4.3 - June 2021Arunkumar KNo ratings yet

- Huawei DBS3900 Commissioning MOP - V1 - 2 20090515Document30 pagesHuawei DBS3900 Commissioning MOP - V1 - 2 20090515yetunde77100% (5)

- A SIEM Solution Implementation: TEK-UP UniversityDocument39 pagesA SIEM Solution Implementation: TEK-UP UniversityKaisSlimeniNo ratings yet

- A Machine Learning Approach For Air Writing RecognitionDocument10 pagesA Machine Learning Approach For Air Writing RecognitionIJRASETPublicationsNo ratings yet

- Uah 2018 PDR PresentationDocument84 pagesUah 2018 PDR PresentationAdarshNo ratings yet

- Dibaj Azhar Nano AssignmentDocument4 pagesDibaj Azhar Nano Assignmentdiba azharNo ratings yet

- Objective: 2.1 Approach - Defining The RequirementsDocument2 pagesObjective: 2.1 Approach - Defining The RequirementsprasjainNo ratings yet

- Cisco SIEM Deployment GuideDocument19 pagesCisco SIEM Deployment GuideShruthi Kavya KNo ratings yet

- Jason HartDocument19 pagesJason HartRajvardhan JaidevaNo ratings yet

- Sonifier SFX250 and SFX550 Cell Disruptors and HomogenizersDocument6 pagesSonifier SFX250 and SFX550 Cell Disruptors and HomogenizersAlison AlcarazNo ratings yet

- 360 Modena ECU Error CodesDocument21 pages360 Modena ECU Error CodesDamien Jorgensen100% (2)

- Technical Overview On AHUDocument12 pagesTechnical Overview On AHUJahidul IslamNo ratings yet

- Finite State Machine Implementation: Prith Banerjee Ece C03 Advanced Digital Design Spring 1998Document31 pagesFinite State Machine Implementation: Prith Banerjee Ece C03 Advanced Digital Design Spring 1998Hemant SaraswatNo ratings yet

- Certificate: of ConformityDocument3 pagesCertificate: of ConformityGerson SouzaNo ratings yet

- G. P. Gaya: Lecture Notes On Modern Techniques of Material Management:Jit/Sap/ErpDocument13 pagesG. P. Gaya: Lecture Notes On Modern Techniques of Material Management:Jit/Sap/ErpMurugan MNo ratings yet

- VP-540i Intialize The LimitDocument2 pagesVP-540i Intialize The LimitEzawaliNo ratings yet

- MXTDocument18 pagesMXTMaxey HigginbothamNo ratings yet

- CHPC Transfer Switch Closed Transition: Description FeaturesDocument9 pagesCHPC Transfer Switch Closed Transition: Description FeaturesBNo ratings yet

- Visual Basic For Applications Netcomm Serial Port Software ExampleDocument8 pagesVisual Basic For Applications Netcomm Serial Port Software ExampleMaria MartinNo ratings yet

- Institute of Engineering & Technology, AlwarDocument5 pagesInstitute of Engineering & Technology, AlwarsidearthmanNo ratings yet

- The Impact of Information and Communication Technologies On The Human Development in The Gulf Cooperation Council Countries: An Empirical StudyDocument35 pagesThe Impact of Information and Communication Technologies On The Human Development in The Gulf Cooperation Council Countries: An Empirical StudyGuivis ZeufackNo ratings yet

- Irjet V6i492Document5 pagesIrjet V6i492GunawanNo ratings yet

- Edited Research ProposalDocument4 pagesEdited Research Proposalal_badwiNo ratings yet

- Light and Lighting - Lighting of Work Places - Part 1: Indoor Work PlacesDocument9 pagesLight and Lighting - Lighting of Work Places - Part 1: Indoor Work Placesrakib.techlinkNo ratings yet

- Mobility-Online: User Guide For Degree StudentsDocument7 pagesMobility-Online: User Guide For Degree StudentsNurdin HefniNo ratings yet

- Types of Residual Current Devices (RCD)Document3 pagesTypes of Residual Current Devices (RCD)job_pNo ratings yet

- Spectrum AnalayzerDocument8 pagesSpectrum Analayzerعقود السمNo ratings yet

- Fixture Inspection ReportDocument1 pageFixture Inspection ReportAvinash Mulik100% (1)

- Safety Selfie Game EditableDocument1 pageSafety Selfie Game Editableheri suyantoNo ratings yet