Professional Documents

Culture Documents

CAM - QP Set

Uploaded by

naga sathvikCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CAM - QP Set

Uploaded by

naga sathvikCopyright:

Available Formats

I of Mechanical Engineering

IV B.I Q•ch.I Seinester. MID <emester Examination

Cojnputer Aided Manufacturing

Date: 28-09-2022 I 3 to 5 PM Max. Marks.' 3()

,VOle.•Anssser all questions.

While anssseling, clearly jnention the question nurnber on the left-hand side MARGIN.

Provide Nj;.A'j' SK IA CtlIL'S vsherever possible.

Maintain NEA"I'and CLEAR hand writing.

I What are the applications where numerical control is most suitable'? [51

What is adaptive control optimisation? I low is it used in CNC machines? [51

6) I low does a linear electric motor work? Mention its advantages. [51

4 What are the requiretnents Corusing ceramics in machining? [51

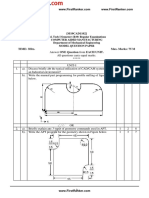

5 Prepare process plan and write complete part program for the following part using the ISO [101

codes, Choose the datum as the centre of the bottom left-hand hole.

Drill Ø 5 mm thru

and tap M6

12.

(3) holes

R40

R52.

450 12

fi12,5

16

Drill Ø5 mm thru g SECTION A-A

counterbore 8 x 10 mm deep

NATIONAL INSTITUTE OF TECHNOLOGY WARANGAL

Deparuncnt of Mechanical Engineering

IV B.Tech, I Semester, End Semester Examination

ME402 Computer Aided Manufacturing

Date: os-12-2022 Time: 2.30 to 5.30 PM Max. Marks: 50

Provide NEAT SKETCHES wherever applicable

Draw a neat figure of SCARA robot. Write any two applications of it. [21

Write any four limitations of group technology. [21

Differentiate production and mix flexibilities related to FMS. [2]

How does touch trigger probe work? Draw neat figure. [21

(e)Ä Draw a neat figure of CIM wheel. [21

2 (a) Explain principle of absolute and incremental optical encoders with neat figures. [41

(b) How are axes designated for horizontal and vertical CNC machines? [41

151-4—

3 For the component shown, make a part program

on a machiningcentre equipped with an ISO

standard controller. Clearly show the set point

and axes on the sketch of the part. Also, prepare

—60100 Tools used

the planning sheet as used in the laboratory. I Centre drill

2 Twistdrill mm

2 Twist drill ØIO mm

3 Slot drill øto

55

4 For the component shown, develop complete [81

part program using the APT language. R25

8

150

8200

R12i

8 RI o;

R15

70 150

Tool: slot drill Ø16 mm

milling depth: 6 mm

Parts

5 Apply the rank-order clustering technique to the

part-machineincidence matrix in the following Madlines A B c D E F G H

1

table to identify logical part families and 2 1

machinegroups. 3

4 1 1

5 1

6

7

8

6 Explain the working principles of following additive manufacturingprocesses with the help of neat

sketches. Also mention their applications.

(a) Selective laser melting

(b) Fused deposition modeling

You might also like

- Token Ring Technology ReportFrom EverandToken Ring Technology ReportNo ratings yet

- CAM LAB MANUALl - 2171903 - ODD SEM-2019 PDFDocument14 pagesCAM LAB MANUALl - 2171903 - ODD SEM-2019 PDFMeet PatelNo ratings yet

- CAM Dip CAT July 2021Document3 pagesCAM Dip CAT July 2021MARSDEN RONNYNo ratings yet

- NX CAM Post Processing Errors Machine Data File Ge PDFDocument7 pagesNX CAM Post Processing Errors Machine Data File Ge PDFSHARAD CHANDRANo ratings yet

- NX CAM Errors Machine DataDocument7 pagesNX CAM Errors Machine DataRamNo ratings yet

- Mechanical, B.Tech-4 Year (7 Sem) (Pre University Test), 2017-2018 Computer Aided Manufacturing (NME-031)Document2 pagesMechanical, B.Tech-4 Year (7 Sem) (Pre University Test), 2017-2018 Computer Aided Manufacturing (NME-031)chandra shekharNo ratings yet

- Setup & Development of 5-Axis CNC Machining CenterDocument10 pagesSetup & Development of 5-Axis CNC Machining CenterShane MurrayNo ratings yet

- Scanner Option A844 Parts Location and ListDocument15 pagesScanner Option A844 Parts Location and Listtecni suNo ratings yet

- Me6611-Cad Cam LabDocument71 pagesMe6611-Cad Cam Labl8o8r8d8s8i8v8No ratings yet

- MVGR College Mechanical Engineering Lab ExamDocument6 pagesMVGR College Mechanical Engineering Lab ExamVamsi KrishnaNo ratings yet

- Manufacturing Technology II Exam QuestionsDocument3 pagesManufacturing Technology II Exam QuestionscbeprabhugmailNo ratings yet

- Project Progress Seminar Phase 2: To Design CNC Machine For PCB MillingDocument23 pagesProject Progress Seminar Phase 2: To Design CNC Machine For PCB Millingantariksh mendheNo ratings yet

- Phaser 7100Document40 pagesPhaser 7100luterocoruna8342No ratings yet

- 08 SzivkovicDocument6 pages08 SzivkovicbuttercupniceNo ratings yet

- V. S. B Engineering College CAD/CAM Lab ManualDocument121 pagesV. S. B Engineering College CAD/CAM Lab ManualvinodkumarNo ratings yet

- Service Bulletin: Office Imaging Products Device Quality Assurance CenterDocument4 pagesService Bulletin: Office Imaging Products Device Quality Assurance Centercopiadoras manuelNo ratings yet

- LG-6001 Lead Gage: Operation ManualDocument24 pagesLG-6001 Lead Gage: Operation ManualSukumarNo ratings yet

- MET385 - Ktu QbankDocument7 pagesMET385 - Ktu Qbankmohammedmaz0786No ratings yet

- 6 V May 2018Document12 pages6 V May 2018A 60 Rohan bansiyarNo ratings yet

- 1412 Motoman mh5 Robot Adatlap PDFDocument2 pages1412 Motoman mh5 Robot Adatlap PDFAlbeiro Zambrano CruzNo ratings yet

- ED7111Document117 pagesED7111palaniappan_pandianNo ratings yet

- 22565-2019-Winter-Model-Answer-Paper (Msbte Study Resources)Document14 pages22565-2019-Winter-Model-Answer-Paper (Msbte Study Resources)Shivraj KolambekarNo ratings yet

- 3 Hours / 100 Marks: Seat NoDocument26 pages3 Hours / 100 Marks: Seat NoPandit BarelaNo ratings yet

- Mee 210-Ipe 210.Document2 pagesMee 210-Ipe 210.dreamivory29No ratings yet

- EAO MC 61 Main-Catalogue En-469531Document104 pagesEAO MC 61 Main-Catalogue En-469531Saheer AmbadanNo ratings yet

- 71 Bosnjakovic Selir CIM2015 Article OKDocument6 pages71 Bosnjakovic Selir CIM2015 Article OKmladbos6065No ratings yet

- Installation InstructionsDocument4 pagesInstallation InstructionsPRESS-NEW-BALKANNo ratings yet

- Always Committed Quality Tech InnovationDocument59 pagesAlways Committed Quality Tech Innovationfarid said errahmani50% (2)

- CSEC Technical Drawing June 2005 P032Document8 pagesCSEC Technical Drawing June 2005 P032Patrick ClarkeNo ratings yet

- Cad Cam - 22.12.15-1 PDFDocument87 pagesCad Cam - 22.12.15-1 PDFGuru MaheshNo ratings yet

- Optimization of CNC MachiningDocument3 pagesOptimization of CNC MachiningVIVA-TECH IJRINo ratings yet

- Report Cam (Edited)Document13 pagesReport Cam (Edited)anisshwaranNo ratings yet

- Seco Thread Turning BrochureDocument24 pagesSeco Thread Turning BrochurecestahlNo ratings yet

- HMI Components for Shipbuilding and Panel BuildingDocument26 pagesHMI Components for Shipbuilding and Panel BuildingSebastián RomeroNo ratings yet

- Sri Ganesh Engg - ProfileDocument19 pagesSri Ganesh Engg - Profileshikharc100% (1)

- Dr. JNMGP Amreli Cam Termwork Jan-April 2016 (Gtu) : Exp. No-1 Study of Construction Features of NC/CNC MachineDocument2 pagesDr. JNMGP Amreli Cam Termwork Jan-April 2016 (Gtu) : Exp. No-1 Study of Construction Features of NC/CNC MachineDhaval UpadhyayNo ratings yet

- Kongu Engineering College: 11me507 Cad/Cam LaboratoryDocument46 pagesKongu Engineering College: 11me507 Cad/Cam LaboratoryVignesh KumarNo ratings yet

- V2i2 Ijertv2is2330Document5 pagesV2i2 Ijertv2is2330abdollahzadehNo ratings yet

- CNC TURNING MachineDocument14 pagesCNC TURNING MachineFaiz AhmedNo ratings yet

- Objective: Surface Mount Technology by Aimal Khan AchakzaiDocument5 pagesObjective: Surface Mount Technology by Aimal Khan AchakzaiwasiNo ratings yet

- Machine Drawing With CAD Lab - MAE204Document100 pagesMachine Drawing With CAD Lab - MAE204Rohit KaushikNo ratings yet

- VideoJet Excel 170i Illustrated Parts BreakdownDocument51 pagesVideoJet Excel 170i Illustrated Parts Breakdownmacaco logo100% (1)

- B446Document55 pagesB446sitaramsahandsonsNo ratings yet

- CNC Milling Center Training Purposes Concept MILL 55Document4 pagesCNC Milling Center Training Purposes Concept MILL 55Mez NacerNo ratings yet

- R5410302 CadcamDocument1 pageR5410302 CadcamsivabharathamurthyNo ratings yet

- Fabrication in Trichy Helicoidal Screw Fabrication in Trichy Factory Helicoidal Screw Fabrication in Trichy FactoryDocument10 pagesFabrication in Trichy Helicoidal Screw Fabrication in Trichy Factory Helicoidal Screw Fabrication in Trichy Factoryवैभव धुरीNo ratings yet

- Design and Fabrication of Spur Gear Cutting Attachment For Lathe MachineDocument10 pagesDesign and Fabrication of Spur Gear Cutting Attachment For Lathe MachineIJRASETPublicationsNo ratings yet

- Lab 3 (Virtual) : NtroductionDocument13 pagesLab 3 (Virtual) : NtroductionJibran AhmedNo ratings yet

- Calculating The Workpiece Quality Using A Hobbing SimulationDocument5 pagesCalculating The Workpiece Quality Using A Hobbing SimulationthisisjineshNo ratings yet

- CIM LAB Manual-1 PDFDocument40 pagesCIM LAB Manual-1 PDFgagan100% (1)

- GMO 0313 CONV MillingDocument66 pagesGMO 0313 CONV MillinghudarusliNo ratings yet

- Cad-Cam Lab ManualDocument41 pagesCad-Cam Lab ManualAnonymous CFkk91INo ratings yet

- Sams ComputerFacts - Apple II, II PlusDocument66 pagesSams ComputerFacts - Apple II, II PlusOscar Arthur KoepkeNo ratings yet

- CNC ADC _QUESTION BANKDocument6 pagesCNC ADC _QUESTION BANKpala srinivas reddyNo ratings yet

- I Year Manual BookDocument69 pagesI Year Manual BookBalram RajputNo ratings yet

- Computer Integrated ManufacturingDocument10 pagesComputer Integrated ManufacturingnayayathNo ratings yet

- (M19CAD1102) I M. Tech I Semester (R19) Regular ExaminationsDocument2 pages(M19CAD1102) I M. Tech I Semester (R19) Regular Examinationsraja raoNo ratings yet

- AMP-Winter-question-paper (Msbte Study Resources) PDFDocument3 pagesAMP-Winter-question-paper (Msbte Study Resources) PDFVarad DateNo ratings yet

- 3 Hours / 70 Marks: Seat NoDocument4 pages3 Hours / 70 Marks: Seat Noakashdhurde2880No ratings yet

- Just-in-Time and Lean Production Systems: Professor AhmadiDocument29 pagesJust-in-Time and Lean Production Systems: Professor AhmadiawaisjinnahNo ratings yet

- Food DirectoryDocument20 pagesFood Directoryyugam kakaNo ratings yet

- Compounding Pharmacy Information SheetDocument2 pagesCompounding Pharmacy Information SheetSatish HiremathNo ratings yet

- HYBRIFLEX® RRH Hybrid Cable Solution 12 X 24, 6AWG, Low-Inductance, Single-Mode Fiber, DLC Connectors Top and Bottom, 240 FTDocument3 pagesHYBRIFLEX® RRH Hybrid Cable Solution 12 X 24, 6AWG, Low-Inductance, Single-Mode Fiber, DLC Connectors Top and Bottom, 240 FTNoame Pauline SimbajonNo ratings yet

- Energy Conversion and Management: Gvidonas Labeckas, Stasys Slavinskas, Irena KanapkieneDocument25 pagesEnergy Conversion and Management: Gvidonas Labeckas, Stasys Slavinskas, Irena KanapkieneVỵ ĐặngNo ratings yet

- (MT 6322 - MYCO VIRO LAB) Unit 7 Laboratory Diagnosis For Negative-Sense (-) ssRNA VirusesDocument15 pages(MT 6322 - MYCO VIRO LAB) Unit 7 Laboratory Diagnosis For Negative-Sense (-) ssRNA VirusesAbbas MaghazehiNo ratings yet

- Mind Map AvalanchesDocument3 pagesMind Map AvalanchescgmaliaNo ratings yet

- Mktech PDFDocument7 pagesMktech PDFAlexander WieseNo ratings yet

- Occupation Certificate DocumentsDocument1 pageOccupation Certificate Documentsarungupta366No ratings yet

- NCERT Solutions For Class 8 Science Chapter 6Document4 pagesNCERT Solutions For Class 8 Science Chapter 6D Rong saNo ratings yet

- EC538 LTspice IntroDocument10 pagesEC538 LTspice IntroTeferi LemmaNo ratings yet

- Hepatitis - Seminary WorkDocument15 pagesHepatitis - Seminary WorkDraganaNo ratings yet

- Noun Form Answers PDFDocument11 pagesNoun Form Answers PDFChinna LingamNo ratings yet

- Acoustic Design For Call CenterDocument16 pagesAcoustic Design For Call CenteraliNo ratings yet

- Creating A 3D-Map Using Reference Points: Cfr-19-Stm-CanadasatDocument14 pagesCreating A 3D-Map Using Reference Points: Cfr-19-Stm-Canadasattuguldur bayaraaNo ratings yet

- An Example of A HypothesisDocument2 pagesAn Example of A HypothesisAjibade TaofikNo ratings yet

- OL Lect 9 Seismic Acquisition NewDocument106 pagesOL Lect 9 Seismic Acquisition NewMohammad BilalNo ratings yet

- Mine Pool AtlasDocument172 pagesMine Pool AtlasRishiraj SahooNo ratings yet

- (Elsevier) The Influence of Circumferential Weld-Induced Imperfections On The Buckling of Silos ADocument12 pages(Elsevier) The Influence of Circumferential Weld-Induced Imperfections On The Buckling of Silos AMateo PaladinoNo ratings yet

- An Overview of Muga and Eri Silk Industry in The North Eastern Region of India: An Empirical Study Dr. Jatindra Nath SaikiaDocument11 pagesAn Overview of Muga and Eri Silk Industry in The North Eastern Region of India: An Empirical Study Dr. Jatindra Nath Saikiajatin_saikiaNo ratings yet

- "Fragile" - StingDocument4 pages"Fragile" - StingFabián ReinosoNo ratings yet

- Manifest Guide Ebook PDFDocument4 pagesManifest Guide Ebook PDFAnonymous dqCHWEADzNo ratings yet

- SR-21 SniperDocument6 pagesSR-21 SniperBaba HeadquaterNo ratings yet

- Ashok M.tech CompleteDocument65 pagesAshok M.tech CompleteAshok BhatiaNo ratings yet

- Chiller Maintenance Service 2015Document29 pagesChiller Maintenance Service 2015Huong Ban MaiNo ratings yet

- Learning Activity Sheet In: Computer Systems ServicingDocument12 pagesLearning Activity Sheet In: Computer Systems ServicingCarvalds 0315No ratings yet

- Easytronic Micro II 28 05 2010 08 35 20 Revision 05 Controller 1 PDFDocument10 pagesEasytronic Micro II 28 05 2010 08 35 20 Revision 05 Controller 1 PDFСергей Заика100% (1)

- PM TB Solutions C03Document5 pagesPM TB Solutions C03Vishwajeet Ujhoodha100% (5)

- 00 - Orientation LessonDocument32 pages00 - Orientation LessonRekha ShahNo ratings yet

- Site Mobilisation ManagementDocument12 pagesSite Mobilisation ManagementmizaNo ratings yet