Professional Documents

Culture Documents

F6198 CMM 011

Uploaded by

airbusa420Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

F6198 CMM 011

Uploaded by

airbusa420Copyright:

Available Formats

COMPONENT MAINTENANCE MANUAL

COCKPIT AMPLIFIER LOUDSPEAKER

TRANSMITTAL SHEET

TO: HOLDERS of COMPONENT MAINTENANCE MANUAL for COCKPIT AMPLIFIER

LOUDSPEAKER (ATA 31-53-22) Revision No. 11 dated Sep 25/20 is attached and covers

all components held by every operator.

FILING INSTRUCTIONS

- Affected pages are listed on the LIST OF EFFECTIVE PAGES and designated as follows:

N = New (to be incorporated)

R = Revised (to be replaced)

D = Deleted (to be removed)

- Make certain that the content of the manual agrees with the LIST OF EFFECTIVE PAGES.

- Update the RECORD OF REVISIONS page accordingly.

- File the TRANSMITTAL SHEET separately.

- Remove and destroy the pages that are affected by this revision.

FILING INSTRUCTIONS

The attached HIGHLIGHTS describe the changes.

TS

Page 1

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

COCKPIT AMPLIFIER LOUDSPEAKER

PAGE INTENTIONALLY LEFT BLANK

TS

Page 2

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

COCKPIT AMPLIFIER LOUDSPEAKER

TO: HOLDERS of COMPONENT MAINTENANCE MANUAL for COCKPIT AMPLIFIER

LOUDSPEAKER (ATA 31-53-22).

HIGHLIGHTS

Revision No. 11 - Sep 25/20

The HIGHLIGHTS of the revision are:

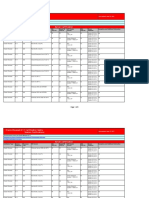

TITLE PG MVT REASON FOR CHANGE

Title Page 1 R Revised to reflect this revision

SERVICE BULLETIN LIST 1 R SB List updated

LIST OF EFFECTIVE PAGES 1 R Revised to reflect this revision.

TABLE OF CONTENTS 1 R Revised to reflect this revision.

INTRODUCTION

TASK 31-53-22-871-801-A01 INTRO 1 R Introduction updated Table

TASK 31-53-22-879-803-A01 INTRO 10 R paragraph D deleted

TASK 31-53-22-879-804-A01 INTRO 17 R Symbols and conversion updated

TASK 31-53-22-871-802-A01 INTRO 20 Abbreviations added

DESCRIPTION AND OPERATION

TASK 31-53-22-872-802-A01 3 R Description updated

Graphic 31-53-22-991-024-A01 7 N Figure added

TESTING AND FAULT

ISOLATION

TASK 31-53-22-700-802-A01 1002 D Task deleted

DISASSEMBLY

TASK 31-53-22-000-801-A01 3001 R Procedure updated

TASK 31-53-22-000-802-A01 3003 R Procedure updated

TASK 31-53-22-000-803-A01 3005 R Procedure updated

Graphic 31-53-22-991-023-A01 3007 R Figure updated

HIGHLIGHTS

Page 1 of 4

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

COCKPIT AMPLIFIER LOUDSPEAKER

TO: HOLDERS of COMPONENT MAINTENANCE MANUAL for COCKPIT AMPLIFIER

LOUDSPEAKER (ATA 31-53-22).

HIGHLIGHTS

Revision No. 11 - Sep 25/20

TITLE PG MVT REASON FOR CHANGE

CLEANING

TASK 31-53-22-100-801-A01 4001 R Procedure updated

REPAIR

TASK 31-53-22-300-801-A01 6002 R Procedure updated

TASK 31-53-22-300-802-A01 6005 R Procedure updated

TASK 31-53-22-300-803-A01 6007 R Procedure updated

TASK 31-53-22-300-805-A01 6010 R Procedure updated

TASK 31-53-22-300-806-A01 6014 R Procedure updated

TASK 31-53-22-300-807-A01 6018 R Procedure updated

SUBTASK 31-53-22-350-015-A01 6019 R Procedure updated

ASSEMBLY

TASK 31-53-22-400-801-A01 7001 R Procedure updated

TASK 31-53-22-400-802-A01 7003 R Procedure updated

TASK 31-53-22-400-803-A01 7007 R Procedure updated

TASK 31-53-22-400-804-A01 7011 R Procedure updated

TASK 31-53-22-400-805-A01 7013 R Procedure updated

TASK 31-53-22-400-806-A01 7015 R Procedure updated

TASK 31-53-22-400-807-A01 7017 R Procedure updated

FITS AND CLEARANCES

TASK 31-53-22-940-802-A01 8001 N Torque value table added

HIGHLIGHTS

Page 2 of 4

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

COCKPIT AMPLIFIER LOUDSPEAKER

TO: HOLDERS of COMPONENT MAINTENANCE MANUAL for COCKPIT AMPLIFIER

LOUDSPEAKER (ATA 31-53-22).

HIGHLIGHTS

Revision No. 11 - Sep 25/20

TITLE PG MVT REASON FOR CHANGE

SPECIAL TOOLS, FIXTURES,

EQUIPMENT AND CONSUM-

ABLES

TASK 31-53-22-940-801-A01 9001 R Consumable list updated

SPECIAL PROCEDURES

TASK 31-53-22-300-809-A01 11002 R Procedure updated

TASK 31-53-22-860-801-A01 11003 N Procedure added

STORAGE

TASK 31-53-22-550-801-A01 15001 R Procedure updated

SUBTASK 31-53-22-550-001-A01 15001 D Procedure deleted

ILLUSTRATED PART LIST

TASK 31-53-22-871-803-A01 INTRO IPL 1 R Introduction updated

TASK 31-53-22-871-804-A01 INTRO IPL 4 R Introduction updated

TASK 31-53-22-879-805-A01 INTRO IPL 9 R Introduction updated

DETAILED PARTS LIST

Figure 01 10001-0 R Figure and part list updated

Figure 03 10003-0 R Figure and part list updated

Figure 04 10004-0 R Part list updated

HIGHLIGHTS

Page 3 of 4

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

COCKPIT AMPLIFIER LOUDSPEAKER

PAGE INTENTIONALLY LEFT BLANK

HIGHLIGHTS

Page 4 of 4

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

COCKPIT AMPLIFIER LOUDSPEAKER

LIST OF TEMPORARY REVISIONS

The Temporary Revisions which follow have been included in the revision dated Sep 25/20 and

must be removed and discarded.

Update the RECORD OF TEMPORARY REVISIONS page.

TR No.: 31-091

All Temporary Revisions dated from Aug 25/20 onwards must be kept unless the Highlights of a

revision or the issue of a Temporary Revision which replaces it, tells you differently.

The Temporary Revisions which follow remain effective after the revision dated Sep 25/20

is added.

TR No.: None

** End of List **

TRL

Page 1

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

COCKPIT AMPLIFIER LOUDSPEAKER

PAGE INTENTIONALLY LEFT BLANK

TRL

Page 2

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

F6198

COMPONENT MAINTENANCE MANUAL

WITH

ILLUSTRATED PART LIST

COCKPIT AMPLIFIER LOUDSPEAKER

CMM 31-53-22

Revision No. 11 - Sep 25/20

This document and all information contained herein is the sole property of AIRBUS OPERATIONS S.A.S.

No intellectual property rights are granted by the delivery of this document or the disclosure of its content.

This document shall not be reproduced or disclosed to a third party without the express written consent of

AIRBUS OPERATIONS S.A.S.

This document and its content shall not be used for any purpose other than that for which it is supplied.

The statements made herein do not constitute an offer. They are based on the mentionned assumptions and are

expressed in good faith.

Where the supporting grounds for these statements are not shown, AIRBUS OPERATIONS S.A.S. will be pleased

to explain the basis thereof.

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

License for SPRING AIRLINES only

F6198

COMPONENT MAINTENANCE MANUAL

WITH

ILLUSTRATED PARTS LIST

COCKPIT AMPLIFIER LOUDSPEAKER

PNR:

35-0D5-1002

35-0D5-1003

TP

Revision No.: 11 Page 1

Issue: Sep 30/87 31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

COCKPIT AMPLIFIER LOUDSPEAKER

PAGE INTENTIONALLY LEFT BLANK

TP

Revision No.: 11 Page 2

Issue: Sep 30/87 31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

RECORD OF REVISIONS

REV ISSUE INSERTED REV ISSUE INSERTED

No. DATE DATE BY No. DATE DATE BY

ROR

Page 1

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 30/87

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

PAGE INTENTIONALLY LEFT BLANK

ROR

Page 2

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 30/87

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

RECORD OF TEMPORARY REVISIONS

TEMP INSERTED REMOVED

ISSUE PAGE No.

REV.

DATE DATE BY DATE BY

No.

RTR

Page 1

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 30/87

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

PAGE INTENTIONALLY LEFT BLANK

RTR

Page 2

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 30/87

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

LIST OF SERVICE BULLETINS

The SB List reflects the incorporation status of Service Bulletins edited by AIRBUS OPERATIONS

S.A.S. - AVIONICS AND SIMULATION PRODUCTS (Vendor Code F6198).

The SB List has the following five columns to indicate SBs and their status :

** SB number (SB No.) **

This is the number of the SB.

If no SB affects the manual content, the comment None is given.

** Revision number (Rev No.) **

This is the revision number of the SB.

** Modification number (MOD. No.) **

This is the modification number of the unit.

** Incorporation date (INCORP. DATE) **

SB status or incorporation date is indicated in this column as follow:

If the SB is fully incorporated into the manual, the incorporation date is indicated.

If the SB is partially incorporated into the manual, the field is left blank.

If the SB data does not affect the manual content, the comment NO EFFECT is given.

** Title **

This is the title of the SB.

NOTE: The Service Information Letters (SIL) which affect the manual content are listed at the

end of the table.

SBL

Page 1

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

LIST OF SERVICE BULLETINS (Cont'd)

INCORP.

SB No. Rev No. MOD. No. TITLE

DATE

35-0D5-31-001 FEE0D5-001 Sep 30/90 Evolution to Amdt A

35-0D5-31-002 FEE0D5-002 Jul 30/92 From 35-0D5-1002 to 35-0D5-1003

35-0D5-31-003 FEE0D5-003 Nov 15/93 Evolution to Amdt B (New box)

35-0D5-31-004 FEE0D5-004 Jun 03/04 Evolution to Amdt D (New spacer

loudspeaker)

List of SILs:

F6198-00-013 None Jun 03/04 Recommended Repair Facilities

F6198-00-018 None Sep 25/20 Equivalent PNR for components

SBL

Page 2

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

LIST OF EFFECTIVE PAGES

SUBJECT PAGE DATE

TITLE PAGE 1/1 R Sep 25/20

RECORD OF REVISIONS 1/2 Sep 30/87

RECORD OF TEMPORARY REVISIONS 1/2 Sep 30/87

LIST OF SERVICE BULLETINS 1/2 R Sep 25/20

LIST OF EFFECTIVE PAGES 1/2 R Sep 25/20

TABLE OF CONTENTS 1/4 R Sep 25/20

LIST OF ILLUSTRATIONS 1/2 R Sep 25/20

INTRODUCTION 1/20 R Sep 25/20

DESCRIPTION AND OPERATION 1/24 R Sep 25/20

TESTING AND FAULT ISOLATION 1001/1012 R Sep 25/20

SCHEMATIC AND WIRING DIAGRAMS 2001/2004 Dec 09/11

DISASSEMBLY 3001/3012 R Sep 25/20

CLEANING 4001/4002 R Sep 25/20

CHECK 5001/5002 Dec 09/11

REPAIR 6001/6022 R Sep 25/20

ASSEMBLY 7001/7018 R Sep 25/20

FITS AND CLEARANCES 8001/8002 R Sep 25/20

SPECIAL TOOLS, FIXTURES,

EQUIPMENT AND CONSUMABLES 9001/9002 R Sep 25/20

SPECIAL PROCEDURES 11001/11004 R Sep 25/20

STORAGE 15001/15002 R Sep 25/20

LEP

Page 1

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

LIST OF EFFECTIVE PAGES (Continued)

SUBJECT PAGE DATE

ILLUSTRATED PARTS LIST TP 10001/10002 Sep 25/20

IPL INTRO 1/22 Sep 25/20

Vendor Code Identification 1/2 Sep 25/20

NUMERICAL/ALPHABETICAL INDEX 1/6 Sep 25/20

DETAILED PARTS LIST DPL 10001/10001 Sep 25/20

10001-01/10001-11 R Sep 25/20

10002-01/10002-5 R Sep 25/20

10003-01/10003-7 R Sep 25/20

10004-01/10004-1 R Sep 25/20

LEP

Page 2

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

TABLE OF CONTENTS

SUBJECT PAGE

INTRODUCTION .......................................................................

..................... INTRO 1

1. General .................................................................... .................... INTRO 1

A. Purpose of the manual ............................................. .................... INTRO 1

B. Correspondence .................................................... .................... INTRO 1

C. Manual breakdown arrangement ................................. .................... INTRO 2

D. Page block (PAGEBLOCK) assignment ......................... .................... INTRO 2

E. List of Recommended Repair Facilities .......................... .................... INTRO 5

2. General arrangement .................................................... .................... INTRO 6

A. Preliminary pages at the beginning of the CMM ............... .................... INTRO 6

B. Introduction (INTRO) structure .................................... .................... INTRO 6

C. Description and Operation (DO) structure ....................... .................... INTRO 7

D. Maintenance Procedure (MP) structure ......................... .................... INTRO 7

3. Maintenance Task Oriented Support System (MTOSS)

Task/Subtask numbering ................................................ .................. INTRO 10

A. General ............................................................... .................. INTRO 10

B. Structure of Task/Subtask numbers .............................. .................. INTRO 10

C. MTOSS function codes ............................................. .................. INTRO 12

4. Symbols and Definitions ................................................. .................. INTRO 17

A. Units and Measurement ............................................ .................. INTRO 17

B. Reference Designator Index (RDI) ............................... .................. INTRO 17

C. Definition of Terms .................................................. .................. INTRO 18

5. Glossary of Abbreviations ............................................... .................. INTRO 20

DESCRIPTION AND OPERATION .................................................. .............................. 1

1. General .................................................................... ............................. 1

A. System architecture ................................................ ............................. 1

2. Description ................................................................ ............................. 3

A. Presentation ......................................................... ............................. 3

B. Equipment ............................................................ ............................. 4

C. Characteristics ....................................................... ........................... 10

3. Operation .................................................................. ........................... 12

A. General ............................................................... ........................... 12

B. AMPLIFIER card .................................................... ........................... 14

TESTING AND FAULT ISOLATION................................................. ..........................1001

1. General .................................................................... .........................1001

2. Checking of the unit consumption ..................................... .........................1003

3. Test of the warning channels ........................................... .........................1004

4. Test of the AUDIO channel ............................................. .........................1007

5. Test of the loudspeaker .................................................. .........................1010

6. Test of output peak clipping (for P/N 35-0D5-1003 only) ........... ......................... 1011

TOC

Page 1

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

TABLE OF CONTENTS (Cont'd)

SUBJECT PAGE

SCHEMATIC AND WIRING DIAGRAMS........................................... ..........................2001

1. AMPLIFIER card ......................................................... .........................2001

DISASSEMBLY.........................................................................

..........................3001

1. Removal of the equipped card ......................................... .........................3001

2. Removal of the AMPLIFIER card ...................................... .........................3003

3. Removal of the rear face ................................................ .........................3005

4. Removal of the loudspeaker ............................................ .........................3007

5. Removal of the anti-vibrations seal .................................... .........................3009

6. Removal of the dust filter ................................................ .........................3010

7. Removal of the box ...................................................... ......................... 3011

CLEANING ..............................................................................

..........................4001

1. Cleaning ................................................................... .........................4001

CHECK...................................................................................

..........................5001

1. Visual inspection ......................................................... .........................5001

REPAIR ..................................................................................

..........................6001

1. Introduction ................................................................ .........................6001

2. Prepare the workstation ................................................. .........................6002

3. Removal of the protective varnish ..................................... .........................6005

4. Application of the protective varnish ................................... .........................6007

5. Replacement of a card or module ..................................... .........................6008

6. Replacement of a component with leads ............................. .........................6010

7. Replacement of a surface-mount component (SMC) ............... .........................6014

8. Replacement of a flat-pack, low-pitch SMC .......................... .........................6018

ASSEMBLY .............................................................................

..........................7001

1. Installation of the equipped card ....................................... .........................7001

2. Installation of the AMPLIFIER card .................................... .........................7003

3. Installation of the rear face .............................................. .........................7007

4. Installation of the loudspeaker ......................................... ......................... 7011

5. Installation of the anti-vibrations seal ................................. .........................7013

6. Installation of the dust filter ............................................. .........................7015

7. Installation of the box .................................................... .........................7017

FITS AND CLEARANCES............................................................

..........................8001

1. Torque Value Table ....................................................... .........................8001

SPECIAL TOOLS, FIXTURES, EQUIPMENT AND CONSUMABLES ........ ..........................9001

1. Consumable Materials ................................................... .........................9001

TOC

Page 2

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

TABLE OF CONTENTS (Cont'd)

SUBJECT PAGE

SPECIAL PROCEDURES ............................................................

........................ 11001

1. Supply card - Specific instructions ..................................... ....................... 11001

2. Replacement of screw type ............................................. ....................... 11002

3. Amplifier card – Specific instructions .................................. ....................... 11003

REMOVAL ...............................................................................

........ NOT APPLICABLE

INSTALLATION.........................................................................

........ NOT APPLICABLE

SERVICING .............................................................................

........ NOT APPLICABLE

STORAGE ...............................................................................

........................ 15001

1. Storage ..................................................................... ....................... 15001

REWORK (SERVICE BULLETIN ACCOMPLISHMENT PROCEDURES)

........

... NOT APPLICABLE

ILLUSTRATED PARTS LIST.........................................................

.................... TP 10001

INTRODUCTION .....................................................................

................ INTRO IPL 1

1. General .............................................................................. INTRO IPL 1

2. Detailed Parts List (DPL) ......................................................... INTRO IPL 4

3. How to use .......................................................................... INTRO IPL 9

4. Effectivity of cards and amendments ......................................... INTRO IPL 15

5. Equivalence table ................................................................ INTRO IPL 16

Vendor Code Identification .......................................................

......................... VCI 1

NUMERICAL/ALPHABETICAL INDEX ..........................................

................. NI/ALPHA 1

DETAILED PARTS LIST ............................................................

.................. DPL 10001

TOC

Page 3

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

PAGE INTENTIONALLY LEFT BLANK

TOC

Page 4

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

LIST OF ILLUSTRATIONS

FIGURE No. SUBJECT PAGE

DESCRIPTION AND OPERATION

1 System Organization (SHEET 1) 2

2 CAL - Dimensions (SHEET 1) 7

3 Amplifier card PNR 35-0D5-650 - Varnished

areas (SHEET 1) 8

(SHEET 2) 9

4 Connector P1 - Pin Location (SHEET 1) 10

5 CAL - Synoptic Diagram (SHEET 1) 13

6 Supply Circuit - Schematic Diagram (SHEET 1) 16

7 Warning Input Circuit - Schematic Diagram (SHEET 1) 17

8 Radio Signal Circuit - Schematic Diagram (SHEET 1) 18

9 Sum Circuit - Schematic Diagram (SHEET 1) 19

10 Amplifier Circuit - Schematic Diagram

35-0D5-450, -460, -550 (SHEET 1) 22

35-0D5-560, -650 (SHEET 2) 23

SCHEMATIC AND WIRING DIAGRAMS

2001 AMPLIFIER Card - Schematic Diagram

35-0D5-450, -460 (SHEET 1) 2002

35-0D5-550 (SHEET 2) 2003

35-0D5-560, -650 (SHEET 3) 2004

DISASSEMBLY

3001 CAL - Exploded View (SHEET 1) 3008

REPAIR

6001 Workstation Preparation (SHEET 1) 6004

ILLUSTRATED PARTS LIST

Introduction

1 Example - Detailed Parts List (SHEET 1) INTRO IPL 8

2 Breakdown of a Card or Module from its P/N (SHEET 1) INTRO IPL 10

3 Higher Assembly of a Card or Module from its (SHEET 1) INTRO IPL 11

P/N

4 Effectivity of a Card or Module from its P/N (SHEET 1) INTRO IPL 12

5 Designation of a Part from its P/N (SHEET 1) INTRO IPL 13

6 Name and Address of Vendor from a P/N (SHEET 1) INTRO IPL 14

LI

Page 1

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

LIST OF ILLUSTRATIONS (Cont'd)

FIGURE No. SUBJECT PAGE

DETAILED PARTS LIST

01 Cockpit Amplifier Loudspeaker

without Amendment D (SHEET 1) 10001-01

with Amendment D (SHEET 2) 10001-02

02 AMPLIFIER Card

AMPLIFIER 1A and 1B Cards (SHEET 1) 10002-01

AMPLIFIER 1C and 1D Cards (SHEET 2) 10002-02

03 AMPLIFIER Card

AMPLIFIER 2A, 2B and 2C Cards (SHEET 1) 10003-01

AMPLIFIER 2D and 2E Cards (SHEET 2) 10003-02

04 AMPLIFIER Card (SHEET 1) 10004-01

AMPLIFIER 3A AND 3B Cards

LI

Page 2

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

INTRODUCTION

TASK 31-53-22-871-801-A01

1. General

A. Purpose of the manual

The Component Maintenance Manual (CMM) conforms to ATA Specification

No. 2200.

The CMM provides shop verified procedures that will enable a mechanic to

restore the component to its serviceable condition in the overhaul shop.

The Abbreviated Component Maintenance Manual (ACMM) is a brief version

of the CMM, for simple components which require periodic maintenance and/or

testing.

The ACMM/CMM is prepared by the Manufacturer for each Repairable or

Overhaulable unit.

AIRBUS OPERATIONS S.A.S. Technical Publications use both metric and

non-metric system of measurement. The system used in the original reference

documents is quoted first, followed by the conversion into the other system

in brackets.

B. Correspondence

To place an order, please contact:

AIRBUS OPERATIONS S.A.S.

AVIONICS AND SIMULATION PRODUCTS

VENDOR CODE F6198

M8621 - 316, route de Bayonne

31060 TOULOUSE Cedex 09

France

Mailbox: systems.support@airbus.com

Website: https://w3.airbus.com/1T28/

For any information on the subject, please contact us through TechRequest tool:

https://w3.airbus.com/crs/TRM/ContentGadgets/index_nce.html

INTRO

Page 1

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

If no access to TechRequest tool, you can also contact us on our mailbox:

avionics.techsupport@airbus.com

C. Manual breakdown arrangement

The information contained in the CMM has been divided into three main

categories:

– Description and Operation (DO),

– Maintenance Procedure (MP),

– Illustrated Parts List (IPL).

The table below gives the various identifications under which the three types

of publications can be found.

D. Page block (PAGEBLOCK) assignment

PAGEBLOCK TYPE PAGEBLOCK PAGEBLOCK

NUMBER PAGINATION

INTRODUCTION 0 1-99

DESCRIPTION AN OPERATION 1 1-999

TESTING AND FAULT ISOLATION 1000 1001-1999

SCHEMATIC AND WIRING DIAGRAMS 2000 2001-2999

DISASSEMBLY 3000 3001-3999

CLEANING 4000 4001-4999

INSPECTION/CHECK 5000 5001-5999

REPAIR 6000 6001-6999

ASSEMBLY 7000 7001-7999

FITS AND CLEARANCES 8000 8001-8999

SPECIAL TOOLS, FIXTURES, EQUIPMENT AND

CONSUMABLES 9000 9001-9999

SPECIAL PROCEDURES 11000 11001-11999

REMOVAL 12000 12001-12999

INSTALLATION 13000 13001-13999

SERVICING 14000 14001-14999

INTRO

Page 2

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

PAGEBLOCK TYPE PAGEBLOCK PAGEBLOCK

NUMBER PAGINATION

STORAGE (including TRANSPORTATION) 15000 15001-15999

REWORK (Service Bulletin Accomplishment 16000 16001-16999

Procedures)

ILLUSTRATED PARTS LIST 10000 10001-10999

(1) Introduction

Explain the make up and the use of the CMM (DO and MP parts only).

For IPL part: see IPL INTRO (PAGEBLOCK 10000).

Include a listing of non standard abbreviations.

(2) Description and Operation

Give general overall information.

Give a mechanical and an electrical description.

Explain the configuration and the operation of the component.

(3) Testing and Fault Isolation

Contain specific tests and procedures required to determine the condition of a

component.

Include fault isolation.

(4) Schematic and Wiring Diagrams

Provide all schematic diagrams, wiring and interconnecting diagrams of

cards, chassis wiring, modules, subassemblies, and external connector

interconnnections within the component.

(5) Disassembly

Provide step-by-step disassembly instructions in a logical sequence (in order

of IPL item numbers), referencing figure item numbers from IPL illustration(s)

where applicable.

(6) Cleaning

INTRO

Page 3

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

Provide step-by-step description of the cleaning operations for the component

and its parts.

(7) Check

Provide the full check procedures that are necessary during shop maintenance.

(8) Repair

Contain detailed repair procedures and specifications necessary to put a worn or

damaged part to serviceable condition.

(9) Assembly

Provide step-by-step assembly instructions in a logical sequence, referencing

figure item numbers from IPL illustration(s) where applicable.

(10) Fits and Clearances

Provide torque tightening values.

(11) Special Tools, Fixtures, Equipment and Consumables

List all special tools, fixtures, equipment and consumables necessary for

completing any maintenance actions given in the other page blocks.

(12) Illustrated Parts List

Contain the complete list of all parts of the component (For detailed description

see IPL INTRO).

(13) Special Procedures

Contain the tasks which are not required elsewhere in the manual, but are

necessary as a result of other maintenance tasks.

Tasks are self-contained repairs or preventive maintenance.

(14) Removal

Not applicable.

(15) Installation

INTRO

Page 4

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

Not applicable.

(16) Servicing

Not applicable.

(17) Storage

Contain preparation for transportation, special handling, packaging, storage and

preservation requirements associated with the component after assembly or test.

(18) Rework

Not applicable.

E. List of Recommended Repair Facilities

(1) Refer to VSIL F6198-00-013.

INTRO

Page 5

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

TASK 31-53-22-879-802-A01

2. General arrangement

A. Preliminary pages at the beginning of the CMM

(1) Transmittal Sheet (TS)

List page numbers of the revised pages and a brief description of the revision

to affected pages.

Include insertion instruction for all supplied pages.

(2) Title Page (TP)

(3) Record of Revisions (ROR)

(4) Record of Temporary Revisions (RTR)

List the temporary revisions which shall be removed from the manual or which

remain still effective.

(5) List of Service Bulletins (LSB)

List the Service Bulletins and the Service Information Letters which are

applicable for the equipment.

(6) List of Effective Pages (LEP) (printed CMMs only)

List all effective pages for a given revision issue.

New pages are indicated by N, revised by R or deleted by D.

(7) Table of Contents (TOC)

List all major sub-divisions of each page block contained in the manual.

(8) List of Illustrations (LI)

List all illustrations contained in the manual.

B. Introduction (INTRO) structure

The introduction is broken down into Tasks.

The Tasks are:

INTRO

Page 6

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

(1) General

This Task gives general information of the CMM content and the List of

Recommended Repair Facilities.

(2) General arrangement

(3) Maintenance Task Oriented Support System (MTOSS) Task/Subtask numbering

This Task explains MTOSS Task/Subtask numbering.

(4) Symbols and Definitions

(5) Glossary of Abbreviations

C. Description and Operation (DO) structure

The DO is broken down into Tasks.

The Tasks are:

(1) General

This Task gives general overall information.

(2) Description

This Task gives a mechanical and an electrical description.

(3) Operation

This Task explains the configuration and the operation of the subassemblies

(modules/cards) of the component.

D. Maintenance Procedure (MP) structure

The MP is broken down into Tasks and Subtasks. Each Task is broken down

into five Topics:

– Reason for the job,

– Job set-up information,

– Job set-up,

INTRO

Page 7

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

– Procedure,

– Close-up (if applicable).

(1) Content of Topic "Reason for the job"

This topic is used to explain the reason for the Task, but if the Task title fully

explains the reason for the Task, then the mention "Self explanatory" is used.

(2) Content of Topic "Job set-up information"

This Topic is broken down into four Tables:

– Fixtures, Tools and Support Equipment,

– Consumable Materials,

– Expendable Parts,

– Referenced Information.

(a) Fixtures, Tools and Support Equipment

This Table lists the fixtures, tools and support equipment required for the

maintenance procedure.

They are identified:

– either by their Part/Number when they are listed in the illustrated Tool

and Equipment Manual (TEM),

– or by their main features. In this case the mention "No specific" is used

for the reference.

(b) Consumable Materials

This Table lists all materials which are prescribed during maintenance

procedure.

These materials are referenced in AMM chapter 20-31-00.

(c) Expendable Parts

This Table lists the IPC CSN (Catalogue Sequence Number) of expendable

parts.

Use the IPL to find the corresponding Part/Numbers.

INTRO

Page 8

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

(d) Referenced Information

This Table lists all external cross-references.

(3) Content of Topic "Job set-up"

This Topic indicates the information that is required for job preparation.

Requirements are broken down into Subtasks.

(4) Content of Topic "Procedure"

This Topic indicates the required actions for job realisation.

Actions are broken down into Subtasks.

(5) Content of Topic "Close-up"

This Topic indicates the required actions to put the component back to its initial

configuration.

Actions are broken down into Subtasks.

INTRO

Page 9

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

TASK 31-53-22-879-803-A01

3. Maintenance Task Oriented Support System (MTOSS) Task/Subtask numbering

A. General

The functional arrangement of data and the numbering system form the basis for

the assignment of maintenance Task/Subtask numbers to each maintenance

operation (Task) described in the CMM.

Task/Subtask numbers are mainly for the use of the Data management and have

no significance for the reader of the CMM.

The Introduction (INTRO) and the Description and Operation (DO) are broken

down into Tasks.

The Maintenance Procedures (MP) are broken down into Tasks and Subtasks.

(1) TASK

A TASK is defined as:

– A maintenance work procedure which contains a sequence of work steps,

which may be organised into Subtasks.

– A block of data e.g. Description and Operation.

– A table, an illustration or a multi-sheet illustration e.g. Figure x Sheets 1

through to 4 will all be part of one Task.

(2) SUBTASK

A SUBTASK is a single-skill work step or group of work steps within a Task,

which provides detail of a significant part of the procedure. The completion of a

SUBTASK must be possible in one location at one time.

B. Structure of Task/Subtask numbers

Form tag name -xx-xx-xx -xxx -xxx -xxx -xxx

Element 1 2 3 4 5 6

(1) Element 1

The tag name is the word TASK, SUBTASK or GRAPHIC.

(2) Element 2

INTRO

Page 10

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

ATA number (six digits).

(3) Element 3

MTOSS function code (three digits).

It is used to indicate the particular maintenance function involved.

For each tag name, this code is selected from numbers 000 through 999 as

listed in the tables in Para. 3.C..

(4) Element 4

Sequencial number of the function code (three digits).

It enables a unique identification number to be allocated for all Tasks/Subtasks

which are similarly numbered throughout the preceding elements.

Tasks and Subtasks are numbered differently:

– Task idents begin at 801 and rise, sequentially, to 999 (maximum) within the

procedure,

– Subtask idents begin at 001 and rise, sequentially, to 800 (maximum) within

the procedure.

– Illustrations and Tables are considered as Tasks. These Task idents begin at

001 and rise, sequentially, to 999 (maximum) within the procedure.

NOTE: If a particular Task or Subtask is deleted, the Task/Subtask number must

not be re-used.

(5) Element 5

Alphanumeric indicator (three characters):

– the first character is a letter to indicate a different configuration due to different

criteria configuration (modification, Service Bulletin(s), variations of work

practices, ...),

– the second and third characters are digits to indicate alternative

methods/techniques of maintenance.

(6) Element 6

Alphanumeric indicator (three characters).

INTRO

Page 11

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

It is to be assigned by an airline to highlight unique airline data.

(7) Example

Example TASK -XX-YY-ZZ -000 -801 -A01

Element tag name 1 2 3 4

ELEMENT DEFINITION

1 ATA number of the computer

2 MTOSS function code

000 = REMOVAL AND DISASSEMBLY

3 Sequential number of the function code

801 = first Task of the REMOVAL AND DISASSEMBLY type

4 A = first configuration

01 = first method

C. MTOSS function codes

The first two digits of the numbering system fourth element are in accordance

with the ATA Specification No. 100, although in some instances there is variation

by using a third digit for further breakdown of the basic function.

000 REMOVAL AND DISASSEMBLY

010 Removal of complete component from transportation/work stand

020 Disassembly of unit into modular units

030 Disassembly of modules into subassemblies

040 Disassembly of subassemblies into individual parts

050 Removal of accessories/components not part of subject unit/opening panels for

access

060 Disassembly of accessories into subassemblies

070 Disassembly of accessory subassemblies into individual parts

080 Remove test equipment

090 Disassemble support equipment

INTRO

Page 12

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

100 CLEANING

110 Chemical cleaning/power flushing

120 Wet or dry abrasive cleaning

130 Ultrasonic cleaning

140 Mechanical/hand cleaning

150 Unassigned

160 Compressed air/miscellaneous hand cleaning or combination of procedures

170 Foam/water wash

180 Electro-mechanical test of solutions to identify materials

190 Unassigned

200 INSPECTION

210 Visual examination to determine serviceability/unserviceability of unit

220 Visual/dimensional comparison with specifications/acceptance limits

230 Fluorescent penetrant NDT

240 Magnetic particle NDT

250 Eddy current NDT

260 X-ray NDT

270 Ultrasonic NDT

280 Any special inspection

290 Unassigned

300 REPAIR

310 Welding, brazing and soldering

320 Machining

330 Metallic coating removal/application

340 Plasma/flame spraying of coating

350 Repairs using hand tools, including necessary disassembly/assembly

360 Bonding and moulding

370 Heat treating

380 Surface treatment - painting, aluminizing, etc., including masking

INTRO

Page 13

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

300 REPAIR

390 Machine riveting and flaring

400 INSTALLATION AND ASSEMBLY

410 Installation of complete component into transportation/work stand

420 Assembly of complete unit from modular units

430 Assembly of modules

440 Assembly of subassembly from parts

450 Installation of accessories/closing of panels, removed/opened for access

460 Assembly of accessory from subassemblies

470 Assembly of accessory subassembly from individual parts

480 Install test equipment

490 Assemble support equipment

500 MATERIAL HANDLING

510 Shipping

520 Receiving

530 Packing

540 Unpacking

550 Storage

560 Collecting parts required for task(s) in holding area prior to release (Marshalling)

570 Work before and after air transportation of a unit

580 Unassigned

590 Unassigned

600 SERVICING/PRESERVING/LUBRICATING

610 Servicing

620 Preserving

630 De-preserving

640 Lubricating

650 Unassigned

INTRO

Page 14

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

600 SERVICING/PRESERVING/LUBRICATING

660 Unassigned

670 Unassigned

680 Unassigned

690 Unassigned

700 TESTING/CHECKING

710 Oil flow measurement

720 Air flow measurement

730 Fuel flow measurement/functional check

740 Water flow measurement/functional check

750 Electrical functional checks/measurement of parameters to determine serviceability,

may include fault isolation

760 Functional test of systems/performance check

770 Functional test of an accessory carte

780 Pressure check of system/component normally pressurized

790 Leak check

800 MISCELLANEOUS

810 Fault isolation

820 Adjusting/aligning/calibrating

830 Rigging/adjusting component linkage

840 Service Bulletin incorporation

850 Part number change/application

860 Special procedure

870 Description and Operation (DO)

871 General

872 Description

873 Operation

874 Effectivity of cards and amendments

875 Unassigned

INTRO

Page 15

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

800 MISCELLANEOUS

876 Unassigned

877 Unassigned

878 Location

879 How to use

880 Approved vendor processes

890 Airline maintenance program (customer use)

900 TOOLS, PARTS LIST, ILLUSTRATIONS

910 Special support equipment maintenance

920 Standard support equipment maintenance

930 Local manufacture of tool required for component maintenance

940 List of special tools, equipment and consumable materials

950 IPL detailed parts list

951 Sel from table

952 Equivalence table

960 IPL equipment designator index

970 IPL alpha/numerical index

980 IPL list of alternative vendors

990 Unique number assigned to enable data retrieval of illustrations, tables, preliminary

pages, etc.

991 Illustrations

992 Table illustrations

INTRO

Page 16

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

TASK 31-53-22-879-804-A01

4. Symbols and Definitions

A. Units and Measurement

(1) Symbols

SI SYSTEM US SYSTEM

ABBREVIATION DEFINITION ABBREVIATION DEFINITION

bar bar psi pound square inch

deg.C degrees Celsius deg.F degrees Fahrenheit

g gram oz ounce

kg kilogram lb pound

m meter ft foot/feet

N.m Newton.meter lbf.in pound force.inch

lbf.ft pound force.foot

mm millimeter in inch

(2) Conversion table

FROM SI SYSTEM TO US SYSTEM

1 bar 14.5037 psi

1g 0.0353 oz

1 kg 2.2046 lb

1m 3.2809 ft

1 N.m 8.851 lbf.in

0.738 lbf.ft

1 mm 0.0394 in

Temperature conversion from degrees Celsius (deg.C) to degrees Fahrenheit

(deg.F): deg.F = (1.8 x deg.C) + 32.

B. Reference Designator Index (RDI)

The designation of a component (RDI) consist of:

– a code letter according to the following table,

INTRO

Page 17

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

– a sequential number.

TYPE OF COMPONENT (RDI) CODE LETTER

Battery BT

Capacitor C

Connector J or P

Coil L

Diode, zener diode, bridge diode D or CR

Fuse F

Integrated circuit, microcircuit IC

Jumper, strap CV

Light Emitting Diode, light DS

Quartz, Oscillator Y

Relay K

Resistor, potentiometer, resistor network R

Switch, pushbutton switch S

Test point TP

Thermal resistor RT

Transformer T

Transistor, thyristor Q

Varistor RV

C. Definition of Terms

The following terms are used in the CMM and are defined as follows :

WARNING: CALLS ATTENTION TO USE OF MATERIAL, PROCESSES,

METHODS, PROCEDURES OR LIMITS WHICH MUST BE

FOLLOWED PRECISELY TO AVOID INJURY OR DEATH TO

PERSONS.

CAUTION: CALLS ATTENTION TO METHODS AND PROCEDURES WHICH

MUST BE FOLLOWED TO AVOID DAMAGE TO EQUIPMENT.

NOTE: Calls attention to methods which make the job easier or provide

supplementary or explanatory information.

INTRO

Page 18

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

The term "TIGHTEN" is generally used in locations where no torque value

is specified in the text.

The term "TORQUE" is used in the text together with a given specific torque

value.

INTRO

Page 19

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

TASK 31-53-22-871-802-A01

5. Glossary of Abbreviations

AR: As Require

AMU: Audio Management Unit

CAL: Cockpit Amplifier Loudspeaker

CVR: Cockpit Voice Recorder

DET: Details

FWC: Flight Warning Computer

GPWS: Ground Proximity Warning System

HI: HIgh point

LO: LOw point

REF: Reference

CNT: CouNTry of manufacture

DMF: Manufacture Date

ESD: Electrostatic Sensitive Device

ICC: International Commodity Code

MFR: ManuFactureR cage code

NHA: Next Higher Assembly

PDT: Part Description Text

PNR: Part Number

RFID: Radio Frequency IDentification

SER: SERial number

SWI: SoftWare Indicator

UIC: UID Construct Number

INTRO

Page 20

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

DESCRIPTION AND OPERATION

TASK 31-53-22-871-808-A01

1. General

A. System architecture

(Ref. Fig. 1)

The Cockpit Amplifier Loudspeaker (CAL) is part of the aural warning system.

Two CAL are installed on aircraft.

The Cockpit Amplifier Loudspeaker transmits all the navigation aids aural and

vocal information and broadcasts the aural warnings.

It amplifies and transmits via the loudspeaker :

– the radio communication and radio navigation information managed by the

Audio Management Unit (AMU),

– the various audio warning signals and voice announcements generated by

the Flight Warning Computers (FWC1 and FWC2),

– the synthetic voice generated by the Ground Proximity Warning System

(GPWS),

– the information recorded by the Cockpit Voice Recorded (CVR).

Page 1

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

System Organization

Figure 1/GRAPHIC 31-53-22-991-013-A01

Page 2

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

TASK 31-53-22-872-802-A01

2. Description

A. Presentation

(Ref. Fig. 2)

The assembly is in the form of a rectangular box with truncated edges, the front

face is rectangular.

For unit without amendment B, the left and right faces have ventilation holes.

For unit with amendment B, the ventilation holes are on the upper and lower

faces.

(1) Dimensions

Over-all length : 113 mm (4.449 in) MAX

Length : 102 mm (4.016 in)

Width : 108 mm (4.252 in)

Height : 148 mm (5.827 in)

(2) Weight

Less than 1 kg (2.2 lb)

(3) Unit Protection

The unit is made from black plastic (ULTEM 1000) and the grille from dark blue

plastic (ULTEM 1000).

The rear faces PNR 35-0D5-312 and 35-0D5-412 are treated with Alodine 1200

and protected by black paint (SIKKENS 744 or ALEXIT-FST404-12-9227).

The rear faces PNR 35-0D5-512 and subsequent PNR are treated with

SURTEC650 without paint.

(4) Amplifier card protective treatment

CAUTION: SOME AREAS OF THE AMPLIFIER CARD PNR 35-0D5-650 ARE

NOT VARNISHED (Ref. Fig. 3).

Amplifier card PNR 35-0D5-550, 35-0D5-560 and 35-0D5-650 are protected by

varnish PNR 0299100600 (HPA05L) (Refer to SIL F6198-00-018).

Page 3

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

B. Equipment

(1) Front face

The front face comprises :

– the dark blue loudspeaker grille,

– four captive attaching screws.

(2) Identification labels

Two identification labels and one amendment label are affixed to the rear face.

(a) Permanent label

There are two types of permanent label.

1 Label that indicates:

- Equipment designation

- Manufacturer’s name and trademark

- Serial number

- Date of manufacture

- Inspection mark.

2 Label with data matrix and RFID that indicates:

NOTE: RFID data complies with ATA Spec 2000, chapter 9.

- Manufacturer's name

- Serial number (SER)

- Manufacturer's code (MFR)

- Date of manufacture (DMF)

- Part description (PDT)

- Inspection mark

- RFID tag (Refer to ATA Spec 2000, chapter 9 for more

information about RFID).

- Data matrix code (2D) which includes:

Page 4

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

• Manufacturer's code (MFR)

• Serial number (SER)

• Date of manufacture (DMF).

(b) Replaceable label

There are two types of replaceable label.

1 Label that indicates:

- Equipment part number

- Code number

- Manufacturer’s address

- Date of inspection

- Inspection mark.

2 Label with data matrix that indicates:

- Part number (PNR)

- CMS number

- Inspection mark

- Manufacturer's country

- Data matrix code (2D) which includes

• Manufacturer’s code (MFR)

• Serial number (SER)

• Date of manufacture (DMF).

(c) Amendment label

The amendment label indicates the amendment of equipment.

(3) Internal components

The AMPLIFIER card comprising the electronics components and the

input/output connector, is attached to the rear face.

The loudspeaker is attached to the front face of the box.

Page 5

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

An anti-vibration seal and a dust filter are placed between the loudspeaker and

the front grille.

(4) External connections

(Ref. Fig. 4)

The connections to the associated equipment are made via the 19-pin connector

P1 located on the rear face.

Page 6

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

CAL - Dimensions

Figure 2/GRAPHIC 31-53-22-991-014-A01

Page 7

31-53-22 Sep 25/20

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

Amplifier card PNR 35-0D5-650 - Varnished areas

(Sheet 1 of 2)

Figure 3/GRAPHIC 31-53-22-991-024-A01

Page 8

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

Amplifier card PNR 35-0D5-650 - Varnished areas

(Sheet 2 of 2)

Figure 3/GRAPHIC 31-53-22-991-024-A01

Page 9

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

Connector P1 - Pin Location

Figure 4/GRAPHIC 31-53-22-991-015-A01

Connector (P1) receives the following signals :

Pin Signal Pin Signal

A +28VDC K SYNT. VOICE input (HI)

B Electrical ground L SYNT. VOICE input (LO)

C Muting control M WARNING2 input (HI)

D AUDIO output (HI) N WARNING2 input (LO)

E AUDIO output (LO) P 0V floating (+13VDC)

F RADIO input (HI) R VOICE input (HI)

G RADIO input (LO) S VOICE input (LO)

H WARNING1 input (HI) T Mechanical ground

J WARNING1 input (LO) U Loudspeaker input (HI)

V Loudspeaker input (LO)

C. Characteristics

(1) Electrical characteristics

(a) Power supply

– Nominal voltage : +28VDC.

– Maximum voltage : +32VDC.

– Minimum voltage : +17VDC.

Page 10

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

(2) Environmental characteristics

(a) Temperature

– Normal operating temperatures

-15 deg.C to +55 deg.C (+5 deg.F to +131 deg.F).

– Extreme operating temperatures

-15 deg.C to +70 deg.C (+5 deg.F to +158 deg.F).

– Normal storage temperatures

-20 deg.C to +40 deg.C (-4 deg.F to +104 deg.F).

– Extreme storage temperatures

-55 deg.C to +85 deg.C (-67 deg.F to +185 deg.F).

Page 11

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

TASK 31-53-22-873-801-A01

3. Operation

A. General

(Ref. Fig. 5)

The Cockpit Amplifier Loudspeaker is a completely analog system which enables

:

– the reception,

– the processing,

– the amplification,

– the transmission via the loudspeaker,

of the warning signals and aural information generated by the flight

warning computers, and the radio information required for navigation and

communications.

To eliminate feed back, the radio communications return is filtered (MUTING)

when the onboard microphones are used.

The Cockpit Amplifier Loudspeaker is supplied with +28VDC.

Page 12

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

CAL - Synoptic Diagram

Figure 5/GRAPHIC 31-53-22-991-016-A01

Page 13

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

B. AMPLIFIER card

(Ref. Fig. 2001)

(1) General

The card is divided into five parts :

– Supply circuit,

– Warning channel input,

– Radio input,

– Warning and radio channel summing,

– Power amplification.

(2) Supply circuit

(Ref. Fig. 6)

The supply circuit delivers the following voltages to the amplifier circuit :

– +26VDC,

– +13VDC (zero volt floating),

– 0V (electrical ground).

Diode (D1) protects the circuit against polarity inversion and zener diode (D9)

against overvoltages which may occur on the 28VDC mains.

Resistor (R40) limits the current in order to limit the power absorbed by diode

(D9) during an overvoltage.

Transistors (Q1 and Q2) are in common-base configuration, the emitter voltage

follows the base voltage.

The (Q1, R41, C3, C2, C1 (types 450 and 460)) or (Q1, R41, C104, C2, C1

(type 550)) or (Q1, R41, C40, C2, C1 (types 560 and 650)) assembly filters the

spurious signals which affect the +28VDC.

As the power absorbed by transistor (Q1) varies from 0.32W to 2.6W, a heat

sink is required.

The (Q2, R42, R43, R44, C4, C5, C6 (types 450 and 460) plus C105 (type 550)

or C41 (types 560 and 650)) assembly fixes the floating 0V to value of +13VDC

with respect to the ground.

The (C42, C43 (types 560 and 650)) assembly filters the +26VDC.

Page 14

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

Resistors (R42, R43) comprise the divider which attacks base of transistor (Q2).

The emitter voltage of transistor (Q2) follows that of its base :

Ve = Ub + 0.6V = (1/2 power supply voltage).

The emitter of transistor (Q2) delivers a voltage equal to half of the +26VDC

(+13VDC). This +13VDC acts as floating 0V for the analog circuits.

Page 15

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

Supply Circuit - Schematic Diagram

Figure 6/GRAPHIC 31-53-22-991-017-A01

Page 16

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

(3) Warning channel input

(Ref. Fig. 7)

There are four warning signals :

– FWC1,

– FWC2,

– GPWS,

– CVR.

These signals are conditioned by four gain 1 unlimited-passband operational

amplifiers (IC1-7, IC1-1, IC1-14 and IC1-8).

The outputs of these amplifiers converge towards a sum circuit comprising four

equal resistors (R10, R11, R12 and R9) and a gain 0.1 operational amplifier

(IC2-14).

The gain for an active input is equal to 0.1.

The passband is limited to 50kHz by capacitor (C25).

Warning Input Circuit - Schematic Diagram

Figure 7/GRAPHIC 31-53-22-991-018-A01

(4) Radio signal

Page 17

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

(Ref. Fig. 8)

Radio signal is conditioned by a gain 0.1 unlimited-passband operational

amplifier (IC2-1).

The radio signal serves to generate radio signals with muting and radio signals

without muting.

The radio signal with muting is taken at the output of gain 1 second order

low-pass filter (IC2-7, R26, R24, C24, R20 and C34).

The frequency range is 20Hz to 2400Hz at -3dB with a slope of 12dB/octave.

The radio signal without muting is taken at the output of presence filter formed

by amplifier (IC6-1, IC6-7 and IC6-8).

The radio signal delivered by amplifier (IC2-1) passes via a gain 1

impedance-adaptor operational amplifier (IC6-7) and via a 6dB bandpass filter

centered at 2kHz (IC6-1, R58, C30, R51, C31).

The signals delivered by amplifiers (IC6-1 and IC6-7) enter an adjustable gain

sum circuit (IC6-8, R55, R56, R52, R18 and C35).

The summing of these two signals raises the high tone frequencies by

6dB/octave around 2kHz.

The passband is limited to 20kHz by the capacitor (C35).

Radio Signal Circuit - Schematic Diagram

Figure 8/GRAPHIC 31-53-22-991-019-A01

Page 18

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

The cell (R22, R23, C23) placed on the radio channel without muting corrects

the response curve of the loudspeaker by raising the high tone frequencies by

6dB/octave in the 2500Hz to 7000Hz range.

Radio channel switching to with or without muting is achieved by analog switch

(IC5).

Analog switch (IC5) is supplied with +7.5VDC and -7.5VDC with respect to the

floating 0V (+13VDC).

The +7.5VDC is achieved by zener diode (D7) and resistor (R28), and the

-7.5VDC by zener diode (D8) and resistor (R27).

Logic 0 of the MUTING CTL# signal selects radio channel with muting.

(5) Summing of radio and warning channels

(Ref. Fig. 9)

Summing of the radio without muting, radio with muting and warning channels is

achieved by amplifier (IC2-8).

The gain of each channel can be independently adjusted.

Sum Circuit - Schematic Diagram

Figure 9/GRAPHIC 31-53-22-991-020-A01

– Warning channels (A),

Gain is adjusted by potentiometer (R16).

Page 19

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

CARD TYPES 450, 460 AND 550 560 AND 650

Minimum gain 0.33 0.18

Maximum gain 0.80 0.44

Gain adjusted 0.47 0.26

– Radio channel with muting (B),

Gain is adjusted by potentiometer (R17).

CARD TYPES 450 460 AND 550 560 AND 650

Minimum gain 0.18 0.16 0.09

Maximum gain 0.56 0.49 0.27

Gain adjusted 0.56 0.49 0.27

– Radio channel without muting (C),

Gain is adjusted by potentiometer (R18).

CARD TYPES 450 460 AND 550 560 AND 650

Minimum gain 0.42 0.37 0.20

Maximum gain 1.25 1.10 0.60

Gain adjusted 1.05 1.05 0.58

The passband is limited to 25kHz by capacitor (C26).

(6) Amplification

(Ref. Fig. 10)

Power amplification of the audio signals is performed by two bridge-connected

type TDA 2030 amplifiers (IC3 and IC4).

Voltage gain of the amplifier stage is :

G = 1 + (R35/R32) + 1 + (R36/R34) = 22 (41 for types 560 and 650) with signal

distortion lower than 0.5%.

The signals are output via two lines :

– AUDIO HI line, delivered by amplifier (IC3-4) to pin D.

– AUDIO LO line, delivered by amplifier (IC4-4) to pin E.

Page 20

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

Pins (D and E) are connected to corresponding loudspeaker pins (U and V)

respectively.

Capacitor (C92) protects the loudspeaker against any DC components by

eliminating the low frequencies.

Capacitors (C19 and C20 (types 450 and 460)) eliminate the frequencies greater

than 100kHz which may affect the signals.

Capacitors (C103, C106, C102 and C101 (type 550) or C36 to C39 (types 560

and 650)) eliminate the high frequencies which may affect the amplifier supplies.

Capacitors (C17, C18, C13 and C14) eliminate the low frequencies which may

affect the amplifier supplies.

Diodes (D10 to D17) keeps the power to a limit (15W maximum).

Page 21

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

Amplifier Circuit - Schematic Diagram

35-0D5-450, -460, -550 (Sheet 1 of 2)

Figure 10/GRAPHIC 31-53-22-991-021-A01

Page 22

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

Amplifier Circuit - Schematic Diagram

35-0D5-560, -650 (Sheet 2 of 2)

Figure 10/GRAPHIC 31-53-22-991-021-A01

Page 23

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

PAGE INTENTIONALLY LEFT BLANK

Page 24

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

TESTING AND FAULT ISOLATION

TASK 31-53-22-871-809-A01

1. General

A. Reason for the job

The tests are carried out:

– after a repair operation,

– before placing card or unit into service.

B. Unit test

(1) Manual test procedure

The manual test procedure is explained in accordance with ATLAS Specifications.

The "GO" message corresponding to the ATLAS Specification is mentioned after

each check requested in the description of the tests.

Troubleshooting aids allow the operator to determine the faulty card or module.

(2) Automatic test

The automatic test of the unit can be performed by means of an Automatic

Test Equipment in accordance with ATLAS Specifications (Ref. CMM App.A

31-53-22A).

Page 1001

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

TASK 31-53-22-700-802-A01

(Deleted)

Page 1002

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

TASK 31-53-22-750-801-A01

2. Checking of the unit consumption

A. Test description

– Apply a 4 ohms, 10W resistor between pins P1-D and P1-E.

– Supply a +28VDC voltage to the unit, between pins P1-A (HI) and P1-B (LO).

– Check that the voltage between pins P1-P (HI) and P1-B (LO) is equal to

12,5 ±1,25VDC.

111000 D-1-1 -- 11.94770 VDC LL 11.2500 UL 13.7500 GO

– Check that the current on voltage +28VDC is equal to 105 ±45mA.

112000 D-1-2 -- .10485 ADC LL .0600 UL .150 GO

B. Troubleshooting aid

– If the two checkings are incorrect, check diode D1, transistor Q1 and its

discrete associated components.

– If the test of voltage 12,5VDC is incorrect, check transistor Q2 or its discrete

associated components.

– If the consumption test is incorrect, carry out all the tests to find out the

defective components.

Page 1003

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

TASK 31-53-22-750-802-A01

3. Test of the warning channels

A. Test description

(1) Preliminary operation

– Apply a 4 ohms, 10W resistor between pins P1-D and P1-E.

– Supply the unit with a +28VDC voltage between pins P1-A (HI) and P1-B (LO).

(2) Checking of the warning channels potentiometer (R16)

– Apply a 0,774Vrms sunusoidal signal (Ve) at a 1000Hz frequency between

pins P1-H (HI) and P1-J (LO).

– Set potentiometer (R16) to the extreme position, moving in a clockwise

direction (maximum amplitude on output).

– Measure output voltage (VS) between pins P1-D (HI) and P1-E (LO).

– Calculate gain in dB A = 20 log (Vs/Ve).

– Set potentiometer (R16) to the extreme position moving in an anti-clockwise

direction (minimum amplitude on output).

– Measure output voltage (Vs') between pins P1-D (HI) and P1-E (LO).

– Calculate gain in dB A' = 20 log (Vs'/Ve).

– Check that the gain difference (A-A') is higher or equal to 7dB.

221200 D-2-1-2 -- 8.04080 DB GE 7.0000 GO

– Adjust potentiometer (R16) to get an output voltage equal to 0,8 ±0,05Vrms

between pins P1-D (HI) and P1-E (LO).

221300 D-2-1-3 -- .80800 VAC LL .7500 UL .8500 GO

– Remove input signal.

(3) Test of "FWC1" warning input (P1-H, P1-J)

– Apply a 0,774Vrms sunusoidal signal at a 1000Hz frequency, between pins

P1-H (HI) and P1-J (LO).

– Check that voltage between P1-D (HI) and P1-E (LO) is equal to 0,8

±0,05Vrms.

Page 1004

31-53-22

© AIRBUS OPERATIONS S.A.S - 2020. All rights reserved. Confidential and Proprietary document.

Sep 25/20

License for SPRING AIRLINES only

COMPONENT MAINTENANCE MANUAL

35-0D5 Series

222100 D-2-2-1 -- .80780 VAC LL .7500 UL .8500 GO

– Increase signal amplitude between P1-H (HI) and P1-J (LO) to 2,5Vrms.

– Check that voltage between P1-D and P1-E is equal to 2,5 ±0,5Vrms.

222200 D-2-2-2 -- 2.66140 VAC LL 2.0000 UL 3.0000 GO

– Remove input signal.

(4) Test of "GPWS" warning input (P1-K, P1-L)

– Apply a 0,774Vrms sunusoidal signal at a 1000Hz frequency, between pins

P1-K (HI) and P1-L (LO).

– Check that voltage between P1-D (HI) and P1-E (LO) is equal to 0,8

±0,05Vrms.

223100 D-2-3-1 -- .80130 VAC LL .7500 UL .8500 GO

– Increase the signal amplitude between P1-K (HI) and P1-L (LO) to 2,5Vrms.