Professional Documents

Culture Documents

2023 10 13 Solo CP Att 12sp Fd30 Laila Esprit

Uploaded by

julailaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2023 10 13 Solo CP Att 12sp Fd30 Laila Esprit

Uploaded by

julailaCopyright:

Available Formats

SOLO LABELLER TECHNOLOGY SDN. BHD.

COMPANY NO.: 879188-P SST No : B16-1808-21002953

NO.: 15, JALAN UTAMA 2/20, TAMAN PERINDUSTRIAN PUCHONG UTAMA,

47140 PUCHONG, SELANGOR, MALAYSIA.

TEL: +603-8061 3842 / 03-8052 2278 FAX: +603-8063 3842

EMAIL: sales@sololabeller.com.my / admin@sololabeller.com.my

WEBSITE: www.sololabeller.com.my

QUOTATION

Quotation No : 2023-10-13-SOLO-CP-ATT-12SP-FD30-LAILA_ESPRIT Date : 13/10/2023

Prepared For Prepared By

ESPRIT CARE SDN BHD Julaila

69, Jalan TPP 1/13, Taman Perindustrian Puchong, 47100 Puchong Selangor Title: Sales Executive

Tel : +603-80604228 H/P: 011-14891684

Email:

Fax : +603-80684226

julaila@sololabeller.com.my

Attention : Liaw Chee Wee (016-2330400)

Email : engineering1@espritcare.com

Total Price

No Description Qty Unit Price (RM)

(RM)

1) SOLO Feeder Compact Top Applicator 1 38,000.00 38,000.00

a) Machine Model : SOLO-CP-ATT-12SP-FD30

b) Labelling Application : Apply labels on top of the sheet (i.e. paper, flat unit carton or

plastic/aluminium bag). There is a feeder to separate and dispense the

sheet on a conveyor for the labelling process.

c) Suitable Product Shape : Flat sheet

d) Conveyor Moving Direction : Left to Right

Machine Specifications 1 Inclusive Inclusive

a) Label Dispensing Speed : Typical 20 m/min

b) Output Capacity : Approx. 40 products/minute*

* Calculated based on typical label dispensing speed and a length of

500 mm (sheet length 250 mm + product gap distance). The output

capacity depends on the label length, product length/diameter,

product gap distance, label dispensing speed and loading skill.

c) Sheet Dimensions : 60 - 300 mm (W) × 80 - 450 mm (L) × 0.15 - 3 mm (T)

d) Accuracy : Label Dispensing ± 1 mm

: Label Placement ± 1-2 mm (depending product shape & consistency)

e) Label Dimensions : 20 - 120 mm (W) × 20 - 400 mm (L)

f) Label Roll Diameter : 76 mm (Inner) / Max 300 mm (Outer)

g) Machine Dimensions : Approx. 1700 mm (L) × 1040 mm (W) × 1650 mm (H)

h) Feeder Conveyor Type : PVC belt

i) Feeder Conveyor Speed : Typical 20 m/min [adjustable up to Max 40 m/min]

j) Feeder Conveyor Dimension : Approx. 550 mm (W) × 1050 mm (L) × 800 mm (H)

k) Supply Voltage : Single phase, 230 Volts AC, 50 Hz

l) Power Cable Length : 3m

Remark : 1. Products must be clean, dry and free from static, dust or other

contaminants.

2. Actual products and labels must be available for review by Solo

Design Engineering Team prior to the order acceptance.

3. The minimum thickness of labels must be 60-80 micron (the

thinner label will be subject for testing).

This is a computer generated quotation and no signature is required. 1 of

Machine Features 1 Inclusive Inclusive

a) Flexible Design : i) Label applicators with 2-axis position adjustment

- vertical axis (adjust the label placement height)

- horizontal axis (adjust the initial label placement)

ii) Adjustable stainless steel sheet feeding tray and collection tray to

accommodate a wide range of sheets

iii) Stainless steel console with caster wheel and leveling pad makes the

machine is moveable and the conveyor height is adjustable

b) User-Friendly : i) PLC controlled with a 5 DM LCD (28mm x 38mm) display module

ii) Displays and records of product and label counters

iii) Label gap sensor with easy teaching function

iv) Low maintenance as fewer moving mechanism direct drive from

motors

v) Sheet is separated and dispensed by a friction belt mechanism

vi) A wide belt conveyor is used to accommodate a wide range of sheet

c) Preventive and Productive : i) Label lock function to stop label dispensing when gap sensor

malfunction

ii) Alarm interlocking protection system for label break and label gap

sensor faulty

iii) Prevent multiple label dispensing function on single product

iv) Label placement delay by pulses setting (0.001mm/sec)

v) Label tongue offset parameter setting for various label length

(0.1mm/pulse)

vi) Robust frame and structure constructed from anodized aluminum,

stainless steel & galvanized steel to withstand harsh working

environment.

Equipment Components 1 Inclusive Inclusive

a) Electrical and Electronics : i) Label dispenser stepper motor (branded high resolution 0.1124°/step)

ii) Conveyor induction motor (Branded)

iii) Conveyor induction motor inverter controller (Branded)

iv) Label gap sensor (Germany Brand)

v) Product sensor (Japan Brand)

vi) 5DM LCD(28mmx38mm) display module (Mitsubishi)

vii) Programmable Logic Controller (PLC) (Mitsubishi)

b) Mechanical : i) Durable Silicon rubber drive roller (replaceable)

2) Upgrade Item(s)

a) Upgrade PVC conveyor width (from 300 mm to 400mm) 1 1,000.00 1,000.00

b) Stainless steel collector 1 2,000.00 2,000.00

c) Indicator - Upgrade to touch screen 1 6,000.00 6,000.00

Machine Price 47,000.00

SST 10%(can be exempted by providing certificate) 4,700.00

Total Investment 51,700.00

3) Commissioning and Training 1 Inclusive

4) Transportation 1 Inclusive

Machine Final Investment 51,700.00

This is a computer generated quotation and no signature is required. 2 of

5) Optional Item(s) (SUBJECT TO 10% SST FOR ALL QUOTATION)

a) Ultrasonic Transparent Label Gap Sensor (German Brand) 1 5,000.00 5,000.00

i) Application : Detect embossed gold or silver on transparent label*

*The release paper/label MUST have eye mark logo for transparent

label without embossed gold or silver.

ii) Feature(s) : - Easy teaching function

b) Upgrade PVC conveyor width (from 300 mm to 400mm) 1 1,000.00 1,000.00

Remark: Additional mechanical parts & controls out of this quotation will be charged accordingly

TERMS AND CONDITION OF SALES

Estimated Delivery : 3 - 4 weeks if Ex-Stock or 6 - 8 weeks upon deposit received, product

sample and label ready.

Validity : 30 days

Warranty : 12 months from the date of delivery against manufacturing defect

(electrical parts). However, damage due to misuse or caused by accident

is excluded under this term.

Commissioning : We undertake the commissioning of the machine offered. This

commissioning includes leveling of the machine at site, making the final

electrical connections (end user is to provide the power point or air point

to the machine), test-running and hand-over.

Price : RM inclusive of delivery to customer site exclude unloading at customer

site

Payment : 50 % confirmation down payment(deposit paid is not refundable),

50% after Factory Acceptance Test (FAT) before delivery

Liability : Solo Labeller Technology Sdn Bhd is not liable for indirect damages,

consequential damages or losses, as e.g. loss of income, loss of use, loss

of production, loss of capital costs or costs which are combined with

interruption of operation.

Exclusions : (a) All foundations, civil works, terrain preparation or other similar

tasks or supply.

(b) Primary supply of utilities such as electricity, water and dry

compressor air.

(c) Forklift for loading or unloading at site or installation.

(d) All not named tasks, parts, supplies or services are excluded.

Contract or Agreement : If the customer requests Solo Labeller Technolgy Sdn Bhd to sign any

Contract or Agreement, an additional legal fee will be be charged on top

of the quoted price, where the company required to consult a legal

advisor to get legal advice.

Intellectual Property : All the design, photos and videos of labelling machine and products

captured in the factory of Solo Labeller Technology Sdn Bhd (SOLO)

are belong to our intellectual property. We reserves the right to use or

disclose such information for the commercial usage.

This is a computer generated quotation and no signature is required. 3 of

Product Sample Photo for Quotation Purpose

Similar Schematic Diagram

Note : Solo reserve the right to change and modify the specification & drawing without any prior notice without sacrifice machine performance

Please log on to our website www.sololabeller.com.my for video review.

This is a computer generated quotation and no signature is required. 4 of

This is a computer generated quotation and no signature is required. 5 of

Our service :

Pre-Sales Service: After-Sales Service:

-Inquiries and consulting support -We will test your products and snap video

-Sample testing support for your viewing before invite to solo

-24 hours on line answer your inquiries factory for FAT

-Welcome to view our factory -We will provide install & commisioning

-Send Similar video to customer and full training

-24 hours on line answer your machine

problem

-24 hours support on site( working hours

within klang valley)

-24 hours spare parts delivery(Standard

wear & tear parts)

Certification:

The benefits that customers can enjoy when they buy labeling machines with license manufacturing from Solo Labeller

Technology Sdn Bhd:

1) High-Quality Products: All labeling machines are manufactured in-house by Solo Labeller Technology, ensuring that they meet

high-quality standards and are reliable and durable.

2) Customized Solutions: Solo Labeller Technology can customize labeling machines to meet the specific needs of customers, such

as labeling requirements, production speed, and material compatibility.

3) Competitive Pricing: With license manufacturing, Solo Labeller Technology can offer competitive pricing to customers, as they

can produce machines at a larger scale and reduce the cost per unit.

4) Technical Support: Customers can enjoy technical support and after-sales service from Solo Labeller Technology's team of

experts. They can help with installation, maintenance, and troubleshooting to ensure optimal machine performance.

5) Innovation and Technology: Solo Labeller Technology invests in research and development to continuously improve their

machines and incorporate new technologies, providing customers with innovative solutions to meet their labeling needs.

Overall, buying labeling machines with license manufacturing from Solo Labeller Technology Sdn Bhd provides customers with

high-quality, customized solutions at competitive prices, with technical support and access to innovative technology.

This is a computer generated quotation and no signature is required. 6 of

This is a computer generated quotation and no signature is required. 7 of

This is a computer generated quotation and no signature is required. 8 of

This is a computer generated quotation and no signature is required. 9 of

This is a computer generated quotation and no signature is required. 10 of

This is a computer generated quotation and no signature is required. 11 of

This is a computer generated quotation and no signature is required. 12 of

You might also like

- YK系列振动筛 XZUM 0700 0202Document15 pagesYK系列振动筛 XZUM 0700 0202Carlos Eugenio LoveraNo ratings yet

- Specification of Pctlr-521a PDFDocument23 pagesSpecification of Pctlr-521a PDFKoosha Azimi100% (2)

- Jaw HarpDocument16 pagesJaw HarpCarlos Blanco RecueroNo ratings yet

- Validation Change Control Maintaining The Validate State-09-2015Document56 pagesValidation Change Control Maintaining The Validate State-09-2015VaLeritha R. Santa MNo ratings yet

- Catia V5 R16 - Part DesignDocument851 pagesCatia V5 R16 - Part DesignHarsh100% (13)

- EFC 16 (Guidelines On Materials Requirements For Carbon and Low Alloy Steels For H2S-Containing Environments in Oil and Gas Production) PDFDocument60 pagesEFC 16 (Guidelines On Materials Requirements For Carbon and Low Alloy Steels For H2S-Containing Environments in Oil and Gas Production) PDFBerkay GünerNo ratings yet

- Asugal Albi 90Document2 pagesAsugal Albi 90Muhammad Aasim Hassan100% (1)

- 02 Chopped Strand Mat Emc300Document2 pages02 Chopped Strand Mat Emc300Carlos AlvaNo ratings yet

- 02 Chopped Strand Mat Emc300 - 240118 - 113602Document2 pages02 Chopped Strand Mat Emc300 - 240118 - 113602GladysNo ratings yet

- Stepper Motor Vinyl Cutting PlotterDocument7 pagesStepper Motor Vinyl Cutting PlotterAlemayehu GebreNo ratings yet

- Elastimold K650J3Document1 pageElastimold K650J3Eduardo FloresNo ratings yet

- Harmony STO - STU - HMISTU855 PDFDocument8 pagesHarmony STO - STU - HMISTU855 PDFlaptop hmkNo ratings yet

- XH-320 Label (Logo) Die-Cutting MachineDocument6 pagesXH-320 Label (Logo) Die-Cutting MachineFranklin MarcanoNo ratings yet

- Brosur - Hdpe Geopipe DW CorrugatedDocument2 pagesBrosur - Hdpe Geopipe DW CorrugatedAdriel ElezarNo ratings yet

- Joiepack Industrial Co., LTD.: QuotationDocument4 pagesJoiepack Industrial Co., LTD.: QuotationAhmed Ali HefnawyNo ratings yet

- Offer For Production Line of N95/FFP2 Protective MasksDocument12 pagesOffer For Production Line of N95/FFP2 Protective MasksRstsetiadiNo ratings yet

- SZ180/SZ160/SZ100S Serises: Foshan Soontrue Zhuguan Intelligent Equipment Co.,LtdDocument12 pagesSZ180/SZ160/SZ100S Serises: Foshan Soontrue Zhuguan Intelligent Equipment Co.,Ltdzarkaa yamamaNo ratings yet

- Nuoya Machinery: Offer For Dpb-100 Blister Packaging Machine For Jam FruitDocument14 pagesNuoya Machinery: Offer For Dpb-100 Blister Packaging Machine For Jam FruitAli BoudjeradaNo ratings yet

- MMS7000 Profiler OverviewDocument5 pagesMMS7000 Profiler Overviewsomkiat kongprasiatNo ratings yet

- AUS240 enDocument6 pagesAUS240 enLilia RadjefNo ratings yet

- Plexo Push-Buttons: 1. USE 3. PreparationDocument3 pagesPlexo Push-Buttons: 1. USE 3. Preparationmohammed.omaraNo ratings yet

- ETICHETTATRICE English ManualDocument20 pagesETICHETTATRICE English Manualivan.pp.dddNo ratings yet

- Company Profile: Industrial InternshipDocument32 pagesCompany Profile: Industrial InternshipKiran KaleNo ratings yet

- Carmel1400M-Brochure 09.2261Document2 pagesCarmel1400M-Brochure 09.2261Ragil AjiNo ratings yet

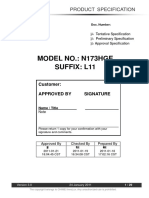

- N173hge L11Document29 pagesN173hge L11范揚鑫No ratings yet

- Robotic Tagging ApplicationsDocument6 pagesRobotic Tagging ApplicationsJJNo ratings yet

- 1+1 Usd Sami Auto Mask Making MachineDocument11 pages1+1 Usd Sami Auto Mask Making MachineSarwo EdhieNo ratings yet

- FO-GFS-16SX User ManualDocument5 pagesFO-GFS-16SX User Manualsehaad.ijmyouNo ratings yet

- Technical Data S3Document2 pagesTechnical Data S3Mario AlejandroNo ratings yet

- Mir500 Data SheetDocument2 pagesMir500 Data SheetS NguyenNo ratings yet

- Data Sheet 6GT2810-2HG80: Radio FrequenciesDocument3 pagesData Sheet 6GT2810-2HG80: Radio Frequenciessef370No ratings yet

- M6 Chopped Strand Mat: Product DescriptionDocument3 pagesM6 Chopped Strand Mat: Product DescriptionMuruga SriNo ratings yet

- Model No.: N133Bge Suffix: E31: Product SpecificationDocument38 pagesModel No.: N133Bge Suffix: E31: Product SpecificationkornolNo ratings yet

- Sieve Shaker TITAN 450: General InformationDocument2 pagesSieve Shaker TITAN 450: General InformationSupriyo PNo ratings yet

- Casepacker C10Document2 pagesCasepacker C10ale hernandezNo ratings yet

- Model No.: N133Ige Suffix: L41: Product SpecificationDocument28 pagesModel No.: N133Ige Suffix: L41: Product SpecificationMauricioNo ratings yet

- Data SheetDocument29 pagesData SheetVDJ JuanchoNo ratings yet

- FTM Company Quotation List For Megnectic Separtor For 20th - 20231201100158Document9 pagesFTM Company Quotation List For Megnectic Separtor For 20th - 20231201100158feyselagencyNo ratings yet

- WAGO 762-3057 000-001en GGDocument4 pagesWAGO 762-3057 000-001en GGahmed eidNo ratings yet

- Plastic CratesDocument9 pagesPlastic CratesfawwazNo ratings yet

- Micro Injection Molding Machine-ANN TONG INDUSTRIAL CODocument4 pagesMicro Injection Molding Machine-ANN TONG INDUSTRIAL COAndreas AlvaroNo ratings yet

- Optrex TCG057QVLGA G00-3181863Document22 pagesOptrex TCG057QVLGA G00-3181863May OchoaNo ratings yet

- PDFDocument14 pagesPDFmdavangeNo ratings yet

- 6GT28216AC32 Datasheet enDocument2 pages6GT28216AC32 Datasheet enabdooooooooooNo ratings yet

- Technical Tectiles - Composites Analysis - SEMDocument4 pagesTechnical Tectiles - Composites Analysis - SEMDr.R.LoganathanNo ratings yet

- Operating Instructions Manual: Model SG-3 Automatic Trayless Packaging MachineDocument16 pagesOperating Instructions Manual: Model SG-3 Automatic Trayless Packaging MachineTelapia MaachNo ratings yet

- Laka / Rcda.: Drum SieveDocument4 pagesLaka / Rcda.: Drum SieveMauricio Viola CastellaNo ratings yet

- 1000mm BOPP Tape Coating Machine Two Color Printing 40 Speed TangerangDocument6 pages1000mm BOPP Tape Coating Machine Two Color Printing 40 Speed TangerangJaja JamaludinNo ratings yet

- Auto Labeling SystemsDocument1 pageAuto Labeling SystemsshrinkfilmNo ratings yet

- 2020 Polaroid P422T Data Sheet 002Document2 pages2020 Polaroid P422T Data Sheet 002Allan AlcantaraNo ratings yet

- Rayfine 100w 3D f10 Fiber LaserDocument9 pagesRayfine 100w 3D f10 Fiber LaserlucaNo ratings yet

- 2020 Wet Wipes OfferDocument6 pages2020 Wet Wipes OfferDwayne PereiraNo ratings yet

- Tablet DedusterDocument4 pagesTablet DedusterSatyam MadameNo ratings yet

- Model No.: N101Lge SUFFIX: L11 (Rev C1) : Product SpecificationDocument31 pagesModel No.: N101Lge SUFFIX: L11 (Rev C1) : Product Specificationyeneider barlizaNo ratings yet

- Sieve Shaker OCTAGON 200: General InformationDocument2 pagesSieve Shaker OCTAGON 200: General InformationSupriyo PNo ratings yet

- Sikahyflex®-140 Construction: Product Data SheetDocument4 pagesSikahyflex®-140 Construction: Product Data SheetNicholas WashingtonNo ratings yet

- Shrink MO3Document5 pagesShrink MO3Ahmed GhonaimNo ratings yet

- Spilt Cleaning Machine Lxc-3000w-MaxDocument14 pagesSpilt Cleaning Machine Lxc-3000w-MaxPablo GajardoNo ratings yet

- Datasheet Dogbone UCODE 8Document2 pagesDatasheet Dogbone UCODE 8Ahmed SakrNo ratings yet

- Water Swallable TapeDocument1 pageWater Swallable TapeSanthosh V RaajendiranNo ratings yet

- Quotation For Army Pharma Ltd.Document7 pagesQuotation For Army Pharma Ltd.US BD TechnologyNo ratings yet

- VIVIX-S 3643VW SpecificationsDocument14 pagesVIVIX-S 3643VW Specificationstejerinaefrain100% (1)

- Color Monitor: Service ManualDocument32 pagesColor Monitor: Service ManualMiguel De RojasNo ratings yet

- Makmal Ukur Tanah, Fakulti Kejuruteraan Awam, Univesiti Teknologi Mara, 40450 Shah Alam, Selangor Darul EhsanDocument4 pagesMakmal Ukur Tanah, Fakulti Kejuruteraan Awam, Univesiti Teknologi Mara, 40450 Shah Alam, Selangor Darul EhsanIsmacahyadi Mohamed JaisNo ratings yet

- PlateRite 4600Document2 pagesPlateRite 4600inregistrare_onlineNo ratings yet

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- Chem Unit 1Document34 pagesChem Unit 1Ismaeel ShamsiNo ratings yet

- QUOTATION For Spare Part: Cylinder Head (G/E) Type S185Dt-EtDocument1 pageQUOTATION For Spare Part: Cylinder Head (G/E) Type S185Dt-EtThư Trực TuyếnNo ratings yet

- Manvi Final BriefDocument6 pagesManvi Final BriefManvi AgarwalNo ratings yet

- MSDS EVA en UsDocument3 pagesMSDS EVA en UsbangsNo ratings yet

- Pu: Rod Seal For Hydraulic Application: FeaturesDocument4 pagesPu: Rod Seal For Hydraulic Application: FeaturesRei_budNo ratings yet

- LenovoDocument93 pagesLenovoAndre OhyNo ratings yet

- Find Changes Logs For A Table Using SM30Document6 pagesFind Changes Logs For A Table Using SM30SrikanthNo ratings yet

- Baan CorporationDocument4 pagesBaan Corporationramankurpandey27No ratings yet

- Fresh and Mechanical Properties of Basalt Fiber Reinforced ConcreteDocument7 pagesFresh and Mechanical Properties of Basalt Fiber Reinforced ConcreteОлег ШибекоNo ratings yet

- Brother Da I-B712 DB I-B760: Instruction ManualDocument16 pagesBrother Da I-B712 DB I-B760: Instruction Manualbrikki4450% (2)

- Welcome To Reason Drum Kits 2.0Document3 pagesWelcome To Reason Drum Kits 2.0Apostolos MantzouranisNo ratings yet

- Practical File TaskDocument7 pagesPractical File TaskRakim SajdadNo ratings yet

- Electrochemistry WordsearchDocument2 pagesElectrochemistry WordsearchnurmudrikahNo ratings yet

- JOB SHEET - Daniel123Document7 pagesJOB SHEET - Daniel123Pam Aliento AlcorezaNo ratings yet

- Simulation in Terminated SystemsDocument17 pagesSimulation in Terminated SystemsSaleem AlmaqashiNo ratings yet

- Shell Air Tool Oil S2 A: Torcula OilsDocument2 pagesShell Air Tool Oil S2 A: Torcula OilsMostafaElHadiNo ratings yet

- Single-Phase Induction MotorsDocument3 pagesSingle-Phase Induction MotorsMikhael Glen LatazaNo ratings yet

- API Plan 99 - ENDocument3 pagesAPI Plan 99 - ENarunima04No ratings yet

- Combined Science Paper 6 Summer 02Document16 pagesCombined Science Paper 6 Summer 02igcsepapersNo ratings yet

- Tetra GageDocument1 pageTetra Gagemarisal efendiNo ratings yet

- Forged Steel Rolls Used For Corrugating Paper MachineryDocument4 pagesForged Steel Rolls Used For Corrugating Paper MachineryJosé de Paula MoreiraNo ratings yet

- Implis Oftware Uide: Simplis Guide © 2009 Mueller & HancockDocument8 pagesImplis Oftware Uide: Simplis Guide © 2009 Mueller & HancockDelikanliXNo ratings yet

- QP-002 Reporting Measurement UncertaintyDocument3 pagesQP-002 Reporting Measurement UncertaintyLuz ContrerasNo ratings yet

- 2020 August, Preliminary Design of Post-Tensioned Transfer GirdersDocument7 pages2020 August, Preliminary Design of Post-Tensioned Transfer GirdersMonika jainNo ratings yet