Professional Documents

Culture Documents

TDK Epcos09573-1

Uploaded by

David VasquezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TDK Epcos09573-1

Uploaded by

David VasquezCopyright:

Available Formats

SIOV metal oxide varistors

Leaded varistors, SuperioR, S20 series

Series/Type: S20

Date: December 2007

Data Sheet

EPCOS AG 2008. Reproduction, publication and dissemination of this publication, enclosures

hereto and the information contained therein without EPCOS’ prior express consent is prohibited.

Leaded varistors

SuperioR, S20 series

Construction

■ Round varistor element, leaded

■ Coating: epoxy resin, flame-retardant to UL 94 V-0

■ Terminals: tinned copper wire

Features

■ High-energy SuperioR series E3

■ Very high surge current ratings of 12 kA

■ High energy ratings up to 320 J

■ PSpice models

Approvals

■ UL

■ CSA

■ CECC

■ VDE

■ IEC

Delivery mode

■ Bulk (standard), taped versions on reel or in Ammo pack upon request.

■ For further details refer to chapter “Taping, packaging and lead configuration” for leaded varistors.

General technical data

Climatic category to IEC 60068-1 40/85/56

Operating temperature to CECC 42 000 – 40 … + 85 °C

Storage temperature – 40 … +125 °C

Electric strength to CECC 42 000 ≥2.5 kVRMS

Insulation resistance to CECC 42 000 ≥10 MΩ

Response time <25 ns

Please read Cautions and warnings and

Important notes at the end of this document. 2 11/07

Leaded varistors

SuperioR, S20 series

Maximum ratings (TA = 85 °C)

Ordering code Type VRMS VDC imax Wmax Pmax

(untaped) (8/20 µs) (2 ms)

SIOV- V V A J W

B72220S3111K101 S20K115E3 115 150 12000 110 1.0

B72220S3131K101 S20K130E3 130 170 12000 130 1.0

B72220S3141K101 S20K140E3 140 180 12000 140 1.0

B72220S3151K101 S20K150E3 150 200 12000 150 1.0

B72220S3171K101 S20K175E3 175 225 12000 180 1.0

B72220S3211K101 S20K210E3 210 270 12000 210 1.0

B72220S3231K101 S20K230E3 230 300 12000 220 1.0

B72220S3251K101 S20K250E3 250 320 12000 250 1.0

B72220S3271K101 S20K275E3 275 350 12000 260 1.0

B72220S3301K101 S20K300E3 300 385 12000 290 1.0

B72220S3321K101 S20K320E3 320 420 12000 320 1.0

Characteristics (TA = 25 °C)

Ordering code Type Vv ∆Vv vc, max ic Ctyp

(untaped) (1 mA) (1 mA) (ic) (1 kHz)

SIOV- V % V A pF

B72220S3111K101 S20K115E3 180 ±10 300 100 1520

B72220S3131K101 S20K130E3 205 ±10 340 100 1340

B72220S3141K101 S20K140E3 220 ±10 360 100 1240

B72220S3151K101 S20K150E3 240 ±10 395 100 1160

B72220S3171K101 S20K175E3 270 ±10 455 100 1000

B72220S3211K101 S20K210E3 330 ±10 550 100 830

B72220S3231K101 S20K230E3 360 ±10 595 100 760

B72220S3251K101 S20K250E3 390 ±10 650 100 700

B72220S3271K101 S20K275E3 430 ±10 710 100 630

B72220S3301K101 S20K300E3 470 ±10 775 100 580

B72220S3321K101 S20K320E3 510 ±10 840 100 540

Please read Cautions and warnings and

Important notes at the end of this document. 3 11/07

Leaded varistors

SuperioR, S20 series

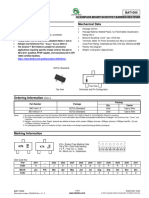

Dimensional drawing Weight

b s Nominal diameter VRMS Weight

mm V g

20 115 … 320 4.0 … 7.0

h

3 max.

1) The weight of varistors in between these

voltage classes can be interpolated.

Bottom view

a

e

ød a

e

1) Seating plane to IEC 60717

VAR0408-C

Dimensions

Ordering code ±1 a ±1 bmax smax hmax Imin d ±0.05

mm mm mm mm mm mm mm

B72220S3111K101 10.0 1.8 22.5 4.8 26.0 25.0 1.0

B72220S3131K101 10.0 2.0 22.5 5.0 26.0 25.0 1.0

B72220S3141K101 10.0 2.1 22.5 5.1 26.0 25.0 1.0

B72220S3151K101 10.0 2.2 22.5 5.2 26.0 25.0 1.0

B72220S3171K101 10.0 2.3 22.5 5.3 26.0 25.0 1.0

B72220S3211K101 10.0 2.4 22.5 5.4 26.0 25.0 1.0

B72220S3231K101 10.0 2.9 22.5 5.9 26.0 25.0 1.0

B72220S3251K101 10.0 3.1 22.5 6.1 27.0 25.0 1.0

B72220S3271K101 10.0 3.3 22.5 6.3 27.0 25.0 1.0

B72220S3301K101 10.0 3.6 22.5 6.6 27.0 25.0 1.0

B72220S3321K101 10.0 3.8 22.5 6.8 27.0 25.0 1.0

Please read Cautions and warnings and

Important notes at the end of this document. 4 11/07

Leaded varistors

SuperioR, S20 series

Reliability data

Test Test methods/conditions Requirement

Varistor voltage The voltage between two terminals with To meet the specified value.

the specified measuring current applied

is called Vv (1 mADC @ 0.2 … 2 s).

Clamping voltage The maximum voltage between two To meet the specified value.

terminals with the specified standard

impulse current (8/20 µs) applied.

Max. AC operating voltage CECC 42 000, test 4.20 |∆V/V (1 mA)| ≤10%

1000 h at UCT

After having continuously applied

the maximum allowable voltage at UCT

±2 °C for 1000 h, the specimen shall be

stored at room temperature and normal

humidity for 1 to 2 h.

Thereafter, the change of Vv shall be

measured.

Surge current derating, CECC 42 000, test C 2.1 |∆V/V (1 mA)| ≤10%

8/20 µs

100 surge currents (8/20 µs), unipolar, (measured in direction

interval 30 s, amplitude corresponding of surge current)

to derating curve for 100 impulses at

No visible damage

20 µs

Surge current derating, CECC 42 000, test C 2.1 |∆V/V (1 mA)| ≤10%

2 ms 100 surge currents (2 ms), unipolar, (measured in direction

interval 120 s, amplitude corresponding of surge current)

to derating curve for 100 impulses at No visible damage

2 ms

Electric strength CECC 42 000, test 4.7 No breakdown

Metal balls method, 2500 VRMS, 60 s

The varistor is placed in a container

holding 1.6 ±0.2 mm diameter metal

balls such that only the terminations of

the varistor are protruding.

The specified voltage shall be applied

between both terminals of the speci-

men connected together and the elec-

trode inserted between the metal balls.

Please read Cautions and warnings and

Important notes at the end of this document. 5 11/07

Leaded varistors

SuperioR, S20 series

Reliability data

Test Test methods/conditions Requirement

Climatic sequence CECC 42 000, test 4.16 |∆V/V (1 mA)| ≤10%

The specimen shall be subjected to: Rins ≥1 MΩ

a) dry heat at UCT, 16 h

b) damp heat, 1st cycle:

55 °C, 93% r. H., 24 h

c) cold, LCT, 2 h

d) damp heat, additional 5 cycles:

55 °C/25 °C, 93% r. H., 24 h/cycle.

Then the specimen shall be stored at

room temperature and normal humidity

for 1 to 2 h.

Thereafter, the change of Vv shall be

measured. Thereafter, insulation resis-

tance Rins shall be measured according

to CECC 42 000, test 4.8 at V = 500 V.

Fast temperature cycling IEC 60068-2-14, test Na, LCT/UCT, |∆V/V (1 mA)| ≤5%

dwell time 30 min, 5 cycles No visible damage

Damp heat, steady state The specimen shall be subjected to |∆V/V (1 mA)| ≤10%

40 ±2 °C, 90 to 95% r. H. for 56 days R ≥1 MΩ

ins

without load / with 10% of the maximum

continuous DC operating voltage VDC.

Then stored at room temperature and

normal humidity for 1 to 2 h.

Thereafter, the change of Vv shall be

measured. Thereafter, insulation resis-

tance Rins shall be measured according

to CECC 42 000, test 4.8 at V = 500 V.

Solderability IEC 60068-2-20, test Ta, The inspection shall be

method 1 with modified conditions for carried out under adequate

lead-free solder alloys: 245 °C, 3 s: light with normal eyesight or

After dipping the terminals to a depth with the assistance of a

of approximately 3 mm from the body magnifier capable of giving

in a soldering bath of 245 °C for 3 s, the a magnification of 4 to

terminals shall be visually examined. 10 times. The dipped sur-

face shall be covered with

a smooth and bright solder

coating with no more than

small amounts of scattered

imperfections such as

pinholes or un-wetted or

de-wetted areas. These

imperfections shall not be

concentrated in one area.

Please read Cautions and warnings and

Important notes at the end of this document. 6 11/07

Leaded varistors

SuperioR, S20 series

Reliability data

Test Test methods/conditions Requirement

Resistance to soldering heat IEC 60068-2-20, test Tb, method 1A, |∆V/V (1 mA)| ≤5%

260 °C, 10 s: No visible damage

Each lead shall be dipped into a solder

bath having a temperature of 260 ±5 °C

to a point 2.0 to 2.5 mm from the body of

the specimen, be held there for 10 ±1 s

and then be stored at room temperature

and normal humidity for 1 to 2 h.

The change of Vv shall be measured

and the specimen shall be visually

examined.

Tensile strength IEC 60068-2-21, test Ua1 |∆V/V (1 mA)| ≤5%

After gradually applying the force No break of solder joint,

specified below and keeping the unit no wire break

fixed for 10 s, the terminal shall be

visually examined for any damage.

Force for wire diameter: 1.0 mm = 20 N

Vibration IEC 60068-2, test Fc |∆V/V (1 mA)| ≤5%

Frequency range: 10 … 55 Hz No visible damage

Amplitude: 0.75 mm or 98 m/s2

Duration: 6 h (3 · 2 h)

Pulse: sine wave

After repeatedly applying a single

harmonic vibration according to the

table above.

The change of Vv shall be measured

and the specimen shall be visually

examined.

Bump IEC 60068-2-29, test Eb |∆V/V (1 mA)| ≤5%

Pulse duration: 6 ms No visible damage

Max. acceleration: 400 m/s2

Number of bumps: 4000

Pulse: half sine

Flammability IEC 60695-2-2 (needle flame test) 5 s max.

Severity: vertical 10 s

Note:

UCT = Upper category temperature

LCT = Lower category temperature

Rins = Insulation resistance to CECC 42 000, test 4.8

Please read Cautions and warnings and

Important notes at the end of this document. 7 11/07

Leaded varistors

SuperioR, S20 series

v/i characteristics

v = f (i) – for explanation of the characteristics refer A = Leakage current for worst-case

to “General technical information”, 1.6.3 B = Protection level varistor tolerances

VAR0616-F

10000

V

A B

v

6000

4000

2000

1000

800

600 320 300

275 250

230 210

400 300

320

275 250 175 150

230 210 140 130

200 175 150 115

140 130

115

100

80

60

40

20

10

8

6

4 _ _4 _3 _2 _1

10 5 10 10 10 10 10 0 10 1 10 2 10 3 10 4 A 10 5

i

SIOV-S20 … E3

Please read Cautions and warnings and

Important notes at the end of this document. 8 11/07

Leaded varistors

SuperioR, S20 series

Derating curves

Maximum surge current imax = f (tr, pulse train)

For explanation of the derating curves refer to “General technical information”, section 1.8.1

VAR0453-X

10 5

A i max

i max tr

10 4

5

1x

2

10 3

5 10

10 2

10 3

10 2 10 4

5 10 5

10 6

10 1

5

10 0

5

_1

10

10 1 5 10 2 5 10 3 5 µs 10 4

tr

SIOV-S20 … E3

Please read Cautions and warnings and

Important notes at the end of this document. 9 11/07

Leaded varistors

SuperioR, S20 series

Cautions and warnings

General

1. EPCOS metal oxide varistors (SIOVs) are designed for specific applications and should not be

used for purposes not identified in our specifications, application notes and data books unless

otherwise agreed with EPCOS during the design-in-phase.

2. Ensure suitability of SIOVs through reliability testing during the design-in phase. SIOVs should

be evaluated taking into consideration worst-case conditions.

3. For applications of SIOVs in line-to-ground circuits based on various international and local

standards there are restrictions existing or additional safety measures required.

Storage

1. Store SIOVs only in original packaging. Do not open the package before storage.

2. Storage conditions in original packaging:

Storage temperature: –25 °C … +45 °C

Relative humidity: <75% annual average,

<95% on maximum 30 days a year.

Dew precipitation: Is to be avoided.

3. Avoid contamination of an SIOV’s surface during storage, handling and processing.

4. Avoid storage of SIOVs in harmful environments that can affect the function during long-term

operation (examples given under operation precautions).

5. The SIOV type series should be soldered within the time specified:

SIOV-S, -Q, -LS 24 months

ETFV and SFS types 12 months.

Handling

1. SIOVs must not be dropped.

2. Components must not be touched with bare hands. Gloves are recommended.

3. Avoid contamination of the surface of SIOV electrodes during handling, be careful of the sharp

edge of SIOV electrodes.

Soldering (where applicable)

1. Use rosin-type flux or non-activated flux.

2. Insufficient preheating may cause ceramic cracks.

3. Rapid cooling by dipping in solvent is not recommended.

4. Complete removal of flux is recommended.

Please read Cautions and warnings and

Important notes at the end of this document. 10 11/07

Leaded varistors

SuperioR, S20 series

Mounting

1. Potting, sealing or adhesive compounds can produce chemical reactions in the SIOV ceramic

that will degrade the component’s electrical characteristics.

2. Overloading SIOVs may result in ruptured packages and expulsion of hot materials. For this rea-

son SIOVs should be physically shielded from adjacent components.

Operation

1. Use SIOVs only within the specified temperature operating range.

2. Use SIOVs only within the specified voltage and current ranges.

3. Environmental conditions must not harm SIOVs. Use SIOVs only in normal atmospheric condi-

tions. Avoid use in the presence of deoxidizing gases (chlorine gas, hydrogen sulfide gas,

ammonia gas, sulfuric acid gas, etc), corrosive agents, humid or salty conditions. Avoid contact

with any liquids and solvents.

Please read Cautions and warnings and

Important notes at the end of this document. 11 11/07

Important notes

The following applies to all products named in this publication:

1. Some parts of this publication contain statements about the suitability of our products for

certain areas of application. These statements are based on our knowledge of typical

requirements that are often placed on our products in the areas of application concerned. We

nevertheless expressly point out that such statements cannot be regarded as binding

statements about the suitability of our products for a particular customer application. As

a rule, EPCOS is either unfamiliar with individual customer applications or less familiar with them

than the customers themselves. For these reasons, it is always ultimately incumbent on the

customer to check and decide whether an EPCOS product with the properties described in the

product specification is suitable for use in a particular customer application.

2. We also point out that in individual cases, a malfunction of passive electronic components

or failure before the end of their usual service life cannot be completely ruled out in the

current state of the art, even if they are operated as specified. In customer applications

requiring a very high level of operational safety and especially in customer applications in which

the malfunction or failure of a passive electronic component could endanger human life or health

(e.g. in accident prevention or life-saving systems), it must therefore be ensured by means of

suitable design of the customer application or other action taken by the customer (e.g.

installation of protective circuitry or redundancy) that no injury or damage is sustained by third

parties in the event of malfunction or failure of a passive electronic component.

3. The warnings, cautions and product-specific notes must be observed.

4. In order to satisfy certain technical requirements, some of the products described in this

publication may contain substances subject to restrictions in certain jurisdictions (e.g.

because they are classed as hazardous). Useful information on this will be found in our

Material Data Sheets on the Internet (www.epcos.com/material). Should you have any more

detailed questions, please contact our sales offices.

5. We constantly strive to improve our products. Consequently, the products described in this

publication may change from time to time. The same is true of the corresponding product

specifications. Please check therefore to what extent product descriptions and specifications

contained in this publication are still applicable before or when you place an order. We also

reserve the right to discontinue production and delivery of products. Consequently, we

cannot guarantee that all products named in this publication will always be available. The

aforementioned does not apply in the case of individual agreements deviating from the foregoing

for customer-specific products.

6. Unless otherwise agreed in individual contracts, all orders are subject to the current version

of the “General Terms of Delivery for Products and Services in the Electrical Industry”

published by the German Electrical and Electronics Industry Association (ZVEI).

7. The trade names EPCOS, BAOKE, Alu-X, CeraDiode, CSSP, DSSP, MiniBlue, MKK, MLSC,

MotorCap, PCC, PhaseCap, PhaseMod, SIFERRIT, SIFI, SIKOREL, SilverCap, SIMDAD,

SIMID, SineFormer, SIOV, SIP5D, SIP5K, ThermoFuse, WindCap are trademarks registered

or pending in Europe and in other countries. Further information will be found on the Internet at

www.epcos.com/trademarks.

12 11/07

You might also like

- TP - MT5510I.PB801 Schematic Diagram PDFDocument10 pagesTP - MT5510I.PB801 Schematic Diagram PDFJORGE75% (8)

- Ifs-400 Operator Manual v1 02Document11 pagesIfs-400 Operator Manual v1 02Dota NgNo ratings yet

- Find Bare Copper Class 2 ConductorDocument1 pageFind Bare Copper Class 2 ConductorKmnzmnNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- PV System ChecklistDocument2 pagesPV System ChecklistzwerrNo ratings yet

- The Beauty of The 6C33Document9 pagesThe Beauty of The 6C33RastekHINo ratings yet

- Siov Metal Oxide Varistors: Leaded Varistors, Superior-Mp, S20 SeriesDocument24 pagesSiov Metal Oxide Varistors: Leaded Varistors, Superior-Mp, S20 SeriesartovolastiNo ratings yet

- Siov Leaded Advanced MP 10mmDocument22 pagesSiov Leaded Advanced MP 10mmNorgen QuinteroNo ratings yet

- SIOV metal oxide varistors data sheetDocument36 pagesSIOV metal oxide varistors data sheetAwadhNo ratings yet

- SIOV Leaded StandarD-81501Document37 pagesSIOV Leaded StandarD-81501Nv TháiNo ratings yet

- Varistor S14Document24 pagesVaristor S14digaocaixetaNo ratings yet

- S07K275 EpcosDocument17 pagesS07K275 Epcosvali dNo ratings yet

- Standard Series: Leaded VaristorsDocument16 pagesStandard Series: Leaded Varistorsأياام زمانNo ratings yet

- SIOV Leaded StandarDDocument47 pagesSIOV Leaded StandarDMee Plengtham Uu-saNo ratings yet

- SIOV Leaded StandarD-1317152Document48 pagesSIOV Leaded StandarD-1317152adyro12No ratings yet

- Varistores EpcosDocument47 pagesVaristores EpcosSidimar SotorivaNo ratings yet

- SIOV Metal Oxide Varistors Standard SeriesDocument69 pagesSIOV Metal Oxide Varistors Standard SeriesPcrossNo ratings yet

- PD 314179Document14 pagesPD 314179Bhavesh KeraliaNo ratings yet

- thermo-fuse-varistors-pbDocument4 pagesthermo-fuse-varistors-pbessen999No ratings yet

- SIOV Metal Oxide Varistors: Data Sheet Data SheetDocument11 pagesSIOV Metal Oxide Varistors: Data Sheet Data Sheetmaykel valdezNo ratings yet

- APC materials piezoelectric propertiesDocument1 pageAPC materials piezoelectric propertiesnamyefNo ratings yet

- Branch CableDocument8 pagesBranch CablevirgiawanpubgNo ratings yet

- Leading Varistor DatasheetDocument11 pagesLeading Varistor DatasheetesetengenhariaNo ratings yet

- Modul Elektroniczny Secop Do bd35f I bd50fDocument2 pagesModul Elektroniczny Secop Do bd35f I bd50fОлександр СасаNo ratings yet

- Siov SMD Cu Surge Varistors PBDocument4 pagesSiov SMD Cu Surge Varistors PBnsebxxNo ratings yet

- 14Φ Series Metal Oxide Varistor (MOV) Data Sheet: FeaturesDocument12 pages14Φ Series Metal Oxide Varistor (MOV) Data Sheet: Featuresirensy vivasNo ratings yet

- Bare Copper Class 2 Conductor Bs en 13602Document1 pageBare Copper Class 2 Conductor Bs en 13602Hridya PradeepNo ratings yet

- Physical and Piezoelectric Properties of APC Materials ChartDocument2 pagesPhysical and Piezoelectric Properties of APC Materials ChartTrương Anh DuyNo ratings yet

- Alfanar Low Voltage Control Cables Catalog PDFDocument52 pagesAlfanar Low Voltage Control Cables Catalog PDFMahmoud GwailyNo ratings yet

- Iso 14001: 2015 Ohsas 18001: 2007Document17 pagesIso 14001: 2015 Ohsas 18001: 2007وهيبه بكرNo ratings yet

- D2n Relay: The Best Rela TionDocument11 pagesD2n Relay: The Best Rela TionИгорьNo ratings yet

- Bzg01 Series 2Document8 pagesBzg01 Series 2drain rainNo ratings yet

- Varistores Uxell DatasheetDocument4 pagesVaristores Uxell DatasheetJorge Adalberto Lugo QuinteroNo ratings yet

- 480-LSOH Installation WiresDocument2 pages480-LSOH Installation WiresJoseph PoplingerNo ratings yet

- Ceramic Transient Voltage Suppressors: EPCOS Sample Kit 2015Document6 pagesCeramic Transient Voltage Suppressors: EPCOS Sample Kit 2015vijayNo ratings yet

- Nayy CableDocument5 pagesNayy CableWidhi ImranovichNo ratings yet

- 7 Transformer Protection DevicesDocument16 pages7 Transformer Protection Devicesyalewlet tarekeggnNo ratings yet

- Nsgafoeu CPR 1,8/3 KV: ApplicationDocument2 pagesNsgafoeu CPR 1,8/3 KV: ApplicationAttila HorvathNo ratings yet

- Industeel: A 22Cr DuplexDocument8 pagesIndusteel: A 22Cr DuplexJoaoNo ratings yet

- CLC 17-12-2L: A 2%mo Containing 18 CR - 10 Ni Austenitic Stainless Steel (316L Grade)Document4 pagesCLC 17-12-2L: A 2%mo Containing 18 CR - 10 Ni Austenitic Stainless Steel (316L Grade)PeterWayNo ratings yet

- CLC 17-13-5LN - High corrosion resistant austenitic stainless steelDocument4 pagesCLC 17-13-5LN - High corrosion resistant austenitic stainless steelPeterWayNo ratings yet

- June 19, 2012Document9 pagesJune 19, 2012ahmed.abdelmegeed78No ratings yet

- CLC 18-10L: General Purpose 18Cr-10Ni Austenitic Stainless Steel (304L Grade)Document4 pagesCLC 18-10L: General Purpose 18Cr-10Ni Austenitic Stainless Steel (304L Grade)PeterWayNo ratings yet

- Voltage Drop - ARD - TameplateDocument6 pagesVoltage Drop - ARD - TameplateJian RoganNo ratings yet

- Bd50f High Start Electronic Unit 101n0230!12!24vdc 08-2011 Dehcei100i602Document2 pagesBd50f High Start Electronic Unit 101n0230!12!24vdc 08-2011 Dehcei100i602msfsilverNo ratings yet

- 1% Thick Film Chip Resistors CR1 SeriesDocument4 pages1% Thick Film Chip Resistors CR1 SeriesDil NawazNo ratings yet

- Nayy 1CDocument1 pageNayy 1Chenry_gtNo ratings yet

- Datasheet VaristoresDocument24 pagesDatasheet VaristoresLuis Alberto GarciaNo ratings yet

- Galaxy Electrical Zener Diodes: FeaturesDocument5 pagesGalaxy Electrical Zener Diodes: FeatureszokiNo ratings yet

- 1vap428831-Db SCBDocument4 pages1vap428831-Db SCBHoon MiewJieNo ratings yet

- EK SPEC 180 Cu-conductor, Stranded, HardDocument1 pageEK SPEC 180 Cu-conductor, Stranded, HardfikeiNo ratings yet

- Instructions: Electronic Unit For BD35F/50F/35K Compressors, 101N0212, 101N0340 and 101N0650, 12/24V DCDocument2 pagesInstructions: Electronic Unit For BD35F/50F/35K Compressors, 101N0212, 101N0340 and 101N0650, 12/24V DCabilio pascoal netoNo ratings yet

- LSHF indoor wire specifications and electrical dataDocument5 pagesLSHF indoor wire specifications and electrical dataMohammed MadiNo ratings yet

- CLC 18-10Nb: A NB Stabilized 18Cr-10Ni Austenitic Stainless Steel (347 Grade)Document4 pagesCLC 18-10Nb: A NB Stabilized 18Cr-10Ni Austenitic Stainless Steel (347 Grade)PeterWayNo ratings yet

- NT75 Miniature Relay Technical Specifications and Product InformationDocument2 pagesNT75 Miniature Relay Technical Specifications and Product InformationАлексей КращенкоNo ratings yet

- Welding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement ConsumablesDocument8 pagesWelding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement Consumableskeymal9195No ratings yet

- Bs 7835 11Kv LSZH Single Core Screened CableDocument2 pagesBs 7835 11Kv LSZH Single Core Screened CablefoaadahmadNo ratings yet

- CLC 18-9L: General Purpose 18Cr-9Ni Austenitic Stainless Steel (304L Grade)Document4 pagesCLC 18-9L: General Purpose 18Cr-9Ni Austenitic Stainless Steel (304L Grade)MichaelNo ratings yet

- Zeners 1NDocument3 pagesZeners 1NGaby FigueroaNo ratings yet

- Matching Transformer Design Specification and Core Loss DataDocument3 pagesMatching Transformer Design Specification and Core Loss DataNaeemo IraqiNo ratings yet

- Metal Oxide Varistors: ElectronicsDocument5 pagesMetal Oxide Varistors: ElectronicscarlosgnNo ratings yet

- Hospital Grade Isolation Transformers: For Healthcare FacilitiesDocument4 pagesHospital Grade Isolation Transformers: For Healthcare Facilitiesرضا میرزانیاNo ratings yet

- Drop Voltage DCDocument2 pagesDrop Voltage DCRifqi WijayaNo ratings yet

- HES KABLO POWERCABLE CATALOGUEDocument292 pagesHES KABLO POWERCABLE CATALOGUEحسن علي جاسمNo ratings yet

- Power Supply TP.MT5510I.PB801 схемаDocument1 pagePower Supply TP.MT5510I.PB801 схемаАнатолий АнатоличNo ratings yet

- K79_D105Document6 pagesK79_D105David VasquezNo ratings yet

- Proyeccion GruposDocument1 pageProyeccion GruposDavid VasquezNo ratings yet

- Svcet: Sri Vidya College of Engg & Tech Unit V Question Bank (Lecture Notes)Document16 pagesSvcet: Sri Vidya College of Engg & Tech Unit V Question Bank (Lecture Notes)omkarNo ratings yet

- Inbound 3490051635054076234Document2 pagesInbound 3490051635054076234John Jayrold MaribojoNo ratings yet

- Power Breakers, Contactors and FusesDocument132 pagesPower Breakers, Contactors and FusesDicr RssNo ratings yet

- Technical specs M12 connector 4A IP67Document1 pageTechnical specs M12 connector 4A IP67loliveir8556No ratings yet

- RG 302 RG 400 PTFE Coaxial Cable TypesDocument7 pagesRG 302 RG 400 PTFE Coaxial Cable TypeskylegazeNo ratings yet

- Siemens - QFA Series - Room Temp and Humidity SensorsDocument2 pagesSiemens - QFA Series - Room Temp and Humidity SensorsrichsalgadoNo ratings yet

- Epc Amiga52 140-151153 Czen 120417Document31 pagesEpc Amiga52 140-151153 Czen 120417memetNo ratings yet

- EXPERIMENT 2 - Individual Lab ReportDocument2 pagesEXPERIMENT 2 - Individual Lab Reportmik AguilarNo ratings yet

- Transistors ReportDocument41 pagesTransistors ReportHannah Grace Almine Pag-iwayan100% (1)

- RHV Lab Mannual 2020-21 RCNDocument39 pagesRHV Lab Mannual 2020-21 RCNVeershett MetreNo ratings yet

- Incandescent BulbDocument24 pagesIncandescent BulbKeempee ArconadaNo ratings yet

- High Voltage Engineering (EEE-491) : Course Teacher: Fahim Mahmud Lecturer Department of EEE, CUETDocument9 pagesHigh Voltage Engineering (EEE-491) : Course Teacher: Fahim Mahmud Lecturer Department of EEE, CUETMD. MAHADI HASAN SAJIB 1602124No ratings yet

- Audio Synthesis Via Vacuum Tubes - VCADocument2 pagesAudio Synthesis Via Vacuum Tubes - VCAMat DalgleishNo ratings yet

- 21SW3000-NDY-4: Professional Low Frequency DriverDocument1 page21SW3000-NDY-4: Professional Low Frequency DriverChrisNo ratings yet

- IH2 Detailed Troubleshooting GuideDocument10 pagesIH2 Detailed Troubleshooting GuideVivek DixitNo ratings yet

- Sauer Danfoss PVE PDFDocument44 pagesSauer Danfoss PVE PDFJhon SyalfiandyNo ratings yet

- Geafolproduct EnglishDocument4 pagesGeafolproduct EnglishkostyaNo ratings yet

- RTD9420 0003 121 1120Document3 pagesRTD9420 0003 121 1120Faustino CañapatañaNo ratings yet

- P6NC60FPDocument10 pagesP6NC60FPJose Angel TorrealbaNo ratings yet

- Millennium Power Manufacturing Corp. AutoTransfer Switch technical parametersDocument5 pagesMillennium Power Manufacturing Corp. AutoTransfer Switch technical parametersLeo BurnsNo ratings yet

- Rele Control NivelDocument76 pagesRele Control NivelIngenieria Electrónica UnapNo ratings yet

- 8261 ControlPanels EK00 III enDocument2 pages8261 ControlPanels EK00 III enAndy Kong KingNo ratings yet

- 100 W Single-Stage CRCM PFC Flyback Converter Using The Irs2982S and Ir1161LDocument51 pages100 W Single-Stage CRCM PFC Flyback Converter Using The Irs2982S and Ir1161LGreenocean100% (1)

- Dra10 Series: 10W Ul / Cul / Tuv / CeDocument3 pagesDra10 Series: 10W Ul / Cul / Tuv / CeHector0412No ratings yet

- NTC Resistor Sensing Element: Building TechnologiesDocument3 pagesNTC Resistor Sensing Element: Building TechnologiesBora ÜnsalNo ratings yet

- Diagrama de Coneccion EMG HZ (ALX)Document4 pagesDiagrama de Coneccion EMG HZ (ALX)Carlos NarvaezNo ratings yet

- ABB A95-30 OLR Thermal - Overload - TechspecsDocument9 pagesABB A95-30 OLR Thermal - Overload - TechspecsTarun AhujaNo ratings yet