Professional Documents

Culture Documents

Stationary Compressors: Principal Data: GA11 - 30/ 10 Bar/ 50 HZ

Uploaded by

Aljamali AlhofashiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Stationary Compressors: Principal Data: GA11 - 30/ 10 Bar/ 50 HZ

Uploaded by

Aljamali AlhofashiCopyright:

Available Formats

Registration code

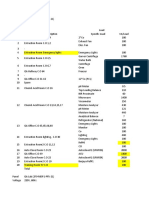

Collection: APC GA11+-30

Tab: 15

INDUSTRIAL AIR DIVISION Edition: Ed. 00

9820 9622 02 apr/06

Stationary compressors: GA11+-30/ 10 bar/ 50 Hz

AML: Principal data

GA11+ GA15+ GA18+ GA22+ GA30

10 10 10 10 10

Reference conditions

1. Absolute inlet pressure bar 1 1 1 1 1

2. Relative air humidity % 0 0 0 0 0

3. Air inlet temperature °C 20 20 20 20 20

4. Effective working pressure bar 9,5 9,5 9,5 9,5 9,5

5. Motor shaft speed r/min 2940 2940 2940 2940 2960

6. Oil type Atlas Copco Roto-injectfluid

7. Setpoint thermostatic valve °C 40 40 40 40 40

Limitations for operations

1. Maximum effective working pressure

- Workplace bar 10 10 10 10 10

- Workplace FF bar 9,75 9,75 9,75 9,75 9,75

2. Minimum effective working pressure bar 4 4 4 4 4

3. Maximum allowable inlet temperature °C 40 40 40 40 40

4. Minimum ambient temperature °C 0 0 0 0 0

Performance data compressor (1)

1. Free air delivery

at reference conditions (2) l/s 26,0 37,8 45,3 54,2 71,0

at effective working pressure stated

- Workplace 10 bar

l/s 25,9 37,7 45,2 54,1 70,9

- Workplace FF 9,75 bar

- Workplace (FF) 8,0 bar l/s 26,5 38,3 45,8 54,7 71,6

- Workplace (FF) 6,0 bar l/s 26,9 38,7 46,2 55,1 72,0

- Workplace (FF) 4,0 bar l/s 27,2 39,0 46,5 55,4 72,3

2. Power data

2.1. Performance data based on shaft input

2.1.1. Shaft power input

at reference conditions

- Workplace kW 11,1 15,8 19,5 23,8 31,8

- Workplace FF kW 11,2 15,9 19,6 23,9 32,2

9820 9622 02 Ed. 00 Page 1/5

GA11+ GA15+ GA18+ GA22+ GA30

10 10 10 10 10

at effective working pressure stated

- Workplace 10,0 bar kW 11,4 16,2 19,7 23,9 32,3

- Workplace FF 9,75 bar kW 11,2 16,0 19,5 23,7 32,6

- Workplace 8,0 bar kW 10,0 14,5 17,5 21,4 29,0

- Workplace FF 8,0 bar kW 10,1 14,6 17,6 21,5 29,7

- Workplace 6,0 bar kW 8,6 12,7 15,4 18,9 25,6

- Workplace FF 6,0 bar kW 8,7 12,8 15,5 19,0 26,3

- Workplace 4,0 bar kW 7,2 10,8 13,2 16,4 22,3

- Workplace FF 4,0 bar kW 7,3 10,9 13,3 16,5 23,0

2.1.2. Specific energy requirement

at reference conditions

- Workplace J/l 427 418 430 439 448

- Workplace FF J/l 431 421 433 441 454

at effective working pressure stated

- Workplace 10,0 bar J/l 439 431 437 443 456

- Workplace FF 9,75 bar J/l 432 423 431 438 460

- Workplace 8,0 bar J/l 377 379 382 391 405

- Workplace FF 8,0 bar J/l 381 381 384 393 415

- Workplace 6,0 bar J/l 320 328 333 343 356

- Workplace FF 6,0 bar J/l 323 331 335 345 365

- Workplace 4,0 bar J/l 265 277 284 296 308

- Workplace FF 4,0 bar J/l 268 279 286 298 318

2.1.3. Shaft input at no load kW 1,9 2,8 3,5 4,4 6,9

2.1.4 Shaft input cooling fan

- Workplace (FF) kW 0,48 0,48 0,48 0,48 0,81

2.2. Performance based on packaged compressor (electrical) power input

Integrated Dryer Type (**) ID44 ID44 ID66 ID66 ID77

2.2.1. Power input

at reference conditions

- Workplace kW 13,4 18,6 22,6 27,4 35,9

- Workplace FF kW 14,3 19,5 23,7 28,5 37,4

at effective working pressure stated

- Workplace 10,0 bar kW 13,7 19,1 22,9 27,6 36,4

- Workplace FF 9,75 bar kW 14,3 19,6 23,6 28,3 37,9

- Workplace 8,0 bar kW 12,1 17,2 20,3 24,7 32,8

- Workplace FF 8,0 bar kW 13,0 18,1 21,5 25,8 34,7

- Workplace 6,0 bar kW 10,5 15,1 18,0 21,9 29,1

- Workplace FF 6,0 bar kW 11,4 16,0 19,1 23,0 31,0

- Workplace 4,0 bar kW 8,9 12,9 15,5 19,1 25,5

- Workplace FF 4,0 bar kW 9,8 13,9 16,6 20,2 27,4

9820 9622 02 Ed. 00 Page 2/5

GA11+ GA15+ GA18+ GA22+ GA30

10 10 10 10 10

2.2.2. Specific energy requirement

at reference conditions (2)

- Workplace J/l 514 493 499 506 505

- Workplace FF J/l 549 517 523 526 527

at effective working pressure stated

- Workplace 10,0 bar J/l 527 507 506 510 514

- Workplace FF 9,75 bar J/l 550 520 521 524 535

- Workplace 8,0 bar J/l 457 448 444 452 458

- Workplace FF 8,0 bar J/l 491 472 468 472 484

- Workplace 6,0 bar J/l 391 390 389 398 404

- Workplace FF 6,0 bar J/l 424 414 413 418 430

- Workplace 4,0 bar J/l 327 332 333 345 352

- Workplace FF 4,0 bar J/l 361 355 357 365 379

2.2.3. Power input at no load (2)

- Workplace kW 3,4 4,5 5,3 6,5 9,8

- Workplace FF kW 4,0 5,1 6,1 7,3 10,7

3. Compressed air temperature at outlet valve

- Workplace - Pack °C 25 25 26 26 27

- Workplace FF - Pack FF °C 20 20 23 23 23

4. Typical oil content of compressed air mg/m³ 2 2 2 2 4

5. Maximum sound pressure level (2)

- Workplace (FF) dB (A) 63 64 66 67 69

9820 9622 02 Ed. 00 Page 3/5

GA11+ GA15+ GA18+ GA22+ GA30

10 10 10 10 10

Design data (1)

Compressor

1. Number of compression stages 1 1 1 1 1

2. Male rotor speed r/min 2752 3791 4583 5421 7172

Motor

1. Drive motor efficiency at full load % 90,2% 90,2% 91,0% 91,0% 92,2%

at no load % 82,0% 84,0% 85,0% 85,0% 80,0%

2. Fan Motor efficiency

- Workplace (FF) % 71,0% 71,0% 71,0% 71,0% 73,0%

Unit

1. Oil capacity (approx.) l 6,7 7 7,5 8 8,3

2. Cooling air flow referred to air inlet grating m³/s 1,05 1,1 1,15 1,2 1,4

3. Dimension of compressed air outlet valve (threaded) G 1 1 1 1 1

4. Inner diameter of condensate drainpipes

- Manual drain mm 4 4 4 4 4

- Automatic drain mm 5,5 5,5 5,5 5,5 5,5

5. Electrical cable passage M 50 50 50 50 50

6. Canopy dimensions

- Workplace (FF)

- Length mm 1225 1225 1225 1225 1225

- Width mm 650 650 650 650 650

- Height mm 1400 1400 1400 1400 1400

7. Net mass (approx.)

- Workplace kg 410 410 430 435 495

- Workplace FF kg 475 475 495 500 560

8. Shipping dimensions

- Workplace (FF)

- Length m 1,38 1,38 1,38 1,38 1,38

- Width m 0,86 0,86 0,86 0,86 0,86

- Height m 1,61 1,61 1,61 1,61 1,61

9. Shipping volume (approx.)

- Workplace (FF) m³ 1,9 1,9 1,9 1,9 1,9

10. Shipping mass (approx.)

10.1 Europe

- Workplace kg 442 442 462 467 527

- Workplace FF kg 507 507 527 532 592

10.2 Overseas

- Workplace kg 508 508 528 533 593

- Workplace FF kg 573 573 593 598 658

9820 9622 02 Ed. 00 Page 4/5

GA11+ GA15+ GA18+ GA22+ GA30

10 10 10 10 10

Integrated Dryer (ID) (*)

1. Integrated dryer type ID44 ID44 ID66 ID66 ID77

2. Pressure dew point Workplace FF

at a=20°C and Rh=100% °C 3 3 3 3 3

3. Pressure drop over dryer bar 0,2 0,2 0,2 0,2 0,25

4. Total power consumption

at full load (a = 20°C and Rh = 100%, including fan) kW 0,8 0,8 1 1 1,12

at no load (a = 20°C and Rh = 0%, fan stopped) kW 0,62 0,62 0,80 0,80 0,90

5. Compressed air outlet temperature (a = 20°C, Rh = 100%) °C 20 20 20 23 23

6. Cooling air flow m³/min 12,6 12,6 17,5 17,5 15,8

7. Heat dissipated by cooling air (a=20°C, Rh=100%) kW 1,4 1,4 3,17 3,17 3,23

8. Refrigerant type R134A R134A R134A R134A R134A

Total amount kg 0,95 0,95 0,95 0,95 0,95

Note : (*) symbols

a: ambient temperature, Rh: relative humidity

(**) The data of 2.2.1 and 2.2.2 prevail for an Integrated Dryer at full load

(ambient a = 40°C and relative humidity Rh = 70%)

(1) Unless otherwise stated, at reference conditions

All values given with a tolerance according to the specified codes are guaranteed

All other values are to be considered typical

(2) Data Code Tolerance

Free air delivery ISO 1217 ed. 1996 5%

Specific energy requirement ISO 1217 ed. 1996 6%

Power consumption at zero flow ISO 1217 ed. 1996 20%

Mean sound level CAGI PNEUROP PN8NTC2.2 dB(A) 2

The international ISO 1217 ed. 1996 standard refers to following standards :

- ISO 5167 - British BS 1571 Part 2

- ISO 9300 - American ASME PTC9

- German DIN 1950

Ed. 00 Document updated to GA11+, GA15+, GA18+, GA22+ and GA30

9820 9622 02 Ed. 00 Page 5/5

You might also like

- Stationary Compressors: Principal Data: GA11 - 30/ 13 Bar/ 50 HZDocument5 pagesStationary Compressors: Principal Data: GA11 - 30/ 13 Bar/ 50 HZAljamali AlhofashiNo ratings yet

- Stationary Compressors: Principal Data: LE 2-20/ 10 Bar/ 50 HZDocument5 pagesStationary Compressors: Principal Data: LE 2-20/ 10 Bar/ 50 HZAljamali AlhofashiNo ratings yet

- GA15 22 Principal DataDocument5 pagesGA15 22 Principal Datajaypc10No ratings yet

- LFX 0.7-2.0 10bar 50Hz AML EN 9820245305 Ed01Document3 pagesLFX 0.7-2.0 10bar 50Hz AML EN 9820245305 Ed01João Machado GilNo ratings yet

- AML SF 4 100 PSIDocument5 pagesAML SF 4 100 PSIjvicher61No ratings yet

- Stationary Compressors: Principal Data: GA11+-30/ 7.5 Bar/ 50 HZ Tropical Thermostat (Optional)Document2 pagesStationary Compressors: Principal Data: GA11+-30/ 7.5 Bar/ 50 HZ Tropical Thermostat (Optional)Aljamali AlhofashiNo ratings yet

- 09-12-18-24 Solar DC Air Conditioner SpecificationDocument1 page09-12-18-24 Solar DC Air Conditioner SpecificationRiyadh MirzaNo ratings yet

- Engine Data 22 Jul 2020Document1 pageEngine Data 22 Jul 2020permonoNo ratings yet

- Ceccato CSC 40-60 AC 400V 13bar 50Hz Technical Data ENDocument4 pagesCeccato CSC 40-60 AC 400V 13bar 50Hz Technical Data ENSegeyNo ratings yet

- Ducted Split: LG Air ConditionersDocument100 pagesDucted Split: LG Air Conditionersjose antonioNo ratings yet

- Report On Visit: Boiler and Oil Burner ServiceDocument4 pagesReport On Visit: Boiler and Oil Burner ServiceGaurav MaithilNo ratings yet

- GA30+ - 45 7.5 Bar 50 HZ AircooledDocument5 pagesGA30+ - 45 7.5 Bar 50 HZ AircooledAmin Aboo BilelNo ratings yet

- Engineering Data Book: Indoor Unit / Outdoor UnitDocument45 pagesEngineering Data Book: Indoor Unit / Outdoor UnitAnand sNo ratings yet

- Bulkline 650-1000 IOM ENDocument24 pagesBulkline 650-1000 IOM ENRobert SerafinNo ratings yet

- 2007 Room Air Conditioners Factory Location GuideDocument61 pages2007 Room Air Conditioners Factory Location Guidejcu 15No ratings yet

- Riello g10 Service ManualDocument24 pagesRiello g10 Service ManualFederico VymazalNo ratings yet

- Fan motor circuit breaker settingsDocument3 pagesFan motor circuit breaker settingsTolias EgwNo ratings yet

- Katalog Techn Unterlagen Kompakt enDocument172 pagesKatalog Techn Unterlagen Kompakt enPisu Miau Pisu MiauNo ratings yet

- TCM C90 - 0200 Engine Type Certificate - E-252 - Rev 29Document3 pagesTCM C90 - 0200 Engine Type Certificate - E-252 - Rev 29Randy WaltonNo ratings yet

- Av Series Vane Pumps 182Document32 pagesAv Series Vane Pumps 182destroNo ratings yet

- MFL62432403 (Saudi) Single Package (60Hz, R22) 0310 FinalDocument92 pagesMFL62432403 (Saudi) Single Package (60Hz, R22) 0310 FinalsasyedaNo ratings yet

- Komatsu PumpDocument64 pagesKomatsu PumpAhmed Rezk98% (40)

- Pool Equipment Installation GuideDocument29 pagesPool Equipment Installation GuideIoan BogdanNo ratings yet

- 4000 InstructionsDocument28 pages4000 Instructionswalace de Souza SerafimNo ratings yet

- Booster MA 7,5-30 KWDocument2 pagesBooster MA 7,5-30 KWJunaid AhmedNo ratings yet

- 150FV054-IFT-Data SheetDocument1 page150FV054-IFT-Data SheetgerardoNo ratings yet

- BLDC COMPRESSOR TCC DA HORIZONTAL r1.0Document18 pagesBLDC COMPRESSOR TCC DA HORIZONTAL r1.0Bruno Souza100% (2)

- Damper DS - 1196DPR-430Document2 pagesDamper DS - 1196DPR-430harishcsharmaNo ratings yet

- Versatility is the Mark of Perfection: Daikin Packaged Air ConditionersDocument24 pagesVersatility is the Mark of Perfection: Daikin Packaged Air ConditionersT Satheesh KumarNo ratings yet

- Daikin AC PDFDocument24 pagesDaikin AC PDFRR POWERNo ratings yet

- 160 Kva Factory Joint Test Report InternalDocument2 pages160 Kva Factory Joint Test Report InternalDebdulal DuttaNo ratings yet

- Procedure for Low Load Unit OperationDocument5 pagesProcedure for Low Load Unit OperationSatyanarayan SinghaNo ratings yet

- US PP-RAC PROD NEOLA-HIGHWALL Specsheet PDFDocument2 pagesUS PP-RAC PROD NEOLA-HIGHWALL Specsheet PDFGeorge H. Gutierrez, PECSANo ratings yet

- Full Synthetic Motor OilDocument1 pageFull Synthetic Motor OilfghdNo ratings yet

- Prince Hydraulics - Sectional Body Series 20 Offered by PRC Industrial SupplyDocument15 pagesPrince Hydraulics - Sectional Body Series 20 Offered by PRC Industrial SupplyPRC Industrial Supply100% (1)

- Littelfuse LFPCN41226Document10 pagesLittelfuse LFPCN41226Miguel VenzNo ratings yet

- Highly Rotary Compressor CatalogueDocument16 pagesHighly Rotary Compressor CatalogueMohamed SaidNo ratings yet

- QA Load SchedDocument4 pagesQA Load SchedReymar BanaagNo ratings yet

- Tmx-r1000 Service ManualDocument61 pagesTmx-r1000 Service Manualroca9o100% (1)

- Service Manual Trucks: Error Codes, Climate Control MID 146 Cu-Bas, Cu-Mcc, Cu-EccDocument52 pagesService Manual Trucks: Error Codes, Climate Control MID 146 Cu-Bas, Cu-Mcc, Cu-Eccrayanto rayantoNo ratings yet

- Service Manual Trucks: Error Codes, Climate Control MID 146 Cu-Bas, Cu-Mcc, Cu-EccDocument52 pagesService Manual Trucks: Error Codes, Climate Control MID 146 Cu-Bas, Cu-Mcc, Cu-Eccrayanto rayantoNo ratings yet

- CWC Mec DTS P001abcdDocument8 pagesCWC Mec DTS P001abcdAlonso1593No ratings yet

- Valvulas Check 2 X 300 Arflu HT 19180200a0005Document1 pageValvulas Check 2 X 300 Arflu HT 19180200a0005Oscar BasantesNo ratings yet

- AIR. NITROGENO GN7.1-7.3Document1 pageAIR. NITROGENO GN7.1-7.3jvicher61No ratings yet

- Crane Duty Motors ChartDocument9 pagesCrane Duty Motors ChartAnil KumarNo ratings yet

- Carrier - 38ye009 AllegroDocument34 pagesCarrier - 38ye009 AllegroJOSENo ratings yet

- Rebrand 29 Hydril Pressue Control Compact 18 15Document2 pagesRebrand 29 Hydril Pressue Control Compact 18 15saidbajuri4No ratings yet

- "Specific" Use and Maintenance Manual: (Translation of The Original Manual)Document16 pages"Specific" Use and Maintenance Manual: (Translation of The Original Manual)Tina ManousiNo ratings yet

- Aesv1s-N 4P 55KW 380KW 50HZ SpecDocument1 pageAesv1s-N 4P 55KW 380KW 50HZ SpecAchmad KNo ratings yet

- Yuje24byj6amo XDocument91 pagesYuje24byj6amo XING. NAHUM CESAR HERNANDEZ SORIANO LIVER PASEO QRONo ratings yet

- Factory Location and Model Specifications for 2007 Frigidaire Room Air ConditionersDocument61 pagesFactory Location and Model Specifications for 2007 Frigidaire Room Air ConditionersEnmanuel J AriasNo ratings yet

- Banco Con Control Electrico Proporcional L218Document60 pagesBanco Con Control Electrico Proporcional L218Agustín TorresNo ratings yet

- Julabo-Service Manual Shaking Water Bath SW21cDocument20 pagesJulabo-Service Manual Shaking Water Bath SW21cAugusto Vieira100% (1)

- GREE Comfort - 1824 - A6G-B1G - Service - Manual PDFDocument92 pagesGREE Comfort - 1824 - A6G-B1G - Service - Manual PDFCarlos LehmanNo ratings yet

- Direct Air HP Msae June 2016 Eng Web 1465898756Document6 pagesDirect Air HP Msae June 2016 Eng Web 1465898756BobNo ratings yet

- TCL Air Conditioner Service Manual SEODocument138 pagesTCL Air Conditioner Service Manual SEOPedro Pablo GonzalezNo ratings yet

- Atlas Copco Air Dryers FD Series Performance DataDocument21 pagesAtlas Copco Air Dryers FD Series Performance Dataroni kurniawanNo ratings yet

- TD62LM & TD62M Thermodynamic Steam Traps With Replaceable Seats ASTM Body (Flanged Connections)Document5 pagesTD62LM & TD62M Thermodynamic Steam Traps With Replaceable Seats ASTM Body (Flanged Connections)Hsalmani1991No ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Analysis of Engineering Cycles: Power, Refrigerating and Gas Liquefaction PlantFrom EverandAnalysis of Engineering Cycles: Power, Refrigerating and Gas Liquefaction PlantNo ratings yet

- Xerox Scan - 30012019115854Document1 pageXerox Scan - 30012019115854Aljamali AlhofashiNo ratings yet

- Stationary Compressors: Principal Data: GA11+-30/ 7.5 Bar/ 50 HZ Tropical Thermostat (Optional)Document2 pagesStationary Compressors: Principal Data: GA11+-30/ 7.5 Bar/ 50 HZ Tropical Thermostat (Optional)Aljamali AlhofashiNo ratings yet

- ZR 55 75 90 ASL EN Antwerp 2930186201Document286 pagesZR 55 75 90 ASL EN Antwerp 2930186201Aljamali AlhofashiNo ratings yet

- Yk 80Document2 pagesYk 80Aljamali AlhofashiNo ratings yet

- Stationary Compressors: Principal Data: GA11+-30/ 7.5 Bar/ 50 HZ Tropical Thermostat (Optional)Document2 pagesStationary Compressors: Principal Data: GA11+-30/ 7.5 Bar/ 50 HZ Tropical Thermostat (Optional)Aljamali AlhofashiNo ratings yet

- Script Wiki Animation Purity Quality EN Antwerp-1Document1 pageScript Wiki Animation Purity Quality EN Antwerp-1Aljamali AlhofashiNo ratings yet

- Atlas Copco: Parts ListDocument246 pagesAtlas Copco: Parts ListAljamali AlhofashiNo ratings yet

- Technical SpecificationsDocument12 pagesTechnical SpecificationsAljamali AlhofashiNo ratings yet

- Engine Shut Down For F3/4L 912/913Document3 pagesEngine Shut Down For F3/4L 912/913Aljamali AlhofashiNo ratings yet

- Rix Model 4V4Bg-11 Spares List: January 2020 Thru December 2020Document3 pagesRix Model 4V4Bg-11 Spares List: January 2020 Thru December 2020Aljamali AlhofashiNo ratings yet

- 4V4B-6.1 High Pressure Oxygen Comressor: FeaturesDocument2 pages4V4B-6.1 High Pressure Oxygen Comressor: FeaturesAljamali Alhofashi100% (1)

- 2v3b High Pressure Oxygen CompressorDocument2 pages2v3b High Pressure Oxygen CompressorwgonzalesmNo ratings yet

- GDC Stakeholder Engagement Topic 05-1 Green Airports and PortsDocument6 pagesGDC Stakeholder Engagement Topic 05-1 Green Airports and PortsDina Willemina RoobolNo ratings yet

- Method Statement For Battery ChargerDocument6 pagesMethod Statement For Battery ChargerUtku Can Kılıç100% (1)

- DELTA - User Manual CellD APS 1500A-230-3 SSW enDocument32 pagesDELTA - User Manual CellD APS 1500A-230-3 SSW enMuhammad Adeel KhanNo ratings yet

- Grounding and Its TypesDocument48 pagesGrounding and Its TypesAqeel � JZ Batch 22No ratings yet

- Berg Uncertainty PrincipleDocument20 pagesBerg Uncertainty PrincipleSiddhi Nitin Mahajan0% (1)

- Primary lithium batteries LS 14500 and LST 14500 technical specificationsDocument2 pagesPrimary lithium batteries LS 14500 and LST 14500 technical specificationsAkshay GargNo ratings yet

- Gis Testing RequirementsDocument7 pagesGis Testing Requirementswaqas_a_shaikh4348No ratings yet

- European Catalog Solenoid Valve Hot Water Steam Service Asco en 6869160Document6 pagesEuropean Catalog Solenoid Valve Hot Water Steam Service Asco en 6869160Hamza EbrahimjiNo ratings yet

- Content Handbook of Energy and Economic Statistics of Indonesia 2022Document111 pagesContent Handbook of Energy and Economic Statistics of Indonesia 2022kktahunanNo ratings yet

- Power Transformer Test Procedure GuideDocument13 pagesPower Transformer Test Procedure GuideDebdeep Mondal100% (1)

- HV CB TestingDocument38 pagesHV CB Testingsujendranarayana100% (1)

- Multiple Choice Questions on Renewable Energy SourcesDocument257 pagesMultiple Choice Questions on Renewable Energy SourcesRenu Dahiya53% (17)

- Strato 35 Series and 70 Series :: ROAL Living EnergyDocument1 pageStrato 35 Series and 70 Series :: ROAL Living EnergyMinhNo ratings yet

- Design of A Single Phase 33 MVA HTS Transformer With OLTC With TertiaryDocument4 pagesDesign of A Single Phase 33 MVA HTS Transformer With OLTC With TertiaryMatejComelNo ratings yet

- Read The Passage and Choose The Correct Answer For Each QuestionDocument3 pagesRead The Passage and Choose The Correct Answer For Each Questionho stanleyNo ratings yet

- Solar EnergyDocument37 pagesSolar EnergySri WahyuniNo ratings yet

- Eaton Residential LV Power Distribution GuideDocument108 pagesEaton Residential LV Power Distribution GuideJustin CronkhiteNo ratings yet

- Cro Bar CalculationDocument2 pagesCro Bar CalculationRamakrishnan AlagarsamyNo ratings yet

- Thomas Kamps Model Jet EnginesDocument109 pagesThomas Kamps Model Jet EnginesMustafa Umut Sarac100% (2)

- Matter, Energy and EnvironmentDocument31 pagesMatter, Energy and EnvironmentKatsu KitaigenNo ratings yet

- Wind Turbine ProposalDocument2 pagesWind Turbine ProposalMusa Abubakar IngawaNo ratings yet

- Technical Guide E2 Drive Quickstart GuideDocument8 pagesTechnical Guide E2 Drive Quickstart GuideIsrael SoaresNo ratings yet

- IEEE ConferenceDocument7 pagesIEEE ConferenceTural AliyevNo ratings yet

- KM Standalone Solar PV GuidelinesDocument24 pagesKM Standalone Solar PV GuidelinesIrf NavaneethNo ratings yet

- Exciter Field - Cat GeneratorDocument5 pagesExciter Field - Cat Generatorwagner_guimarães_10% (1)

- Electricity: NtroductionDocument31 pagesElectricity: Ntroductionanshuman singh100% (1)

- Synchronous Motor Working Principle ExplainedDocument6 pagesSynchronous Motor Working Principle ExplainedHemraj Singh RautelaNo ratings yet

- Lighting TransformerDocument6 pagesLighting Transformerramkumar meilNo ratings yet

- Generator Room Ventilation CalculationDocument2 pagesGenerator Room Ventilation Calculationelmerbayhon86% (28)

- Liebert gxt4 Brochure 5kva To 10kvaDocument8 pagesLiebert gxt4 Brochure 5kva To 10kvaRudi HarjonoNo ratings yet