Professional Documents

Culture Documents

467-NR - PartA - 2023-07 (Plate Diminution)

Uploaded by

altaf.khan139931Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

467-NR - PartA - 2023-07 (Plate Diminution)

Uploaded by

altaf.khan139931Copyright:

Available Formats

Pt A, Ch 2, App 3

4.3.5 The assessment of the thickness measurements is to be performed using the values given in the tables for each structural

element with regard to the four criteria defined above, in the following order:

a) assessment of isolated areas (column 1 in the tables). If the criterion is not met, the wasted part of the item is to be dealt with

as necessary.

b) assessment of items (column 2 in the tables). If the criterion is not met, the item is to be dealt with as necessary in the

measured areas as far as the average condition of the item concerned is satisfactory. In cases where some items are renewed,

the average thicknesses of these items to be considered in the next step are the new thicknesses.

c) assessment of groups of items (column 3 in the tables). If the criterion is not met, a sufficient number of elements are to be

renewed in order to obtain an increased average thickness satisfying the considered criterion of the group (generally the

elements to be renewed are those most wasted). As an example, for the assessment of the group “deck plates” all deck plates

are measured and an average thickness of each of them is estimated. Then the average of all these values is to satisfy the

criteria given for this group.

d) assessment of zones (column 4 in the tables). In principle, the criterion of the zone is met when all groups of items belonging

to the zone meet their own criteria (see c) above). However, a greater diminution than those given in column 3 may be

accepted for one group of items if, considering the other groups of items belonging to the same zone, the overall diminution

of the zone does not exceed the criterion given for it in column 4.

Example: The deck zone consists of two groups of items:

• deck plating, which has an average diminution of 12% (criterion 10%)

• deck longitudinals, which has an average diminution of 4% (criterion 10%).

Even though the deck plating group exceeds its acceptance criterion, the average diminution of the zone, which can be very

roughly estimated at 8%, is acceptable and thus the deck plating group can be accepted as it is.

Note 1: This criterion applicable to the zones is based on the general rule that the current hull girder section modulus is not to be less than 90%

of the rule section modulus within 0,4L amidships. When the zone criterion is used, the assessment is made on the basis of the original

modulus instead of the rule modulus. At the request of the Owner, a direct calculation using the ship’s current thicknesses may be performed

by the Society in order to accept greater diminutions than those given for this criterion.

4.3.6 These criteria take into consideration two main aspects:

• the overall strength of the hull girder

• the local strength and integrity of the hull structure, such as hatch covers, bulkheads, etc.

As a rule, they are applicable to the structure within the cargo area of ships having a length greater than 90 metres. However,

they may also be used for smaller ships and for structure outside the cargo area according to the following principles:

• for ships having a length less than 90 metres, the percentages of acceptable wastage given in the tables can be increased by

5 (%) (e.g. 15% instead of 10%, etc.), except for those of deck and bottom zones

• for structure outside the cargo area, the same 5 (%) increase can be applied,

on the understanding, however, that both conditions cannot be applied at the same time.

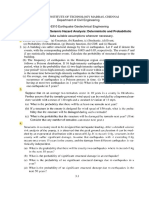

Figure 19 : General cargo ship: layout of items to be assessed

16 13 15 1 2

14

DECK

ZONE

3

17

19 6

20

NEUTRAL

AXIS

4

18 7 ZONE

5

20

9

19 21 11 12

BOTTOM

ZONE

10 8

Rules for the Classification of Steel Ships - NR467 July 2023

Pt A, Ch 2, App 3

139

Pt A, Ch 2, App 3

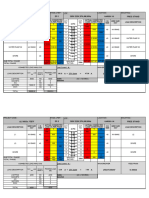

Table 4 : Local and global acceptance criteria for general cargo ships (given in % of wastage)

Group of 1 2 3 4

Description of items

items Isolated area Item Group Zone

ITEMS CONTRIBUTING TO THE LONGITUDINAL STRENGTH (TRANSVERSE SECTION)

DECK ZONE (1) − − − 10

1 Hatch coaming − − 10 −

underdeck girder web 25 20 − −

underdeck girder flange 20 15 − −

2 Upperdeck plating, deck stringer plates and sheer strakes 30 20 10 −

3 Deck longitudinals − − 10 −

web 30 20 − −

flange 25 15 − −

NEUTRAL AXIS ZONE (1) − − − 15

4 Side shell plating 25 20 15 −

5 ‘Tweendeck hatch girder − − 15 −

web 25 20 − −

flange 20 15 − −

6 ‘Tweendeck plating 30 20 15 -

7 ‘Tweendeck longitudinals − − 15 −

web 30 20 − −

flange 25 15 − −

BOTTOM ZONE (1) − − − 10

8 Bilge and bottom strakes and keel plate 25 20 10 −

9 Bottom girders 25 20 10 −

10 Bilge and bottom longitudinals − − 10 −

web 30 20 − −

flange 25 15 − −

11 Inner bottom plating 30 20 10 −

12 Inner bottom longitudinals − − 10 −

web 30 20 − −

flange 25 15 − −

OTHER ITEMS

13 Hatch coaming plating (2) 25 20 − −

14 Hatch coaming brackets 30 25 − −

15 Hatch cover top plating (4) 25 20 15 −

16 Hatch cover skirt plating (4) 30 20 − −

17 Hatch cover stiffeners (4) 30 20 − −

18 Transverse bulkheads (3) (5)

plating 30 20 15 −

stringer web 30 20 − −

stringer flange 25 15 − −

stiffener web 30 20 − −

stiffener flange 25 15 − −

brackets 30 20 − −

19 Side frames

web 30 20 − −

flange 25 15 − −

brackets 30 20 − −

20 Deck/’tweendeck beams

web 30 20 − −

flange 25 15 − −

21 Floors

plating 30 20 − −

Rules for the Classification of Steel Ships - NR467 July 2023

Pt A, Ch 2, App 3

140

Pt A, Ch 2, App 3

Group of 1 2 3 4

Description of items

items Isolated area Item Group Zone

22 Forward and aft peak bulkheads

plating 30 20 15 −

stiffener web 30 20 − −

stiffener flange 25 15 − −

(1) Each zone is to be evaluated separately.

(2) If continuous, to be included in item 1.

(3) For deep tank bulkheads, the values “average of item” and “average of group” are to be increased by 5 (%).

(4) For cargo ships constructed (i.e. keel laid) from 1st January 2012:

• steel renewal is required where the gauged thickness is less than (tnet + 0,5) mm for: single skin hatch covers, plating of double

skin hatch covers, and coaming structures the corrosion additions tC of which are provided in Pt B, Ch 8, Sec 7, Tab 1 of the

July 2021 edition of the Rules (for ships contracted for construction on or after 1st July 2016).

• where the gauged thickness is within the range (tnet + 0,5) mm and (tnet + 1,0) mm, coating (applied in accordance with the

coating manufacturer’s requirements) or annual gauging may be adopted as an alternative to steel renewal. Coating is to be

maintained in GOOD condition. If tnet is not available, the as-built thickness minus the total corrosion addition can be used.

• for the internal structures of double skin hatch covers, thickness gauging is required when hatch cover top or bottom plating

renewal is to be carried out or when this is deemed necessary, at the discretion of the Surveyor, on the basis of the plating

corrosion or deformation condition. In these cases, steel renewal for the internal structures is required when the gauged

thickness is less than tnet. If tnet is not available, the as-built thickness minus the total corrosion addition can be used.

• for corrosion addition tC = 1,0 mm the thickness for steel renewal is tnet and the thickness for coating or annual gauging is

when gauged thickness is between tnet and (tnet + 0,5) mm.

• for coaming structures, the corrosion addition tC of which are not provided in Pt B, Ch 8, Sec 7, Tab 1 of the July 2021 edition

of the Rules, steel renewal and coating or annual gauging are to be in accordance with the requirements of the Society (for

ships contracted for construction on or after 1st July 2016).

For cargo ships constructed (i.e. keel laid) from 1st January 2005:

• for hatch covers in way of cellular cargo holds intended for containers (plating, stiffeners and internals), steel renewal is

required where the gauged thickness is less than tnet. Where the gauged thickness is within the range tnet and (tnet + 0,5) mm,

coating (applied in accordance with the coating manufacturer's requirements) or annual gauging may be adopted as an

alternative to steel renewal. Coating is to be maintained in good condition. If tnet is not available, the as-built thickness minus

the total corrosion addition can be used.

(5) For ships contracted for construction on or after 1 July 2006, with transverse vertically corrugated watertight bulkheads, of length

greater than or equal to 150 m, intended for the carriage of bulk cargoes having dry bulk cargo density 1,0 t/m3 or above where

the unloading system maintains the watertightness during seagoing operations: the vertically corrugated transverse bulkheads

are to be repaired by steel renewal where the gauged thickness is less than (tnet + 0,5) mm, where tnet is the thickness obtained by

applying the strength criteria given in Pt D, Ch 4, Sec 3, [6.1] of the July 2021 edition of the Rules. However, where the gauged

thickness is within the range (tnet + 0,5) mm and (tnet + 1,0) mm, coating (applied in accordance with the coating Manufacturer’s

requirements) or annual gauging may be adopted as an alternative to steel renewal.

Figure 20 : Bulk carrier: layout of items to be assessed

13 15 14 16 12 2

DECK

ZONE

3

4

17

5 6

19

NEUTRAL

18

AXIS

10 11 9 ZONE

BOTTOM

ZONE

20 8 7

Rules for the Classification of Steel Ships - NR467 July 2023

Pt A, Ch 2, App 3

141

Pt A, Ch 2, App 3

Table 5 : Local and global acceptance criteria for bulk carriers (given in % of wastage)

Group of 1 2 3 4

Description of items

items Isolated area Item Group Zone

ITEMS CONTRIBUTING TO THE LONGITUDINAL STRENGTH (TRANSVERSE SECTION)

DECK ZONE (1) − − − 10

1 Strength deck plating, deck stringer, sheer strake and part of 25 20 10 −

side shell plating in way of top side tanks

2 Deck longitudinals − − 10 −

web 25 20 − −

flange 20 15 − −

3 Side shell longitudinals in way of top side tanks − − 10 −

web 25 20 − −

flange 20 15 − −

4 Top side tank sloped plating, including horizontal and 25 20 10 −

vertical strakes

5 Longitudinals connected to top side tank sloped plating − − 10 −

web 25 20 − −

flange 20 15 − −

NEUTRAL AXIS ZONE (1) − − − 15

6 Side shell plating 25 20 15 −

BOTTOM ZONE (1) − − − 10

7 Bilge and bottom plating and keel plate 25 20 10 −

8 Bilge and bottom longitudinals − − 10 −

web 25 20 − −

flange 20 15 − −

9 Bottom girders 25 15 10 −

10 Inner bottom plating and hopper tank sloped plating 25 20 10 −

11 Longitudinals connected to inner bottom and hopper tank − − 10 −

sloped plating

web 25 20 − −

flange 20 15 − −

OTHER ITEMS

12 Hatch coaming plating (2) (6) 25 20 − −

13 Hatch coaming brackets (6) 30 25 − −

14 Hatch cover top plating (5) (6) 25 20 15 −

15 Hatch cover skirt plating (5) (6) 25 20 − −

16 Hatch cover stiffeners (5) (6) 25 20 − −

17 Transverse bulkheads (3)

plating 25 20 15 −

stiffener web 25 20 − −

stiffener flange 20 15 − −

18 Side shell frames (4)

web 25 20 − −

flange 20 15 − −

brackets 20 15 − −

19 Topside and hopper tank web frames

web 25 20 − −

flange 20 15 − −

Rules for the Classification of Steel Ships - NR467 July 2023

Pt A, Ch 2, App 3

142

Pt A, Ch 2, App 3

Group of 1 2 3 4

Description of items

items Isolated area Item Group Zone

20 Floors

plating 25 15 − −

21 Forward and aft peak bulkheads

plating 25 20 15 −

stiffener web 25 20 − −

stiffener flange 20 15 − −

(1) Each zone is to be evaluated separately.

(2) If continuous, to be included in item 1.

(3) For vertically corrugated transverse bulkheads in cargo holds:

• For ships indicated in Ch 6, Sec 2, [1.1] which are to comply with the retroactive requirements according to the schedule

given in Ch 6, Sec 2, [1.2], the bulkhead between the two foremost cargo holds is to be assessed based on the criteria given

in Ch 6, Sec 2, [1.3].

• For ships assigned with the notation bulk carrier or self-unloading bulk carrier, contracted for construction on or after 1 July

1998, with transverse vertically corrugated watertight bulkheads, of length greater than or equal to 150 m, intended for the

carriage of bulk cargoes having dry bulk cargo density 1,0 t/m3 or above where the unloading system maintains the

watertightness during seagoing operations: all bulkheads are to be repaired by steel renewal where the gauged thickness is

less than (tnet + 0,5) mm, where tnet is the thickness obtained by applying the strength criteria given in Pt D, Ch 4, Sec 3, [6.1]

of the July 2021 edition of the Rules. However, where the gauged thickness is within the range (tnet + 0,5) mm and (tnet + 1,0)

mm, coating (applied in accordance with the coating Manufacturer’s requirements) or annual gauging may be adopted as

an alternative to steel renewal.

(4) Steel renewal criteria or other measures (reinforcement or coating) to be taken for the side shell frames and brackets in single

side skin ships with service notation bulk carrier ESP not built in accordance with Part II, Chapter 08, Section 8-03 of the 1st April

1998 edition of the Rules or subsequent editions are given in Ch 6, Sec 2, [5] and Ch 6, App 1, [5]. However, for such ships

which are to comply with Ch 6, Sec 2, [5], the thickness measurements of flanges and side shell plating not covered in Ch 6, Sec

2, [5.3], as well as the thickness measurements of additional intermediate frames fitted for reinforcement in order to comply with

an ice class notation (ice strengthening structure), are to be carried out in accordance with Article [3] and the measured

thicknesses assessed against the criteria indicated in Article [4] and the present Table.

(5) For ships which are assigned one of the service notations bulk carrier ESP, bulk carrier BC-A ESP, bulk carrier BC-B ESP or bulk

carrier BC-C ESP, contracted for construction on or after the 1st July 1998 and for hatch covers on exposed decks:

• for single skin hatch covers and for the plating of double skin hatch covers, steel renewal is required where the gauged

thickness is less than (tnet + 0,5) mm. Where the gauged thickness is within the range (tnet + 0,5) mm and (tnet + 1,0) mm,

coating (applied in accordance with the coating manufacturer’s requirements) or annual gauging may be adopted as an

alternative to steel renewal. If tnet is not available, the as-built thickness, minus the total corrosion addition, can be used.

• for the internal structures of double skin hatch covers, thickness gauging is required when plating renewal is to be carried

out or when this is deemed necessary, at the discretion of the Society’s Surveyor, on the basis of the plating corrosion or

deformation condition.In these cases, steel renewal for the internal structures is required where the gauged thickness is less

than tnet. If tnet is not available, the as-built thickness, minus the total corrosion addition, can be used.

(6) For ships which are assigned one of the service notations bulk carrier BC-A ESP, bulk carrier BC-B ESP, bulk carrier BC-C ESP,

ore carrier ESP, combination carrier/OBO ESP or combination carrier/OOC ESP, contracted for construction on or after 1

January 2004 and for all cargo hatch covers and hatch forward and side coamings on exposed decks in position 1 as defined in

ILLC:

• for single skin hatch covers and for the plating of double skin hatch covers, steel renewal is required where the gauged

thickness is less than (tnet + 0,5) mm. Where the gauged thickness is within the range (tnet + 0,5) mm and (tnet + 1,0) mm,

coating (applied in accordance with the coating manufacturer’s requirements) or annual gauging may be adopted as an

alternative to steel renewal. Coating is to be maintained in good condition. If tnet is not available, the as-built thickness, minus

the total corrosion addition, can be used.

• for the internal structures of double skin hatch covers, thickness gauging is required when plating renewal is to be carried

out or when this is deemed necessary, at the discretion of the Society’s Surveyor, on the basis of the plating corrosion or

deformation condition. In these cases, steel renewal for the internal structures is required where the gauged thickness is less

than tnet. If tnet is not available, the as-built thickness, minus the total corrosion addition, can be used.

• for hatch coamings, steel renewal is required where the gauged thickness is less than (tnet + 0,5) mm. Where the gauged

thickness is within the range (tnet + 0,5) mm and (tnet + 1,00) mm, coating (applied in accordance with the coating

manufacturer’s requirements) or annual gauging may be adopted as an alternative to steel renewal. Coating is to be

maintained in good condition. If tnet is not available, the as-built thickness, minus the total corrosion addition, can be used.

Rules for the Classification of Steel Ships - NR467 July 2023

Pt A, Ch 2, App 3

143

Pt A, Ch 2, App 3

Figure 21 : Oil tanker: layout of items to be assessed

13 3 2

DECK ZONE

15

4 1

NEUTRAL AXIS

ZONE

17 18 7

14 6 5

8

12 10 9

16

BOTTOM ZONE

11

Table 6 : Local and global acceptance criteria for oil tankers (given in % of wastage)

Group of 1 2 3 4

Description of items

items Isolated area Item Group Zone

ITEMS CONTRIBUTING TO THE LONGITUDINAL STRENGTH (TRANSVERSE SECTION)

DECK ZONE (1) − − − 10

1 Deck plating, deck stringer, sheer strake and longitudinal bulkhead 25 20 10 −

upper strake (2)

2 Deck and sheer strake longitudinals − − 10 −

web 25 20 − −

flange 20 15 − −

3 Deck longitudinal girders − − 10 −

web 25 20 − −

flange 20 15 − −

4 Longitudinals connected to longitudinal bulkhead upper strake (2) − − 10 −

web 25 20 − −

flange 20 15 − −

NEUTRAL AXIS ZONE (1) − − − 15

5 Side shell plating (2) 25 20 15 −

6 Side shell longitudinals and stringers (2) − − 15 −

web 25 20 − −

flange 20 15 − −

7 Longitudinal bulkhead plating 25 20 15 −

8 Longitudinal bulkhead longitudinals and stringers − − 15 −

web 25 20 − −

flange 20 15 − −

BOTTOM ZONE (1) − − − 10

9 Bilge and bottom strakes, longitudinal bulkhead lower strake and 25 20 10 −

keel plate (2)

10 Bilge and bottom longitudinals (2) − − 10 −

web 25 20 − −

flange 20 15 − −

11 Longitudinals connected to longitudinal bulkhead lower strake − − 10 −

web 25 20 − −

flange 20 15 − −

Rules for the Classification of Steel Ships - NR467 July 2023

Pt A, Ch 2, App 3

144

Pt A, Ch 2, App 3

Group of 1 2 3 4

Description of items

items Isolated area Item Group Zone

12 Bottom girders − − 10 −

web 25 20 − −

flange 20 15 − −

OTHER ITEMS

13 Deck transverse web frame

web 25 20 − −

flange 20 15 − −

brackets / stiffeners 25 20 − −

14 Side shell web frame

web 25 20 − −

flange 20 15 − −

brackets / stiffeners 25 20 − −

15 Longitudinal bulkhead web frame

web 25 20 − −

flange 20 15 − −

brackets / stiffeners 25 20 − −

16 Bottom transverse web frame

web 25 20 − −

flange 20 15 − −

brackets / stiffeners 25 20 − −

17 Cross tie

web 25 15 − −

flange 20 15 − −

brackets / stiffeners 20 15 − −

18 Transverse bulkheads (3)

plating 25 20 15 −

stringer web 25 20 − −

stringer flange 20 15 − −

stiffener web 30 20 − −

stiffener flange 25 15 − −

(1) Each zone is to be evaluated separately.

(2) For double hull oil tankers, the structural elements of the inner skin (plating, longitudinals, girders, bulkheads) are to be included

in the corresponding elements of the outer skin.

(3) Including swash bulkheads, forward and aft peak bulkheads.

4.4 Buckling strength criterion

4.4.1 This criterion is applicable to ships having a length greater than 120 metres.

The structural items contributing to the longitudinal strength of the ship, such as deck and bottom plating, deck and bottom

girders, etc., are to be assessed with regard to their buckling strength, as deemed necessary by the Surveyor. In such a case, the

values shown in Tab 7 are not to be exceeded.

Note 1: The minimum thickness will be specially considered for ships built with excess hull girder section modulus.

Table 7 : Buckling strength criterion

Material (ReH)

Items Ratio

235 315 355 and 390

Bottom and deck plates s/t 56,0 51,0 49,0

Longitudinals flat bar web hw / tw 20,0 18,0 17,5

Flanged longitudinals / girders web hw / tw 56,0 51,0 49,0

symmetrical flange bf / tf 34,0 30,0 29,0

asymmetrical flange bf / tf 17,0 15,0 14,5

Note 1: Symbols:

ReH : Minimum yield stress of the material, in N/mm2; tw : Web thickness, in mm;

s : Longitudinal spacing, in mm; bf : Flange breadth, in mm;

t : Actual plate thickness, in mm; tf : Flange thickness, in mm.

hw : Web height, in mm;

Rules for the Classification of Steel Ships - NR467 July 2023

Pt A, Ch 2, App 3

145

Pt A, Ch 2, App 3

4.5 Acceptance criteria based on net scantling approach

4.5.1 General

The acceptance criteria for allowable thickness diminution of ship hull structure are given here after.

Symbols:

tas-built : As built thickness, in mm.

tc : Corrosion addition, in mm, as defined in Pt B, Ch 4, Sec 2.

tres : Reserve thickness, taken equal to 0,5 mm.

tvol-add : Thickness for voluntary addition, in mm.

tm : Measured thickness, in mm, on one item, i.e. average thickness on one item using the various measurements taken

on this same item during periodical ship’s in service surveys.

4.5.2 Definitions

a) Deck zone

The deck zone includes all the following items contributing to the hull girder strength:

• strength deck plating

• longitudinal hatch coaming

• sheer strake

• side shell plating

• inner hull and other plane longitudinal bulkhead plating, if any

• topside tank sloped plating, including horizontal and vertical strakes, if any

• longitudinal upper stool, if any

• longitudinal stiffeners, girders and stringers connected to the above mentioned plating.

b) Bottom zone

The bottom zone includes all the following items contributing to the hull girder strength:

• keel plate

• bottom plating

• bilge plating

• bottom girders

• inner bottom plating

• side shell plating

• plane longitudinal bulkheads lower strake

• hopper tank sloping plating, and horizontal plating, if any

• longitudinal lower stool, if any

• longitudinal stiffeners connected to the above mentioned plating.

c) Neutral axis zone

The neutral axis zone includes the following items between the deck zone and the bottom zone, as for example:

• side shell plating

• inner hull plating and longitudinal bulkhead, if any

• double hull girder.

4.5.3 Local corrosion

a) Renewal thickness of local structural elements

Local structural elements include local supporting members and primary supporting members.

Steel renewal is required if the measured thickness, tm in mm, is less than the renewal thickness, tren defined as:

tren = tas-built - tc - tvol_add

b) Renewal area

Areas which need to be renewed based on the renewal criteria in [4.5.3]a) are to be repaired with inserted material which is

to have the same or greater grade and yield stress as the original, and to have a thickness, trepair in mm, not less than:

trepair = tas-built - tvol_add

c) Alternative solutions

When there is a substantial corrosion as defined in Ch 2, Sec 2, [2.2.7], coating applied in accordance with the coating

manufacturer’s requirements or annual gauging may be adopted as an alternative to the steel renewal. The coating is to be

maintained in good condition.

Rules for the Classification of Steel Ships - NR467 July 2023

Pt A, Ch 2, App 3

146

Pt A, Ch 2, App 3

4.5.4 Global corrosion

a) Application

The longitudinal strength of the ship is to be evaluated by using the thickness of structural members measured, renewed and

reinforced, as appropriate, during Class Renewal Surveys, for ships over 10 years of age.

b) Renewal criteria

Hull girder strength criteria are given as detailed below:

• For deck and bottom zones:

The current hull girder section modulus at deck and bottom determined with the thickness measurements are not to be

less than the section modulus calculated according to Pt B, Ch 6, Sec 1 with the gross offered thickness minus 0,5 tc.

Alternatively, the current sectional areas of the bottom zone and of the deck zone which are the sum of the measured

item areas of the considered zones are not to be less than the sectional area of the corresponding zones determined with

the gross offered thickness minus 0,5 tc.

• For neutral axis zone:

The current sectional area of the neutral axis zone, which is the sum of the measured plating areas of this zone, is not to

be less than the sectional area of the neutral axis zone calculated with the gross offered thickness minus 0,5 tc.

If the actual reduction of the gross offered thickness of all items, of a given transverse section which contribute to the hull

girder strength is less than 0,5 tc for the deck, bottom and neutral axis zones, the hull girder strength criteria of this transverse

section is satisfied and there is no need to perform calculation of the zone areas with measured thicknesses.

The gross offered thickness is defined in Pt B, Ch 4, Sec 2.

4.6 Pitting

4.6.1 The maximum acceptable depth for isolated pits is 35% of the as-built thickness.

4.6.2 For areas with different pitting intensity, the intensity diagrams shown in Fig 22 are to be used to identify the percentage

of affected areas.

For areas having a pitting intensity of 50% or more, the maximum average depth of pits is 20% of the as-built thickness. For

intermediate values between isolated pits and 50% of affected area, the interpolation between 35% and 20% is made according

to Tab 8.

4.6.3 In addition, for ships contracted for construction before 1st July 2022, the thickness outside the pits in the area considered

is to be assessed according to [4.3] and [4.4].

Note 1: Application of filler material (plastic or epoxy compounds) is recommended as a means to stop or reduce the corrosion process, but it is

not considered an acceptable repair for pitting exceeding the maximum allowable wastage limits. Welding repairs may be accepted when

performed in accordance with procedures agreed with the society.

Table 8 : Pitting intensity and corresponding maximum average depth of pitting

Pitting Intensity, Maximum average pitting depth,

(%) (% of the as-built thickness)

Isolated 35,0

5 33,5

10 32,0

15 30,5

20 29,0

25 27,5

30 26,0

40 23,0

50 20,0

4.7 Acceptance criteria for CSR ships

4.7.1 General

For ships built under the Common Structural Rules, the acceptance criteria are according to the following rules:

• Chapter 13, “Ships in Operation, Renewal Criteria”, of NR522 CSR for Bulk Carriers

• Section 12, “Ship in Operation Renewal Criteria”, of NR523 CSR for Double Hull Oil Tankers,

and as specified in [4.7.2], [4.7.3], [4.7.4] and [4.7.5].

For ships built under the Common Structural Rules and complying with the requirements of Rule Note NR606 Common

Structural Rules for Bulk Carriers and Oil Tankers, the acceptance criteria are to be in accordance with Part 1, Chapter 13, “Ship

in Operation - Renewal Criteria”, of this NR606.

Rules for the Classification of Steel Ships - NR467 July 2023

Pt A, Ch 2, App 3

147

Pt A, Ch 2, App 3

4.7.2 Pitting corrosion: side structures (CSR bulk carriers)

If pitting intensity, in an area where coating is required according to NR522 CSR for Bulk Carriers Ch 3, Sec 5, or NR606 CSR

for Bulk Carriers and Oil Tankers Part 1, Ch 3, Sec 4, as applicable, is higher than 15% (see Fig 22), thickness measurements are

to be performed to check the extent of pitting corrosion. The 15% is based on pitting or grooving on only one side of a plate. In

cases where pitting is exceeding 15%, as defined above, an area of 300 mm or more, at the most pitted part of the plate, is to be

cleaned to bare metal and the thickness is to be measured in way of the five deepest pits within the cleaned area. The least

thickness measured in way of any of these pits is to be taken as the thickness to be recorded. The minimum remaining thickness

in pits, grooves or other local areas is to be greater than the following values:

• for CSR single and double skin bulk carriers: 70% of the as-built thickness, in the side shell, hopper tank and topside tank

plating attached to the each side frame, over a width up to 30 mm on either side of it

• for CSR single skin bulk carriers: 75% of the as-built thickness, in the frame and end bracket webs and flanges,

without being greater than the renewal thickness tren as defined in [4.7.3].

Figure 22 : Pitting intensity diagrams (from 1% to 50% intensity)

Rules for the Classification of Steel Ships - NR467 July 2023

Pt A, Ch 2, App 3

148

You might also like

- AFPC Cost Estimating Tool (7.02)Document103 pagesAFPC Cost Estimating Tool (7.02)Ammar KhuderNo ratings yet

- Fdocuments - in Toyota Forklift 8fgu30 Service Repair Manual 1598247764Document21 pagesFdocuments - in Toyota Forklift 8fgu30 Service Repair Manual 1598247764uyf40% (5)

- 8 Fgu 15Document618 pages8 Fgu 15German Briceño100% (4)

- Ground Power Unit: GA ModelDocument17 pagesGround Power Unit: GA ModelAngelica Nava0% (1)

- "Uaht" Brake CylindersDocument8 pages"Uaht" Brake CylindersArmando RodriguezNo ratings yet

- Dual-Clutch Transmission: Scalable HybridDocument4 pagesDual-Clutch Transmission: Scalable HybridSamadNo ratings yet

- Gabion DesignDocument6 pagesGabion DesignyasirjurabaNo ratings yet

- Ayurvedam For Hair Related IssuesDocument14 pagesAyurvedam For Hair Related IssuesGangadhar Yerraguntla100% (1)

- Manual CBP 300mDocument38 pagesManual CBP 300mÁzhár ÁlíNo ratings yet

- TB3 - 117 Engine Maintenance Manual: (EMM Book1 TOC) (Chapter 72 TOC)Document27 pagesTB3 - 117 Engine Maintenance Manual: (EMM Book1 TOC) (Chapter 72 TOC)robiny100% (1)

- 974-0753 Onan RDJC RDJF Diesel Engine Service Manual (09-1984)Document64 pages974-0753 Onan RDJC RDJF Diesel Engine Service Manual (09-1984)Leo BurnsNo ratings yet

- Small Unmanned Fixed-wing Aircraft Design: A Practical ApproachFrom EverandSmall Unmanned Fixed-wing Aircraft Design: A Practical ApproachNo ratings yet

- Flow Measurement: By Square-Edged Orifice Plate Using Corner TappingsFrom EverandFlow Measurement: By Square-Edged Orifice Plate Using Corner TappingsRating: 5 out of 5 stars5/5 (1)

- WD12N64FR2X-CO v1 EVDocument22 pagesWD12N64FR2X-CO v1 EVHolman CastiblancoNo ratings yet

- Container CargoDocument20 pagesContainer Cargoajantha31100% (1)

- CZ Parts List (Version 1.0)Document65 pagesCZ Parts List (Version 1.0)Afif Zarrad100% (1)

- Parts Catalog: Dynamic Booklet MakerDocument98 pagesParts Catalog: Dynamic Booklet MakerZorig Ishdo0% (1)

- Mitsubishi FD70N Part 3 Mast & ForksDocument66 pagesMitsubishi FD70N Part 3 Mast & Forksben.williamsNo ratings yet

- Wd10j6410aw-Ax V1 EvDocument20 pagesWd10j6410aw-Ax V1 Evkarla-castellanosNo ratings yet

- AA 3204 Silt Curtain System-20160920-JV FDocument14 pagesAA 3204 Silt Curtain System-20160920-JV FGordon KwanNo ratings yet

- d6t Track-Type Tractor STD, XL Differential Steering Gct00001-Up (Machine) Powered by c9 Engine (Sebp4963 - 45) - Armação Dos Roletes Da EsteiraDocument3 pagesd6t Track-Type Tractor STD, XL Differential Steering Gct00001-Up (Machine) Powered by c9 Engine (Sebp4963 - 45) - Armação Dos Roletes Da EsteiraDouglas FernandesNo ratings yet

- L1204C Plus - Section 4 - PowertrainDocument60 pagesL1204C Plus - Section 4 - PowertrainPeetNo ratings yet

- NullDocument20 pagesNullBrayan NohNo ratings yet

- Douglas Aircraft Co., Inc. Structural Repair Manual: Mar l/T0Document6 pagesDouglas Aircraft Co., Inc. Structural Repair Manual: Mar l/T0Luis Omar AmundarayNo ratings yet

- ContentsDocument1 pageContentsSougataHanraNo ratings yet

- CONTENTSDocument1 pageCONTENTSSougataHanraNo ratings yet

- 424-2863 Air Conditioner GPDocument2 pages424-2863 Air Conditioner GPEdwin Castillo GarcíaNo ratings yet

- L1204C Plus - Section 3 - TransmissionDocument8 pagesL1204C Plus - Section 3 - TransmissionPeetNo ratings yet

- Mastil y Horquillas p5000Document44 pagesMastil y Horquillas p5000jorge humberto arellano almaguer100% (1)

- Ilovepdf MergedDocument100 pagesIlovepdf Mergedfrancis sebastian lagamayoNo ratings yet

- MOI - Riyadh-UL Control Panel With VFD (2 Duty + 1 Standby)Document17 pagesMOI - Riyadh-UL Control Panel With VFD (2 Duty + 1 Standby)Emad AbushrarNo ratings yet

- TEKNA Gravity PartsDocument2 pagesTEKNA Gravity PartsjohnNo ratings yet

- 1 Sample PDFDocument7 pages1 Sample PDFRachel FloresNo ratings yet

- Parts Reference List: Model: DCP-9010CN / MFC-9010CN MFC-9120CN / MFC-9320CWDocument39 pagesParts Reference List: Model: DCP-9010CN / MFC-9010CN MFC-9120CN / MFC-9320CWtraminerNo ratings yet

- Nagano MH35RDocument173 pagesNagano MH35RRafał HubczakNo ratings yet

- Wd11m4473px-Az EvDocument19 pagesWd11m4473px-Az EvMarcio da Silva VendittiNo ratings yet

- Ce056 03 0707Document8 pagesCe056 03 0707חנן שנירNo ratings yet

- Peças Conjunto Dos Filtros de Ar e VedaçõesDocument3 pagesPeças Conjunto Dos Filtros de Ar e VedaçõesAnderson Oliveira SilvaNo ratings yet

- MIL-HDBK-217F: 9.15 Resistors, Variable, Nonwirewound, Film AND PrecisionDocument1 pageMIL-HDBK-217F: 9.15 Resistors, Variable, Nonwirewound, Film AND PrecisiongokulNo ratings yet

- Illustrated Parts Catalogue: Ed. 4 Rev. 3 - November, 2018Document2 pagesIllustrated Parts Catalogue: Ed. 4 Rev. 3 - November, 2018Andrii KlishchevskyiNo ratings yet

- Design of Bracket and Decking SheetDocument18 pagesDesign of Bracket and Decking SheetSaurabh PandeyNo ratings yet

- Id0013 - DLF - Amex New Complex - Civil - Visitors CenterDocument1 pageId0013 - DLF - Amex New Complex - Civil - Visitors CenterNitin AgrawalNo ratings yet

- 2113 SOF - First Facilities Condition Assessment V03 - RevDocument59 pages2113 SOF - First Facilities Condition Assessment V03 - RevEmil ElkinNo ratings yet

- Pipe & Structural Support Local CheckDocument21 pagesPipe & Structural Support Local CheckAdli SyahmiNo ratings yet

- V.D Calculations - 01Document4 pagesV.D Calculations - 01Ahmed MagdyNo ratings yet

- Ecler Dla600 Dual Line Adaptor Service ManualDocument11 pagesEcler Dla600 Dual Line Adaptor Service ManualDSV InnovationsNo ratings yet

- Dav-M: Air Release and Vacuum Break ValvesDocument12 pagesDav-M: Air Release and Vacuum Break ValvesDanilo Perez SilvaNo ratings yet

- Parts Reference List: Model: DCP-9010CN / MFC-9010CN MFC-9120CN / MFC-9125CN MFC-9320CW / MFC-9325CWDocument40 pagesParts Reference List: Model: DCP-9010CN / MFC-9010CN MFC-9120CN / MFC-9125CN MFC-9320CW / MFC-9325CWSoodNo ratings yet

- DWJ D8R Pivot Shaft Bearing - 2Document2 pagesDWJ D8R Pivot Shaft Bearing - 2Kusuma JayaNo ratings yet

- Plate Plates .:, Chap - 13Document1 pagePlate Plates .:, Chap - 13josNo ratings yet

- Field Inspection Vane Tester VT12Document7 pagesField Inspection Vane Tester VT12Abel BernardoNo ratings yet

- Mid-Section: Clamp/Swivel Brackets and Drive Shaft HousingDocument9 pagesMid-Section: Clamp/Swivel Brackets and Drive Shaft HousingRich UrbanNo ratings yet

- Sped Center-Layout1Document1 pageSped Center-Layout1amsdeleon.12No ratings yet

- c1 c2 PDFDocument5 pagesc1 c2 PDFmogali4486No ratings yet

- WSP Revo en 2022 03 Dok50018-001Document10 pagesWSP Revo en 2022 03 Dok50018-001Alfonso Lopez toroNo ratings yet

- 1232Xl Lawn Tractor: Parts CatalogDocument36 pages1232Xl Lawn Tractor: Parts CatalogjanNo ratings yet

- C.E.A. Midterm 4Document4 pagesC.E.A. Midterm 4weza pereiraNo ratings yet

- Worksheet in MP KAP KLB 3.5 - R2 20180417 Update Parcel E Back SectionDocument23 pagesWorksheet in MP KAP KLB 3.5 - R2 20180417 Update Parcel E Back SectionDeden SuhendarNo ratings yet

- Yccttaasasr DesingjDocument5 pagesYccttaasasr DesingjAnonymous 7f2mS44JNo ratings yet

- PART 8 v7.6Document13 pagesPART 8 v7.6Brahim BahriNo ratings yet

- Null 2Document10 pagesNull 2Brayan NohNo ratings yet

- 140h-Cont Val9Document2 pages140h-Cont Val9thiherNo ratings yet

- Bu1916 20230906 122201Document24 pagesBu1916 20230906 122201altaf.khan139931No ratings yet

- CHEKLISTDocument7 pagesCHEKLISTaltaf.khan139931No ratings yet

- BASREC-IMSF-95 JOB INSTRUCTION Rev-2Document2 pagesBASREC-IMSF-95 JOB INSTRUCTION Rev-2altaf.khan139931No ratings yet

- Cummulative ProgressDocument2 pagesCummulative Progressaltaf.khan139931No ratings yet

- H250 H250 H250 H250: Variable Area Flowmeter With 3W2 Angular Position TransmitterDocument40 pagesH250 H250 H250 H250: Variable Area Flowmeter With 3W2 Angular Position TransmitterJustine MarashanyeNo ratings yet

- Wire Rope Lubricant: VSP Vitalife Spray ApplicatorsDocument1 pageWire Rope Lubricant: VSP Vitalife Spray ApplicatorsMulatua SiraitNo ratings yet

- Amotec 12864Q DisplayDocument17 pagesAmotec 12864Q DisplayEdgarNo ratings yet

- Assignment 33 PDFDocument9 pagesAssignment 33 PDFsayan mukherjeeNo ratings yet

- cs229.... Machine Language. Andrew NGDocument17 pagescs229.... Machine Language. Andrew NGkrishnaNo ratings yet

- Case How Innovation Drives Research and DevelopmentDocument4 pagesCase How Innovation Drives Research and DevelopmentMohit KumarNo ratings yet

- Criaturas Do Reino DistanteDocument53 pagesCriaturas Do Reino DistanteDaniel Marinho100% (1)

- Health Group3Document29 pagesHealth Group3Angela OrenseNo ratings yet

- Saga of Hundred Years of Hardinge Bridge: A. GhoshalDocument15 pagesSaga of Hundred Years of Hardinge Bridge: A. GhoshalAnonymous L90AMktANo ratings yet

- Writing Good PI ObjectivesDocument42 pagesWriting Good PI Objectivesfrankiepaul06No ratings yet

- ACP Supplement For SVR AUG 2017Document104 pagesACP Supplement For SVR AUG 2017Kasun WijerathnaNo ratings yet

- Assignment 3 - NTFP&SLE (HNM AgFE IITKGP) - RERUN 2 (3) .NewDocument13 pagesAssignment 3 - NTFP&SLE (HNM AgFE IITKGP) - RERUN 2 (3) .NewDebasish Datta Research Scholar, Dept. of Biochem. Engg., IIT (BHU)No ratings yet

- Equipment: MR 51 / MR 51V42 - Handy Power MR 56 / MR 56V42 - Strong PowerDocument4 pagesEquipment: MR 51 / MR 51V42 - Handy Power MR 56 / MR 56V42 - Strong PowerIsmailBelguithNo ratings yet

- EngineeringDocument107 pagesEngineeringSuezakumeNo ratings yet

- BCA 5005 Minor Project Synopsis Format & GuidelinesDocument7 pagesBCA 5005 Minor Project Synopsis Format & GuidelinesAnu VermaNo ratings yet

- Extravagant - Bethel Music CHORDS PDFDocument2 pagesExtravagant - Bethel Music CHORDS PDFKamila Joseph Hernandez VanegasNo ratings yet

- Theoretical Foundations of Nursing - Review MaterialDocument10 pagesTheoretical Foundations of Nursing - Review MaterialKennethNo ratings yet

- BotanyDocument11 pagesBotanyGirish GuptaNo ratings yet

- ETP Combined Spec - R0Document60 pagesETP Combined Spec - R0Pravash Chandra Senapaty100% (1)

- ER2 Manual 125kg 5t - 04Document144 pagesER2 Manual 125kg 5t - 04Muhammed ShamseerNo ratings yet

- Lecture-I Introduction To Concrete TechnologyDocument102 pagesLecture-I Introduction To Concrete Technologyjs kalyana rama100% (4)

- Seajet 118 Ultra-Build Epoxy PrimerDocument2 pagesSeajet 118 Ultra-Build Epoxy PrimerRai Hasnain Ahmad DahaNo ratings yet

- Baremos Sexual Desire Inventory MEN WomenDocument1 pageBaremos Sexual Desire Inventory MEN WomenGabriNo ratings yet

- Algebra I m5 Topic B Lesson 6 TeacherDocument13 pagesAlgebra I m5 Topic B Lesson 6 TeacherjxhroyNo ratings yet

- Mono and DicotDocument3 pagesMono and Dicotlady chaseNo ratings yet

- Wednesday 12 June 2019: ChemistryDocument32 pagesWednesday 12 June 2019: ChemistryMohammad KhanNo ratings yet