Professional Documents

Culture Documents

HC-300PL-Infrared Hydrocarbon Gas Detector

Uploaded by

Irlan LeiteOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HC-300PL-Infrared Hydrocarbon Gas Detector

Uploaded by

Irlan LeiteCopyright:

Available Formats

AutroSafe Infrared Hydrocarbon Gas Detector HC300PL

Features

• Heated sapphire optics deliver stable, high-performance

detection in demanding environments

• Superior optics protection system.

• No undisclosed failure modes.

• Routine calibration not required.

• Explosion-proof, stainless steel housing with tethered-

weather protection baffle.

• Integral wiring compartment eliminates need for external

junction boxes.

• Built-in tri-colour LED indicates normal, alarm, & fault

conditions at a glance

• Field configuration and calibration option.

• Immune to damage from exposure to constant back-

ground gases or to high gas concentrations.

The AutroPoint HC300PL is capable of detecting

• CENELEC, CE (including ATEX 94/9/EC), and DNV

certifications. hundreds of flammable hydrocarbon vapours. Field-

selectable algorithms are provided for methane

• Certified to CENELEC EEx d, e protection standards for

(default), ethane, propane, butane, ethylene, and

maximum versatility.

propylene. Numerous additional operating parameters

are programmable via an optional HART hand-held

field communicator.

Application / Description A key feature of the HC300PL IR gas detector is the

The AutroPoint HC300PL is a diffusion-based, infrared built-in PowerLoop system technology, enabling the

combustible gas detector that provides continuous, detector to communicate with AutroSafe Integrated

fixed monitoring of flammable hydrocarbon gases in Fire and Gas (IFG) systems on a single pair of wires.

concentrations from 0 to 100% Lower Explosive Limit

(LEL). This compatibility, called the PowerLoop technology, is

a two-wire power and signalling bus connected in a

Ideally suited for protection of challenging on/offshore oil

ring topology and galvanically isolated from the rest of

and gas facilities and other downstream hydrocarbon the system, saving cable cost and weight. Each

applications, the AutroPoint HC300PL is certified for use in detector has a built-in short-circuit isolator, hence no

hazardous areas Zone 1 and Zone 2. In addition, the detectors will be lost because of a single break or

stainless steel construction, sapphire optics, and modular short-circuit in the PowerLoop lines.

design all combine to deliver industrial grade hardness

along with easy installation and the lowest cost of owner- All alarms and faults are signalled via the PowerLoop.

ship available. The detector does not require any local power supply

116-P-HC300PL/CE, Rev. A, 2005-07-05 Protecting life, environment and property...

Infrared Hydrocarbon Gas Detector, HC300PL

Technical specifications:

Input Voltage PowerLoop 20-30VDC Certifications DNV Maritime Approval

Power 7 watts maximum

CENELEC: DEMKO 01 ATEX 129485X

Consumption EEx d e [ib] IIC T5

Warmup Time Two minutes from cold power-up to normal (Tamb –40°C to +40°C)

mode; 1 hour minimum recommended. EEx d e [ib] IIC T4

Detection 0 to 100% LEL standard. (Tamb –40°C to +75°C).

Range Other ranges are configurable. IP67.

Detectable Most flammable hydrocarbon vapours are Intrinsically Safe HART Port:

Gases detectable. Standard gases include meth- Uo = 4.0 V

ane, ethane, ethylene, propane, butane and Io = 100 mA

propylene. Co = 20 µF

Detection of non-standard gases is configur- Lo = 500 nH.

able using the HC375 HART communicator. CE: Conforms to:

Calibration All units are methane-calibrated at the fac- Low Voltage Directive: 73/23/EEC,

tory. EMC Directive: 89/336/EEC,

Device configuration is required for detection ATEX Directive: 94/9/EC.

of vapours other than methane. Shipping 3,4 kg

Device Configuration parameters include tag num- Weight

Configuration ber, measurement range, signal processing

(via HART algorithm, alarm levels, and other selectable

Communicat parameters.

or)

Response Time Without Hydrophobic Filter: T50: 7, T90: 10

With Hydrophobic Filter: T50: 8, T90: 12 Order number Description

Temperature Operating: –40°C to +75°C (–40°F to 116-5861-011.5300 HC300PL, Infrared Hydrocarbon Gas

Range +167°F). Detector

Storage: –55°C to +85°C (–67°F to

+185°F).

Humidity 0 to 99% R.H.

(non- 5 to 95% R.H. (FM/CSA/CENELEC

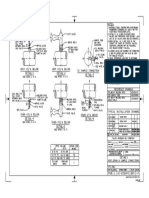

condensing) verified). Dimensions

Alarm Low Alarm: 5 to 60% LEL

Setpoint High Alarm: 5 to 60% LEL.

Range

Accuracy ±3% from 0 to 50% LEL, ±5% from 51 to

100% LEL.

Self- All critical tests performed once per

Diagnostic second.

Test

Ingress IP67 (CENELEC Verified).

Protection

Detector CF8M stainless steel.

Housing

Material

Conduit Entry Two entries, 25 mm.

Options

HART Intrinsically safe (CENELEC/CE).

Communicat

or Port

Optics Weather baffle assembly is Polythalimide

Protection plastic, UV-resistant, static dissipating black.

Optional internal hydrophobic filter recom-

mended for areas with high levels of airborne

particulates or humidity.

Visual Status Tr i-colour LED: Red = alarm

Indicator Green = power on / OK

Yellow = fault.

Wiring Field wiring screw terminals are

Terminals UL/CSA rated for 14 to 24 AWG wire,

and are DIN/VDE rated for 2.5 mm 2

wire. Screw terminal required torque

range is 0.4-0.5 N·m. Wiring compartment

is rated Increased Safety (EEx e).

Autronica Fire and Security AS

Fire and Security, Trondheim, Norway. Phone: + 47 73 58 25 00, fax: + 47 73 58 25 01.

Oil & Gas, Stavanger, Norway. Phone: + 47 51 84 09 00, fax: + 47 51 84 09 99.

Visit Autronica Fire and Security’s Web site: www.autronicafire.com

You might also like

- Detector de Gas IR Eclipse PDFDocument2 pagesDetector de Gas IR Eclipse PDFElvio M100% (1)

- 90-1074-03 (PIR9400) - Specs Sheet PDFDocument2 pages90-1074-03 (PIR9400) - Specs Sheet PDFKasinathan MuniandiNo ratings yet

- 90-1074-03 (Pir9400)Document2 pages90-1074-03 (Pir9400)Donny FitradiNo ratings yet

- Detronics UV-IR Flame Detector Model X5200Document2 pagesDetronics UV-IR Flame Detector Model X5200selvajanarNo ratings yet

- DetTronics GasDetector PIRECLDocument51 pagesDetTronics GasDetector PIRECLyasfin1990No ratings yet

- Vynesys - Product Bro Fx20ex EngDocument2 pagesVynesys - Product Bro Fx20ex EngGokul KoreNo ratings yet

- Infrared Hydrocarbon Gas Detector Open Path Eclipse Model OpeclDocument2 pagesInfrared Hydrocarbon Gas Detector Open Path Eclipse Model Opecldarkchess76No ratings yet

- IR400 Data SheetDocument2 pagesIR400 Data Sheetdarkchess76No ratings yet

- Searchline Excel - Cross DuctDocument4 pagesSearchline Excel - Cross DuctJamarNo ratings yet

- 2 Sgoes Datasheet & Ga r07Document4 pages2 Sgoes Datasheet & Ga r07tung do vanNo ratings yet

- ProReact Digital LHD Installation InstructionsDocument11 pagesProReact Digital LHD Installation InstructionsAlexandru CraiovanNo ratings yet

- Detcon - TP-524D-H2S - Datasheet 965-015420-100Document2 pagesDetcon - TP-524D-H2S - Datasheet 965-015420-100PSC RFQNo ratings yet

- WDG IV O2 AnalyserDocument4 pagesWDG IV O2 Analyserabdul rehmanNo ratings yet

- Detector UVIR X5200Document2 pagesDetector UVIR X5200chicle60No ratings yet

- 45 - 2175 - I fichadurtexDTR X HC PRO v07Document2 pages45 - 2175 - I fichadurtexDTR X HC PRO v07BValidNo ratings yet

- TP-624D H2S Mos PDS PDFDocument2 pagesTP-624D H2S Mos PDS PDFkaleeswaranNo ratings yet

- TEC046-2920FTT-20210527 VarecDocument2 pagesTEC046-2920FTT-20210527 VarecteresaNo ratings yet

- Xgard Bright: Addressable Fixed Point Gas Detector With DisplayDocument4 pagesXgard Bright: Addressable Fixed Point Gas Detector With DisplayPunyawich FungthongjaroenNo ratings yet

- 90 1138 12.1 PireclDocument2 pages90 1138 12.1 PireclPablo Marcelo TolabaNo ratings yet

- Multispectrum Infrared Flame Detector Autroflame X33Document2 pagesMultispectrum Infrared Flame Detector Autroflame X33Angela FasuyiNo ratings yet

- Polytron Pulsar 2 - Open Path Gas Detector - 2Document4 pagesPolytron Pulsar 2 - Open Path Gas Detector - 2Anonymous Wu6FDjbNo ratings yet

- MKD0074 - 1V0 ATEX MODA DatasheetDocument3 pagesMKD0074 - 1V0 ATEX MODA Datasheetนวเรศ สุวรรณมงคลNo ratings yet

- IR400 Data SheetDocument2 pagesIR400 Data Sheets muraNo ratings yet

- Intelligent Low-Flow Duct Smoke Detectors: H VA C S Y S T E M S M O N I T O R I N GDocument4 pagesIntelligent Low-Flow Duct Smoke Detectors: H VA C S Y S T E M S M O N I T O R I N GArgile-assholeNo ratings yet

- Gas Detection Tankmate PDFDocument2 pagesGas Detection Tankmate PDFamirouche15No ratings yet

- IR3 Exd Data Sheet EnUS 11803981579Document3 pagesIR3 Exd Data Sheet EnUS 11803981579ionutenacheNo ratings yet

- Carbon Monoxide DM-100-CO PDSDocument2 pagesCarbon Monoxide DM-100-CO PDSroyvindasNo ratings yet

- XNXDocument5 pagesXNXHaythem AhmedNo ratings yet

- Polytron FX - Old, Obsolete DatasheetDocument2 pagesPolytron FX - Old, Obsolete DatasheetMohamed NaserNo ratings yet

- Cirrus 200D Issue 4Document2 pagesCirrus 200D Issue 4Byron RieraNo ratings yet

- PROLINE Linear Heat Sensor Cables.Document2 pagesPROLINE Linear Heat Sensor Cables.Germán EspinozaNo ratings yet

- ApolloFire XP95 MultisensorDocument2 pagesApolloFire XP95 MultisensorfasiwiNo ratings yet

- Atex Ii 3 G Wdg-Hpii SeriesDocument4 pagesAtex Ii 3 G Wdg-Hpii SeriesEsteban Alejandro CatrilNo ratings yet

- Bid Specification - FV300 - HS - 7467 - ENDocument2 pagesBid Specification - FV300 - HS - 7467 - ENMarthin PurbaNo ratings yet

- FM CODEL GCEM40xx Ap12 PDFDocument6 pagesFM CODEL GCEM40xx Ap12 PDFCandi.nntppNo ratings yet

- TI266ten 0409Document12 pagesTI266ten 0409Keren ArteagaNo ratings yet

- TC906D Eclipse™ Series: Intelligent Duct Smoke Detector and DNRECL HousingDocument2 pagesTC906D Eclipse™ Series: Intelligent Duct Smoke Detector and DNRECL HousingsureshNo ratings yet

- Depliant Iris Enea Inim 1.10 ENGDocument4 pagesDepliant Iris Enea Inim 1.10 ENGKnjigescribdNo ratings yet

- Conventional Fire DetectionDocument18 pagesConventional Fire DetectionkarlamoraNo ratings yet

- Tyco Fire Alarm DevicesDocument4 pagesTyco Fire Alarm DevicesDota NgNo ratings yet

- Det Tronics: Infrared Hydrocarbon Gas Detector Pointwatch Eclipse Model PireclDocument51 pagesDet Tronics: Infrared Hydrocarbon Gas Detector Pointwatch Eclipse Model PireclYasfin Safir100% (1)

- Product Data Sheet ch88 in Situ Flue Gas Oxygen Transmitter Rosemount en 1508434Document12 pagesProduct Data Sheet ch88 in Situ Flue Gas Oxygen Transmitter Rosemount en 1508434cocot 666No ratings yet

- D93 NPM-TECH 42100-Leaflet-20 CompressedDocument4 pagesD93 NPM-TECH 42100-Leaflet-20 Compressedjunaa AlbayatiNo ratings yet

- Intrinsically Safe Analyzer: ATEX SystemDocument4 pagesIntrinsically Safe Analyzer: ATEX Systemarshad13No ratings yet

- WWW - Fyr.Cl: Dispositivos de Bloqueo Control de Emergencies Quimicas Combate de Incendio Y RescateDocument2 pagesWWW - Fyr.Cl: Dispositivos de Bloqueo Control de Emergencies Quimicas Combate de Incendio Y RescateDaniel TorresNo ratings yet

- OCX8800 DatasheetDocument16 pagesOCX8800 DatasheetedipskglNo ratings yet

- Use of HFCDocument10 pagesUse of HFCYamral WubetuNo ratings yet

- AUTOCHIM PRESENTATION Rev 1Document30 pagesAUTOCHIM PRESENTATION Rev 1MGHIRBI HAYKELNo ratings yet

- Atkihc-2020 SetnagDocument2 pagesAtkihc-2020 Setnagcyrano1091No ratings yet

- Pp1095 Xp95 Is Epg Issue 4Document20 pagesPp1095 Xp95 Is Epg Issue 4Aquitec SeguridadNo ratings yet

- Series: Conventional Detector RangeDocument4 pagesSeries: Conventional Detector RangearunNo ratings yet

- Pertronic Industries LTD: Installation Note Linear Heat Detection Cable (LHD)Document4 pagesPertronic Industries LTD: Installation Note Linear Heat Detection Cable (LHD)Podoiu AdrianNo ratings yet

- RF 360 Advanced Ceiling Mount PIR Installation Manual-1Document2 pagesRF 360 Advanced Ceiling Mount PIR Installation Manual-1Imi Michał SmulskiNo ratings yet

- Echotel ... 910Document4 pagesEchotel ... 910Zaki ElsayedNo ratings yet

- Endress-Hauser Proline Promag P 200 5P2B PTDocument4 pagesEndress-Hauser Proline Promag P 200 5P2B PTtiago.angeloNo ratings yet

- Ipes-Ir3 R08Document2 pagesIpes-Ir3 R08naveedfndNo ratings yet

- GD10L IR Open Path Hydrocarbons PDSDocument2 pagesGD10L IR Open Path Hydrocarbons PDSNelson PucheNo ratings yet

- ITAA UserManualDocument24 pagesITAA UserManualIrlan LeiteNo ratings yet

- BHH-300 - Optical Smoke Detector With SelfVerifyDocument2 pagesBHH-300 - Optical Smoke Detector With SelfVerifyIrlan LeiteNo ratings yet

- BF-502-Manual Call Point With Self VeifyDocument2 pagesBF-502-Manual Call Point With Self VeifyIrlan LeiteNo ratings yet

- bd501n CGBDocument4 pagesbd501n CGBIrlan LeiteNo ratings yet

- Basic Intro - Worksheet 05Document1 pageBasic Intro - Worksheet 05Irlan LeiteNo ratings yet

- BOP Presentation Borgny Dolphin SS-65Document13 pagesBOP Presentation Borgny Dolphin SS-65Irlan LeiteNo ratings yet

- All You Need To Refresh Your Knowledge of PumpsDocument48 pagesAll You Need To Refresh Your Knowledge of PumpsMuhammad Bilal100% (1)

- Lift Check Valves: 50 SeriesDocument2 pagesLift Check Valves: 50 Seriesherysyam1980No ratings yet

- 01 CHE312Assign Fall2015Document3 pages01 CHE312Assign Fall2015Peter LiNo ratings yet

- Chapter 2 PDFDocument84 pagesChapter 2 PDFMohammad SaabNo ratings yet

- The Sci Guys - Science at Home - Charles's Law of Ideal GasesDocument5 pagesThe Sci Guys - Science at Home - Charles's Law of Ideal GasesWilfredo Jr. PardorlaNo ratings yet

- Model Cgo Model Cgo HTD Forced Draft Burners GAS Light Oil 98,000 - 19,100,000 Btu/HrDocument2 pagesModel Cgo Model Cgo HTD Forced Draft Burners GAS Light Oil 98,000 - 19,100,000 Btu/HrRafael CalleNo ratings yet

- Conceptual Framework For Predicting The Effectiveness of DRADocument5 pagesConceptual Framework For Predicting The Effectiveness of DRAAndres MarinNo ratings yet

- Drain ConnectionDocument1 pageDrain Connectionnas_mech8208No ratings yet

- Water System Unitary CatalogDocument52 pagesWater System Unitary Catalognairam2003No ratings yet

- Users Manual Zeal Wet Test Gas Flow Meter - 2Document11 pagesUsers Manual Zeal Wet Test Gas Flow Meter - 2Hiran ChathurangaNo ratings yet

- ND 12Document3 pagesND 12el_carlewis100% (1)

- CHE 322 - Gaseous Fuel ProblemsDocument26 pagesCHE 322 - Gaseous Fuel ProblemsDanice LunaNo ratings yet

- Experiment A Carbonate Analysis Molar Volume of Carbon DioxideDocument8 pagesExperiment A Carbonate Analysis Molar Volume of Carbon DioxideThị Ái Thơ ĐoànNo ratings yet

- Agasthya 2013 Series MODEL FLEXIDocument4 pagesAgasthya 2013 Series MODEL FLEXIagniva dattaNo ratings yet

- Challenges API-Safety Relief ValvesDocument5 pagesChallenges API-Safety Relief ValvesheitorgmsNo ratings yet

- Centrifugal PumpDocument5 pagesCentrifugal Pumpsankarsuper83No ratings yet

- SNG From Pet CokeDocument6 pagesSNG From Pet CokeSarath Jose KNo ratings yet

- DoubtsDocument4 pagesDoubtsvarunmalik87No ratings yet

- Electro Pneumatic SystemDocument19 pagesElectro Pneumatic SystemPawan JaiswalNo ratings yet

- PSV Sizing Psv-414 UpdateDocument7 pagesPSV Sizing Psv-414 UpdateBui Khoi NguyenNo ratings yet

- Best Practice For Modeling Thin Liquid Film Coating Flows in ANSYS FluentDocument6 pagesBest Practice For Modeling Thin Liquid Film Coating Flows in ANSYS FluentAhsanNo ratings yet

- Cargill Galapagos Ecuador Steam Installation - Pelletpress Line Conditioner 2x500kgh 240537-P-2002Document1 pageCargill Galapagos Ecuador Steam Installation - Pelletpress Line Conditioner 2x500kgh 240537-P-2002Miguel CujiNo ratings yet

- (1903-14C1906) Inverter Water Cooled Screw ChillerDocument15 pages(1903-14C1906) Inverter Water Cooled Screw Chillerjuan luis loaiza correaNo ratings yet

- Burner Principle and StructureDocument30 pagesBurner Principle and StructureChesya Sera De ClaresyaNo ratings yet

- 2.VD SV Ka 5 GBDocument3 pages2.VD SV Ka 5 GBshanmugamNo ratings yet

- Chapter 3 Vapour Compression Refrigeration Systems L1Document22 pagesChapter 3 Vapour Compression Refrigeration Systems L1Toke BekeleNo ratings yet

- Heat Transfer Lecture#5Document10 pagesHeat Transfer Lecture#5Chemical EngineeringNo ratings yet

- Manipal International University: Lab ReportDocument12 pagesManipal International University: Lab ReportPavan ChinnaNo ratings yet

- Coriolis MeterDocument6 pagesCoriolis Metersuthandira.malarNo ratings yet

- PSV-1100B Rev 3Document6 pagesPSV-1100B Rev 3einhaw1985No ratings yet