Professional Documents

Culture Documents

Cangkang Keong Sawah Kandungan

Uploaded by

Nadirotul RosydahOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cangkang Keong Sawah Kandungan

Uploaded by

Nadirotul RosydahCopyright:

Available Formats

FOODSCITECH

Food Science and Technology Journal

Physicochemical Properties of Golden Apple Snail (Pomacea canaliculata)

Shell Chitosan

1,2 1,2 1,2 3

Sekar Ayu Larasati , Dedin Finatsiyatull Rosida *, Jariyah , Teeradate Kongpichitchoke , Anugerah

1,2 1,2

Dany Priyanto , Andre Yusuf Trisna Putra

1

Department of Food Technology, Faculty of Engineering,

University of Pembangunan Nasional Veteran East Java, Surabaya, 60294, Indonesia

2

Center Innovation of Appropriate Technology for Lowland and Coastal Food, Surabaya, East Java, Indonesia

3

Faculty of Biotechnology,Assumption University, Bangkok, Thailand

Corres Author Emai: dedin.tp@upnjatim.ac.id

ABSTRACT

Pomacea canaliculata, an animal that lives rice fields, is one of the agricultural pests that frequently

affects and may retard the growth of rice plants due to its rapid development. The golden snail shell

contains a chitin polysaccharide which can be reduced to chitosan (β1-4 N-acetyl D-glucosamine)

through the deacetylation stage, namely the process of taking the acetamide group in chitin

(CH3CONH) so that it becomes an amine group (NH2) in chitosan. The manufacture of chitosan is

carried out through 3 stages, namely the process of deproteination, demineralization, and

deacetylation. The purpose of this study was to determine the characteristics and quality of chitosan

produced from golden snail shells. Based on the analysis conducted, chitosan has a yield of 53.91%;

water content 1.68%; ash content 12.31%; molecular weight 640.83 kDa; solubility 95.53; and

deacetylation degree 82.33%.

Keywords: Chitin; Chitosan; Deacetylation; Golden Snail

INTRODUCTION

The golden snail (Pomacea canaliculata) is an animal that can reproduce quickly, which

lives in agricultural areas and eventually becomes the most common pest of rice plants in

several regions in Indonesia. The golden snail pest usually attacks young rice plants that are

less than 1 month old (Sulistiono, 2020). The golden snail lays 1,000-1,200 eggs per month

can reduce the productivity of rice plants by up to 16-40% (Purnamaningsih, 2010). The use

of snails is limited to the consumption of snail meat by some people, which causes the shells

to be very abundant and easy to find. Until now, rice field snail shell waste is mostly

processed as animal (poultry) feed (Nurhaeni et al., 2019).

Chitin is one of the polysaccharides which are one of the main constituents of the shells of

the crustacean group of animals (crabs, shrimp, crabs); molluscs (clams, snails), insects

(cockroaches, scorpions, spiders, beetles), as well as several types of functions, are

naturally non-toxic and biodegradable (Islam et al., 2017). Chitin (C8H13O5N) or ((1-4)-N-

acetyl-D-glucosamine) is the second most abundant natural biopolymer besides cellulose in

nature. Applications of chitin are limited compared to chitosan because chitin is chemically

inert and insoluble in both water and acid, while chitosan is relatively reactive and can be

produced in various forms (Lodhi et al., 2014). Naturally the level of acetylation of chitin is

still low, so that in its utilization in the food or medical sector, it needs to be converted into

chitosan first. Chitin and chitosan contain 5–8 % nitrogen, in which chitin is in the form of

acetylated amine groups and in chitosan in the form of primary aliphatic amine groups, which

makes chitin and chitosan suitable for typical reactions of amines (Islam et al., 2017).

The chitin obtained can be converted into chitosan by changing the acetamide group (-

NHCOCH3) in chitin into an amino group (-NH2). Chitosan is a poly-(2-amino-2-deoxy-β-(1-

4)-D-glucopyranose) compound which is bonded to each other by (1-4) β-glycosidic bonds,

Ayu, Sekar, et al | Physicochemical Properties …. 51

FOODSCITECH, Vol. 6 No. 1 July 2023

ISSN 2622-1985 (print) | ISSN 2622-4127 (online)

DOI: http://dx.doi.org/10.25139/fst.vi.5952

with the molecular formula (C6H11NO4)n, which is an abundant sources biopolymers (Bahri,

2015). Structurally, chitosan contains primary and secondary hydroxyl groups for each

repeating unit, and an amine group for each deacetylated unit, which makes chitosan more

reactive (Islam et al., 2017). Chitosan can be obtained in various forms including irregular

structures, crystalline or semi-crystalline forms. Besides that, it can also be a white solid with

a fixed crystal structure from the initial form of pure chitin. The solubility of chitosan in acidic

solutions and the viscosity of the solution depend on the degree of deacetylation. Currently,

chitosan has received considerable attention for its commercial applications in the

biomedical, food, and chemical industries. Due to its unique biological characteristics,

including biodegradability and nontoxicity, many applications have been found either alone or

blended with other natural polymers (starch, gelatin, and alginates) in the food,

pharmaceutical, textile, agriculture, water treatment, and cosmetics industries (Lodhi et al.,

2014). The purpose of this study was to determine the physicochemical characteristics of the

golden snail shell chitosan, including the functional groups contained.

METHODS

Material

The materials used is golden snail shell obtained from East Jakarta (purchased through

online market), Indonesia, hydrocloric acid 37% (Smart-Lab A 1050), NaOH (Merck 106498),

acetic acid 100% (Smart-Lab A 1001), and aquadest.

Tool

The tools used in this research are crusher (wooden pestle), blender (Philips), 100 mesh

sieve, magnetic stirrer, beaker glass, funnel, filter paper (Whatman), measuring flask,

erlenmeyer glass, stirring rod, spoon, scales, pH paper (Merck), ostwalt viscometer (Iwaki),

and drying oven (Memmert).

Production of Chitosan

Chitosan Preparation (Making of Golden Snail Shells Powder)

The stage of making chitosan was done by making gold snail shell powder with a size of

100 mesh. The golden snail shell first sorted and thoroughly cleaned under running water to

remove any dirt or dust. In order to make the snail shell easier to destroy, then dried at 60°C

for a further 2-3 hours. Then, using of 100 mesh sieve, the dry, clean snail shells were

crushed. The powder has been sifted and now prepared for processing to create chitosan.

Deproteination Process

The process of making chitosan was based on Nurhaeni et al., (2019). The

deproteination process was carried out by weighing 100 mesh gold snail shell powder and

reacted with 4% NaOH solution, with a ratio (w/v) of 1:10. Then, the shell powder and NaOH

solution were heated for two hours at 65°C on a hotplate. After the stirring stage was

finished, the residue was filtered through filter paper and rinsed with distilled water until it

reaches a neutral ( pH 7). The neutral residue is then put in a cabinet dryer with a

temperature of 60oC for 2-3 hours or until dry.

Demineralization Process

This step was carried out by mixing the deproteination residue and 1 M HCl in a ratio of

1:15 (w:v). The solution was then stirred using a magnetic stirrer for 3 hours at room

temperature (25-30oC), and then filtered using filter paper. The demineralized residue

Ayu, Sekar, et al | Physicochemical Properties …. 52

FOODSCITECH, Vol. 6 No. 1 July 2023

ISSN 2622-1985 (print) | ISSN 2622-4127 (online)

DOI: http://dx.doi.org/10.25139/fst.vi.5952

obtained usually still with a pH of 5-6, and must be washed with distilled water until neutral

( pH 7). The neutral residue is then put in a cabinet dryer with a temperature of 60 oC for 2-3

hours or until dry. The residue obtained after the deproteination and demineralization

process is chitin.

Deacetylation Process

The deacetylation process was carried out by mixing the obtained chitin with a NaOH

solution with a concentration of 60%, and stirring on a hotplate stirrer at a temperature of

120oC for 3 hours. After the process completea, it cooled at room temperature for 1 hour.

Chitosan obtained was then washed using distilled water until a neutral pH was obtained

( pH 7). The neutral residue then put in a cabinet dryer with a temperature of 60 oC for 2-3

hours or until dry. The chitosan obtained was ready to be used for other analyzes.

Test Parameters

Yield

The yield was calculated based on the weight of the chitosan (product weight after

deacetylation) and compared with the weight of chitin (product weight before deacetylation).

Final yield could be calculated with given formula (Agustina et al., 2015):

Yield (%) = x 100%

Water content

Testing the water content was carried out by placing 1 gram of sample into a weighing

bottle whose constant weight is known. The samples were then heated in an oven at 100-

105oC for 8 hours, then removed, put in a desiccator, and weighed. The process was then

repeated every 2 hours to obtain a constant weight. Water content can be calculated using

given formula (AOAC, 2005) :

Water Content (%) = x 100%

Ash content

The ash content test was carried out by weighing 0.5 gram of the sample and putting it in

a weighing bottle whose constant weight was previously known. The sample was then

burned in a furnish for 6 hours at a temperature of 600 oC degrees before being taken out,

after 6 hours the sample was removed and heated at 100 degrees to lower the temperature,

then placed in a desiccator for 30 minutes, and weighed. The ash content can be calculated

with given formula (AOAC, 2005):

Ash Content (%) = x 100%

Solubility

Chitosan dissolution was carried out by dissolving 1 gram of chitosan in 100 ml of 2%

acetic acid. The solution is stirred until homogeneous or vortex for 10 seconds. The solution

was then centrifuged for 15 minutes, then filtered to get residue on filter paper. The filter

paper was then in the oven at 100-105oC for 2 hours, the process was repeated until a

constant weight was obtained. Solubility is obtained by insert into the formula (Shon et al,

2011) :

Insolubility (%) = x 100%

Solubility (%) = 100% - Insolubility

53 Ayu, Sekar, et al | Physicochemical Properties ….

FOODSCITECH, Vol. 6 No. 1 July 2023

ISSN 2622-1985 (print) | ISSN 2622-4127 (online)

DOI: http://dx.doi.org/10.25139/fst.vi.5952

Molecular weight

Molecular weight testing was carried out using an Ostwald viscometer, a chitosan solution

(which was dissolved in 1% acetic acid) was prepared with a concentration of 0.2%; 0.4%;

0.6%; 0.8%; up to 1%. After that, the solution is pumped through the viscometer's pipe as the

flow rate is calculated. The same thing was done with 1% acetic acid (without chitosan).

Determination of the molecular mass of chitosan was carried out by entering the intrinsic

viscosity data obtained from the curve between reduced viscosity and concentration into the

Mark-Houwink equation (Mujianto, 2012), namely :

[η] = k.M.va

Descriptions :

= intrinsic viscosity, obtained from the curve (intercept value)

k = 1.46 x 10-4

M = Molecular Weight

a = 0.83

FTIR functional groups

First, 0.02 g sample mixed with 200 mg KBr until homogeneous. The mixture was put into

a pellet to be compacted and vacuumed. The pellet then inserted into the cell placement

chamber, then shouted with an IR beam. The FTIR histogram recordings was produced on

the monitor during detection using the detector button. The histogram displays the peak data

of a sample's functional groups. To gather both qualitative and quantitative data, the

histogram was first obtained and then examined (Muyonga et al., 2004)

Degree of deacetylation

The degree of deacetylation can be determined using “Base Line” method. The

absorbance value at wave number 1655 cm -1 (amide absorption band) and wave number

3450 cm-1 was compared to determine the degree of deacetylation (DD) (hydroxyl band

absorption). Value of deacetylation degree could be measured with given formula

(Czechowska et al., 2012) :

Deacetylation Degree (%) = (( ))

Description:

A1655 = Amide group (CH3CONH) absorption band at wave number 1655 cm -1

A3450 = Hydroxyl/amine group (CH3CONH) absorption band at wave number 3450 cm-1

1,33 = Constant for perfect degree of deacetylation

Data Analysis

Data analysis using Microsoft Excel software in calculating the average in each parameter

RESULT AND DISCUSSIONS

Physcochemical Characteristics of Chitosan

The golden snail shell chitosan as a result of analysis has a light brown powder form,

comparable to research by Dewi et al., (2016) who used escargot snail shells and produced

chitosan's final product in the form of a brownish white powder. This complies with the

Ayu, Sekar, et al | Physicochemical Properties …. 54

FOODSCITECH, Vol. 6 No. 1 July 2023

ISSN 2622-1985 (print) | ISSN 2622-4127 (online)

DOI: http://dx.doi.org/10.25139/fst.vi.5952

standards set by SNI in 2013, that the color of chitosan powder is light brown to white.

Further list of chitosan characteristics can be seen in Table 1.

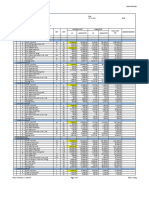

Table 1. Golden apple snail shells chitosan characteristics

Chitosan

Parameter

Analysis Result Reference

Form Powder Powder a

Colour Light brown White-ish browna

Yield (%) 53.91 0.79 34.66a

Water Content (%) 1.68 ± 0.10 3.26 ± 0.45b

Ash Content (%) 12.31 ± 0.17 10.11 ± 0.38b

Solubility (%) 95.53 0.38 97,65c

Molecular Weight (kDa) 640.83 0.64 640.48d

d

Deacetylation Degree (%) 82.33 83.23

a) b) c) d)

Reference : Dewi et al., (2016), Kusumaningsih et al., (2004), Hossain and Iqbal (2014) Nurhaeni

et al., (2019)

The yield obtained was 53.91%. The results of this chitosan yield are greater than the

comparative studies, namely research by Dewi et al. (2016). The difference in yield is most

likely caused by the difference in raw materials used as well as the difference in the process

of making chitosan, namely by deacetylating chitosan at 110 oC for 1 hour. Based on Mursal

et al. (2022) which deacetylated chitin with various temperature variations, namely 110 oC,

120oC, and 130oC, with 60% NaOH (1:20) for 4 hours stated that temperature causes a rise

in the number of reactions, and the more reactions are occurred in the process, the more

they affect the yield of the finished product.

Thus according Table 1, the water content of the golden snail shell chitosan obtained was

1.68%, this figure was relatively lower when compared to the figure in Kusumaningsih et al.,

(2004), which was 3.26%, the resulting water content was meet the standards set by SNI,

namely a maximum of 12%. The existence of differences in numbers can be influenced by

raw materials and differences in the deacetylation process carried out, research belonging to

Kusumaningsih et al., (2004) used snail (bekicot) shell raw materials that just had been dried

for only 3 hours. Although the numbers obtained in this study were low, they still met the

standards of Protan Laboratories (1989), namely ≤10%. According to Mursal et al., (2022)

the drying process or method, drying duration, quantity of dried chitosan, and surface area of

dried chitosan are all factors that influence the moisture content of chitosan. Drying time and

the reduction in water content are closely linked. The water content will decrease more

quickly as the material dries since the amount of water in it reduces.

The ash content of chitosan is a parameter that indicates the total mineral content and

measures the efficiency of demineralization. The ash content found in the golden snail shell

chitosan was 12.78%. The figure obtained is still higher when compared to the literature

belonging to Kusumaningsih et al., (2004), which is 10.11%, but when compared to other

studies that also use snail shells, namely Dewi et al., (2016) it is 87.40% and Puspitasari

(2007) at 95%. The percentage of ash content obtained was very high, so it did not meet the

standard of Protan Laboratories (1989), namely ≤2%. The ineffectiveness of the washing

process after the deacetylation process and the high levels of minerals, particularly calcium

carbonate that incorporate with chitin in the snail shell, are the two factors that affect the ash

content of chitosan. The first one as per Mursal et al., (2022), the chitosan washing process

can affect the ash content. The process of neutralization will be affected by the higher NaOH

content. Na atom will stay in the chitosan, giving it a relatively high ash content, if the

washing procedure is improperly done and the pH level does not reach neutrality. According

55 Ayu, Sekar, et al | Physicochemical Properties ….

FOODSCITECH, Vol. 6 No. 1 July 2023

ISSN 2622-1985 (print) | ISSN 2622-4127 (online)

DOI: http://dx.doi.org/10.25139/fst.vi.5952

to Islami and Anita (2014), the golden snail shell's high mineral content is the second

contributing component. Their ash content is 65.96 %, it is likely that the high ash content in

the final chitosan is caused by the high total minerals in the golden snail shell because the

chitosan neutralization process has produced a neutral pH of 7-8. As a result, a higher

concentration of HCl is required so that the demineralization process is more efficient.

Solubility is one of the standards used to determine the quality of chitosan, the higher the

solubility of chitosan, the better the quality. The resulting chitosan has a solubility of 95.53%,

this figure is still smaller than the literature belonging to Hossain and Iqbal (2014) which is

equal to 97.65% with chitosan from shrimp shells. The nature of chitosan limits its ability to

dissolve in water and dissolve in dilute acids such as acetic, formic and citric. The example of

a weak acid in the carboxylic acid group with a carboxyl group is acetic acid (COOH). A

carbonyl group and a hydroxyl group are both present in the carboxyl group. Chitosan will

dissolve more easily due to hydrogen bonding interaction between the amine groups in

chitosan and the carboxyl groups in acetic acid (Rochima, 2007).

The molecular weight of chitosan was calculated based on the calculation of the intrinsic

viscosity value, using the Mark-Khun Houwing equation. Based on Table 1 the molecular

weight of chitosan from the research results is 640.83 kDa or 640.836 Da. The figures

obtained are not significantly different from the research of Nurhaeni et al., (2019) with

chitosan of field snail shells, which is 640.48 kDa. The molecular weight of chitosan obtained

complies with commercial chitosan standards, with a moderate molecular weight category,

based on Santoso et al, (2020). Chitosan is grouped into three based on its molecular

weight, low molecular weight (<100 kDa), medium molecular weight (100–1000 kDa), and

high molecular weight (>1000 kDa).

The degree of deacetylation is the percentage ratio of chitosan formed when compared to

chitin. Based on the results of the analysis, the degree of deacetylation of golden snail shell

chitosan was 82.33%. The figures obtained are not much different from the research of

Nurhaeni et al., (2019), which found out that chitosan of rice field snail is 83.23%. The

resulting degree of deacetylation of chitosan complied with the SNI chitosan standard (2013),

namely ≤70%. The high NaOH concentration and longer deacetylation time of chitin to

chitosan were responsible for the high number that was obtained. According to Bahri et al.,

(2015) the increase quantity of NaOH used, the more hydroxyl groups available for the

deacetylation process, thereby increasing the possibility of elimination of the carbonyl group

due to addition by hydroxyl, resulting in the formation of more and more amine groups.

Functional Group of Chitosan Identification

The deacetylated golden snail shell chitosan was then characterized using infrared

spectroscopy (FTIR) (Figure 1) and then compared with the infrared spectrum of chitosan

based on the research of Darman et al., (2016) who synthesized chitosan from mangrove

snail shells, the comparation results can be seen in Table 2.

Based on Table 2, it can be seen that there is absorption at the wavelength number 3200-

3500 cm-1 which indicate the presence of OH and NH functional groups, based on Pavia et

al., (2001) in Hayati (2020) the amine group (NH) appears at a wavelength of 3500 -3300 cm-

1

, while the hydroxyl group appears at a wavelength of 3400-3300, there is a peak at wave

number 3136.25; 3234.62 and 3275.13 cm -1, the peak widens and shifts to shorter wave

numbers as a result of hydrogen bonding, which results in overlap with the amine groups or

NH groups, this is in accordance with Fessenden (1989) in Darman et al., (2016) OH and NH

groups are found between wave numbers 3000-3700 cm-1. There is also an absorption at a

Ayu, Sekar, et al | Physicochemical Properties …. 56

FOODSCITECH, Vol. 6 No. 1 July 2023

ISSN 2622-1985 (print) | ISSN 2622-4127 (online)

DOI: http://dx.doi.org/10.25139/fst.vi.5952

wavelength of 2515.18 which is an absorption of the carboxylic acid OH group which is

visible at a wavelength of 2500-3600 cm-1, based on Darman et al., (2016) this group has a

weak absorption band because to the NH stretching vibration of the amine

Figure 1. Infrared Spectrum of Golden Apple Snail Shells Chitosan

Table 2. Characterization of the FTIR spectrum of golden snail shell chitosan

Wavelength (cm-1)

Functional Groups Chitosan Reference Chitosan

Obtained (Darman et al., 2016)

3136.25

OH (Hydroxyl) dan NH 3234.62 3448.72

3275.13

2725.42

2872.01 2922.16

CH (Alkanes)

2926.01 2856.58

2980.02

2515.18

OH (Carboxylic acid) 2515.18 2362.8

2320.37

C=O 1793.8 1741.72

1435.04

CH (Bending) 1462.04

1454.33

C-O-C 1082.07 -

991.41

NH (Swish) 979.84 999.13

875.68 871.82

858.32

Absorption at a wavelength of 2725.42; 2872.01; 2926.01 and 2980.02 cm -1 indicate the

presence of CH groups from alkanes, which according to Darman et al., (2016) associated

with CH2 stretching vibrations. Meanwhile, the absorption at wavelengths of 1435.04 and

1454.33 cm-1 shows an asymmetrical C-H vibration of CH3. There is absorption at a

wavelength of 1793.8 cm-1 which is the absorption stretch of the C=O group from the

secondary amide, according to Silverstein (1989) in Dompeipen (2017) there is a weak

stretch at 1650 cm-1 which indicates a C=O group on the (-NHCOC3) bond. Absorption at a

57 Ayu, Sekar, et al | Physicochemical Properties ….

FOODSCITECH, Vol. 6 No. 1 July 2023

ISSN 2622-1985 (print) | ISSN 2622-4127 (online)

DOI: http://dx.doi.org/10.25139/fst.vi.5952

wavelength of 1082.07 cm-1 is a stretching vibration of the C-O-C group, based on Hayati

(2020) which denotes the presence of a glycosidic bond.

CONCLUSION

Chitosan is a chitin-derived compound that can be found in various sources. In this study,

chitosan was extracted from golden snail shells, which were obtained through 3 stages,

namely demineralization, deproteination, and deacetylation. Based on the analysis

conducted, chitosan has a yield of 53.91%; water content 1.68%; ash content 12.31%;

molecular weight 640.83 kDa; solubility 95.53; and deacetylation degree 82.33%. Results

revealed that the water content and level of deacetylation met SNI criteria, but not the ash

content, which was significantly higher than the standard, indicating the ineffectiveness of the

mineral removal procedure in chitin. The FTIR analysis results additionally indicated that the

extracted compound was chitosan because it contained the typical chitosan groups of

hydroxyl (OH) and amine (NH), but there remains chitin compounds that exist in chitosan as

demonstrated by the presence of the C=O group in the acetamide group (-NHCOC3).

ACKNOWLEDGMENTS

We would like to thank the Directorate General of High Education, Research and

Technology through Applied Research and Innovation Centre of Appropriate Technology of

Lowland of Coastal Food, University of Pembangunan Nasional "Veteran" East Java,

Surabaya, Indonesia.

REFERENCES

Agustina. (2015). Isolasi Kitin, Karakterisasi, dan Sintesis Kitosan dari Kulit Udang (Isolation

of Chitin, Characterization, and Synthesis of Chitosan from Shrimp Shells). Jurnal Kimia

(Chemistry Journal) 9(2): 271–278.

Atika. (2013). Potensi Zat Kitin Pada Hama Keong Mas (Pomacea canaliculata) Sebagai

Pengawet Organik Buah Klimaterik Lokal Kalimantan Barat Dalam Upaya Mewujudkan

Ketahanan Pangan Nasional (Potential of Chitin Substances in the Golden Snail Pest

(Pomacea canaliculata) As an Organic Preservative of West Kalimantan Local

Climacteric Fruits in an Effort to Realize National Food Security)

Bahri, S., Rahim, E.A. and Syarifuddin, S. (2015). Derajat deasetilasi kitosan dari cangkang

kerang darah dengan penambahan naoh secara bertahap (The degree of deacetylation

of chitosan from blood clam shells with the gradual addition of NaOH). Kovalen Jurnal

Riset Kimia (Kovalen Chemistry Research Journal), 1(1)

Czechowska-Biskup, R., Jarosińska, D., Rokita, B., Ulański, P. and Rosiak, J.M. (2012).

Determination of degree of deacetylation of chitosan-comparision of methods. Progress

on Chemistry and Application of Chitin and its Derivatives, (17), pp.5-20.

Darman, P., Bahri, S. and Sumarni, N.K. (2016). Pemanfaatan Kitosan Cangkang Keong

Bakau (Telescopium SP) Sebagai Pengikat Ion Logam Timbal (Pb) Dalam Larutan

(Utilization of Mangrove Snail (Telescopium SP) Shell Chitosan As Lead (Pb) Metal Ion

Binder in Solution). Kovalen Jurnal Riset Kimia (Kovalen Chemistry Research Journal),

2(1)

Ayu, Sekar, et al | Physicochemical Properties …. 58

FOODSCITECH, Vol. 6 No. 1 July 2023

ISSN 2622-1985 (print) | ISSN 2622-4127 (online)

DOI: http://dx.doi.org/10.25139/fst.vi.5952

Dewi, N. L., B. S. and H. J. (2016). Penggunaan berbagai tekanan dan waktu hidrolisis pada

produksi glukosamin hidroklorida dari kitosan cangkang Bekicot (Achatina fulica) (Use

of various hydrolysis pressures and times on the production of glucosamine

hydrochloride from Snail (Achatina fulica) shell chitosan). Kovalen Jurnal Kimia

(Kovalen Chemical Journal), 2(1)

Dompeipen. (2017). Isolasi kitin dan kitosan dari limbah kulit udang (Isolation of chitin and

chitosan from shrimp shell waste). Majalah Biam, 12(1), pp.32-39.

Fadhli, A. (2018). Pengaruh Rasio Massa Kitin/Naoh dan Waktu Reaksi Terhadap

Karakteristik Kitosan yang Disintesis dari Limbah Industri Udang Kering (Effect of

Chitin/Naoh Mass Ratio and Reaction Time on Chitosan Characteristics Synthesized

from Dried Shrimp Industry Waste). Jurnal Sains Materi Indonesia (Journal of

Indonesian Material Science) 18(2): 61-67.

Fessenden, R. (1989). Kimia Organik. Third Edition

Hayati C. (2020). Pengaruh Berat Katalis Kitosan-Hidrotalsit Terhadap Hasil Konversi

Biodesel dari Minyak Kelapa Sawit dengan Metode Refluks (The Effect of Weight of

Chitosan-Hydrotalsite Catalyst on the Conversion of Biodiesel from Palm Oil by Reflux

Method). Universitas Islam Indonesia (University of Islam Indonesia).

Hossain, M., & Iqbal, J. A. (2014). Production and Characterization of Chitosan from Shrimp

Waste. Journal of the Bangladesh Agricultural University, 12(1): 153–160.

Islam. (2017). Chitin and chitosan: structure, properties and applications in biomedical

engineering. Polymers and the Environment 25(3), pp.854-866.

Islami N, Itnawita, Anita S. (2014). Potensi abu cangkang keong mas (Pomacea canaliculata)

sebagai adsorben Tembaga dalam larutan (Potential of golden snail shell ash

(Pomacea canaliculata) as an adsorbent for copper in solution). Universitas Riau

(University of Riau). Pekanbaru.

Kusumaningsih. (2004). Pembuatan kitosan dari kitin cangkang bekicot (Achatina fulica)

(Production of chitosan from snail shell chitin (Achatina fulica)). Biofarmasi, 2(2), pp.64-

68.

Lodhi, G., Kim, Y. S., Hwang, J. W., Kim, S. K., Jeon, Y. J., Je, J. Y., Ahn, C. B., Moon, S.

H., Jeon, B. T., & Park, P. J. (2014). Chitooligosaccharide and its derivatives:

Preparation and biological applications. BioMed Research International, 2014.

Mursal, I.L.P., Farhamzah, F., Selistiawati, A., Meli, D.S., Chaerani, N., Muyasyar, N.,

Latipah, T. and Vidia, V. (2022). Uji Kualitas Kitosan dari Limbah Tulang Sotong dengan

Variasi Suhu Deasetilasi (Quality Test of Chitosan from Cuttlefish Bone Waste with

Deacetylation Temperature Variations). Jurnal Buana Farma (Buana Farma Journal),

2(2), pp.72-77

Mujianto. (2012). Sintesis dan Modifikasi Kitosan dari Limbah Kulit Udang Untuk Aplikasi

Enhanced Oil Recovery (Synthesis and Modification of Chitosan from Shrimp Shell

Waste for Enhanced Oil Recovery Applications). Institut Teknologi Bandung (Bandung

Institute of Technology).

Muyonga, J. H., Cole, C. G. B., & Duodu, K. G. (2004). Fourier transform infrared (FTIR)

spectroscopic study of acid soluble collagen and gelatin from skins and bones of young

and adult Nile perch (Lates niloticus). Food Chemistry, 86(3), 325–332.

59 Ayu, Sekar, et al | Physicochemical Properties ….

FOODSCITECH, Vol. 6 No. 1 July 2023

ISSN 2622-1985 (print) | ISSN 2622-4127 (online)

DOI: http://dx.doi.org/10.25139/fst.vi.5952

Nurhaeni., Ridhay, A., and Langgaeng. A. R. (2019). Depolymerization of chitosan from snail

(Pilla ampullaceae) field shell using α-amylase. Journal of Physics : Conference series.

Vol 1242 (1). IOP Publishing.

Nurhaeni. Ridhay, A., and L. A. R. (2019). Optimization of Degree of Deacetylation of

Chitosan Snail Shells (Pilla ampulaceae). Asian Journal of Chemistry, 31 2083(6)

Official Methods of Analysis of Association of Official Analytical Chemists. (2005).

Pavia, L., Lampman, G., and Goerge, S. K. (2001). Introduction to Spectroscopy.

Introduction to Spectroscopy :a Guide for Students or Organic Chemistry. Philadhelphia:

Harcourt College.

Purnamaningsih. (2010). Pengaruh Penambahan Tepung Keong Mas (Pomacea

canaliculata) dalam Ransum Terhadap Kualitas Telur Itik (Effect of Addition of

Golden Snail Flour (Pomacea canaliculata) in Rations on Duck Egg Quality). Skripsi.

Fakultas Pertanian. Universitas Sebelas Maret (University of Sebelas Maret). Surakarta.

Puspitasari, A. (2007). Pembuatan dan Pemanfaatan Kitosan Sulfat dari Cangkang

Bekicot (Achatina fulica) sebagai adsorben zat warna Remazol Yellow FG 6

(Production and Utilization of Chitosan Sulfate from Snail Shells (Achatina fulica) as an

adsorbent for dye Remazol Yellow FG 6). Universitas Sebelas Maret (University of

Sebelas Maret).

Rochima, E. (2007). Karakterisasi Kitin dan Kitosan Asal Limbah Rajungan Cirebon Jawa

Barat (Characterization of Chitin and Chitosan from Cirebon West Java Crab Waste).

Buletin Teknologi Hasil Pertanian (Agricultural Product Technology Bulletin) X(1): 9-22.

Santoso. (2020). Effect of acetic acid hydrolysis on the characteristics of water-soluble

chitosan. IOP Conference Series: Earth and Environmental Science Vol. 414, No. 1, p.

12-21

Shon. (2011). Effect of processing conditions on functional properties of collagen powder

from skate (Raja kenojei) skins. Food Science and Biotechnology. 20(1):99-106.

Silverstein, R. (1989). Spectrometric identification of organic compounds. Seventh Edition.

Sulistiono. (2020). Cara Aman Mengendalikan Keong Emas (How to Safely Control the

Golden Apple Snail). Institut Pertanian Bogor (Bogor Agricultural Institute).

Ayu, Sekar, et al | Physicochemical Properties …. 60

You might also like

- The Effect of Time Deacetylation To Characterize Chitosan From Waste ShrimpDocument16 pagesThe Effect of Time Deacetylation To Characterize Chitosan From Waste ShrimpIgnatius AgustaNo ratings yet

- Ijesrt: International Journal of Engineering Sciences & Research TechnologyDocument11 pagesIjesrt: International Journal of Engineering Sciences & Research TechnologyAna MariaNo ratings yet

- 289 Monodon) Using Enzymes Chitosanase of BacterialDocument9 pages289 Monodon) Using Enzymes Chitosanase of BacterialMohammad Ramadhan PrasetyoNo ratings yet

- Atributos Sensoriales de Carpa Herbívora Con Quitosano Almacenados A 4°C-2017Document13 pagesAtributos Sensoriales de Carpa Herbívora Con Quitosano Almacenados A 4°C-2017Camilo Huertas CamposNo ratings yet

- A Process For The Preparation of Chitin and Chitosan From Prawn Shell WasteDocument8 pagesA Process For The Preparation of Chitin and Chitosan From Prawn Shell WasteApt Fitri RosdianaNo ratings yet

- Papaya and ChitosanDocument7 pagesPapaya and ChitosanZion Edgar NunagNo ratings yet

- (19-24) Production of Cellulose From Barley Husks As A Partial Ingredient of Formulated Diet For Tilapia FingerlingsDocument7 pages(19-24) Production of Cellulose From Barley Husks As A Partial Ingredient of Formulated Diet For Tilapia FingerlingsAlexander DeckerNo ratings yet

- Yudhistira 2019 IOP Conf. Ser. Earth Environ. Sci. 246 012046Document8 pagesYudhistira 2019 IOP Conf. Ser. Earth Environ. Sci. 246 012046ermawati lestariNo ratings yet

- The Chitosan Cembrane Cffectiveness of Anadara Granosa Clam Shells To Remove Total Coliform in GreywaterDocument7 pagesThe Chitosan Cembrane Cffectiveness of Anadara Granosa Clam Shells To Remove Total Coliform in GreywaterIJPHSNo ratings yet

- Fish ScaleDocument13 pagesFish ScaleRhea May Lourene MagsinoNo ratings yet

- Physical and Antimicrobial Properties of Banana Flour and Chitosan BiodegradableDocument6 pagesPhysical and Antimicrobial Properties of Banana Flour and Chitosan BiodegradableLC7040861No ratings yet

- Chitosan Extracted From Mud Crab (Scylla Olivicea) Shells - Physicochemical and Antioxidant PropertiesDocument10 pagesChitosan Extracted From Mud Crab (Scylla Olivicea) Shells - Physicochemical and Antioxidant PropertiesChemistryNo ratings yet

- Produksi Kitosan Secara Enzimatik Oleh Bacillus Sampah Perikanan Enzymatic Chitosan Production by New Isolated Bacillus From Fisheries WasteDocument9 pagesProduksi Kitosan Secara Enzimatik Oleh Bacillus Sampah Perikanan Enzymatic Chitosan Production by New Isolated Bacillus From Fisheries WasteAkuba HijrahNo ratings yet

- 27817-Article Text-92478-2-10-20200206Document11 pages27817-Article Text-92478-2-10-20200206siti faridahNo ratings yet

- Kitosan Sebagai Pengawet (Harjanti 2014)Document8 pagesKitosan Sebagai Pengawet (Harjanti 2014)RinaNo ratings yet

- Kori 2018Document9 pagesKori 2018izzaaaaawNo ratings yet

- Extraction and Characterization of Chitin and Chitosan From Blue Crab and Synthesis of Chitosan Cryogel ScaffoldsDocument14 pagesExtraction and Characterization of Chitin and Chitosan From Blue Crab and Synthesis of Chitosan Cryogel ScaffoldsApt Fitri RosdianaNo ratings yet

- 100-2010 Zhabg PDFDocument8 pages100-2010 Zhabg PDFMrSomnambululNo ratings yet

- William 2019 J. Phys. Conf. Ser. 1358 012002Document8 pagesWilliam 2019 J. Phys. Conf. Ser. 1358 012002ReemaNo ratings yet

- Article Wjpps 1451625165Document12 pagesArticle Wjpps 1451625165Arturo DíazNo ratings yet

- 995 2157 1 PBDocument11 pages995 2157 1 PBANNISA ZAHRA RAMADHANNo ratings yet

- New Process For Synthesizing Chitosan From Snail Shells: Journal of Physics: Conference SeriesDocument7 pagesNew Process For Synthesizing Chitosan From Snail Shells: Journal of Physics: Conference SeriesReemaNo ratings yet

- Extraction and Characterization of Gelatin: A Functional BiopolymerDocument4 pagesExtraction and Characterization of Gelatin: A Functional BiopolymerTrần Thị QuỳnhNo ratings yet

- 1 s2.0 S135951131100448X MainDocument8 pages1 s2.0 S135951131100448X MainIngrid DantasNo ratings yet

- Dliyauddin 2020Document8 pagesDliyauddin 2020Kenyavi SyahdhaniNo ratings yet

- 7.biochemical and Structural Characterization of Sturgeon FishDocument10 pages7.biochemical and Structural Characterization of Sturgeon FishJonathanCoralNo ratings yet

- Extraction and Characterization of Chitin and Chitosan PDFDocument9 pagesExtraction and Characterization of Chitin and Chitosan PDFJordan Ulloa BelloNo ratings yet

- $RHZ3KN3Document39 pages$RHZ3KN3va.tmcbogorNo ratings yet

- Shrimp ShellDocument11 pagesShrimp ShellSaranya RathanNo ratings yet

- Extraction and Characterization of Chitin PDFDocument8 pagesExtraction and Characterization of Chitin PDFdiegojrendonbNo ratings yet

- Dragon Fruit PDFDocument8 pagesDragon Fruit PDFNguyễn Võ Hoài PhươngNo ratings yet

- 1 s2.0 S2405844023039191 MainDocument7 pages1 s2.0 S2405844023039191 MainRicardo David Andrade PizarroNo ratings yet

- Science, Technology, Engineering, and Mathematics Ligao National High School - Senior High SchoolDocument10 pagesScience, Technology, Engineering, and Mathematics Ligao National High School - Senior High SchoolMaria Kyla Peñafiel TeodoroNo ratings yet

- Acute Toxicity Studies of The Dried Aqueous Extract of Cestrum Nocturnum Leaves On Clarias Batrachus JuvenilesDocument6 pagesAcute Toxicity Studies of The Dried Aqueous Extract of Cestrum Nocturnum Leaves On Clarias Batrachus JuvenilesDr. Jawale Chetan S.No ratings yet

- 1 PBDocument6 pages1 PBAngga PratamaNo ratings yet

- 1 s2.0 S0141813013003292 MainDocument8 pages1 s2.0 S0141813013003292 Mainruben alvaradoNo ratings yet

- Effect of Dragon Fruit Peel Powder On Quality and Acceptability of Fish Nuggets Stored in A Solar Cooler (5 1 °C)Document13 pagesEffect of Dragon Fruit Peel Powder On Quality and Acceptability of Fish Nuggets Stored in A Solar Cooler (5 1 °C)Ashley CarandangNo ratings yet

- 7713-Article Text-36533-1-10-20221129 PDFDocument11 pages7713-Article Text-36533-1-10-20221129 PDFAndika Fadhilah Saji PratamaNo ratings yet

- Bioethanol Production From Alkaline-Pretreated Sugarcane BagasseDocument7 pagesBioethanol Production From Alkaline-Pretreated Sugarcane BagasseCuartos Amueblados JennyJohnnyNo ratings yet

- Chitin Chitosan ProductionDocument19 pagesChitin Chitosan ProductionOmer MukhtarNo ratings yet

- Chemical Analysis of Duck Bone Meal (Anatidae) From Traditional Food Processing Waste Typical of SidrapDocument5 pagesChemical Analysis of Duck Bone Meal (Anatidae) From Traditional Food Processing Waste Typical of Sidrapzn artikelNo ratings yet

- Application of Chitosan Shells Meti Batissa ViolacDocument12 pagesApplication of Chitosan Shells Meti Batissa Violacnia herianiNo ratings yet

- Amitha, Et AlDocument7 pagesAmitha, Et AlAMAANINo ratings yet

- Cached PDF: /arts/ Seaweed .HTMDocument3 pagesCached PDF: /arts/ Seaweed .HTManon-386954No ratings yet

- Milkfish FlourDocument8 pagesMilkfish FlourJinnie R. MamhotNo ratings yet

- Astuti 2021 IOP Conf. Ser. Earth Environ. Sci. 924 012034Document6 pagesAstuti 2021 IOP Conf. Ser. Earth Environ. Sci. 924 012034Della AzzuraNo ratings yet

- Preparation and Characterization of Chitosan ObtaiDocument12 pagesPreparation and Characterization of Chitosan ObtaiMargonoNo ratings yet

- Indian Journal 2020Document6 pagesIndian Journal 2020Hassan AL-HillaliNo ratings yet

- V. Panchakshari, Et AlDocument8 pagesV. Panchakshari, Et AlZulfikran Azis SyahNo ratings yet

- Ijrtsat 3 3 5Document3 pagesIjrtsat 3 3 5STATPERSON PUBLISHING CORPORATIONNo ratings yet

- J Ijbiomac 2017 04 119Document37 pagesJ Ijbiomac 2017 04 119nezarahayuNo ratings yet

- Kinetika Reaksi Deasetalisasi Sintesa Kitosan Dengan PendekatanDocument6 pagesKinetika Reaksi Deasetalisasi Sintesa Kitosan Dengan PendekatanAxel DaffaNo ratings yet

- Yang2000 PDFDocument8 pagesYang2000 PDFBéo Béo DragonNo ratings yet

- Undergraduate Research Proposal: Proposed TitleDocument8 pagesUndergraduate Research Proposal: Proposed TitleHanshiya RagaNo ratings yet

- Vaishali Randive, Et AlDocument8 pagesVaishali Randive, Et AlOENDRIL DASNo ratings yet

- J Polymdegradstab 2009 06 021Document5 pagesJ Polymdegradstab 2009 06 021Koreab KoeenNo ratings yet

- I J R P S: Proximate, Minerals, and Vitamins in Chayote FlourDocument4 pagesI J R P S: Proximate, Minerals, and Vitamins in Chayote FlourHazel BalonglongNo ratings yet

- Aquaponics systems, fish. Volume 3: Sistemas de acuaponíaFrom EverandAquaponics systems, fish. Volume 3: Sistemas de acuaponíaNo ratings yet

- Black Soldier Fly Products: Generic Description and Analysis of the Production Process for Chitosan, Proteins and Lipid from Black Soldier Fly Larvae.From EverandBlack Soldier Fly Products: Generic Description and Analysis of the Production Process for Chitosan, Proteins and Lipid from Black Soldier Fly Larvae.Rating: 4 out of 5 stars4/5 (1)

- Aquaponics Systems, Fish. Volume 6: Sistemas de acuaponíaFrom EverandAquaponics Systems, Fish. Volume 6: Sistemas de acuaponíaNo ratings yet

- Piping Cost BreakdownDocument2 pagesPiping Cost BreakdownMarie100% (1)

- A Study of Residual Oils Recovered From Spent Bleaching Earth: Their Characteristics and ApplicationsDocument6 pagesA Study of Residual Oils Recovered From Spent Bleaching Earth: Their Characteristics and Applicationsfatiya rizkiyaniNo ratings yet

- Aalco Metals LTD Stainless Steel Innosoft Innoclean Innoprotect 127Document5 pagesAalco Metals LTD Stainless Steel Innosoft Innoclean Innoprotect 127sijinjoyNo ratings yet

- 61302-Article Text-114824-1-10-20101022Document4 pages61302-Article Text-114824-1-10-20101022Oscar MacíasNo ratings yet

- Sample Cylinders, Accessories, and Outage Tubes: FeaturesDocument9 pagesSample Cylinders, Accessories, and Outage Tubes: Featuresulfah nur khikmahNo ratings yet

- Biodegradation NewDocument37 pagesBiodegradation NewAyesha AbbasiNo ratings yet

- Full Download Genetic Analysis An Integrated Approach 3rd Edition Sanders Test BankDocument15 pagesFull Download Genetic Analysis An Integrated Approach 3rd Edition Sanders Test Bankdopemorpheanwlzyv100% (42)

- Chapter 6 - Slip and Creep Performance For Metallized Connection Faying Surfaces Used in Steel Bridge ConstructionDocument10 pagesChapter 6 - Slip and Creep Performance For Metallized Connection Faying Surfaces Used in Steel Bridge ConstructionDavid C HouserNo ratings yet

- Nitrogen Purge Rev1Document2 pagesNitrogen Purge Rev1sasa hhNo ratings yet

- Science of The Total EnvironmentDocument14 pagesScience of The Total EnvironmentKArenNo ratings yet

- Resin Based Restorative Dental Materials. Characteristics and Future PerspectivesDocument13 pagesResin Based Restorative Dental Materials. Characteristics and Future PerspectivesDan MPNo ratings yet

- JBL Sinter PlantDocument77 pagesJBL Sinter PlantShashi Kant Tiwari100% (2)

- Mole Conversions Practice Answer KeyDocument1 pageMole Conversions Practice Answer Keyapi-376281962No ratings yet

- Thermic-Fluids 500 & 600Document2 pagesThermic-Fluids 500 & 600Chetan SharmaNo ratings yet

- Bio Project .. RoshuDocument14 pagesBio Project .. RoshuIts Me100% (1)

- CHEM F111: General Chemistry: PilaniDocument25 pagesCHEM F111: General Chemistry: Pilanicukdbjsisns shsusbsbvzNo ratings yet

- Cape Chemistry, 2016, U1, P2, Q#4Document4 pagesCape Chemistry, 2016, U1, P2, Q#4Mariah BissoonNo ratings yet

- Perfrez 9021A: Technical DatasheetDocument1 pagePerfrez 9021A: Technical DatasheetDipesh PhapeNo ratings yet

- Thermo Mock SolutionsDocument14 pagesThermo Mock Solutionsmanjeet gajbhiyeNo ratings yet

- Chemistry ProjectDocument19 pagesChemistry ProjectMuhammed Äméèñ100% (4)

- Index: Combustion Technology: Essential of Flames and Burners, First Edition SDocument3 pagesIndex: Combustion Technology: Essential of Flames and Burners, First Edition SirNo ratings yet

- Khaùng Sinh Phenicol: Cloramphenicol (Tifomycin)Document19 pagesKhaùng Sinh Phenicol: Cloramphenicol (Tifomycin)Dreamline de SkyNo ratings yet

- Paper Name: Chemistry-I Code: BS-CH201 Contacts: 3L +1T Credits: 4Document5 pagesPaper Name: Chemistry-I Code: BS-CH201 Contacts: 3L +1T Credits: 4ME39Arnaw KumarNo ratings yet

- CollisionTheorySE Revised For MYP-GizmosDocument9 pagesCollisionTheorySE Revised For MYP-GizmosNo HumorNo ratings yet

- Equipment in Chemistry LaboratoryDocument5 pagesEquipment in Chemistry LaboratoryIstiva AmeiliaNo ratings yet

- Extraction and Analysis of Eugenol From Cloves: Jdefrancesco@luc - EduDocument9 pagesExtraction and Analysis of Eugenol From Cloves: Jdefrancesco@luc - Edu01Syafira Khairunissa M100% (1)

- Edexcel Chemistry Unit 3 NotesDocument113 pagesEdexcel Chemistry Unit 3 Notessabila86% (22)

- Penetapan Bilangan PeroksidaDocument4 pagesPenetapan Bilangan PeroksidaPuspitaNo ratings yet

- The Structural Components of The Cell Membrane and Its Functions, With Transport Mechanisms.Document17 pagesThe Structural Components of The Cell Membrane and Its Functions, With Transport Mechanisms.Vieyah Angela VicenteNo ratings yet

- Chromatography Lab SheetDocument2 pagesChromatography Lab SheetDaniel GutierrezNo ratings yet