Professional Documents

Culture Documents

TDS - Vinyl 901-3 (En)

Uploaded by

OXY Composite TechOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TDS - Vinyl 901-3 (En)

Uploaded by

OXY Composite TechCopyright:

Available Formats

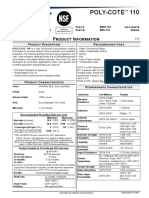

SWANCOR 901-3

Epoxy Vinyl Ester Resins

Product Description Typical clear casting properties of cured resin

3

Property SI* US Standard Test Method

SWANCOR 901-3 is a Bisphenol A type epoxy vinyl ester resin. It

Tensile Strength 80~95MPa 11,000~14,000psi ASTM D638

is a premium resin with improved reactivity and purity. It provides

5

excellent corrosion resistance to a broad range of organic and Tensile Modulus 3.3~3.6GPa 4.8~5.2 X 10 psi ASTM D638

inorganic acids, alkalis, oxidizing chemicals and salt solutions etc. Tensile Elongation 5.0~6.0% 5.0~6.0% ASTM D638

It also provides very good mechanical strength such as tensile and Flexural Strength 125~152MPa 18,000~22,000psi ASTM D790

flexural while incorporated with reinforcement such as glass fiber, 5

Flexural Modulus 3.1~3.6GPa 4.5~5.2 X 10 psi ASTM D790

carbon fiber or kevlar fiber etc. SWANCOR 901-3 is designed to

provide superior toughness with excellent fatigue resistance due Volume Shrinkage 7.5~8.0% 7.5~8.0% ASTM D2566

to high heat distortion temperature. Heat Distortion o o

4 105~110 C 221~230 F ASTM D648

Temperature *

Advantages Barcol Hardness 30~38 30~38 ASTM D2583

3

* SI values based on conversion.

Lower viscosity i.e. better fiber wet-put. 4

* Cure condition for HDT: 24 hours at room temperature then

Less or no DMA is needed i.e. easier formulation and cost o

2 hours at 105 C.

saving.

Lower casting color i.e. better see-through for bubble

checking.

Typical gel time of SWANCOR 901-3

Lower exotherm i.e. less cracking, less cycles and quality

Gel Time

improvement. Materials 10~20 min 20~40 min 40~60 min

Temperature

Longer shelf life i.e. better inventory control. 5

Cured by MEKP/CoOct/DMA*

MEKP 2.00% 2.00% 2.00%

Applications o o

18 C/64 F CoOct 0.60% 0.40% 0.40%

DMA 0.10% 0.06% 0.02%

Chemical storage tanks, pipes, flue gas desulfurization

systems (FGD), scrubbers, ducts. MEKP 1.20% 1.20% 1.20%

o o

Corrosion resistant flooring while incorporated with 25 C/77 F CoOct 0.40% 0.30% 0.15%

aggregates. DMA 0.04% --- ---

Waste water treatment systems. MEKP 1.00% 1.00% 1.00%

o o

Food storage tanks and pure water system. 30 C/86 F CoOct 0.30% 0.10% 0.07%

Marine use for yachts and boats. DMA --- --- ---

5

* Concentration: MEKP: 55%, CoOct: 6%, DMA: 100%

Fabrication Methods

Can be easily applied by hand lay-up laminating, spray-up, NOTICE IN USE

pultrusion, resin transfer molding (RTM) and filament

winding. 1. If SWANCOR 901-3 is blended with cobalt-salt promoters,

Can be used in polymer concrete casting. shelf life will be shortened. Promoted SWANCOR 901-3 must

Can comply with US FDA regulation 21 CFR 177.2420 if the be used within three months.

resin is properly formulated and cured. 2. The gel time of SWANCOR 901-3 is affected primarily by

catalyst concentration and temperature. The variations of cure

Typical properties of liquid resin characteristics may be caused by the variations of catalyst,

1 humidity, pigment, fillers and other additives. It is

Property* Value

recommended that the fabricators check the cure

Appearance Clear yellowish liquid

characteristics with a small quantity resin before proceeding for

Solid Content (%) 55 +/- 1 bulk production.

Viscosity *

2

350 +/- 100 cps 350 +/- 100 mPa.s 3. SWANCOR 901-3 contains organic solvent (styrene). Keep

away from heat, sparks and flames.

Specific Gravity 1.04 +/- 0.01

4. SWANCOR 901-3 is a potentially reactive chemical. Please

Shelf Life (months) 9 store it in dark and keep away from heat and direct sunshine.

1 o

* Measurement was obtained under 25 C. 5. Containers, not completely emptied must be closed

2 o

* LVT-#3-60rpm@25 C. immediately after use.

The data presented herein are believed to be accurate and reliable. We require customers to inspect and test our product before use and to satisfy

themselves as to contents and suitability for their specific applications. Information herein is to assist customers in determining whether our products

are suitable for their applications but not to be taken as a guarantee, express warranty or implied warranty of merchantability or fitness for

particular purpose, nor is any protection form any law or patent to be inferred. All patent rights are reserved. The exclusive remedy for all proven

claims is limited to replacement of our material and in no event shall we be liable for special, incidental or consequential damages.

Page 1/2 Document Code:NT26-011-E Issue Date:AUG/2009

No. 9 Industry South 6 Road, Nantou City 54066, Taiwan

SWANCOR IND. CO., LTD. Tel: +886 49 225 5420 Fax: +886 49 225 1534

E-mail: nantou@swancor.com.tw

www.swancor.com

SWANCOR 901-3

Epoxy Vinyl Ester Resins

MATERIAL SAFETY AND HANDLING INFORMATION WASTE DISPOSAL

Destroy by liquid incineration in accordance with applicable

SKIN CONTACT: regulation. Contaminated absorbent should be disposed in

Thoroughly wash exposed area with soap and water immediately. accordance to government regulations.

Remove contaminated clothing. Launder contaminated clothing

before re-use.

PACKAGE

EYE CONTACT: Standard packing is 200 kg steel drum.

Flush with large amount of water immediately and continuously for

20 minutes, lifting upper and lower lids occasionally. Get medical

attention.

INGESTION:

Do not induce vomiting. Keep person warm, quiet and get medical

attention. Aspiration of material into the lungs can cause chemical

pneumonitis which can be fatal.

INHALATION:

If affected, remove individual to fresh air. If breathing is difficult,

administer oxygen. If breathing has stopped, give artificial

respiration. Keep person warm, quiet, and get medical attention.

PERSONAL PROTECTION:

Do not breathe vapors. High concentration of vapor can be

hazardous. Keep out of sewers. Eliminate all sources of ignition in

vicinity of spill or released vapor to avoid fire or explosion. For

large spills, warn public of downwind explosion hazard. Check

area with explosion meter before re-entering area. Ground and

bond all containers and handling equipment.

RESIN STORAGE

Keep away from ignition sources; flames, pilot lights, electrical

sparks, and sparking tools. NO SMOKING. Do not store in direct

sunlight. Store separate from oxidizing materials, peroxides, and

metal salts. Keep container closed when not in use. To ensure

maximum stability and maintain optimum resin properties, resins

o

should be stored in closed containers at temperatures below 25 C

o

(77 F). Copper or copper containing alloys should be avoided as

containers.

SPILLS

Eliminate all ignition sources (flares, flames, including pilot lights

electrical sparks). Persons not wearing protective equipment

should be exclude from area of spill until clean-up has been

completed. Stop spill at source, dike area of spill to prevent

spreading, pump liquid to salvage tank. Remaining liquid may be

taken up on sand, clay, earth, floor absorbent or other absorbent

material and shoveled into containers.

The data presented herein are believed to be accurate and reliable. We require customers to inspect and test our product before use and to satisfy

themselves as to contents and suitability for their specific applications. Information herein is to assist customers in determining whether our products

are suitable for their applications but not to be taken as a guarantee, express warranty or implied warranty of merchantability or fitness for

particular purpose, nor is any protection form any law or patent to be inferred. All patent rights are reserved. The exclusive remedy for all proven

claims is limited to replacement of our material and in no event shall we be liable for special, incidental or consequential damages.

Page 2/2 Document Code:NT26-011-E Issue Date:AUG/2009

No. 9 Industry South 6 Road, Nantou City 54066, Taiwan

SWANCOR IND. CO., LTD. Tel: +886 49 225 5420 Fax: +886 49 225 1534

E-mail: nantou@swancor.com.tw

www.swancor.com

You might also like

- SWANCOR 901-3: Epoxy Vinyl Ester ResinsDocument2 pagesSWANCOR 901-3: Epoxy Vinyl Ester ResinsSofya Andarina100% (1)

- A Review of Catastrophic Flow Failures of Deposits of Mine WateDocument17 pagesA Review of Catastrophic Flow Failures of Deposits of Mine WateAbraham FIgueroa ARevaloNo ratings yet

- Mme405 PDFDocument129 pagesMme405 PDFkanakatharavijayanNo ratings yet

- GP 2 Diagnostic Test Answer KeyDocument11 pagesGP 2 Diagnostic Test Answer KeyPatricia TorrecampoNo ratings yet

- Swancor 901-3: Epoxy Vinyl Ester ResinsDocument2 pagesSwancor 901-3: Epoxy Vinyl Ester Resinswongpengchiong7205No ratings yet

- TDS - Vinyl 907-1 (En)Document2 pagesTDS - Vinyl 907-1 (En)OXY Composite TechNo ratings yet

- HT Swancor 901-Pt-Ve-30Document3 pagesHT Swancor 901-Pt-Ve-30Fernando Cesar PérezNo ratings yet

- 907 1TDSDocument2 pages907 1TDSJainam Shah100% (1)

- Swancor 901Document2 pagesSwancor 901jdiaz87No ratings yet

- TDS - Vinyl 905-2 (En)Document2 pagesTDS - Vinyl 905-2 (En)OXY Composite Tech100% (1)

- TDS SW 901 3Document5 pagesTDS SW 901 3Frans Hendra WinartaNo ratings yet

- Swancor Chempulse 907: Novolac Epoxy Vinyl Ester ResinDocument4 pagesSwancor Chempulse 907: Novolac Epoxy Vinyl Ester ResinEVLYNNo ratings yet

- Protective & Marine Coatings: Polysiloxane 1KDocument4 pagesProtective & Marine Coatings: Polysiloxane 1KAna CabreraNo ratings yet

- Aegis5-14 Film Validation Guide: Five-Layer, 14 Mil Cast Fi LMDocument15 pagesAegis5-14 Film Validation Guide: Five-Layer, 14 Mil Cast Fi LMCampaign MediaNo ratings yet

- TDS Castrol Perfecto XPG - Power VersionDocument2 pagesTDS Castrol Perfecto XPG - Power VersionTeguh SNo ratings yet

- L-TSELF Long Service Life Extreme Pressure Turbine OilDocument3 pagesL-TSELF Long Service Life Extreme Pressure Turbine OilQuy NguyenNo ratings yet

- Cx5 14 Single Use Film Validation Guide REFER For ABOUT FILMDocument15 pagesCx5 14 Single Use Film Validation Guide REFER For ABOUT FILMCampaign MediaNo ratings yet

- F F O P L: Epofine - 740 / Finehard - 918 / Accelerator - 062Document4 pagesF F O P L: Epofine - 740 / Finehard - 918 / Accelerator - 062Karishma Prabhu100% (1)

- TGSB (M) Turbine OilDocument3 pagesTGSB (M) Turbine OilQuy NguyenNo ratings yet

- L-TSE Turbine OilDocument3 pagesL-TSE Turbine OilYoong TanNo ratings yet

- Belzona 1321: Product Specification SheetDocument2 pagesBelzona 1321: Product Specification Sheetmehdi kamaliNo ratings yet

- Epofine 221 - Finehard 964 - Accelerator 070Document4 pagesEpofine 221 - Finehard 964 - Accelerator 070Karishma PrabhuNo ratings yet

- TGF - (M) 32 Extreme Pressure Gas Turbine OilDocument3 pagesTGF - (M) 32 Extreme Pressure Gas Turbine OilQuy NguyenNo ratings yet

- Novolac Vinyl Ester Resin: Asecorr 970Document2 pagesNovolac Vinyl Ester Resin: Asecorr 970Mohammed SafwanNo ratings yet

- Protective & Marine Coatings: DTM Acrylic Primer/FinishDocument4 pagesProtective & Marine Coatings: DTM Acrylic Primer/FinishAna CabreraNo ratings yet

- Epofine 556 - Finehard 22962Document5 pagesEpofine 556 - Finehard 22962Karishma PrabhuNo ratings yet

- Eneral-Purpose Injection Moulding Grade: POKETONE Polymer M630ADocument2 pagesEneral-Purpose Injection Moulding Grade: POKETONE Polymer M630AmacNo ratings yet

- DTM Acrylic Pimer Finish B66W1Document4 pagesDTM Acrylic Pimer Finish B66W1Vernon Jiménez FonsecaNo ratings yet

- Asi2677 Single Use Film Validation GuideDocument17 pagesAsi2677 Single Use Film Validation GuideCampaign MediaNo ratings yet

- Acrolon 218 HsDocument4 pagesAcrolon 218 HsKARENNo ratings yet

- ReportDocument21 pagesReportFaisal AkhterNo ratings yet

- L-TSA Classic Turbine OilDocument3 pagesL-TSA Classic Turbine OilQuy NguyenNo ratings yet

- Technical Data Sheet: Epoguard EnamelDocument3 pagesTechnical Data Sheet: Epoguard Enameltrường phạmNo ratings yet

- TDS - Premix Marine ThixotropeDocument3 pagesTDS - Premix Marine ThixotropegmNo ratings yet

- LLDPE-218BJ EditDocument3 pagesLLDPE-218BJ EditChu ChuNo ratings yet

- DuraplateDocument4 pagesDuraplatelovaldes62No ratings yet

- Acrolon 218 HS Acrylic PolyurethaneDocument4 pagesAcrolon 218 HS Acrylic PolyurethaneJohn ReevesNo ratings yet

- Ceramic Brush On - 95010K-1Document2 pagesCeramic Brush On - 95010K-1NazmiNo ratings yet

- Iso-Superior Glycols-Plain: Product Features & ApplicationsDocument1 pageIso-Superior Glycols-Plain: Product Features & ApplicationsEldiyar AzamatovNo ratings yet

- Devcon Plastic Steel Putty ADocument3 pagesDevcon Plastic Steel Putty AAZLAN ABDULLAINo ratings yet

- Crystic Ve671Document2 pagesCrystic Ve671M Taufik WijayaNo ratings yet

- Atlac 590 002126 - 1520269898Document2 pagesAtlac 590 002126 - 1520269898Jainam ShahNo ratings yet

- Ceramic Rebuild Putty: Technical Reference InformationDocument2 pagesCeramic Rebuild Putty: Technical Reference InformationAbdul Rafii100% (1)

- 11ropoten KB-02-208Document1 page11ropoten KB-02-208cwqccqNo ratings yet

- Pipes Resin - SpecsDocument3 pagesPipes Resin - SpecsAmr Abdelmegid abdelsalam husseinNo ratings yet

- Dura-Plate Uhs Primer NSF: Protective & Marine CoatingsDocument4 pagesDura-Plate Uhs Primer NSF: Protective & Marine CoatingscerorideNo ratings yet

- Protective & Marine Coatings: Acrolon™ 218 HsDocument4 pagesProtective & Marine Coatings: Acrolon™ 218 Hshector gomezNo ratings yet

- 226NDocument2 pages226NUmaibalanNo ratings yet

- PS 14 Anchor Bolt TolerancesDocument4 pagesPS 14 Anchor Bolt TolerancesjebrijaNo ratings yet

- Epofine 6071A80/ Finecure 197/ Finecure 190/ Finehard 986/ Accelerator 062 Toughened PrepregDocument5 pagesEpofine 6071A80/ Finecure 197/ Finecure 190/ Finehard 986/ Accelerator 062 Toughened PrepregKarishma PrabhuNo ratings yet

- Belzona 1121: Product Specification SheetDocument2 pagesBelzona 1121: Product Specification SheetQuy RomNo ratings yet

- Acrolon 218 FTDocument4 pagesAcrolon 218 FTEdwin VSNo ratings yet

- TDS Mfe 711 (New)Document2 pagesTDS Mfe 711 (New)Wahyudi Rendiana NyotoNo ratings yet

- Interline 399+br+eng PDFDocument2 pagesInterline 399+br+eng PDFMohamed NouzerNo ratings yet

- Epofine 740 - Finehard 5200Document4 pagesEpofine 740 - Finehard 5200Karishma PrabhuNo ratings yet

- Corothane® I Galvapac 1K Zinc Primer PDFDocument4 pagesCorothane® I Galvapac 1K Zinc Primer PDFImam Situmeang100% (1)

- Poly-Cote 110 (Aug'22)Document4 pagesPoly-Cote 110 (Aug'22)David cNo ratings yet

- Product Data Energol THB: DescriptionDocument2 pagesProduct Data Energol THB: Descriptionkarim karimNo ratings yet

- Pro Mastic Ste 87Document4 pagesPro Mastic Ste 87ahmedyahea181No ratings yet

- Tds of Eterset 2844Document2 pagesTds of Eterset 2844Nandkumar PawarNo ratings yet

- Corothane I Galvapac 1K Zinc Primer NSF: Protective & Marine CoatingsDocument4 pagesCorothane I Galvapac 1K Zinc Primer NSF: Protective & Marine CoatingsScott NorrisNo ratings yet

- TDS - Tooling GC P-92PR (En)Document2 pagesTDS - Tooling GC P-92PR (En)OXY Composite TechNo ratings yet

- TDS - Vinyl 905-2 (En)Document2 pagesTDS - Vinyl 905-2 (En)OXY Composite Tech100% (1)

- TDS - UTEK - PET Tissue 30 (EN)Document1 pageTDS - UTEK - PET Tissue 30 (EN)OXY Composite TechNo ratings yet

- Wax in StyreneDocument16 pagesWax in StyreneOXY Composite TechNo ratings yet

- Repoly 196-Msds (NCC)Document6 pagesRepoly 196-Msds (NCC)OXY Composite TechNo ratings yet

- Determination Arsenic by AASDocument13 pagesDetermination Arsenic by AASMartuaHaojahanSaragihSidabutarNo ratings yet

- Box Culvert - ISDocument14 pagesBox Culvert - ISShyamontika Choudhury ChakrabartiNo ratings yet

- Maintenance Tips On OilDocument12 pagesMaintenance Tips On OilAndrea StoneNo ratings yet

- Gaurav Jayaswal Day2 Green Hydrogen in India April2023Document39 pagesGaurav Jayaswal Day2 Green Hydrogen in India April2023Praneet PayodhiNo ratings yet

- NCI - MV Cables CatalogueDocument75 pagesNCI - MV Cables Cataloguemughees_itcompNo ratings yet

- IRC 58 (Plain Jointed Rigid Pavements Design Highways)Document61 pagesIRC 58 (Plain Jointed Rigid Pavements Design Highways)herculesbhai73% (11)

- Concrete & RCC (BMC 3)Document41 pagesConcrete & RCC (BMC 3)Arsh ChaudharyNo ratings yet

- Cleaning Pig Designs and ApplicationsDocument24 pagesCleaning Pig Designs and ApplicationsChristopher BrownNo ratings yet

- Chemlube 215 229 230 501 751 822Document2 pagesChemlube 215 229 230 501 751 822Suprastowo Bin SarinoNo ratings yet

- High Strength Micro ConcreteDocument4 pagesHigh Strength Micro ConcreteSantosh Kumar PatnaikNo ratings yet

- Sarvatobhadra VatiDocument3 pagesSarvatobhadra VatiHarshaNo ratings yet

- Product Dissection Project BicycleDocument18 pagesProduct Dissection Project BicycleSaroya ਮੀਤNo ratings yet

- Thermo 5th Chap15 P068Document21 pagesThermo 5th Chap15 P068IENCSNo ratings yet

- Pengantar Rekayasa Pertambangan: To MiningDocument30 pagesPengantar Rekayasa Pertambangan: To MiningSasaki HaiseNo ratings yet

- ERT 206/4 Thermodynamics: The First Law and Other Basic ConceptsDocument31 pagesERT 206/4 Thermodynamics: The First Law and Other Basic ConceptsMuhammed FuadNo ratings yet

- Heat and Mass Transfer of Single Droplet Particle DryingDocument9 pagesHeat and Mass Transfer of Single Droplet Particle DryingLiliam Teresita Manrique DelgadoNo ratings yet

- VCS STD 5711 102 09 2005 Method Statement PDFDocument4 pagesVCS STD 5711 102 09 2005 Method Statement PDFFadi MagdyNo ratings yet

- SCCS1624 Eng PH Salinity SodicityDocument39 pagesSCCS1624 Eng PH Salinity SodicityMenzi CekwaneNo ratings yet

- Experiment 9: Direct Titration of Lead With Eriot and Edta SynopsisDocument2 pagesExperiment 9: Direct Titration of Lead With Eriot and Edta SynopsisAhmed AliNo ratings yet

- IMDG Class 1-9Document53 pagesIMDG Class 1-9Rheymart FloresNo ratings yet

- Water Spliting On Titanate Photocatalysts PDFDocument9 pagesWater Spliting On Titanate Photocatalysts PDFDanCosminNo ratings yet

- Mil L 46010BDocument18 pagesMil L 46010BaguNo ratings yet

- Consolidation - Odoemeter TestDocument30 pagesConsolidation - Odoemeter TestLuqman YusofNo ratings yet

- COA MetforminDocument12 pagesCOA MetforminPrasad Babu A100% (1)

- INOCHE2 Final Exam Reviewer 2T AY14-15 PDFDocument8 pagesINOCHE2 Final Exam Reviewer 2T AY14-15 PDFroxy8marie8chanNo ratings yet

- Compression Deflection Hardness Chart: Shore OODocument1 pageCompression Deflection Hardness Chart: Shore OOAisya IbrahimNo ratings yet