Professional Documents

Culture Documents

Welding Tran

Uploaded by

Muhd Shabeeb A0 ratings0% found this document useful (0 votes)

4 views1 pageA welding transformer is a step-down transformer that delivers high current for arc welding by taking alternating current from the power line and outputting low voltage and high amperage current. It has a magnetic core and primary winding with many turns and a secondary winding with fewer turns but a larger cross-sectional area, allowing it to output less voltage but higher current than the input. Taps on the secondary winding can adjust the output voltage for the required welding current, which produces heat through contact resistance to melt the electrode and join metal pieces.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentA welding transformer is a step-down transformer that delivers high current for arc welding by taking alternating current from the power line and outputting low voltage and high amperage current. It has a magnetic core and primary winding with many turns and a secondary winding with fewer turns but a larger cross-sectional area, allowing it to output less voltage but higher current than the input. Taps on the secondary winding can adjust the output voltage for the required welding current, which produces heat through contact resistance to melt the electrode and join metal pieces.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views1 pageWelding Tran

Uploaded by

Muhd Shabeeb AA welding transformer is a step-down transformer that delivers high current for arc welding by taking alternating current from the power line and outputting low voltage and high amperage current. It has a magnetic core and primary winding with many turns and a secondary winding with fewer turns but a larger cross-sectional area, allowing it to output less voltage but higher current than the input. Taps on the secondary winding can adjust the output voltage for the required welding current, which produces heat through contact resistance to melt the electrode and join metal pieces.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 1

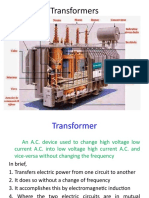

WELDING TRANSFORMER

A welding transformer is a step-down transformer capable of delivering the high

current required for arc welding. Welding Transformers are used in AC machines to change

alternating current from the power line into a low-voltage, high amperage current in the

secondary winding.

CONSTRUCTION OF WELDING TRANSFORMER:

It has a magnetic core with primary winding which is thin and has large number of

turns on one arm. A secondary winding with less number of turns and high cross-sectional

area on the other arm. Due to this type of windings in primary and secondary it behaves as

step down transformer. So we get less voltage and high current from the secondary winding

output. This is the construction of AC welding transformer. A dc welding transformer also

has same type of winding the only difference is that we connect a rectifier (which converts ac

to dc) at the secondary to get dc output. We also connect an inductor or filter to smooth the dc

current. This will be construction of dc welding transformer.

WORKING OF WELDING TRANSFORMER:

As it is a step down transformer, we have less voltage at secondary which is nearly 15

to 45 volts and has high current values which is nearly 200 A to 600 A. It can also be higher

than this value. For adjusting the voltage on secondary side there are tapings on secondary

winding by this we can get required amount of secondary current for welding. These tapings

are connected to several high current switches. Now one end of secondary winding is

connected to the welding electrode and the other end is connected to the welding pieces as

shown in figure. When a high current flows a large amount of heat is produced due to

contact resistance between welding pieces and electrode. Because of this high heat the tip

of electrode melts and fills the gap between the welding pieces.

You might also like

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- STEM: Science, Technology, Engineering and Maths Principles Teachers Pack V10From EverandSTEM: Science, Technology, Engineering and Maths Principles Teachers Pack V10No ratings yet

- Auto Transformer: Auto Transformer Is Kind of Electrical Transformer Where Primary and Secondary Shares SameDocument8 pagesAuto Transformer: Auto Transformer Is Kind of Electrical Transformer Where Primary and Secondary Shares SameAbhishek PareekNo ratings yet

- Auto TransformerDocument11 pagesAuto TransformerMuhd Shabeeb ANo ratings yet

- Construction & WorkingDocument22 pagesConstruction & WorkingShah Aizat Razali100% (1)

- Siddharth PhyDocument12 pagesSiddharth Physiddharthdeuri476No ratings yet

- Presentation On Transformer EasyDocument19 pagesPresentation On Transformer EasyBensaron KadiriNo ratings yet

- Power Supply: Block DiagramDocument14 pagesPower Supply: Block DiagramVamsi SakhamuriNo ratings yet

- TransformerDocument11 pagesTransformerahmed saidNo ratings yet

- Basic TransformerDocument13 pagesBasic Transformeraswardi8756No ratings yet

- Power SupplyDocument5 pagesPower Supplyapi-19653075100% (1)

- TransformersDocument2 pagesTransformersYenny TigaNo ratings yet

- Auto Transformer ConnectionDocument3 pagesAuto Transformer Connectionamirubote4No ratings yet

- Project On InverterDocument22 pagesProject On InverterSaikat Mitra43% (7)

- Autotransformer and Variable Auto Transformer PDFDocument6 pagesAutotransformer and Variable Auto Transformer PDFaesthetepkNo ratings yet

- The AutotransformerDocument7 pagesThe AutotransformerJohn Brix BalisterosNo ratings yet

- Characteristics of A TransformerDocument13 pagesCharacteristics of A TransformerGUIDO, ALDENNo ratings yet

- Shielded Metal Arc Welding Manual Metal Arc Welding Stick WeldingDocument50 pagesShielded Metal Arc Welding Manual Metal Arc Welding Stick WeldingRafli RamadhaniNo ratings yet

- Transformers: 1 K Hinds - 2012Document5 pagesTransformers: 1 K Hinds - 2012Jelani GreerNo ratings yet

- Autotransformer BasicsDocument6 pagesAutotransformer BasicsWaseem KambohNo ratings yet

- Buck ConverterDocument52 pagesBuck Convertermayankrkl50% (2)

- Chapter 3 MSDocument42 pagesChapter 3 MSRounak ChoudhuryNo ratings yet

- Project PhysicsDocument19 pagesProject Physics84863755511No ratings yet

- Complete Basics and Theory of Electrical TransformerDocument6 pagesComplete Basics and Theory of Electrical Transformergokul srinivasanNo ratings yet

- Transformer: Presented byDocument23 pagesTransformer: Presented byPrashant PuriNo ratings yet

- First Quadrant Single Phase Ac To DC Converter Semiconverter Separately Excited DC MotorDocument9 pagesFirst Quadrant Single Phase Ac To DC Converter Semiconverter Separately Excited DC MotorzaidNo ratings yet

- ContentDocument12 pagesContentHarishNo ratings yet

- Question 01Document9 pagesQuestion 01Ahmed zia tahirNo ratings yet

- Unit IIIDocument11 pagesUnit IIIAshok BNo ratings yet

- Arc Welding PPT FinishDocument50 pagesArc Welding PPT FinishmahendraNo ratings yet

- Electromagnetism Part 4 StudentsDocument16 pagesElectromagnetism Part 4 StudentsSharvinder SinghNo ratings yet

- WWW Dos4ever Impttant ComDocument13 pagesWWW Dos4ever Impttant ComClerk LoloNo ratings yet

- T10A Converters and Inverters: Chapter - 4Document11 pagesT10A Converters and Inverters: Chapter - 4lvsaruNo ratings yet

- Back To Transformer UniversityDocument27 pagesBack To Transformer Universityregistracijus100% (1)

- List of ComponentsDocument13 pagesList of ComponentsBenita AgbagwaraNo ratings yet

- Transformer Over View: S P S PDocument18 pagesTransformer Over View: S P S PSai Tarun TNo ratings yet

- ReportDocument21 pagesReporthrishikesh anvekarNo ratings yet

- Chapter 4Document42 pagesChapter 4Udin RosleeNo ratings yet

- Regulated DC Power SupplyDocument15 pagesRegulated DC Power SupplynalumilanimeNo ratings yet

- 220v Ac To 12vdc Rectifier CircuitDocument10 pages220v Ac To 12vdc Rectifier CircuitSandeep Guha NiyogiNo ratings yet

- Transformers ResearchDocument3 pagesTransformers ResearchTassi SonikishNo ratings yet

- Unit 1 - Transformers IntroductionDocument52 pagesUnit 1 - Transformers IntroductionNIHAL GUPTANo ratings yet

- Alternating Current ElectricityDocument34 pagesAlternating Current Electricityahmadhassan1364No ratings yet

- How To Build A DC Power SupplyDocument5 pagesHow To Build A DC Power SupplyJason RobinsonNo ratings yet

- Basic Electrical EngineeringDocument22 pagesBasic Electrical EngineeringLipi SinghNo ratings yet

- Documents - MX Battery-EliminatorDocument35 pagesDocuments - MX Battery-EliminatorAliNo ratings yet

- SUBstation Equipmens TLDocument12 pagesSUBstation Equipmens TLJecer Casipong NuruddinNo ratings yet

- Department of Electrical and Computer Engineering North South UniversityDocument12 pagesDepartment of Electrical and Computer Engineering North South UniversityFaria SharifNo ratings yet

- Welding MCQDocument116 pagesWelding MCQRohan YaduvanshiNo ratings yet

- Tanishq Bhawsar Project 12th B PhysicsDocument14 pagesTanishq Bhawsar Project 12th B PhysicsTanmayNo ratings yet

- Study of AC and-WPS OfficeDocument6 pagesStudy of AC and-WPS OfficeBeena PalNo ratings yet

- Report Content - Digital Water MeterDocument44 pagesReport Content - Digital Water MeteramiraNo ratings yet

- TramsformerDocument16 pagesTramsformerAshutosh Sharma100% (1)

- An Ordinary TransformerDocument4 pagesAn Ordinary Transformersopan saNo ratings yet

- Final ReviewDocument19 pagesFinal ReviewSanyam JainNo ratings yet

- HayuDocument5 pagesHayuHayu BayisaNo ratings yet

- Power Supply Projects: A Collection of Innovative and Practical Design ProjectsFrom EverandPower Supply Projects: A Collection of Innovative and Practical Design ProjectsRating: 3 out of 5 stars3/5 (2)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- TED (15) - 3021 Reg. No: Electrical & Electronics EngineeringDocument3 pagesTED (15) - 3021 Reg. No: Electrical & Electronics EngineeringMuhd Shabeeb ANo ratings yet

- IMSDocument13 pagesIMSMuhd Shabeeb ANo ratings yet

- Diploma Examination in Engineering/Technology/ Management/Coümercial Practice - October, 2018Document2 pagesDiploma Examination in Engineering/Technology/ Management/Coümercial Practice - October, 2018Muhd Shabeeb ANo ratings yet

- b864 Pistonless Pump ForDocument23 pagesb864 Pistonless Pump Forakshay_punde100% (1)

- 3023 Manufacturing Process - QPDocument3 pages3023 Manufacturing Process - QPMuhd Shabeeb ANo ratings yet

- 3021 Electrical - Electronics Engg - QPDocument4 pages3021 Electrical - Electronics Engg - QPMuhd Shabeeb ANo ratings yet

- Fluid Mechanics and Pneumatics: (REVISION - 2015)Document2 pagesFluid Mechanics and Pneumatics: (REVISION - 2015)Muhd Shabeeb ANo ratings yet

- Ted (15) 2021Document2 pagesTed (15) 2021Muhd Shabeeb ANo ratings yet

- Diploma Examination in Engineering/Technology/ Management/Commercial Practice - Aprial, 2019Document2 pagesDiploma Examination in Engineering/Technology/ Management/Commercial Practice - Aprial, 2019Muhd Shabeeb ANo ratings yet

- Diploma Examination in Engineering/Technology/ Management/Commercial Practice - October, 2018Document2 pagesDiploma Examination in Engineering/Technology/ Management/Commercial Practice - October, 2018Muhd Shabeeb ANo ratings yet

- Adharsh PDocument13 pagesAdharsh PMuhd Shabeeb ANo ratings yet

- 3001 Environmental Science - Disaster Management - QP ADocument3 pages3001 Environmental Science - Disaster Management - QP AMuhd Shabeeb ANo ratings yet

- Internship Report ContentDocument16 pagesInternship Report ContentMuhd Shabeeb ANo ratings yet

- Fuel From Plastic WasteDocument18 pagesFuel From Plastic WasteMuhd Shabeeb ANo ratings yet

- Ted (15) 4026Document4 pagesTed (15) 4026Muhd Shabeeb ANo ratings yet

- AkhilDocument20 pagesAkhilMuhd Shabeeb ANo ratings yet

- Mod 4Document39 pagesMod 4Muhd Shabeeb ANo ratings yet

- Dyna Cam EngineDocument24 pagesDyna Cam EngineMuhd Shabeeb ANo ratings yet

- 4022 Automobile Engineering - QPDocument2 pages4022 Automobile Engineering - QPMuhd Shabeeb ANo ratings yet

- Electrical InstrumentsDocument5 pagesElectrical InstrumentsMuhd Shabeeb A100% (1)