Professional Documents

Culture Documents

挤塑一体板 en

挤塑一体板 en

Uploaded by

myq120Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

挤塑一体板 en

挤塑一体板 en

Uploaded by

myq120Copyright:

Available Formats

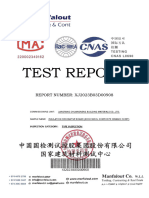

TEST REPORT

REPORT NUMBER: XJ2023B03D00908

COMMISSIONING UNIT: LANGFANG CHUANGNENG BUILDING MATERIALS CO., LTD.

SAMPLE NAME: Insulation (extruded board) decorative integrated board

INSPECTION CATEGORY: TYPE INSPECTION

+ 974 4476 2799

+ 974 5588 3447

+ 974 3043 8884

REPORT NUMBER: XJ2023B03D00908

sample name Rock wool composite ceramic Test category Type test

sheet

Requester Langfang Chuangneng Building Sample source: commissioned

Materials Co., Ltd.

Production Langfang Chuangneng Building Trademark (not supplied)

Unit Materials Co., Ltd.

Sample June 27, 2023 Sample status: Meet testing requirements

collection date:

Sample 12 decorative panels, core material Model specifications: 900mm×600mm×58mm

quantity: 14 panels

Production -------- Test date/batch number June 29-July 21, 2023

date/batch

number

Testing base Please see the data page for details of the testing basis for each testing item.

Judgment basis JG/T287-2013 "Insulation Decorative Panel Exterior Wall Insulation System

Materials"

GB/T30595-2014 "Extruded polystyrene board (XPS) thin plaster exterior wall

external insulation system material"

Test items:. There are 15 items in total including appearance, mass per unit area, etc. See

pages 2~4 for details.

Test After testing, the thermal conductivity results of the sample insulation materials

conclusion: were in compliance with the technical requirements for extruded panels with skin

slots in GB/T30595-2014, and the results of other test items were in compliance

with the standard JG/T287-2013 on the decorative surface technology of Type 1

thermal insulation decorative panels. Require. The test results are shown on

pages 2~4.

Note: 1. (Provided by the client) The insulation layer of the thermal insulation decorative board

is 50mm thick double-sided slotted extruded board with skin, and the protective layer is

8mm thick calcium silicate board, with a real stone paint finish on the surface.

2. Among the testing items, items 1-8 are tested for composite panels, items 9-11 are

tested for insulation material extruded boards, and items 12-15 are tested for decorative

surfaces.

+ 974 4476 2799

+ 974 5588 3447

+ 974 3043 8884

REPORT NUMBER: XJ2023B03D00908

Standard Individual

No. Test Item Test Result Test Basis

Requirement Conclusion

Uniform color, no Uniform color, JG/T 287-

1 Appearance Conforms

damage no damage 2013

JG/T 287-

2 Unit Area Mass <20kg/m² 17kg/m² Conforms

2013

Tensile Adhesion Original strength JG/T 287-

3 0.20MPa Conforms

Strength ≥0.10MPa 2013

Impact JG/T 287-

4 10J impact pass 10J impact pass Conforms

Resistance 2013

Not less than the JG/T 159-

5 Flexural Load 1390N/860N Conforms

weight of the plate 2004

Water JG/T 287-

6 ≤500g/m² 275g/m² Conforms

Absorption 2013

No penetration

No penetration on the

Water on the inner JG/T 287-

7 inner side of the Conforms

Impermeability side of the 2013

system

system

Dimensional Length, width, Within required JG/T 287-

8 Conforms

Deviation thickness ±2.0mm range 2013

GB/T

9 Thermal <0.030W/(mK) 0.027W/(mK) Conforms

10801.2-2018

Conductivity of

+ 974 4476 2799

+ 974 5588 3447

+ 974 3043 8884

Standard Individual

No. Test Item Test Result Test Basis

Requirement Conclusion

Insulation

Material

GB/T 2406.2-

10 Oxygen Index ≥26% 32.3% Conforms

2009

Various criteria

Meets criteria

including flame

for non- GB/T 8626-

Combustion spread, smoke

11 flammability Conforms 2007, GB/T

Performance production, and

and smoke 20284-2006

burning

production

droplets/particles

Acid Resistance No GB/T 9274-

12 No abnormalities Conforms

(48h) abnormalities 1988 (2004)

Alkali Resistance No GB/T 9265-

13 No abnormalities Conforms

(96h) abnormalities 2009

Salt Spray

GB/T 1771-

14 Resistance No damage No damage Conforms

2007

(500h)

No blistering, peeling, GB/T 1865-

Aging Resistance Passes all

15 cracking, chalking, or Conforms 2009, GB/T

(1000h) criteria

color change 1766-2008

**Installation Instructions for Combustion Test Samples:**

1. The test samples were installed according to the provisions of GB/T 20284-2006, section 5.2.2b).

2. The backing board for the samples was a 12mm thick calcium silicate board with a density of 800kg/m³,

measuring 1000mm x 1500mm and 570mm x 1500mm.

+ 974 4476 2799

+ 974 5588 3447

+ 974 3043 8884

3. The samples were homogeneous products, and the fire-exposed surface could be any one of the surfaces.

**Remarks:**

The results of the combustion performance test are only related to the performance of the product samples

under specific test conditions and should not be used as the sole basis for evaluating the potential fire

hazard of the product in actual use.

Remarks: (blank here)

End of this report

+ 974 4476 2799

+ 974 5588 3447

+ 974 3043 8884

You might also like

- BOQ CulvertDocument38 pagesBOQ CulvertDeepak_pethkarNo ratings yet

- LLBF 122FDocument1 pageLLBF 122FYefrain J. ArzolayNo ratings yet

- Insulation Integrated Board Data Sheet - enDocument6 pagesInsulation Integrated Board Data Sheet - enmyq120No ratings yet

- EN-cybrid Sealant TDS 1Document2 pagesEN-cybrid Sealant TDS 1loydtarrosaNo ratings yet

- Ube Nylon 5034bDocument1 pageUbe Nylon 5034bDiegoTierradentroNo ratings yet

- Manfalout Por.Document21 pagesManfalout Por.myq120No ratings yet

- Thermal Efficiency Block Walling Masterlite Ultra Tds File038401Document3 pagesThermal Efficiency Block Walling Masterlite Ultra Tds File038401Ibrahim FawwazNo ratings yet

- 3layer Coating - 03Document5 pages3layer Coating - 03Christian EzeaguNo ratings yet

- SN-803-2020 Staron Exterior Wall CladdingDocument13 pagesSN-803-2020 Staron Exterior Wall CladdingIsma IzriNo ratings yet

- Duracon M25-44Document5 pagesDuracon M25-44AVLight AutomotivesNo ratings yet

- 1 MAGKOR - K - Zement - ISO - ENDocument1 page1 MAGKOR - K - Zement - ISO - ENValyJaraFariasNo ratings yet

- CAMPUS® Datasheet: Akulon® F223-D - PA6 DSM Engineering MaterialsDocument7 pagesCAMPUS® Datasheet: Akulon® F223-D - PA6 DSM Engineering MaterialsAgoenk KertawijayaNo ratings yet

- TDS 523 Jotamastic 87 Aluminium Euk GBDocument6 pagesTDS 523 Jotamastic 87 Aluminium Euk GBBarathan RajandranNo ratings yet

- Arylic An Cư NGDocument40 pagesArylic An Cư NGPhuong ThaiNo ratings yet

- Self Adhering Sheet Waterproofing Bituthene 3000 and Bituthene Low Temperature GSWP 003A v2Document5 pagesSelf Adhering Sheet Waterproofing Bituthene 3000 and Bituthene Low Temperature GSWP 003A v2200365530No ratings yet

- KXNEDocument2 pagesKXNEJan GawełNo ratings yet

- Sé Etec: ApplicationsDocument1 pageSé Etec: ApplicationsMohit MohataNo ratings yet

- TDS 515 Jotamastic 87 Euk GBDocument6 pagesTDS 515 Jotamastic 87 Euk GBManuel LópezNo ratings yet

- Mdpe Dx800: Application / Use CaseDocument1 pageMdpe Dx800: Application / Use CaseJaime222No ratings yet

- Lab Test Report For Optical Fibre - Jorge PDFDocument6 pagesLab Test Report For Optical Fibre - Jorge PDFtrubacoNo ratings yet

- PEPET Film (35754-E Data Sheet)Document2 pagesPEPET Film (35754-E Data Sheet)Anthony BokovNo ratings yet

- MATERIAL SPECIFICATION DuranexDocument7 pagesMATERIAL SPECIFICATION Duranexhamdany danyNo ratings yet

- 01ML0030 ES-08009 - C - Especificação de MPDocument2 pages01ML0030 ES-08009 - C - Especificação de MPRafah1212No ratings yet

- 7417-16992-TPS-001 Onshore PipesDocument3 pages7417-16992-TPS-001 Onshore PipesFerryNo ratings yet

- StoPox-KU-601 TDS enDocument6 pagesStoPox-KU-601 TDS enemilNo ratings yet

- Technyl Star S 218 V30 BK 31NDocument3 pagesTechnyl Star S 218 V30 BK 31Nratz23695No ratings yet

- Linear Low Density Polyethylene: Blown Film GradeDocument1 pageLinear Low Density Polyethylene: Blown Film GradeChetan BholeNo ratings yet

- 3m - Scotch - 2228 Rubber Mastic TapeDocument3 pages3m - Scotch - 2228 Rubber Mastic TapeLuis NovaisNo ratings yet

- Jotamastic 87 PDFDocument6 pagesJotamastic 87 PDFGurdeep Sungh AroraNo ratings yet

- Ultrason E3010 NATDocument7 pagesUltrason E3010 NATDaniel Lack PendásNo ratings yet

- LLBF 218aDocument1 pageLLBF 218aYefrain J. ArzolayNo ratings yet

- ABS N Fisa TehnicaDocument1 pageABS N Fisa TehnicaFloare de PrimavaraNo ratings yet

- Polyethylene GeomembranesDocument18 pagesPolyethylene GeomembranesPalo DushiiNo ratings yet

- 3 Property H1501 EngDocument1 page3 Property H1501 EngMohit MohataNo ratings yet

- Jotamastic 87 GFDocument5 pagesJotamastic 87 GFBiju_PottayilNo ratings yet

- Property ComparisonDocument2 pagesProperty Comparisondiadam07No ratings yet

- Type B GeotextileDocument13 pagesType B GeotextileVincent KongNo ratings yet

- Green Cast Setacryl UKDocument4 pagesGreen Cast Setacryl UKgillestalbotNo ratings yet

- TDS - TR144 - Astm (Eng)Document2 pagesTDS - TR144 - Astm (Eng)Darwin Lenin Iza PradoNo ratings yet

- Lldpe FN810 (Octeno Sin Slip)Document2 pagesLldpe FN810 (Octeno Sin Slip)Hữu LộcNo ratings yet

- 3M™ Tape # 2228 TdsDocument3 pages3M™ Tape # 2228 TdsKishan MohtaNo ratings yet

- RHODIA Technyl A218 V30Document3 pagesRHODIA Technyl A218 V30paquienNo ratings yet

- Utek PYJ9114 SMC SHEETDocument2 pagesUtek PYJ9114 SMC SHEETFrederik TjonnelandNo ratings yet

- Pink Anti Static Bag BondlineDocument2 pagesPink Anti Static Bag Bondlineeky susilowatiNo ratings yet

- CAMPUS® Datasheet: Ultramid® T KR 4355 G5 - PA6T/6-GF25 BasfDocument6 pagesCAMPUS® Datasheet: Ultramid® T KR 4355 G5 - PA6T/6-GF25 BasfcurioushoainamNo ratings yet

- TDS 525 Jotamastic 87 GF Euk GBDocument5 pagesTDS 525 Jotamastic 87 GF Euk GBhidayatNo ratings yet

- Sikaproof 808Document4 pagesSikaproof 808happyNo ratings yet

- S1005 TairiproDocument1 pageS1005 TairiproJacquelin DelgadoNo ratings yet

- Intel RMZ2 Ecsp-3 Project-Solar Collectors Test CertificateDocument3 pagesIntel RMZ2 Ecsp-3 Project-Solar Collectors Test Certificatevksolarsystems2020No ratings yet

- Séetec: ApplicationsDocument1 pageSéetec: ApplicationsAdonis BasilioNo ratings yet

- Esh M11P19 BDocument3 pagesEsh M11P19 Bjose luisNo ratings yet

- TDS 515 Jotamastic 87 Euk GBDocument6 pagesTDS 515 Jotamastic 87 Euk GBBarathan RajandranNo ratings yet

- Dow Elite 5400G TDSDocument2 pagesDow Elite 5400G TDSAli RazuNo ratings yet

- TUNDISH COVER RefractoryDocument3 pagesTUNDISH COVER RefractoryMashiur RahmanNo ratings yet

- H1 AftDocument4 pagesH1 Aftmp3475No ratings yet

- polarlite-UK 4mmDocument4 pagespolarlite-UK 4mmoportunidade.engenharia.slzNo ratings yet

- 3MTM VHBTM Structural Glazing Tape B23F - 20230923Document6 pages3MTM VHBTM Structural Glazing Tape B23F - 20230923Trí TrừNo ratings yet

- GRP Properties 2016 01Document1 pageGRP Properties 2016 01Carlos GarridoNo ratings yet

- Memo 097.7 - 122719 - Item 454 Tunnel WaterproofingDocument6 pagesMemo 097.7 - 122719 - Item 454 Tunnel WaterproofingBai Alleha MusaNo ratings yet

- Especificación Membrana GeotextilDocument1 pageEspecificación Membrana GeotextilMiguel RamírezNo ratings yet

- Outline Specifications SampleDocument4 pagesOutline Specifications SampleRapha RachoNo ratings yet

- Tall Building Session IDocument42 pagesTall Building Session Imalik atikNo ratings yet

- KONE Scenic Elevators: Elevators With An Inspiring ViewDocument16 pagesKONE Scenic Elevators: Elevators With An Inspiring ViewPietrus NimbusNo ratings yet

- Channels Compliance Sheet As Per QCSDocument6 pagesChannels Compliance Sheet As Per QCSeng_asayedNo ratings yet

- RIAI CIM Reading List 2015Document4 pagesRIAI CIM Reading List 2015Will WalshNo ratings yet

- School of Architecture and Planning: Anna University Chennai 25 Department of ArchitectureDocument5 pagesSchool of Architecture and Planning: Anna University Chennai 25 Department of ArchitecturenavinNo ratings yet

- National Building CodeDocument30 pagesNational Building CodeKamille Sinfuevo TañadaNo ratings yet

- Great Mosque of Djenné - WikipediaDocument15 pagesGreat Mosque of Djenné - WikipediaRabiya AnwarNo ratings yet

- Soal Bahasa InggrisDocument12 pagesSoal Bahasa InggrisEvi YuliantiniNo ratings yet

- 09.11.2020 DOM Vocabulary Repetytorium Macmillan cz.1 - TestDocument4 pages09.11.2020 DOM Vocabulary Repetytorium Macmillan cz.1 - Testzalewskifilip15No ratings yet

- Concrete Construction Article PDF - Construction of Elevated Concrete SlabsDocument7 pagesConcrete Construction Article PDF - Construction of Elevated Concrete Slabsnihadm007No ratings yet

- 3.5 BV Doshi-1Document49 pages3.5 BV Doshi-1Fathima NazrinNo ratings yet

- Conversa Entre Peter Eisennmann e Richard SerraDocument9 pagesConversa Entre Peter Eisennmann e Richard SerraRenataScovinoNo ratings yet

- History of Architecture 4Document4 pagesHistory of Architecture 4Desiree WangNo ratings yet

- Rodrigo PCS002 Tla2pDocument4 pagesRodrigo PCS002 Tla2pChristian John SaludarNo ratings yet

- Atdp Es 000212Document35 pagesAtdp Es 000212peetholNo ratings yet

- Chapter 8: Design of One-Way SlabsDocument15 pagesChapter 8: Design of One-Way SlabsPankaj YadavNo ratings yet

- QuoteDocument3 pagesQuotemjnasar khan jamalNo ratings yet

- Eldeco Inspire Offers Ideal Homes For Comfort Living in NoidaDocument19 pagesEldeco Inspire Offers Ideal Homes For Comfort Living in NoidaeldecoinspireNo ratings yet

- Fingerlings Semi-Final Pow2Document211 pagesFingerlings Semi-Final Pow2AYSON N. DELA CRUZNo ratings yet

- Defects Due To DampnessDocument7 pagesDefects Due To DampnessDevendra KumarNo ratings yet

- Project IDocument2 pagesProject ITarang ShethNo ratings yet

- Folded PlatesDocument23 pagesFolded Platesbhushruti100% (1)

- Barda Perimetral Fase 2 Bandal Concepto Unidad Cantidad Precio Unitario ImporteDocument2 pagesBarda Perimetral Fase 2 Bandal Concepto Unidad Cantidad Precio Unitario ImportegusNo ratings yet

- Module 2 Provincial Style 1Document52 pagesModule 2 Provincial Style 1lalu mikeyNo ratings yet

- Fiber Reinforced Concrete (FRC) : Advancement of Concrete Properties Against Blast Loadings by Using SMFRCDocument16 pagesFiber Reinforced Concrete (FRC) : Advancement of Concrete Properties Against Blast Loadings by Using SMFRCAamirKhattakNo ratings yet

- Sas B.ing KLS 4Document6 pagesSas B.ing KLS 4Reny FebriyaniNo ratings yet

- Presentation On Fly-Ash Paver BlockDocument31 pagesPresentation On Fly-Ash Paver BlockBaharulHussain75% (8)

- Uas Bit Arsi 20211Document16 pagesUas Bit Arsi 20211MichaelNo ratings yet