Professional Documents

Culture Documents

MG 5193

Uploaded by

PalmOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MG 5193

Uploaded by

PalmCopyright:

Available Formats

MG5193

Tunable S-Band Magnetron

The data should be read in conjunction with the Magnetron

Preamble and with British Standard BS9030 : 1971.

ABRIDGED DATA

Mechanically tuned pulse magnetron intended primarily for

linear accelerators.

Frequency range (cooling water 40 8C) . 2993 to 3002 MHz

Peak output power . . . . . . . . . . 2.6 MW

Magnet . . . . . . . . . . . . . . separate

Output . . . . . . . . to no. 10 (WR 284) waveguide

(72.14 x 34.04 mm internal)

Cooling . . . . . . . . . . . . . . . water

The use of an isolator is recommended (see note 1)

GENERAL DATA

Electrical

Cathode . . . . . . . . . . . . indirectly heated

Heater voltage (see note 2) . . . . . . . 8.5 V dc

Heater current . . . . . . . . . . . 9.0 A

Peak heater starting current,

not to be exceeded . . . . . . . . 20 A max

Cathode pre-heating time (minimum) . . . . 3.0 min

Mechanical

Overall dimensions . . . . . . . . . . . see outline

Net weight . . . . . . . . . . . . 8 kg approx

Tuner revolutions to cover frequency range

(see note 3) . . . . . . . . . . . 4.75

Mounting position (see note 4) . . . . . . . . . any

Accessories

Electromagnet (see notes 5 and 6) . . . MG6061/MG6062

Waveguide transition . . . . . . . . . . . M4152S

Cooling

The magnetron is water cooled and has an integral water

jacket. The recommended water flow is 5 litres per minute or

more; a pressure of approximately 1.25 kg/cm2 will be

necessary to give this rate of flow. The outlet water

temperature must not exceed 50 8C.

e2v technologies (uk) limited, Waterhouse Lane, Chelmsford, Essex CM1 2QU, UK Telephone: +44 (0)1245 493493 Facsimile: +44 (0)1245 492492

e-mail: enquiries@e2v.com Internet: www.e2v.com Holding Company: e2v technologies plc

e2v technologies inc. 4 Westchester Plaza, PO Box 1482, Elmsford, NY10523-1482 USA Telephone: (914) 592-6050 Facsimile: (914) 592-5148

e-mail: enquiries@e2vtechnologies.us

# e2v technologies (uk) limited 2005 A1A-MG5193 Issue 6, July 2005

181/7010

MAXIMUM AND MINIMUM RATINGS NOTES

(Absolute values) 1. It is recommended that the magnetron should be isolated

These ratings cannot necessarily be used simultaneously, and from the load by means of an isolator of approved design.

no individual rating should be exceeded. Information on the characteristics of a suitable isolator may

be obtained from e2v technologies.

Min Max

2. With no anode input power.

Magnetic field (see notes 5 and 7) . 100 157.5 mT

1000 1575 gauss It is recommended that a DC power supply is used to

Heater voltage (see note 2) . . . . . 8.0 10 V dc operate the heater. Use of an AC supply may result in

Heater starting current (peak) . . . . – 20 A damage to the heater circuit. The use of an AC heater

Anode voltage (peak) . . . . . . . – 48 kV supply during HT operation may result in frequency

Anode current (peak) . . . . . . 60 110 A modulation of the RF pulses. Contact e2v technologies for

Input power (mean) . . . . . . . – 6.0 kW further information.

Pulse duration . . . . . . . . . – 5.0 ms The heater voltage must be reduced within 5 seconds after

Rate of rise of voltage pulse the application of HT according to the schedule shown on

(see note 8) . . . . . . . . 80 120 kV/ms page 4.

Outlet water temperature . . . . . – 50 8C The magnetron heater must be protected against arcing by

VSWR at output coupler the use of a minimum capacitance of 4000 pF shunted

(see note 1) . . . . . . . . . – 1.5:1 across the heater directly at the input terminals; in some

Pressurising of waveguide cases a capacitance as high as 2 mF may be necessary

(see note 9) . . . . . . . . . – 3.1 kg/cm2 depending on the equipment design.

3. The tuner mechanism is driven by means of three tapped

TEST CONDITIONS AND LIMITS holes in the tuner knob (see outline drawing) via a flexible

The magnetron is tested to comply with the following electrical drive. The torque required is 0.7 kg-cm minimum; the

specification. torque applied must not exceed 5.0 kg-cm.

Test Conditions 4. To minimise frequency deviation when the magnetron is

rotated about a horizontal axis, this axis should be parallel

Magnetic field (see notes 5 and 7) . . . 155.0 + 2.5 mT to the axis of the tuner.

1550 + 25 gauss

Heater voltage (for test) . . . . . . . . 0 V 5. The magnetron is designed for use with a separate

Anode current (peak) . . . . . . . . 110 A permanent magnet or electromagnet. The north seeking

Duty cycle (see note 10) . . . . . . . . 0.001 pole of the magnet must be adjacent to the cathode

Pulse duration . . . . . . . . . . . 5.0 ms terminal, marked C. The position of the magnet must be

VSWR at output coupler . . . . . . . 1.1:1 adjusted so that the axis of the field is in line with the axis

Minimum rate of rise of of the anode and is at right angles to the H plane of the

voltage pulse (see note 8) . . . . . 120 kV/ms system waveguide. The user is invited to consult e2v

technologies on the choice of magnets.

Limits 6. The MG5193 can be used at lower power levels by

reducing both the magnetic field (which controls the peak

Min Max voltage) and the peak current (see graph); this is necessary

Anode voltage (peak) . . . . . 42 48 kV for maintaining a good RF spectrum and constant

Output power (peak) impedance.

(see note 11) . . . . . . . . 2.5 – MW 7. Using a small Hall effect probe, the magnetic field

Frequency (see notes 12, 13 and 14): measured at each pole face of the magnet must be within

lower end of tuning range { . . . – 2993 MHz the following limits.

upper end of tuning range { . 3002 – MHz (a) At the centre of the pole face and 37.287 mm from the

RF bandwidth at 1/4 power . . . . – 1.5 MHz surface, the field must be 155.0 + 2.5 mT (1550 + 25

Frequency pulling (VSWR gauss).

not less than 1.5:1) . . . . . – 7.0 MHz

(b) At four or more points equispaced on a circle of

Stability (see note 15) . . . . . – 0.5 %

33 mm diameter concentric with the pole face and

Heater current . . . . . . . . . . . . see note 16

6.35 mm from its surface, including a point nearest the

{ Inlet water at 40 8C. back limb of the magnet, the field must be as follows.

At all points the field must be between 9.0 and 27 mT

LIFE TEST (90 and 270 gauss) greater than the field measured at

The quality of all production is monitored by the random the centre of the pole face; the variation between the

selection of tubes which are then life-tested under typical points must not exceed 13 mT (130 gauss).

operation conditions. If the tube is to be operated under 8. Defined as the steepest tangent to the leading edge of the

conditions other than those specified herein, e2v technologies voltage pulse above 80% amplitude. Any capacitance in

should be consulted to verify that the life of the magnetron will the viewing system must not exceed 6.0 pF.

not be impaired.

MG5193, page 2 # e2v technologies

9. At the maximum pressure of 3.1 kg/cm2 gauge the

maximum leakage will be such that with an enclosed HEALTH AND SAFETY HAZARDS

volume of 1 litre the pressure will not drop by more than e2v technologies magnetrons are safe to handle and operate,

70 kPa in 7 days. provided that the relevant precautions stated herein are

It is recommended that the pressurised arc suppressant gas observed. e2v technologies does not accept responsibility for

used in the waveguide should contain no more helium than damage or injury resulting from the use of electronic devices it

is typically found in air, i.e. 0.0005%. produces. Equipment manufacturers and users must ensure that

10. The various parameters are related by the formula: adequate precautions are taken. Appropriate warning labels and

Pi = iapk x vapk x Du notices must be provided on equipments incorporating e2v

technologies devices and in operating manuals.

where Pi = mean input power in watts

iapk = peak anode current in amperes

High Voltage

vapk = peak anode voltage in volts

Equipment must be designed so that personnel cannot come

and Du = duty cycle.

into contact with high voltage circuits. All high voltage circuits

11. The maximum variation of mean output power when the and terminals must be enclosed and fail-safe interlock switches

magnetron is rotated through 3608 around any axis of the must be fitted to disconnect the primary power supply and

magnetron will not be greater than 4%. discharge all high voltage capacitors and other stored charges

12. The frequency of the magnetron will vary after the before allowing access. Interlock switches must not be

application of anode voltage. Typically the frequency will bypassed to allow operation with access doors open.

be 0.5 MHz high 20 seconds after switching on HT and

0.1 MHz high 5 minutes after switching on.

RF Radiation

13. With a water flow rate of 5.0 litres per minute.

Personnel must not be exposed to excessive RF radiation. All

14. The maximum variation of frequency when the magnetron

RF connectors must be correctly fitted before operation so that

is rotated through 3608 around any axis of the magnetron

no leakage of RF energy can occur and the RF output must be

will not be greater than 0.7 MHz.

coupled efficiently to the load. It is particularly dangerous to

15. With the magnetron operating into a VSWR of 1.15:1. look into open waveguide or coaxial feeders while the device is

Pulses are defined as missing when the RF energy level is energised. Screening of the cathode sidearm of high power

less than 70% of the normal energy level in a 0.5% magnetrons may be necessary.

frequency range. Missing pulses are expressed as a

percentage of the number of input pulses applied during

the period of observation after a period of 10 minutes X-Ray Radiation

operation. High voltage magnetrons emit a significant intensity of X-rays

16. Measured with heater voltage of 8.5 V and no anode input not only from the cathode sidearm but also from the output

power, the heater current limits are 8.0 A minimum, 10.0 A waveguide. These rays can constitute a health hazard unless

maximum. adequate shielding for X-ray radiation is provided. This is a

characteristic of all magnetrons and the X-rays emitted

correspond to a voltage much higher than that of the anode.

# e2v technologies MG5193, page 3

HEATER VOLTAGE REDUCTION SCHEDULE

10 6526B

4

HEATER VOLTAGE (V)

0

0 1.0 2.0 3.0 4.0

MEAN INPUT POWER (kW)

MG5193, page 4 # e2v technologies

RECOMMENDED PARAMETERS FOR VARIOUS POWER LEVELS

MAGNETIC FIELD (mT)

110 120 130 140 150 160

3.0

6709A

2.0

NORMAL

OPERATING

CONDITIONS

OUTPUT POWER (MW)

1.0

30 35 40 45

ANODE VOLTAGE (kV)

70 80 90 100 110

ANODE CURRENT (A)

72.5 72.0 71.5 71.0 70.5 0

FREQUENCY CHANGE (MHz)

# e2v technologies MG5193, page 5

OUTLINE (All dimensions without limits are nominal)

6828A 1AB

HOLE 1F

ON AF PCD

2 HOLES THREADED

1

/4"-28 UNF-2B BY Z DEEP

228

228

1X 1H

8 HOLES 1AA

ON AF PCD HOLE 1Y

SEE NOTE 3 1AC ON AF PCD

AE

REFERENCE REFERENCE

PLANE ‘A’ PLANE ‘B’

C

SEE NOTE 1

U V K J

SEE NOTE 2

3 HOLES THREADED A

T 10-32 UNF-2B BY G DEEP

EQUISPACED ON H PCD

SEE NOTE 4

‘X’

S WATER JACKET

CONNECTIONS

THREADED 1/4" BSP

Q L B

1N

R D

1P F

1M 1E

SEE NOTE 5

8 HOLES 1AG

EQUISPACED ON AH PCD

SEE NOTE 3

HOLE THREADED

M8 x 1.25-6H

BY AJ DEEP

Scrap View in Direction ‘X’

MG5193, page 6 # e2v technologies

Ref Millimetres

A 370.0

B 135.5

C 89.0

D 3.2

E 104.9

F 35.0

G 6.5

H 19.05

J 73.82 + 0.20

K 25.0

L 12.5 + 0.5

M 133.5

N 94.85

P 91.82

Q 5.55

R 31.4

S 191.5

T 55.96 + 0.16

U 6.35 + 0.10

V 107.0 + 0.3

W 51.0

X 38.0

Y 6.40 + 0.05

Z 6.0 max

AA 8.0 + 0.1

AB 152.25

AC 19.0

AD 8.00 + 0.05

AE 107.0

AF 139.7

AG 6.4 + 0.1

AH 120.65 + 0.13

AJ 15.0 max

Outline Notes

1. This surface is marked with the letter ’C’ to indicate the

cathode terminal.

2. The magnetron will fit between magnet poles 76.45 mm

diameter and 75.44 mm apart.

3. Positional tolerance of holes 0.15 mm diameter.

4. Positional tolerance of holes 0.05 mm diameter.

5. Positional tolerance of flange 1.5 mm diameter with respect

to reference planes A and B.

Whilst e2v technologies has taken care to ensure the accuracy of the information contained herein it accepts no responsibility for the consequences of any use

thereof and also reserves the right to change the specification of goods without notice. e2v technologies accepts no liability beyond that set out in its standard

conditions of sale in respect of infringement of third party patents arising from the use of tubes or other devices in accordance with information contained herein.

# e2v technologies Printed in England MG5193, page 7

You might also like

- Marine Magnetron MG241Document4 pagesMarine Magnetron MG241Fernando EtchegarayNo ratings yet

- MG5436 Magnetron BrochureDocument4 pagesMG5436 Magnetron BrochureTaufiq Omar HasanNo ratings yet

- MG5222 E2V MagnetronDocument5 pagesMG5222 E2V MagnetronhishamuddinohariNo ratings yet

- E2V Technologies MG5436 X-Band Magnetron: Maximum and Minimum RatingsDocument4 pagesE2V Technologies MG5436 X-Band Magnetron: Maximum and Minimum RatingsTomasz ZawadzkiNo ratings yet

- MG5241Document4 pagesMG5241Royal Revolt 01No ratings yet

- B3LT1018Document1 pageB3LT1018ErnaNo ratings yet

- Kondezatori Za Motore Formule ItdDocument21 pagesKondezatori Za Motore Formule ItdkoskeruNo ratings yet

- E2V Technologies MG5232F X-Band Magnetron: Abridged DataDocument4 pagesE2V Technologies MG5232F X-Band Magnetron: Abridged DataahmedshirazarNo ratings yet

- Abridged Data: MG4004 X-Band MagnetronDocument5 pagesAbridged Data: MG4004 X-Band MagnetronNamiJen LobatoNo ratings yet

- MG5436Document4 pagesMG5436can doganNo ratings yet

- SMI983Document8 pagesSMI983ade.achielNo ratings yet

- MG5222 X-Band Magnetron: Maximum and Minimum RatingsDocument5 pagesMG5222 X-Band Magnetron: Maximum and Minimum RatingsadityoNo ratings yet

- MG5223F NewDocument5 pagesMG5223F NewThullyNo ratings yet

- X Band Magnetron Model No. M1568BS: ReleasedDocument3 pagesX Band Magnetron Model No. M1568BS: ReleasedParul MehtaNo ratings yet

- MG5248Document4 pagesMG5248Royal Revolt 01No ratings yet

- Protection of Induction MotorDocument30 pagesProtection of Induction MotorNivesh AgarwalNo ratings yet

- Stefan Mayer Instruments: - February 2018Document10 pagesStefan Mayer Instruments: - February 2018SaadNo ratings yet

- Hyundai Elantra 1.6 Engine Electrical1Document55 pagesHyundai Elantra 1.6 Engine Electrical1MANUALES2000CLNo ratings yet

- Havells TechnicalDocument94 pagesHavells TechnicalBhaumik PathakNo ratings yet

- Operation Manual For Single Axis Fluxgate Magnetometers With Mag Probes B-GDocument18 pagesOperation Manual For Single Axis Fluxgate Magnetometers With Mag Probes B-GSteveAbonyiNo ratings yet

- STAMFORD MX322 Automatic Voltage RegulatorDocument20 pagesSTAMFORD MX322 Automatic Voltage RegulatorPyae Phyo AungNo ratings yet

- MRT 97-M: Installation and Operating InstructionsDocument15 pagesMRT 97-M: Installation and Operating InstructionsSofyan HadiNo ratings yet

- KTZ54X41SANXX Specification G02Document14 pagesKTZ54X41SANXX Specification G02Alfonso Lopez toroNo ratings yet

- Waveform Generator Circuit Explain PDFDocument37 pagesWaveform Generator Circuit Explain PDFMio2008No ratings yet

- Instruction Manual: MX322 Automatic Voltage Regulator (AVR)Document20 pagesInstruction Manual: MX322 Automatic Voltage Regulator (AVR)TariqMaqsoodNo ratings yet

- 271-123 221-BgeDocument80 pages271-123 221-Bgecastel100% (8)

- Ab9zp0fa (EPS-ing)Document17 pagesAb9zp0fa (EPS-ing)Jose Antonio IglesiaNo ratings yet

- Wfm-Series: Pulse Meter InstructionsDocument4 pagesWfm-Series: Pulse Meter Instructionscamus1125No ratings yet

- Application Note: Power Card For Motor DriveDocument13 pagesApplication Note: Power Card For Motor DriveHamid BassourNo ratings yet

- Static Excitation SystemDocument44 pagesStatic Excitation Systemgigelu79No ratings yet

- X Band Magnetron Model No. M1568B (J) : ReleasedDocument3 pagesX Band Magnetron Model No. M1568B (J) : ReleasedsajujohnyNo ratings yet

- Generator Protection: 1. Internal FaultsDocument16 pagesGenerator Protection: 1. Internal FaultsRadhika Singhal100% (2)

- TECO GS510 ManualDocument52 pagesTECO GS510 ManualMr.K ch75% (4)

- Magnetic Acuator ManualDocument7 pagesMagnetic Acuator ManualSUDDHA CHAKRABARTYNo ratings yet

- V5 - 2022 - 23 MWOC Lab FinalDocument45 pagesV5 - 2022 - 23 MWOC Lab FinalCHINNI CHINNINo ratings yet

- PDFDocument15 pagesPDFNilesh KhareNo ratings yet

- 4.2.9. Stator Ground Fault Protection For Generators in ParallelDocument7 pages4.2.9. Stator Ground Fault Protection For Generators in ParallelKuenley TiNy OndeNo ratings yet

- Motor Control: Instruction ManualDocument12 pagesMotor Control: Instruction ManualRICHIHOTS2No ratings yet

- Triac Sereies HV Switching Circuit PDFDocument12 pagesTriac Sereies HV Switching Circuit PDFJubari FikriNo ratings yet

- Nitronex An9Document9 pagesNitronex An9sanghomitraNo ratings yet

- EWD Speed Monitor DeviceDocument11 pagesEWD Speed Monitor DeviceTran Dinh0% (1)

- E2V Technologies MG5424 X-Band Magnetron: Maximum and Minimum RatingsDocument4 pagesE2V Technologies MG5424 X-Band Magnetron: Maximum and Minimum RatingssajujohnyNo ratings yet

- Capacitors Capacitors Capacitors Capacitors Capacitors: For Motor ApplicationsDocument21 pagesCapacitors Capacitors Capacitors Capacitors Capacitors: For Motor ApplicationsMechanical PowerNo ratings yet

- Moc3051 PDFDocument9 pagesMoc3051 PDFlookb64No ratings yet

- Time Control Technique: Timer MK 9906N, On Delayed MinitimerDocument4 pagesTime Control Technique: Timer MK 9906N, On Delayed MinitimerKim Hảo Hoàng NguyễnNo ratings yet

- Gen. Electrical ProtectionDocument4 pagesGen. Electrical ProtectionMOHITKUMAR GOHILNo ratings yet

- Manual Generador ENGGADocument20 pagesManual Generador ENGGAmanuel100% (2)

- X Band Magnetron Model No. MAF1565N: ReleasedDocument3 pagesX Band Magnetron Model No. MAF1565N: ReleasedsajujohnyNo ratings yet

- Afv 2000Document9 pagesAfv 2000bbvolador2016No ratings yet

- Universal Calibrator 3001mDocument19 pagesUniversal Calibrator 3001mKrishnaraj Dhavala0% (2)

- Ca 3083Document4 pagesCa 3083tabassam7801No ratings yet

- 11kw 220v 1450rpm Afs225x Datasheet Jop DCDocument6 pages11kw 220v 1450rpm Afs225x Datasheet Jop DCcherif yahyaouiNo ratings yet

- 5SYA2034-02 June 07 Gate Drive Recommendations For PCTDocument12 pages5SYA2034-02 June 07 Gate Drive Recommendations For PCTKanhaiya NavaleNo ratings yet

- General Questions About Gate DriversDocument5 pagesGeneral Questions About Gate DriversmoabdolyNo ratings yet

- User Manual: 170.IU0.TMS.000 4.3-99/DDocument30 pagesUser Manual: 170.IU0.TMS.000 4.3-99/DCristianNo ratings yet

- TC Abb Tpu 2012Document98 pagesTC Abb Tpu 2012macNo ratings yet

- 1 Performance DataDocument9 pages1 Performance DataYusep KurniaNo ratings yet

- Generator Protection XZCDocument25 pagesGenerator Protection XZCblaagica100% (1)

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- Service Experience 2023Document37 pagesService Experience 2023신영호No ratings yet

- Effects of Advanced Injection Timing On PerformancDocument6 pagesEffects of Advanced Injection Timing On PerformancPalmNo ratings yet

- Itl9 1Document4 pagesItl9 1PalmNo ratings yet

- 2SA1072Document2 pages2SA1072PalmNo ratings yet

- F AlmabouadaDocument5 pagesF AlmabouadaPalmNo ratings yet

- PESC02 Sea Level Failuresof Power MOSFETsDocument7 pagesPESC02 Sea Level Failuresof Power MOSFETsPalmNo ratings yet

- RF PaperDocument7 pagesRF PaperPalmNo ratings yet

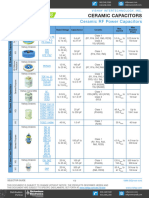

- Ceramic RF Power CapacitorsDocument2 pagesCeramic RF Power CapacitorsPalmNo ratings yet

- Us 4818916Document10 pagesUs 4818916PalmNo ratings yet

- AN3025Document2 pagesAN3025PalmNo ratings yet

- PlasmaLight SS Neuro10Document1 pagePlasmaLight SS Neuro10PalmNo ratings yet

- Journal of Power and Energy Systems: Evolution and Future Trend of Large Frame Gas Turbine For Power GenerationDocument10 pagesJournal of Power and Energy Systems: Evolution and Future Trend of Large Frame Gas Turbine For Power GenerationPalm100% (1)

- Bernoulli Chapter 3 PDFDocument45 pagesBernoulli Chapter 3 PDFMirrovshan SagdullaevNo ratings yet

- IGM Additives Product GuideDocument20 pagesIGM Additives Product GuideColoke AdesivosNo ratings yet

- Oil Seal GuideDocument7 pagesOil Seal GuideSenthil KumarNo ratings yet

- Properties of SemiconductorsDocument34 pagesProperties of SemiconductorsMohammad Gulam AhamadNo ratings yet

- Axial Loading: JU. Dr. Ibrahim Abu-AlshaikhDocument88 pagesAxial Loading: JU. Dr. Ibrahim Abu-AlshaikhqusayNo ratings yet

- Manufacturing Process 2nd Edition by U K Singh and Manish DwivediDocument290 pagesManufacturing Process 2nd Edition by U K Singh and Manish DwivediManjunath MaratheNo ratings yet

- Yg Pocket 2014 En18572 PDFDocument437 pagesYg Pocket 2014 En18572 PDFliceuNo ratings yet

- Relative PermittivityDocument7 pagesRelative PermittivityEthiopia HagereNo ratings yet

- Parison of Dia para FerroDocument4 pagesParison of Dia para FerroMUNAZIRR FATHIMA FNo ratings yet

- Ring Wall Foundation Pond SumuranDocument6 pagesRing Wall Foundation Pond SumuranHanafiahHamzahNo ratings yet

- Final Exam Mec630Document2 pagesFinal Exam Mec630aimanazuddinNo ratings yet

- Injection Molding Without The DryingDocument3 pagesInjection Molding Without The DryingHalloy1No ratings yet

- Abutment Design ExampleDocument56 pagesAbutment Design Examplezrilek1No ratings yet

- Solved Problems in Transport ProcessesDocument2 pagesSolved Problems in Transport ProcessesKristine Ann Villanueva60% (5)

- Performance Test Report - Novaguard 890 PDFDocument2 pagesPerformance Test Report - Novaguard 890 PDFPeter Callán100% (1)

- Design of Reinforced Concrete Structures: July 2008Document6 pagesDesign of Reinforced Concrete Structures: July 2008KarthikNo ratings yet

- Diecasting GuidebookDocument8 pagesDiecasting GuidebookMariver LlorenteNo ratings yet

- Synthesis and Characterization of Zinc Ferrite Nanoparticles Obtained by Self-Propagating Low-Temperature Combustion MethodDocument6 pagesSynthesis and Characterization of Zinc Ferrite Nanoparticles Obtained by Self-Propagating Low-Temperature Combustion MethodIetha Sunshine Of LoveeNo ratings yet

- CH 8 Radiation-Shape Factors, Network MethodDocument37 pagesCH 8 Radiation-Shape Factors, Network MethodHarsha IndurtiNo ratings yet

- ENGN.2060 Assignment 02 SolutionDocument4 pagesENGN.2060 Assignment 02 SolutionCloie ChavezNo ratings yet

- Physics XII CH 1 MCQ Electric Charges and FieldsDocument33 pagesPhysics XII CH 1 MCQ Electric Charges and Fieldsmanu patankarNo ratings yet

- CWB Level 2 MODULE 7 RESIDUAL STRESS & DISTORTION Flashcards - Quizlet - PDF (CWB 2)Document17 pagesCWB Level 2 MODULE 7 RESIDUAL STRESS & DISTORTION Flashcards - Quizlet - PDF (CWB 2)HusnainAhmedNo ratings yet

- Covalent CompoundsDocument4 pagesCovalent Compoundsrayan.ashroffNo ratings yet

- Turbulent Flow PDFDocument18 pagesTurbulent Flow PDFVinod Kumar PatelNo ratings yet

- Autofrettage in Pressure VesselsDocument28 pagesAutofrettage in Pressure Vesselssran1986No ratings yet

- BEE Tutorial 8Document2 pagesBEE Tutorial 8Atharva NairNo ratings yet

- Semiconductor DiodesDocument127 pagesSemiconductor DiodesKimberly BañesNo ratings yet

- Non-Consolidating Plugging Material For Wellbore and AnnulusDocument18 pagesNon-Consolidating Plugging Material For Wellbore and AnnulusSLACKENGINEERNo ratings yet

- Stiffening Effect of Refractory Lined Piping - Carmagen EngineeringDocument1 pageStiffening Effect of Refractory Lined Piping - Carmagen EngineeringnaeandNo ratings yet