Professional Documents

Culture Documents

271-123 221-Bge

Uploaded by

castelOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

271-123 221-Bge

Uploaded by

castelCopyright:

Available Formats

Generator Management Module

GMM 10

DESCRIPTION OF OPERATION

Copyright STN ATLAS Marine Electronics

Contents

Page

Author: Knirsch MBA3 Rev.: H Doc-No.: 271.123 221.BGE

Date : 05.01.2001 Page 1 of 80

Generator Management Module GMM 10

Description of Operation

1. Generator Protection 4

2. Basic Functions 5

3. Undervoltage Coil Support System 10

4. Connection of Peripherals 11

4.1 Digital Inputs 11

4.2 Relay Outputs 13

4.3 Analogue and Transformer Inputs 16

4.4 Module's Power Supply 17

4.5 Analogue Outputs 18

4.6 Serial Interfaces 19

5. Synchronization 19

6. Active Load Sharing 21

6.1 Electronic Diesel Controller 21

7. Mains Monitor (Automatic Blackout System) 22

8. Differential Protection 23

9. Earth-Fault Protection 26

9.1 Mains earth-Fault Protection with high impedance

earthing generator starpoint

26

9.2 Generator Earth-Fault Protection with high impedance

mains-earthing and collective-current-transformer 27

9.3 Mains earth-fault protection and generator earth-fault

protection with high impedance starpoint earthing and

collective-current-transformer 28

10. Control and Display Panel 29

10.1 Alarm Displays 30

10.2 Parameter Displays / Adjustment 34

10.3 Measured Value Displays 37

Author: Knirsch MBA3 Rev.: H Doc-No.: 271.123 221.BGE

Date : 05.01.2001 Page 2 of 80

Generator Management Module GMM 10

Description of Operation

10.4 Test indication / Simulation 40

10.5 Relay Indicator Lamps on Front Panels 48

11. Automatic Power Supply with GMM 10, Diesel Control

DMU 10 and Remote Display on BAT 406 49

12. GMM 10 as Shaft Generator Management Module 51

12.1 GMM 10 for STN Frequency Controlled Shaft Generator51

12.2 GMM 10 for Synchronous Shaft Generator 53

13. Integrated Load Monitor Function (with Extension

ZDM 401) 55

14. Bus Bar Monitor 61

15. Signal Diagram 62

16. Additional functions (not included in standard software) 64

16.1 Vector surge relay 64

16.2 df/dt monitoring 66

16.3 Undervoltage positive-sequence-relay 68

17. Contact numbers of freely programmable relays 70

18. Parameter backup and settings via PC 74

19. Overview about PC-board configurations GMM 10 75

Author: Knirsch MBA3 Rev.: H Doc-No.: 271.123 221.BGE

Date : 05.01.2001 Page 3 of 80

Generator Management Module GMM 10

Description of Operation

1. Generator Protection

The GMM 10 electronic Generator Management Module has been

developed specifically for monitoring the operation of

three-phase ship's mains supplies.

The module is supplied with power by a system achieving

redundancy through the use of the associated generator via

an external transformer, or an external 24 V DC battery.

Particular emphasis was placed on ensuring that the

management module is resistant to interference.

The electronics are electrically isolated from both the

supply voltage and all of the I/O lines.

The generator management module fulfills all the

requirements for a modern system for monitoring a ship's

mains supply. In addition to using the familiar monitoring

criteria such as current, voltage and frequency limits, it

also carries out sliding frequency regulation, and provides

differential and earth-fault protection.

Additional functions such as active load sharing,

synchronization, mains monitoring and load monitoring

supplement these facilities to turn the GMM 10 module into a

powerful component of a complete power supply system.

This description takes relation to the parameter description

(for instance par 3.3).

Parameter-list see separate document 271.123 221.TDE Revue L

2. Basic Functions

The module monitors the following functions :

Author: Knirsch MBA3 Rev.: H Doc-No.: 271.123 221.BGE

Date : 05.01.2001 Page 4 of 80

Generator Management Module GMM 10

Description of Operation

A) Energizing of Undervoltage Coil (par. 3.3)

Generator circuit-breaker may be switched on

when V > 0.8*Vrated

Undervoltage coil disconnection opens the generator

circuit-breaker in the event of :

- Undervoltage/Phase Failure

- Short Circuit

- Overcurrent

- Overvoltage

- Overfrequency

- Underfrequency

- Phase Current Asymmetry

- Reverse Power

- Differential current

- Short-circuit in Generator

B) Undervoltage (par 3.13/3.14)

Trip: voltage 50% to 100% *Urated

Delay: 0.2 to 100 s

Opens generator circuit-breaker

Phase failure

U < 0.5*Urated in one phase (par 3.1), delay 1s, not

active for short-circuit

Opens generator circuit-breaker

C/1) Short-circuit Protection (par. 3.4/3.5)

Trips : 100 to 400 %*Irated

Delay : 60 ms to 10 s

opens generator circuit-breaker

Author: Knirsch MBA3 Rev.: H Doc-No.: 271.123 221.BGE

Date : 05.01.2001 Page 5 of 80

Generator Management Module GMM 10

Description of Operation

C/2) Short-circuit Protection, Stage 2 (par. 3.6/3.7)

Trips : 300 to 800 %*Irated

Delay : 60 ms to 10 s

opens generator circuit-breaker

D) Overcurrent Protection (par. 3.8/3.9/3.10)

opens generator circuit-breaker :

- trips : 100 to 400 %*Irated

delay : 1 to 100 s

- or trips according to

fuse characteristic (par.3 .8):

integral ∫(I2-Irated2)dt > limit

opens generator circuit-breaker

E) Phase Current Asymmetry (par. 3.17/3.18)

opens generator breaker

trips : 20 to 120 %*Irated

delay : 1 to 100 s

F) Reverse Power Protection (par. 3.11/3.12)

trips : -1 to -50 %*Prated

delay : 1 to 100 s

opens generator circuit-breaker

G) Overvoltage Monitoring (par 3.15/3.16)

trips : 100 to 200 %*Vrated

delay : 1 to 100 s

opens generator circuit-breaker

H) Overfrequency Monitoring (par 3.31 / 3.32)

trips : 100 to 200 %*frated

delay : 1 to 100 s

opens generator circuit-breaker

Author: Knirsch MBA3 Rev.: H Doc-No.: 271.123 221.BGE

Date : 05.01.2001 Page 6 of 80

Generator Management Module GMM 10

Description of Operation

I) Underfrequency Monitoring (par. 3.27/3.28)

trips : 50 to 100 %*frated

delay : 1 to 100 s

opens generator circuit-breaker

J) Underfrequency Warning (par 3.29 / 3.30)

triggered : 50 to 100 %*frated

delay : 1 to 100 s

triggers alarm only

K) Overcurrent Load Disconnection, 1st Stage

(par. 3.19/3.20)

trips : 30 to 400 %*Irated

delay : 0.5 to 100 s

disconnects unimportant loads in group 1

L) Overcurrent Load Disconnection, 2nd Stage (par.

3.21/3.22)

trips : 30 to 400 %*Irated

delay : 0.5 to 100 s

disconnects unimportant loads in group 2

M) Overcurrent Load Disconnection, 3rd Stage (par.

3.23/3.24)

trips : 30 to 400 %*Irated

delay : 1 to 100 s

disconnects unimportant loads in group 3

N) Underfrequency Load Disconnection (par. 3.25/3.26)

trips : 50 to 100 %*frated

delay : 1 to 100 s

disconnects unimportant loads in groups 1,2 and 3

O) Thermistor Overtemperature Sensor (par 4.13)

Warning

Author: Knirsch MBA3 Rev.: H Doc-No.: 271.123 221.BGE

Date : 05.01.2001 Page 7 of 80

Generator Management Module GMM 10

Description of Operation

P) Stator Protection (par 3.33/3.34)

Trip: 3 to 100 %*Irated

Delay: 0.5 to 10.0 s

De-excitation and connection lock is current does not

decay after opening of circuit-breaker.

Q) Monitoring of excitation (par 3.35/3.36/4.6/6A.5)

Trip: 10 to 200 %*Srated reactive power difference

Delay: 1 to 100 s

Warning or possibly start enable to next generating

set

Opens with leading de-excitation

Optional extensions:

R) Differential Protection

Exceeding of the permissible differential current

between generator output and starpoint leads to

immediate de-excitation and opening of the generator

circuit-breaker. The current differential is a

function of the generator current. The threshold and

slope of the characteristic can be set with

potentiometers and code switches in case of analog PC

boards (GDS401).

If digital PC boards are used (GDE404) (available

about since 5.97) The threshold and slope of the

characteristic can be set via Parameter 4.10 and 6A.8

S) Earth-Fault Protection

The mains or the generator starpoint shall be

connected to earth with a high impedance resistor. An

earth-fault is detected with a current transformer at

the star point of the generator to ship ground or with

a summary current transformer.

- Earth-fault external to the generator :

Only displays alarm, does not disconnect the

generator circuit-breaker

- Earth-fault inside the generator :

Author: Knirsch MBA3 Rev.: H Doc-No.: 271.123 221.BGE

Date : 05.01.2001 Page 8 of 80

Generator Management Module GMM 10

Description of Operation

Alarming or De-excitation and circuit-breaker

will be opened

Author: Knirsch MBA3 Rev.: H Doc-No.: 271.123 221.BGE

Date : 05.01.2001 Page 9 of 80

Generator Management Module GMM 10

Description of Operation

Load disconnection (current or underfrequency)

In the event of the ship's mains supply being

overloaded, safety cut-outs K) to N) lead to the

unimportant loads being disconnected, thereby ensuring

that the ship's mains supply is maintained for the

important loads.

Opening of circuit-breaker

All faults that lead to the generator's circuit-

breaker opening are displayed visually on the module

and are stored. The circuit-breaker can be switched on

again if all trip- fault are acknowledged.

Trip alarms can be acknowledged local or remote. But

the following faults can only be acknowledged local:

- stator protection tripped

- short-circuit protection tripped

- differential protection tripped

- short-circuit inside the generator

- circuit-breaker failure

- phase asymmetry

Sliding frequency (par 4.4)

Limits for voltage, current and frequency monitoring

are adapted automatically for sliding frequency

controlling. Current, voltage and frequency limits are

calculated from the frequency setting according to the

characteristic of the ship's mains supply.

Acknowledge push-button

An acknowledgment (Quit) button and error message

display are provided on the module and externally.

Author: Knirsch MBA3 Rev.: H Doc-No.: 271.123 221.BGE

Date : 05.01.2001 Page 10 of 80

Generator Management Module GMM 10

Description of Operation

3. Undervoltage Coil Support System

The undervoltage coil support system USS402 is used to

prevent premature tripping of the generator's circuit

breaker during the short-circuit tripping delay.

If the electronic short-circuit cut-out system of the GMM 10

fails, in the event of a short circuit the generator's

circuit-breaker is nevertheless opened after the support

time of the undervoltage coil has elapsed.

Trip-on power : 140 W

Support power : 15 W (standard)

22.5 W if 3 support capacitors are used

Support time : 550 ms at V = 50 %

Author: Knirsch MBA3 Rev.: H Doc-No.: 271.123 221.BGE

Date : 05.01.2001 Page 11 of 80

Generator Management Module GMM 10

Description of Operation

4. Connection of Peripherals

The connections of the inputs and outputs of the generator

management module are shown on the complete circuit diagram

(see chapter 15) . The functions of the inputs and outputs

are explained below :

4.1 Digital Inputs

The GMM 10 can be controlled with digital inputs. The

digital input "Generator circuit-breaker is ON" is essential

for the operation of the unit. All of the other inputs can

be freely selected as required.

- Automatic (X4 : 1,2) switch DI5

o Preselecting "Automatic" activates active load

sharing.

Depending on the parameters set for the automatic

mode, once the diesel has been run up to speed,

automatic synchronization and connection are carried

out

o either automatically

o or only when the "Connect generator" button is

pressed

(compare parameters 4.1 / 4.2 / 4.3)

- Connect generator (X3 : 5,6) button DI3

If the automatic mode is not selected, the

synchronization and connection can be initiated with

the "Connect generator" button.

"Automatic" must likewise be selected for this.

- Generator circuit-breaker OFF

(switch-off diesel) (X3 : 1,2) button DI1

In the automatic mode, and when there is active load

sharing, the generator is relieved of load first, and

then its circuit-breaker opened, and disconnection of

the diesel can also be initiated.

(See Spare Relay, section 4.2 and Parameter 5.1)

After standstill of the unit, re-starting is possible

with the load or mains monitor.

Author: Knirsch MBA3 Rev.: H Doc-No.: 271.123 221.BGE

Date : 05.01.2001 Page 12 of 80

Generator Management Module GMM 10

Description of Operation

In the automatic mode, a stop is not performed if the power

balance does not permit this. The message

P>Stoprelease is given on the BAT. If the automatic

mode is not selected, the generator circuit-breaker is

opened immediately. A manual stop is always performed,

even if it produces a black-out. If the circuit-

breaker is opened manually without the GMM 10, the

command "Circuit-breaker OFF" is to be given to the

management module from a second level of buttons in

order to suppress the circuit-breaker failure message.

- Generator Circuit-breaker is ON (X3 : 3,4) switch DI2

The return signal from the generator circuit-breaker

enables the underfrequency and undervoltage

monitoring.

- Alarm Acknowledgment ('Quit') (X3 : 7,8) button DI4

All of the alarms are stored in the module and shown

on the display. Once acknowledged the alarms stored

are deleted.

- Not ready / CO2 / 3 min. - Stop Procedure for Diesel

(X4 : 2,3) continuous contact DI6

This input prevents connection. If the generator is on

mains and the mains monitor is active (parameter 4.12)

another diesel is started and the disturbed diesel

will be stopped if the actual load permits this.

- Current display IL2, IL3 (X4 : 4,5,6) switches DI7 and

DI8

These digital inputs are used to preselect which phase

current is displayed on the analog output. No input,

effects the display IL1. (Alternatively, Preselection

DI7 and Diode Fault DI8, see par. 1.18).

- High / low (X4 : 5,7,8) buttons DI9 and DIA

Manual adjustment on electronic diesel controller. In

the manual mode the speed setting (or the load

Author: Knirsch MBA3 Rev.: H Doc-No.: 271.123 221.BGE

Date : 05.01.2001 Page 13 of 80

Generator Management Module GMM 10

Description of Operation

sharing, see Par. 6.6) can be adjusted on the

electronic speed controller.

Author: Knirsch MBA3 Rev.: H Doc-No.: 271.123 221.BGE

Date : 05.01.2001 Page 14 of 80

Generator Management Module GMM 10

Description of Operation

4.2 Relay Outputs

The GMM 10 has 10 relay outputs :

The contact load must not exceed 4 A. A system for damping

overvoltages shall be provided by the user (servomotor, AC

contacts with R-C dam-ping, DC contacts with freewheeling

diodes). The damping protects of the contacts of the card

relays is important against EMC-interference.

- Generator circuit-breaker ON (X9 : 20,22)

The generator circuit-breaker is closed by means of

this 220 V contact.

- Tension / Circuit-breaker unbloked in manual mode

(X8 : 1,2)

In the automatic mode, the preload spring of the

circuit-breaker is tensioned before closing;

(tensioning pulse 2 to 10 s see Par. 5.4)

In the manual mode, this contact is always closed,

if a connection is permitted

(generator voltage > min., no locking due to short-

circuit etc.).

The contact is designed for 220 V.

- High/Low (X7 : 3,4,5,6,7)

The diesel engine's servomotor is connected to these

contacts.

DC motors (up to 24 V) and capacitor motors (up to 220

V) can be connected. (If High/Low commands are not

required, e.g. in the case of the electronic

controller, these contacts can be freely programmed

with parameters 7.2 and 7.3).

- Motor Power Supply (X7 : 1,2)

The separate supply for the servomotors is connected

to these contacts.

Author: Knirsch MBA3 Rev.: H Doc-No.: 271.123 221.BGE

Date : 05.01.2001 Page 15 of 80

Generator Management Module GMM 10

Description of Operation

- Undervoltage Coil (X11 : 24,26 and X17 : 1,3)

The undervoltage coil support system is built-in. The

undervoltage coil is connected to terminals

X11 : 24,26. If the built-in undervoltage coil support

system is not used, the holding contact of the

undervoltage relay can be connected via contacts

X17:1,3. In this case a freewheeling diode is also not

provided in the module.

Lay twisted connecting cable separate from 24 V signal

lines.

- Watchdog/cycle error (X8 : 11,12)

In the event of a fault in the module or loss of

voltage this contact releases. In normal conditions

the cycle relay is activated.

- Freely programmable relays

Relays DA 1 to DA 8 have default assignments. Based on

the parameter settings (1.8 to 1.15), assignments can

be varied as necessary. The contact-numbers for

parameters 1.8 to 1.15 and 7.2 and 7.3 see chapter 19.

All contacts are normally open, inverse function is

achieved by software.

- DA 1 at X5 : 1,2 24V contact (function can be

set by par. 1.8; default: unimportant loads 2,

opens at alarm

- DA 2 at X5 : 5,6 24V contact (par. 1.9, default:

unimportant loads 1, opens at alarm

- DA 3 at X8 : 3,4 220V contact (par. 1.10,

default: circuit breaker fault)

Author: Knirsch MBA3 Rev.: H Doc-No.: 271.123 221.BGE

Date : 05.01.2001 Page 16 of 80

Generator Management Module GMM 10

Description of Operation

- DA 4 at X5 : 3,4 24V contact (par. 1.11,

default: collective alarm GMM 10 opens at alarm)

Relays DA 5 to DA 8 are only provided if the

additional board DEA 401 is installed (must be

initialized by using parameter 1.16), DA 7 and DA 8

use a common terminal.

- DA 5 at X4 : 7,8 24V contact (par. 1.12,

default: de-excitation)

- DA 6 at X8 : 9,10 24V contact (par. 1.13,

default: thermistor alarm , opens at alarm, for

shaft generator: SG required, hold HAMA)

- DA 7 at X8 : 6,8 24V contact (par. 1.14,

default: start command from load monitor/mains

monitor/BAT406)

- DA 8 at X8 : 7,8 24V contact (par. 1.15,

default: stop command from load monitor/mains

monitor/BAT406)

Author: Knirsch MBA3 Rev.: H Doc-No.: 271.123 221.BGE

Date : 05.01.2001 Page 17 of 80

Generator Management Module GMM 10

Description of Operation

4.3 Analog and Transformer Inputs

- Generator voltage (X9 : 24,26,28)

- Mains voltage (X9 : 30,32)

In mains up to 450 V the generator voltage and mains

voltage can be input without interstage transformers.

The rated voltage and the transformation ratio of the

interstage transformer can be set parametrically (par

2.3 and 2.4).

Voltage input of GMM Vmax. rated = 450 V

Installed load: 5 VA

- Generator current (X10 : 20,22,24,26,28,30)

The current transformers of the GMM must be operated

as secondary transformers to the busbar transformers.

Current transformer of GMM Imax. rated = 1 A

Real effective values are measured.

The rated current and transformation ratio of the

busbar transformer can be set parametrically (par 2.1

and 2.2).

Installed load 1 VA.

- Thermistor sensor (X5 : 7,8 X6 : 1)

A system for evaluating the signals from thermistor

sensors (up to six in series) is incorporated in the

GMM 10. In the event of the temperature being

exceeded, the spare relay contact (normally closed)

and general alarm are activated. The generator

circuit-breaker and the unimportant loads are not

affected.

Alarm set if impedance: R > 2000 Ω

alarm release if: R < 1500 Ω

Author: Knirsch MBA3 Rev.: H Doc-No.: 271.123 221.BGE

Date : 05.01.2001 Page 18 of 80

Generator Management Module GMM 10

Description of Operation

4.4 Module's Power Supply

- Module supply (X6 : 2,3,4) and

undervoltage coil supply (X11 : 28,30,32)

It is proposed to provide the module's power supply

and the supply for the undervoltage coil on the

switchboard side from a common three-phase transformer

T1 with two secondary windings :

Primary voltage : rated voltage of generator

Secondary voltage 1 : 3*24V, 0.6 A at X6 : 2,3,4

Even in the case of a generator

overvoltage, the module's power

supply must not exceed 35 V

Secondary voltage 2 : 3*150V, 0.1 A at X17 :

28,30,32

with 220 V, 20 W undervoltage coil

An earthed screen winding is required.

- Support from 24V automation battery (X6 : 5,6,7,8)

The module's power supply can be supported by an

automation battery. Such support is only necessary if

mains monitoring functions are also to be covered by

the generator protection module, or an electronic die-

sel controller is incorporated.

Current : 1.5 A max.

Fuse : 6.3 A

Author: Knirsch MBA3 Rev.: H Doc-No.: 271.123 221.BGE

Date : 05.01.2001 Page 19 of 80

Generator Management Module GMM 10

Description of Operation

4.5 Analog Outputs

- Analog-output AA1 Power indication terminals (X1,2 :

6,7,8)

The power is measured, even with asymmetric loads and

phase currents with harmonics, with a tolerance of

about 1 %.

An analog output of a power signal is provided to

allow an indication on a moving-coil instrument (0 to

10 V). The scale can be set parametrically.

(See Par 1.4 and 1.7)

Minimal terminal resistance 500 Ω.

- Analog-output AA2 Current indication terminal (X2 :

6,7,8)

The phase current can be passed to a 2nd analog output

(0 to 20 mA). The phase, L1, L2 or L3, to be indicated

can be selected (see digital inputs DI6 and DI7).

(Alternatively apparent power, reactive power, power

indication , or power-factor cos(ϕ), see parameter

1.18)

The scale can be set parametrically.

(See Par 1.6 and 6A.4)

Maximum terminal resistance 500 Ω.

Author: Knirsch MBA3 Rev.: H Doc-No.: 271.123 221.BGE

Date : 05.01.2001 Page 20 of 80

Generator Management Module GMM 10

Description of Operation

4.6 Serial Interfaces

- GMM-Bus (X2 : 1,2,3,4,5)

All of the GMM 10 modules are interlinked by serial

ring communications. This data communication is used

to achieve active load sharing, to prevent generators

from being connected simultaneously in the event of a

blackout, for mains monitoring functions, for load

monitoring functions and the monitoring of excitation

(data transfer relates to active power, apparent

power, reactive power, frequencies, currents, start

commands passed on, synchronization enabling).

- GEAPAS-Bus (X1 : 1,4,5)

All of the information available from the GMM 10

module can be transmitted via this RS 485 interface to

a higher-level diesel monitoring system or a data

logging system. An input and output expander for the

particular systems can also be connected to this

interface (Data transfer relates to diesel

malfunctions, start and stop signals).

Normally, the RS485 of the GEAPAS bus has a bus termination on the ZKG404.

Accordingly, the GMM 10 must be used as end unit. If this cannot be implemented by the

user, the resistors R35, R36, R37 must be removed from ZKG404.

5. Synchronization

The synchronization unit carries out the following:

- frequency matching of the governermotor before the

circuit-breaker is closed

- frequency matching of the ship's mains supply before a

synchronous shaft-driven generator is connected

- closing the generator circuit-breaker when its

voltage, frequency and phase are identical to those of

the supply (circuit-breaker time of 100 ms is taken

into consideration);

allowable phase difference 20 degrees (par 5.3);

allowable frequency difference -0.15 / +0.35 Cy

- connecting one generator in the event of a blackout.

Author: Knirsch MBA3 Rev.: H Doc-No.: 271.123 221.BGE

Date : 05.01.2001 Page 21 of 80

Generator Management Module GMM 10

Description of Operation

In the automatic mode, the synchronization unit becomes

active when 80% of the generator voltage (Vmin par 3.3) is

reached.

- 2 seconds after reaching Vmin, the undervoltage coil

picks up and tensioning of the circuit-breaker is

initiated

- this circuit-breaker process may take 2 to 10 seconds

(parameter 5.4); after that, circuit-breaker closing

is enabled.

Enabling of the synchronization unit is with the par 4.1 or

4.2.

The circuit-breaker does not close under the following

conditions:

- VGen-Vmains > 10% Vrated

- VGen < Vmin (par. 2.3/3.3)

- fGen < fmin (par. 2.5/3.13)

- not ready / CO2 / 3 min. diesel stop (DI6 X4:2,3)

- after circuit-breaker failure

- permanent contact circuit-breaker OFF (DI1 X3:1,2)

- unacknowledged circuit-breaker fault at GMM10 is

blocking

- circuit-breaker fault

- another unit has already been connected following

short-circuit and still blackout. That is in case the

first set has one second after connection a short

circuit trip.

- after warning synchronization error

- if two generating sets with the same set number have

mistakenly been assigned

- if a set is in automatic mode and is disconnected

manually or by the mains monitor, there is no

connection in the follow-up time (par. 5.1). This does

not apply to the blackout case. The follow-up is

canceled when to set is switched from automatic to

manual mode and then back to automatic mode, or it

will be "started" again in the follow-up time via the

load monitor

- if the maximum number of sets has been reached (see

parameter 7.6 and section 14).

- not in automatic mode (DI5)

Author: Knirsch MBA3 Rev.: H Doc-No.: 271.123 221.BGE

Date : 05.01.2001 Page 22 of 80

Generator Management Module GMM 10

Description of Operation

- digital contact DI2 (generator is connected) is given

Author: Knirsch MBA3 Rev.: H Doc-No.: 271.123 221.BGE

Date : 05.01.2001 Page 23 of 80

Generator Management Module GMM 10

Description of Operation

6. Active Load Sharing

The active load sharing system implements the following

functions :

- symmetrical sharing of load by diesel generators

- unsymmetrical load sharing of shaft-driven generators

and turbo-generators, minimizing the output from the

diesel generators

- regulation of frequency at rated value

- load sharing with frequency characteristic set by the

synchronous shaft-driven generator

- reduction of frequency at sliding frequency service

(par 4.4)

- relieving load on the generator before disconnection /

dieseling

- parallel operation using frequency static’s in the

event of serial communication failure

Adjustments see parameters 4.3 and 5.5 to 5.13

6.1 Electronic Diesel Controller

An electronic diesel controller is recommended in mains

operating under highly dynamic conditions. The GMM 10 is

additionally provided with the controller card EDR401. The

GMM 10 is capable of controlling the diesel generator with

all of the conventional actuators. With this module the

frequency regulation and load sharing leads to smaller

deviations than with mechanical diesel controllers. The

measured electrical power is used for disturbance - variable

compensation.

En electronic diesel controller is especially recommended if

continuously parallel running with a synchronous generator

has to be achieved.

Speed sensing : Pick ups up to a frequency of 10 kCy

Supply voltage : 15 V (supply pick up from GMM 10)

Fuel supply setting : Preset with current signal of 0 to 200 mA

Parameter adjustment (parameter group 6) in general by STN.

Author: Knirsch MBA3 Rev.: H Doc-No.: 271.123 221.BGE

Date : 05.01.2001 Page 24 of 80

Generator Management Module GMM 10

Description of Operation

For the electronic diesel control a separate description is

available. The document number by STN is 271.132 244.BGE for

the English version.

7. Mains Monitor (Automatic Blackout System)

In the event of a blackout or fault this system starts the

diesel generator with the highest priority.

The generating set with the lowest number has the highest

priority. Generating sets with preselected priority will be

started. Precondition for starting is the automatic mode.

o The following faults cause another generator to be

started:

- blackout

- 3 min. diesel stop (DI6 X4: 2,3)

- excitation fault (par. 4.6). To effectively

protect the mains in the event of an excitation

fault, a further generating set is started. As

soon as the power balance permits, the disturbed

set is switched off. To prevent the remaining

sets from being under-excited during switch-off,

the faulty set is de-excited 3 seconds prior to

opening of the circuit-breaker. The reactive

power is thus transferred to the functional sets

prior to a stop.

- Shaftgenerator fault or reduction main engine

(par 2.15 / 2.16)

o Sets are available for the mains monitor if

- they are in automatic mode

- they are ready (DI6 X4: 2,3); in the case of the

DMU 10, ready message via the GEAPAS bus

Author: Knirsch MBA3 Rev.: H Doc-No.: 271.123 221.BGE

Date : 05.01.2001 Page 25 of 80

Generator Management Module GMM 10

Description of Operation

- there are no unacknowledged circuit-breaker

actions preventing synchronization (see section 5).

Author: Knirsch MBA3 Rev.: H Doc-No.: 271.123 221.BGE

Date : 05.01.2001 Page 26 of 80

Generator Management Module GMM 10

Description of Operation

8. Differential Protection

The differential protection system monitors generators and

transformers for internal faults. To achieve this, the input

(star point) and output currents of each phase are compared

with one another. The protected area is that one between the

two current transformers of each phase. Within its range of

effectiveness the differential protection system detects all

two and three-pole short circuits, as well as double-earth

faults, on the condition that one earth-fault is within the

protected area. In the case of machines with permanently

earthed star point, single-pole short circuits (earth-fault)

are also detected when such faults arise within the

protected area of the current transformers.

Figure 8.1 shows the basic circuit diagram of the

differential protection system. The tripping criterion is a

difference between the phase currents. The voltages which

are proportional to the currents will be tapped (off) at the

loads of the current transformers. Then the magnitude and

the phase angle of these voltages will be compared

(differential measurement). Faults that arise within the

protected area lead to a deviation at the output of the

differential measurement system, which causes the protection

device to trip immediately.

Faults involving large changes in current arising outside

the protection area can lead to erroneous tripping as a

result of different transformer characteristics. To prevent

this, the sensitivity of operation is decreased with

increasing current.

The detection of the difference current is done by the PC-

board GDS401 in analogue technique. A new development

achieves the differential protection in digital technique

with the PC-board GDE404 (see chapter 19). The difference

between both ways is the adjustment of the sensivity via

hardware or via software. In case of the digital solution,

different transformer currents in the starpoint and in the

phases can be adapted. (See parameter 6A.11)

Author: Knirsch MBA3 Rev.: H Doc-No.: 271.123 221.BGE

Date : 05.01.2001 Page 27 of 80

Generator Management Module GMM 10

Description of Operation

Figure 8.2 shows a typical characteristic for operation with

high sensitivity at up to 3 times the rated current. The

break-point and slope of the characteristic are adjustable.

Enabling of the differential protection is with parameter

4.7. It is possible to choose between two modes:

- circuit-breaker trip and de-excitation (par 4.7 set to 1)

- and additional dieselstop (parameter 4.7 set to 2)

µP

sensivity

+ +

Generator +

-

+

currentdifference

Figure 8.1 Basic circuit diagram of Differential Protection

System

Author: Knirsch MBA3 Rev.: H Doc-No.: 271.123 221.BGE

Date : 05.01.2001 Page 28 of 80

Adjustment of differential protection tripping on PC board GDS401

The tripping level of the difference current increases with the increasing current level.

peak tripping

difference current (I1 -I11)

8

6

triggering function

5

4

K

3

B Generatorphasecurrent(I1-I11 )/2[A]

A

0 1 2 3 4 5 6 7 8 9 10 11

Figure 8.2 Tripping Graph of Differential Protection

A) Minimum sensivity in case of small current

Zeropoint of the threshold sensitivity A is adjusted at potentiometer R9. The signal is measured at

point TB4.4 - TB2.6 on GDS401. The basic adjust is -0.4V conforming to 0.4A. In relation to the peak

value of the Phasecurrent that are 28%.

B) The increase of the sensivity is 0,2A/A from zero to the break-point B. Adjustment break-point B is

done via small switches on PC-board GDS401:

switch S1.7 on GDS401 S1.8 break-point-volt (TB4.5)

off off 3.97V ≡ 3.97A

off on

3.5V ≡ 3.5A

on x

3.0V ≡ 3.0A **

K) Slope K determinates unsensivity in case of great currents. The increase outside the break-point

can be adjusted too on PC-board GDS401

S1.1 = S1.3 = S1.5 S1.2 = S1.4 = S1.6 R15 = R16 = R17 K

off off 0 0.89

off on 0 0.71

on x 0 0.56

off off 4.99kΩ 0.94

off on 4.99kΩ 0.76

on x 4.99kΩ 0.61

off off 10kΩ 0.99 **

off on 10kΩ 0.81

on x 10kΩ 0.66

** adjustment in factory

Author: Knirsch MBA3 Rev.: H Doc-No.: 271.123 221.BGE

Date : 05.01.2001 Page 29 of 80

Generator Management Module GMM 10

Description of Operation

9. Earth-Fault Protection

For the monitoring of the earth-fault it is important to know,

that all earthing-transformers, earthing-resistances, current

transformers are not part of GMM 10. They have to be

dimensioned and delivered to the requirements of each special

system.

9.1 Earth-Fault Protection with high impedance earthing generator

starpoint

Because of high impedance earthing of the generator starpoint an

assumed earth fault-current has a calculated limit. On the figure

below an earth-fault current in the mains or in the generator will

cause a current over the transformer in the starpoint of the

generator. With the PC-board SWK402 (separate supply, not

incorporates in the GMM10) the earth-fault current will be

transformed into a DC-Voltage signal and connected to the GMM10. The

earth-resistance should be dimensioned in that way, that the earth-

current will not exceed about 5 to 20 A. The primary current

transformer should be so dimensioned, that in case of earth-fault an

earth current Iearth on the transformer secondary side is limited to

maximum 1 Ampere. The trigger level in GMM 10 is adjustable between

0.01 A and 0.55 A. The adjustment of the earth-fault protection is

done by par 4.8 / 4.11 and 7.9:

- To release alarm earth-fault set

parameter 4.8 to 1 or 2, depending on

used inputs to GMM10. The connection via

X19 is only foreseen, if the PC-boards of

differential protection are incorporated.

- Trigger level and delaytime for U(Iearth)

GMM10

SWK402 can be parameterized with parameter 4.11

I X1 X2 0Volt X19 or X1

and 7.9.

:1 :4 :1 :8

U U(Iear) :2 :2

:4 :3

Author: Knirsch MBA3 Rev.: H Doc-No.: 271.123 221.BGE

Date : 05.01.2001 Page 30 of 80

Generator Management Module GMM 10

Description of Operation

9.2 Generator Earth-Fault Protection with high impedance mains-

earthing and collective-current-transformer

Another way for earth-fault protection is possible, if the

mains has a high-resistance earthing in all three phases, and

the phases are supplied with a summary-current transformer (see

figure below). In this case it is possible to detect the

generator-internal earth-fault. A failure-current only can base

on a generator-internal earth-fault. The measurement of the

earth-fault signal with GMM10 is done with the transformer-

module SWK402. It is the presupposition, that for the

measurement of the generator internal earth-fault, the

extension for the differential protection is installed. In case

of differential protection with analogue PCBs (GDS401) the

earth-fault signal is connected to plug X19:1,2. In case of

differential protection with digital PCBs (GDE404) the earth-

fault signal is connected to plug X19:3,4.

For this variation 9.2 of earth-fault detection, the setting of

the parameters has to be done in the following way.

- To suppress general earth-fault set parameter 4.8 to 0.

- To release generator-internal earth-fault set parameter 4.9

to 1 or, if an additional breaker trip and de-excitation is

wanted, set par 4.9 to 2.

- tripping level and delaytime see parameter 4.11 and 7.9

GMM10

either or

SWK402 GDS401 GDE404

X19 X19

Iearth X1 X2 0Volt :1 :4

:1 :4

U(Iearth) :2 :3

:4 :3

Author: Knirsch MBA3 Rev.: H Doc-No.: 271.123 221.BGE

Date : 05.01.2001 Page 31 of 80

Generator Management Module GMM 10

Description of Operation

9.3 Mains earth-fault protection and generator earth-fault

protection with high impedance starpoint earthing and

collective-current-transformer

In case of high-resistant earthing of the generator starpoint,

it is possible to recognize the direction of the earth-fault

(generator internal or in the mains). For the generator earth-

fault detection, the summary of all three phase-currents and

the starpoint is build. The signal is feed to GMM 10 via a

SWK402, like described in 9.2. Additional a general earth-fault

is measured via a second current transformer in the starpoint

of the GMM10. The GMM 10 detects out of the general earth-fault

a mains-earth-fault, if there is not a generator internal

earth-fault at the same time.

For this variation 9.3 of earth-fault detection the setting of

the parameters has to be done in the following way.

- To release general earth-fault set parameter 4.8 to 1.

- To release generator-internal earth-fault set parameter 4.9

to 1 or, if an additional breaker trip and de-excitation is

wanted, set par 4.9 to 2.

- tripping level and delaytime see parameter 4.11 and 7.9

GMM10

either or

SWK402 GDS401 GDE404

X1 X2 X19 X19

IGen earth 0Volt :1 :4

:1 :4

:2 :3

U(I earth)

:4 :3

SWK402

I earth X1 X2 0Volt X1 X19

:1 :4 :8 :2

U(Iearth) :2 :1

:4 :3

Author: Knirsch MBA3 Rev.: H Doc-No.: 271.123 221.BGE

Date : 05.01.2001 Page 32 of 80

Generator Management Module GMM 10

Description of Operation

10. Control and Display Panel

The control and display panel mounted on the front of the

card cage has 4 different control and display levels.

Measured values are displayed in the normal mode (operating

values)

Alarm displays replace the measured value displays. They

must be acknowledged before being replaced by the measured

value displays again.

The button "-Parameter" can be used to suppress an alarm

for 15 minutes. This can be canceled prematurely by pressing

the QUIT button.

The TEST button provides an overview of the peripheral

inputs and tripping times.

Displaying and setting of parameters takes precedence and is

only to be activated when commissioning the module.

Author: Knirsch MBA3 Rev.: H Doc-No.: 271.123 221.BGE

Date : 05.01.2001 Page 33 of 80

Generator Management Module GMM 10

Description of Operation

10.1 Alarm displays

The first alarm to arise is shown on the display. The display "Ù"

and display "Ú" buttons can be used to scroll through the

display in order to find out whether there are more alarms. The

alarms are acknowledged and hence deleted with the Quit button.

Only the alarm shown on the display is acknowledged. If there are

several alarms, the QUIT button must be pressed several times.

Meaning of the status:

S h o r t c i r c 1

PARAMETER DISPLAY

- + Ú Ù

P1 P2 TEST QUIT

PARAMETER ALARM

T: trip

Q: must be acknowledged (at unit/control computer/Bat 406)

E: must be unlocked (acknowledged). Remote acknowledgement

via Bat 406 or via control computer not possible

M: message; alarm remains as long as cause exists and then

disappears automatically

V: unimportant loads disconnected

Author: Knirsch MBA3 Rev.: H Doc-No.: 271.123 221.BGE

Date : 05.01.2001 Page 34 of 80

Generator Management Module GMM 10

Description of Operation

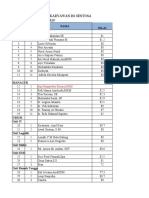

Alarms possible:

Display / Status Meaning See Parameters

Overcurrent 1 T+Q Overcurrent 3.9 + 3.10

Overcurrent 2 T+Q Overcurrent integral of I2dt 3.8

Reverse power T+Q Reverse power 3.11 + 3.12

Overvoltage T+Q Overvoltage 3.15 + 3.16

Undervoltage T+Q Undervoltage 3.13 + 3.14

Overfrequency T+Q Overfrequency 3.31 + 3.32

Underfrequency T+Q Underfrequency 3.27 + 3.28

Frequwarning T+Q Underfrequency warning 3.29 + 3.30

Short circ 1 T+E Short circuit, stage 1 3.4 + 3.5

Short circ 2 T+E Short circuit, stage 2 3.6 + 3.7

Phase failure T+Q Phase failure 3.1

Phase asymm T+E Phase current asymmetry 3.17 + 3.18

Stator prot. E Stator protection, phase current

after circuit breaker off 3.33 + 3.34

Exciter f. Q (+T) Reactive power asymmetric

3.35 +3.36+ 4.6

I difference T+E Differential current --> de-excitation

Earth fault Q Earth fault --> warning

Gen earth fault T+E Generator earth fault --> off + de-excitation

Uniload st 1 Q+V Disconnection of unimportant loads, 1 overcurrent

stage 1 3.19 + 3.20

Uniload st 2 Q+V Disconnection of unimportant loads 2, overcurrent

stage 2 3.21 + 3.22

Author: Knirsch MBA3 Rev.: H Doc-No.: 271.123 221.BGE

Date : 05.01.2001 Page 35 of 80

Generator Management Module GMM 10

Description of Operation

Display / Status Meaning See Parameters

Uniload st 3 Q+V Disconnection of unimportant loads 3, overcurrent

stage 3 3.23 + 3.24

Uniload 90%f Q+V Disconnection of unimportnat loads, 1 + 2,

underfrequency 3.25 + 3.26

Thrmtemp>max Q Thermistor has tripped 4.13

CB fault E Circuit breaker fault, not closing might tension time too

short 5.4

Connectshort Q+E Connection to short circuit

T-sync>max Q Synchronization time > 60 seconds 7.8

Mixed mode M Mixed MANUAL/AUTO mode with sliding frequency

GMMBus reception E No reception of telegrams on GMM bus

GMMBus open M Open circuit for telegrams on GMM bus

EEPROM error E Parameter checksum wrong -> take over default values

for parameters, the unit has to become new

parametrized

Failure ± 15V M Failure of ± 15V voltage for electronics

SPI bus SLE/A69 Q Serial/parallel interface to SLE401 on card place A69

has fault

SPI bus SLE/A1 Q Serial/parallel interface to SLE401 on card place A1

has fault

Power fuse Q NEG437 power supply fuse or only 2-phase power

supply for module

Cablebr PicUp E Fault in pick up speed sensor (with electronic diesel

controller only)

Cablebr coil E Break in wire of plunger coil of the actuator (with

electronic diesel controller only)

Blackout-CBO M Blackout but circuit breaker On: no connection possible

in blackout condition

Author: Knirsch MBA3 Rev.: H Doc-No.: 271.123 221.BGE

Date : 05.01.2001 Page 36 of 80

Generator Management Module GMM 10

Description of Operation

Display / Status Meaning See Parameters

rev.rotfield M connection error of generator voltages, negative-

sequence voltage is detected

ZDM bus fault M Telegram transmission to load monitoring module

ZDM401 disturbed

DMU bus fault M Telegram transmission to diesel monitoring module

DMU 10 disturbed

P>Stoprelease M The power balance does not permit stop enable

Diode failure Q Failure of generator exciter diodes (DE7 X4:4.5) 1.18

DG trouble T+Q Diesel generator not ready/3 min. stop

procedure/generator temperature (DI6 X4:2,3)

SG trouble T+Q Shaft generator trouble

(DI6 X4:2,3) --> demands DG Start 2.15

diesel start Q diesel start in case main engine is reducing speed (only

SG)

(DIA X4:8,6) --> demands DG Start 2.16

GovernMotErr Q Speed, servomotor failure 7.4

P-reserve<min M Start not possible from load monitor (gen.sets in Man.

Button no diesel start)

DG underload M Stop not possible from load monitor (button no diesel

stop)

Error DEA401 Q The PC-board EDR401 is missing or erroneous. Alarm

only active if par 6.0 is set to 1.

Error EDR401 Q The PC-board DEA401 is missing or erroneous. Alarm

only active if par 1.16 is set to 2. Alarm is only given if

DEA401 is modified.

Vectorbreak Q Vector surge has been detected (see chapter 16.1)

df/dt > max Q df/dt has been released (see chapter 16.2)

Undervol.Vsp Q Undervoltage positive-sequence (see chapter 16.3)

6A.9 and 6A.10

Cons.connect The connection of a big consumer oversteps the time

limit

System Reset Q The microprocessor has got a reset by a disturbance.

It may be caused by wrong RAM or EPROM or by non-

damped relays (see chapter 4.2)

Author: Knirsch MBA3 Rev.: H Doc-No.: 271.123 221.BGE

Date : 05.01.2001 Page 37 of 80

Generator Management Module GMM 10

Description of Operation

10.2 Parameter Displays/Adjustment

Parameters

The parametric mode is used for displaying and adjusting

limits, delays and control parameters and enabling software

modules.

Potentiometers are no longer used for adjusting and setting

limits. Parameters are selected and changed using the

display and buttons on the front panel. The values are

stored in the EEPROM without relying on the supply voltage.

In new modules, or in the event of a fault in a module, a

checksum error is detected automatically. All of the

parameters are then preset on default values. The EEPROM

error is displayed and must be acknowledged.

The parametric mode is entered by pressing buttons P1 or P2

for about 3 seconds.

The name and value of the parameter are shown on the

display. The Display "Ù" and Display "Ú" buttons can be

used to scroll through the display in order to look at other

parameters.

The parameters can be viewed at any time. They can only be

changed when the first parameter "ChangeCODE" is set on

"91". This lock prevents an unauthorized person changing any

of the other parameters.

Once all of the settings have been made a code other than

'91' is to be entered to act as a lock providing continued

security.

Author: Knirsch MBA3 Rev.: H Doc-No.: 271.123 221.BGE

Date : 05.01.2001 Page 38 of 80

Generator Management Module GMM 10

Description of Operation

Using the P1 + P2 buttons the first parameter of the

following (P2) or preceding (P1) groups of parameters can be

selected.

The Parameter + and Parameter - buttons can be used to

change the values of the parameters within appropriate

limits. The tens, hundreds and thousands digits of the

setting values can be scrolled by permanently pressing and

briefly releasing the adjustment buttons.

The default setting is adopted if both buttons are pressed

simultaneously.

The parametric mode is left automatically if no button is

pressed for ten minutes. It can be left immediately by

pressing the Quit button. The parameters are burnt into the

EEPROM when the parametric mode is left. It is therefore

important not to switch off the power supply too early.

F r a t e d 60.0Cy

PARAMETER DISPLAY

- + Ú Ù

P1 P2 TEST QUIT

PARAMETER ALARM

Author: Knirsch MBA3 Rev.: H Doc-No.: 271.123 221.BGE

Date : 05.01.2001 Page 39 of 80

Generator Management Module GMM 10

Description of Operation

Summary of Parameter Groups

Parameter-list see separate document 271.123 221.TDE Revue I

Parameter group 1 (Configuration of hardware)

Parameter group 2 (Rating and scaling)

Parameter group 3 (Tripping limits and delays)

Parameter group 4 (Extended functions)

Parameter group 5 (Control characteristics of active load and

synchronization controllers)

Parameter group 6 (Electronic diesel controller)

Parameter group 6A (adjustments for two mains operation,

special functions)

Parameter group 7 (Extension diesel control module DMU10 /

servomotor / limitation of the number of

sets)

Parameter group 8 (Load monitor with ZDM401)

Parameter group 9 (not yet used)

Parameter group 10 (Version number)

Author: Knirsch MBA3 Rev.: H Doc-No.: 271.123 221.BGE

Date : 05.01.2001 Page 40 of 80

Generator Management Module GMM 10

Description of Operation

10.3 Measured Value Displays

Measured values are shown on the display. The Display "Ù"

and Display "Ú" buttons can be used to scroll through the

display in order to look at further measured values.

The Parameter button permits suppression of an alarm for 15

minutes. It can be ended prematurely with the QUIT button.

F g e n 60.0Cy

PARAMETER DISPLAY

- + Ú Ù

P1 P2 TEST QUIT

PARAMETER ALARM

Author: Knirsch MBA3 Rev.: H Doc-No.: 271.123 221.BGE

Date : 05.01.2001 Page 41 of 80

Generator Management Module GMM 10

Description of Operation

Display Meaning

'COSphi 0.80' Power factor (cos-phi)

'I1 A' Phase current L1

'I2 A' Phase current L2

'I3 A' Phase current L3

'Fgen . Cy' Generator frequency

'Fmains . Cy' Mains frequency

'Vgen1 V' Generator voltage L1-L2

'Vgen2 V' Generator voltage L2-L3

'Vgen3 V' Generator voltage L3-L1

'Vmains V' mains voltage L1-L2

'Peff kW' Effective power

'Preac kVA' Reactive power

'Papp kVA' Apparent power

'S rpm' Diesel speed with electronic diesel controller

'Fslide . Cy' Rated value, red. value in sliding freq.mode

'SG-Limit %' Load limit shaft generator as a function of the shaft

speed (Analog input X1:2)

'Charge . mA' Coil current, charge control if using electronic diesel

controller

'Iearth . V' measuring signal earth current, either analog input

X19:1,2 or X1:2 (see parameter 4.8)

Author: Knirsch MBA3 Rev.: H Doc-No.: 271.123 221.BGE

Date : 05.01.2001 Page 42 of 80

Generator Management Module GMM 10

Description of Operation

Display Meaning

'Igeneart . V' measuring signal generator earth current, analog

input X19:1,2

'Gmns-gen d' Phase-shift between generator and mains in degrees

(Connection at zero, if synchronizing).

'E kWh' active energy display, for a proper energy-display the

RAM D2 on ZKG404 must be achieved with a

incorporated battery (special supply). The energy-

counter is set to zero, if the three push buttons

parameter +, parameter - and QUIT will be pressed

for 15 seconds.

' kVrh' reactive energydisplay, for a proper energy-display

the RAM D2 on ZKG404 must be achieved with a

incorporated battery (special supply). The reactive

energy-counter is set to zero, if the three push

buttons parameter +, parameter - and QUIT will be

pressed for 15 seconds. For lack of sufficient digits,

“kVarh“ is shortened to “kVrh“

'Vps V' display positive-sequence-voltage (see chapter 16.3)

Author: Knirsch MBA3 Rev.: H Doc-No.: 271.123 221.BGE

Date : 05.01.2001 Page 43 of 80

Generator Management Module GMM 10

Description of Operation

10.4 Test indications / simulation

The indication changes to the test mode when the Test button

is pressed.

The Display "Ù" and "Display "Ú" buttons can be used to

scroll through the display in order to look at further test

functions.

Alarm suppression is always activated in the test mode. The

test mode is left with the Quit button. If Quit is only

pressed briefly, the alarm indications are not canceled.

In the test of the load monitor (see below), the - Parameter

and

+ Parameter buttons are used to falsify the actual power

reserve. This permits simulation of starting and stopping of

the diesel sets.

DI 1______8_A

PARAMETER DISPLAY

- + Ú Ù

P1 P2 TEST QUIT

PARAMETER ALARM

The test functions appear in form of a general summary,

followed by a detailed description.

Author: Knirsch MBA3 Rev.: H Doc-No.: 271.123 221.BGE

Date : 05.01.2001 Page 44 of 80

Generator Management Module GMM 10

Description of Operation

Display Meaning

V_____St.__ Load monitor function: summary of loads selected. Start from load monitor

V_____Sp.__ /mains monitor and Stop from load monitor

S1____kVA__S What will the load monitor do next?

Sw____kW__s The power reserve and the residual time up to the next start or stop of the set

will be displayed here

DO________ All digital outputs at a glance

DI________ All digital inputs at a glance

Imax___A__s Overcurrent tripping

1lul___A__s Disconnection of unimportant loads 1

2lul___A__s Disconnection of unimportant loads 2

3lul___A__s Disconnection of unimportant loads 3

Ful__._Cy__s Disconnection of unimportant loads 1 and 2 due to underfrequency

Vmax___V__s Overvoltage tripping

Vmin__V__s Undervoltage tripping

Fmax__._Cy_s Overfrequency tripping

Fmin__._Cy__s Underfrequency tripping

Fwng__._Cy__s Underfrequency warning

lasy___A__s Disconnection due to phase asymmetry

Prev___kW__s Reserve power switch off

Qre___kVA__s Excitation fault warning

T____________ Display of all set-numbers of the members of the serial interface in the ring

communication

Author: Knirsch MBA3 Rev.: H Doc-No.: 271.123 221.BGE

Date : 05.01.2001 Page 45 of 80

Generator Management Module GMM 10

Description of Operation

Display Meaning

V_______St.___ Load monitor function: Summary of loads selected. Loads selected for

connection will flash (V1 to V6). The ident. number of loads connected is

displayed permanently. If no loads are selected, the numbers are suppressed.

Summary of start command passed on from load monitor/mains monitor and

V_______Sp.___ stop from load monitor. The ident. number of sets which are started or stopped

is displayed. The command is passed on to the GMM 10 with the set number.

This GMM 10 is then responsible for the execution; see DA test item number 2

and 4. The start number appears prior to commencement of start up to 15

seconds after the set is on the bus bar. The stop number appears for 4 sec.

Author: Knirsch MBA3 Rev.: H Doc-No.: 271.123 221.BGE

Date : 05.01.2001 Page 46 of 80

Generator Management Module GMM 10

Description of Operation

Display Meaning

What will the load monitor do next?

The power reserve appears here (sumPrated -Pactual). In addition, the time and the

ident letter (S1, S2, Sr, Sp, Sw) for the criterion which would initiate a start or

stop next appears. The assignment depends on the parameter remarks given

below. The indicated power reserve is usually the apparent power reserve. Only

if a start takes place due to insufficient active power reserve (ident letter Sw) the

active power reserve is displayed. (positive indication: reserve remains, negative

indication: the rated power of the sets has already been exceeded)

S1____kVA__s Apparent power reserve 1: limit values, parameters 8.2/8.4

S2____kVA__s Apparent power reserve 2: limit values, parameters 8.5/8.6

Sr____KvA__s Apparent power reserve relative: limit values parameters 8.3/8.4

Sp____kVA__s Apparent power reserve for initiating stop: limit values parameters 8.9/8.10

Sw____kW__s Active power reserve: limit values parameters 8.7/8.8

Load monitor simulation (only if Parameter 8.1 = 1)

The apparent power reserve can be changed with the buttons

-Parameter / + Parameter. This simulated power leads to actual start or stop of

the set. A stop is not performed by the respective set if the power reserve does

not permit disconnection.

The fact that the power reserve has been changed by simulation is indicated by

the unit kVA - and kVA ¯. The simulated power is reset when this indication is

left.

S1 50kV_ 4s The power reserve is greater than in reality

Sp 4500kV_30s The power reserve is lower than in reality

Author: Knirsch MBA3 Rev.: H Doc-No.: 271.123 221.BGE

Date : 05.01.2001 Page 47 of 80

Generator Management Module GMM 10

Description of Operation

Display Meaning

All digital outputs at a glance. Set number means the digital output has been

set. The numbers 1 to 4 are not actual digital outputs but are digital conditions.

Refer to chapter 4 for relay outputs not mentioned here.

DO________

DO123456789A "1" º set automatic, ready for start, load monitor/mains monitor. Remains if

set is on the bus.

"2" º start contact (can be parameterized as relay output or is transmitted to

DMU 10 by telegram)

"3" º disconnection, means not only the load relieving phase but also the time

for dieseling, transmitted to DMU 10 by telegram

"4" º stop contact (can be parameterized as relay output or is transmitted to

DMU10 by telegram)

"5" º DO5; X4:7,8 relay output via DEA401

function can be parameterized; default: de-excitation

"6" º DO6; X8:9,10 relay output via DEA401

function can be parameterized; default: thermistor trigger

"7" º DO7; X8:6,8 relay output via DEA401

function can be parameterized; default: start contact

"8" º DO8;X8:7,8 relay output via DEA401

function can be parameterized: default: stop contact

"9" º servo motor HIGH relay output; X7:3,4

"A" º servo motor LOW relay output; X7:4,5

Author: Knirsch MBA3 Rev.: H Doc-No.: 271.123 221.BGE

Date : 05.01.2001 Page 48 of 80

Generator Management Module GMM 10

Description of Operation

Display Meaning

DI________ All digital inputs at a glance. Set number means the digital output has been set

(contact closed)

DI123456789A "1" º disconnection; X3:1

"2" º generator circuit breaker ON; X3:3

"3" º generator to be connected (enable ON); X3:5

"4" º alarm acknowledgement button; X3:7

"5" º automatic; X4:1

"6" º diesel/shaft generator not ready (3 min. disturbance); X4:3

"7" º indication II2 selected via analog output; X4:4

"8" º indication II3 selected via analog output; X4:6

"9" º speed adjustment HIGH (for electronic diesel controller); for shaft

generator: generator ready; X4:7

"A" º speed adjustment LOW (for electronic diesel controller); for shaft

generator: generator start command passed on (reduced); X4:8

Imax___A_s Indication of max. value of all three phase currents and tripping time/residual

time for overcurrent. Counts with flashing numbers from 0 until circuit breaker is

Imax1444A20s tripped when the allowable current has been exceeded.

If the test button is held during a test display (and only as long as it is held), the

current is increased by the current increase factor (see parameter 1.5). Actual

circuit breaker tripping can therefore be tested even if the mains power is not

sufficient for this. Depending on the selection of the factor, short-circuit tripping

and the disconnection of unimportant loads can become active.

1lul____A__s Indication of maximum value of all three phase currents and the tripping

time/residual time for the disconnection of unimportant loads 1. Flashing

numbers towards 0 until the loads have been disconnected if the allowable

1lul956A10s current is exceeded.

Current increase factor, see Imax.

Author: Knirsch MBA3 Rev.: H Doc-No.: 271.123 221.BGE

Date : 05.01.2001 Page 49 of 80

Generator Management Module GMM 10

Description of Operation

Display Meaning

2lul___A__S Indication of maximum value of all three phase currents and tripping

time/residual time for the disconnection of unimportant loads 2. Flashing

2lul956A10s numbers towards 0 until the loads have been disconnected if the allowable

current is exceeded.

Current increase factor, see Imax.

3lul___A__S Indication of maximum value of all three phase currents and tripping

time/residual time for the disconnection of unimportant loads 3. Flashing

3lul956A10s numbers towards 0 until the loads have been disconnected if the allowable

current is exceeded.

Current increase factor, see Imax.

Ful___._Cy__s Indication of generator frequency and tripping time/residual time for

disconnection of unimportant loads 1 and 2 due to underfrequency. Flashing

numbers towards 0 until the loads are disconnected if the frequency is below the

Ful60.1Cy10s allowable frequency

Vmax____V__s Indication of maximum value of all three phase voltages and tripping

time/residual time for overvoltage: Flashing numbers towards 0 until the circuit

Vmax_440V18s breaker has tripped, if the allowable voltage has been exceeded.

Vmin____V__s Indication of minimum value of all three phase voltages and tripping

time/residual time for undervoltage: Flashing numbers towards 0 until the circuit

Vmin_440V18s breaker has tripped, if the voltage is below allowable voltage

Fmax__._Cy_s Indication of generator frequency and tripping time/residual time for circuit

breaker tripping due to overfrequency. Flashing numbers towards 0 until the

Fmax60.1C10s circuit breaker is switched off, if the allowable frequency is exceeded.

Fmin__._Cy_s Indication of generator frequency and tripping time/residual time for circuit

breaker tripping due to underfrequency. Flashing numbers towards 0 until the

Fmin60.1C10s circuit breaker is switched off, if the frequency is below the allowable value.

Author: Knirsch MBA3 Rev.: H Doc-No.: 271.123 221.BGE

Date : 05.01.2001 Page 50 of 80

Generator Management Module GMM 10

Description of Operation

Display Meaning

Fwng__._Cy_s Indication of generator frequency and tripping time/residual time for

underfrequency warning. Flashing numbers towards 0 until the circuit breaker

warning has tripped if the frequency is below the allowable value

Fwng60.1C10s

lasy____A__s Indication of greatest difference between all three phase currents and tripping

time/residual time for switch-off due to phase asymmetry. Flashing numbers

towards 0 until circuit breaker has tripped due to allowable current differential

lasy 300A20s being exceeded

Prev___kW__s Indication of active power and tripping time/residual time for reverse power.

Flashing numbers towards 0 until the circuit breaker has tripped if the allowable

Pre1000kW-5s reverse power is not reached

Qre____kVA__s Indication of reactive power difference to that generators who is the nearest

to the own generator and tripping time / residual time for excitation faults.

Flashing numbers towards 0, until the warning is triggered if the allowable

Qre800kVA__7s reactive power difference has been exceeded.

In the case of differently large generators, the percentage reactive power

difference is multiplied by the own rated power.

T____________ Display of all set-numbers which are members of the serial interface in the ring

communication

In the serial interface GMM-bus telegrams are send in the ring. Each member

T012345678EF (each GMM10) marks its telegram with its unit number (par 1.3). If a telegram is

received, so the number in the display is fired for 200 ms. In case of three to four

units in the ring, the numbers of the members should be continuously fired. In

case of more members, the numbers will show a flashlight (the telegram-runtime

per member accounts about 60 ms). The test-display is useful to check the

distribution of the set-numbers and the function of the GMM-bus.

Author: Knirsch MBA3 Rev.: H Doc-No.: 271.123 221.BGE

Date : 05.01.2001 Page 51 of 80

Generator Management Module GMM 10

Description of Operation

10.5 Relay indicator lamps on the front panels

The front panels of ZKG-403 and SWK-401 have control diodes

which show the status of the respective card relays.

The functions of the relays are as follows:

ZKG-403 K1: Relay DA 1, X5:1,2 (default: unimportant

load, stage 2, normally closed)

K2: Relay DA 4, X5:3,4 (default: collective

alarm, normally closed)

K3: Relay DA 2, X%.5,6 (default: unimportant

load, stage 1, normally closed)

K4: Cycle relay / watchdog, X8: 11,12 (opens in

the case of voltage or equipment failure)

SWK-403 K1: Undervoltage coil tensioned, X11:24,26 or

X17: 1,3

K2: Tension circuit breaker, X8:1,2

K3: Relay DA 3 X8:3,4 (default: message circuit

breaker failure)

K4: Generator circuit breaker switch-on signal, X9:20,22

Author: Knirsch MBA3 Rev.: H Doc-No.: 271.123 221.BGE

Date : 05.01.2001 Page 52 of 80

Generator Management Module GMM 10

Description of Operation

11. Automatic Power Supply with GMM 10, Diesel Control DMU 10

and Remote Display BAT 406

The generator management module GMM 10 can be integrated in

a networked automation structure. The diesel control module

DMU 10 and the control and display panel can be linked with

the GMM 10 via the GEAPAS bus. Diesel start and stop are

then effected from the GMM 10 via the GEAPAS bus to the DMU

10. BAT 406 permits remote control/display for a GMM 10 and

DMU 10 jointly. Operating values and alarm indications from

both units are shown on BAT 406.

If a BAT406 and the DMU are used, the parameter 7.1 is set

and parameter 1.17 is reset (the BAT 406 is controlled from

the DMU 10). If only a BAT 406 is used without a DMU 10

(e.g. for shaft generators or external diesel control units)

only the parameter 1.17 must be set.

Author: Knirsch MBA3 Rev.: H Doc-No.: 271.123 221.BGE

Date : 05.01.2001 Page 53 of 80

Generator Management Module GMM 10

Description of Operation

Author: Knirsch MBA3 Rev.: H Doc-No.: 271.123 221.BGE

Date : 05.01.2001 Page 54 of 80

Generator Management Module GMM 10

Description of Operation

12. GMM 10 as Shaft Generator Management Module

12.1 GMM 10 for STN Frequency Controlled Shaft Generator

Extended with additional software GMM 10 can be used as

shaft generator control system. Relay extension DEA 4011 is

needed. Parameters 1.16 / 2.14 / 2.15 / 2.16 / 4.3 must be

adjusted properly for shaft generator use. All the functions

described above apply. Is the parameter 2.14 set to 1, so

the GMM 10 software is programmed for a frequency controlled

shaft generator. In that case ( par 2.14 is set to 1) the

following functions will be added to the normal functions:

- When the shaft generator is disconnected (DI1 button

X3:1,2), the generator is initially unloaded as usual.

Subsequently, the SG STOP is given (relay contact X8: 7,8).

The circuit breaker is only opened 5 seconds later.

Normally, the shaft generator will already have disconnected

itself via the electronic from the shaft generator from the

bus bar before this.

- The contact "SG Failure" (DI6 X4: 2,3) leads to a start

command for diesel generators in the automatic mode (see

parameter 2.15). If there are sufficient diesel generators

are started and connected, the faulty shaft generator is

subsequently unloaded and disconnected from the bus bar. In

the display is shown "SG trouble "

- The contact "Diesel start" (DIA X4: 5,8) leads to start

command for diesel generators in the automatic mode (see

parameter 2.16). In the display is shown "Diesel Start". In

this case the shaft generator will not be disconnected by

the GMM 10.

- The contact "shaft generator indispensable" (DO6 X8: 9,10)

is given when not enough diesels run parallel to the shaft

generator so that the shaft generator power can be taken

over by the diesel generators. If the shaft generator has

1

Located on DEA 401: jumper X2:5-6 and 7-8

Author: Knirsch MBA3 Rev.: H Doc-No.: 271.123 221.BGE

Date : 05.01.2001 Page 55 of 80

Generator Management Module GMM 10

Description of Operation

given the contact "Diesel start". The relay output will be

taken of, after sufficient diesel generators are connected

to the bus bar.

- The maximum active power is limited via the analog input

X1: 2,8. This signal comes from the shaft generator

electronic. It corresponds to the main engine speed. 5 V

corresponds to 100% power enable. The display of the value

is selectable on the BAT407

("SG-limit xx%").

- In connection with a BAT 406, a manual start of the shaft

generator is passed on via the output "SG Start" (relay

contact DO7 X8: 6,8) if the shaft generator indicates that

it is ready via the digital input "SG ready" (contact DI9

X4: 5,7).

- The shaft generator never will be started and stopped by

the load monitor.

Author: Knirsch MBA3 Rev.: H Doc-No.: 271.123 221.BGE

Date : 05.01.2001 Page 56 of 80

Generator Management Module GMM 10

Description of Operation

12.2 GMM 10 for Synchronous Shaft Generator

For the synchronous shaft-generator, there other functions

then for the frequency controlled shaft generator. If

parameter 2.14 is set to 2 or 3, then GMM 10 activates the

specific functions of the synchronous shaft-generator.

Parameters 1.16 / 2.14 / 2.15 / 2.16 / 4.3 must be adjusted

properly for shaft generator use. All the functions

described above apply.

Is the parameter 2.14 set to 2 or 3, so the following

functions will be added to the normal functions:

The "Start" of the synchronous shaft generator will a) be

initiated via the key synchronization or b) by releasing

the excitation:

a) If the shaft generator is permanent excited, so the

synchronization is started via the input DI3 X3:5,6

"Synchronization in manual mode" (parameter 4.1 set)

b) If it is desired to release the excitation only for

connection and not if the shaft generator is in no-load

running, so you can switch the excitation via the relay DO5.

The parameter 1.12 has to be set to 423 if the contact opens

for excitation. He has to be set to 424 if the relay opens

for switching on the excitation.

- With the digital input DI3 X3:5,6 the excitation is

released. After excitation the synchronization will be done

automatically, if parameter 4.2 is set.

- Via the input DI1 X3:1,2 "Disconnection" the breaker is

opened and in addition to that the excitation is switched

off.

The excitation (and connection) and the de-excitation (and

disconnection) of the shaft-generator can also be done

remote with the keys start and stop on the BAT406.

If PC board DEA401 is installed, an external start of the SG

needs the "ready" signal via DI9 (X4:5,7).

Author: Knirsch MBA3 Rev.: H Doc-No.: 271.123 221.BGE

Date : 05.01.2001 Page 57 of 80

Generator Management Module GMM 10

Description of Operation

- The contact "SG Distribution" (DI6 X4:2,3) releases in

automatic operation a start to the diesel generators ( see

parameter 2.15). For instance this contact can be supplied

with the function "main engine reduces". If there are

sufficient diesel generators are started and connected, and

the alarm still is active, the disturbed shaft generator is

relieved of load and disconnected. The display shows "SG

trouble "

- The shaft generator never will be started and stopped by

the load monitor.

Permanent parallel running between synchronous shaft

generator and diesel generators is only possible, if the

diesel generators are supplied with an electronic diesel

governor. Otherwise parallel running is only for taking over

load. With parameter 2.14 you can choose two different

parallel running modes:

a) Parameter 2.14 is set to 2. In this case the parallel

running is not limited by the GMM 10.

b) Parameter 2.14 is set to 3. Then the parallel running

only is used to relieve load. Starting of the diesel

generator or excitation of the shaft generator is done by

the personnel. The stopping of the sets if there is a mixed

mode is done automatically:

- If the shaft generator has been connected last, the diesel

generators are stopped automatically.

- If a diesel generator has been connected last, the

synchronous shaft generator is relieved and disconnected

automatically. If the diesel generators can’t take the load

of the shaft generator, so the shaft generator keeps on the

mains until the personnel has started sufficient diesel

generators, then the shaft generator is stopped.

Author: Knirsch MBA3 Rev.: H Doc-No.: 271.123 221.BGE

Date : 05.01.2001 Page 58 of 80

Generator Management Module GMM 10

Description of Operation

13. Integrated Load Monitor Function (with Extension ZDM 401)

Functions of the load monitor :

- Starting and stopping of generator sets according to the

power demand.

- Connecting of single loads with high power after creating

reserve power.

Load monitor function is enabled by parameter 8.1. Digital

extension ZDM 401 must be provided for the required digital

inputs and relay outputs. The load monitor is selectable at

each GMM 10. But in general, he should only become activated

at one unit. exceptions see next page load monitor in case

of two bus bars.

A diesel start takes place, when the required power reserve