Professional Documents

Culture Documents

Lyngsø Marine EMS Platinum-ME User Manual

Uploaded by

Radu VasilacheOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lyngsø Marine EMS Platinum-ME User Manual

Uploaded by

Radu VasilacheCopyright:

Available Formats

Lyngsø Marine A/S

EMS Platinum-ME

Engine Manoeuvring System

MAN Diesel ME/ME-C Engines

User Manual

Doc. No.: 810.001.751-01

Lyngsø Marine A/S

Lyngsø Allé

DK - 2970 Hørsholm

Denmark

Telephone: +45 45 16 62 00

Telefax: +45 45 16 62 62

Engine Manoeuvring System, EMS Platinum-ME Page 1 of 116

User Manual for MAN Diesel ME/ME-C Engines 2010.06.28

Contents

SUBJECT INDEX ............................................................................................................................................... 4

1. EMS PLATINUM-ME INTRODUCTION .................................................................................................... 8

1.1 REFERENCES .................................................................................................................................... 10

1.2 DEFINITIONS AND ABBREVIATIONS ...................................................................................................... 10

2. EMS PLATINUM-ME SYSTEM OVERVIEW........................................................................................... 12

2.1 EMS PANELS FOR REMOTE CONTROL................................................................................................ 13

2.1.1 EMS Panel Functions.................................................................................................................. 14

2.2 MANUAL ECR CONTROL EQUIPMENT ................................................................................................. 19

2.3 LOCAL OPERATOR PANEL FUNCTIONS ................................................................................................ 20

2.4 SAFETY SYSTEM FOR THE MAIN ENGINE............................................................................................. 22

2.5 MAIN ENGINE SPEED MEASUREMENT ................................................................................................. 23

2.6 TELEGRAPH TRANSMITTER AND RPM SETPOINT CONTROL ................................................................. 23

2.6.1 Electrical Shaft System ............................................................................................................... 23

2.6.1.1 Bridge Centre and Wings Control Transfer ...................................................................................... 24

2.6.2 Emergency Telegraph System.................................................................................................... 24

3. EMS PLATINUM-ME FUNCTIONAL DESCRIPTION ............................................................................. 26

3.1 CONTROL POSITION CHANGE-OVER ................................................................................................... 26

3.1.1 ECS Control Station Priority ........................................................................................................ 27

3.1.2 Operation of Control Station Transfer ......................................................................................... 27

3.1.2.1 From Bridge Control to ECR Control ................................................................................................ 28

3.1.2.2 From Bridge Control to Local Control............................................................................................... 28

3.1.2.3 From ECR Control to Bridge Control ................................................................................................ 29

3.1.2.4 From ECR Control to Local Control ................................................................................................. 29

3.1.2.5 From Local Control to ECR Control ................................................................................................. 29

3.1.2.6 From Local Control to Bridge Control............................................................................................... 30

3.1.3 Forced EMS Control Transfer ..................................................................................................... 31

3.1.3.1 Forced EMS Transfer from Bridge Control to ECR Control .............................................................. 31

3.1.3.2 Forced EMS Transfer from Bridge Control to Local Control............................................................. 32

3.1.3.3 Forced EMS Transfer from ECR Control to Local Control ............................................................... 32

3.1.3.4 Forced EMS Transfer from Local Control to ECR Control ............................................................... 33

3.1.4 Forced ECS Control Transfer ..................................................................................................... 34

3.1.4.1 Forced ECS Transfer from Bridge Control to Local Control ............................................................. 34

3.1.4.2 Forced ECS Transfer from ECR Control to Local Control ................................................................ 35

3.1.4.3 Forced ECS Transfer from Bridge Control to Manual ECS Control in ECR ..................................... 35

3.1.4.4 Forced ECS Transfer from Local Control to Manual ECS Control in ECR ....................................... 36

3.1.5 Setpoint Levers Alignment .......................................................................................................... 37

3.1.5.1 From Bridge Control ......................................................................................................................... 37

3.1.5.2 From ECR Control............................................................................................................................ 37

3.1.5.3 From Local Control .......................................................................................................................... 37

3.1.5.4 Cable Failure on Setpoint Levers ..................................................................................................... 37

3.1.6 Control Station Selected at Power-Up ........................................................................................ 38

3.2 SUBTELEGRAPH ................................................................................................................................ 39

3.2.1 Conditions for Finished With Engine ........................................................................................... 41

3.2.2 Conditions for Standby ................................................................................................................ 41

3.2.3 Conditions for At Sea Mode ........................................................................................................ 41

3.2.4 Subtelegraph alarm ..................................................................................................................... 42

3.2.5 Subtelegraph status selected at Forced Take-over of Control Station ....................................... 42

3.2.6 Serial communication to ECS stop working ................................................................................ 42

3.2.7 Subtelegraph status selected at Power-Up................................................................................. 42

3.3 MAIN ENGINE START/STOP ................................................................................................................ 44

3.3.1 Automatic Bridge Control ............................................................................................................ 44

3.3.2 ME-Engine ECS System Responsibility ...................................................................................... 44

3.3.2.1 Manual ECR Control ........................................................................................................................ 45

3.3.2.2 Local LOP Control ............................................................................................................................ 45

3.3.3 ME-Engine Slowturning from EMS.............................................................................................. 46

810.001.751-01 Lyngsø Marine A/S

Engine Manoeuvring System, EMS Platinum-ME Page 2 of 116

User Manual for MAN Diesel ME/ME-C Engines 2010.06.28

3.3.3.1 Automatic Slowturning ..................................................................................................................... 46

3.3.3.2 Manual Slowturning .......................................................................................................................... 46

3.3.4 ME-Engine Start blockings in EMS ............................................................................................. 46

3.3.4.1 ME-Engine Ready to Start Indication in EMS................................................................................... 47

3.4 MAIN ENGINE SHUTDOWN .................................................................................................................. 48

3.5 MAIN ENGINE SLOWDOWN ................................................................................................................. 49

3.6 SETPOINT SYSTEM ............................................................................................................................ 51

3.6.1 Setpoint lever adjustments .......................................................................................................... 52

3.6.2 Main Engine RPM Governor Setpoint ......................................................................................... 52

3.6.2.1 Constant RPM Setpoint.................................................................................................................... 52

3.6.2.2 PTO Minimum RPM ......................................................................................................................... 52

3.6.2.3 Panel Fine Adjustment of RPM ........................................................................................................ 53

3.6.2.4 PMS Fine Adjustment for Frequency Control ................................................................................... 53

3.6.2.5 Slowdown RPM Setpoint .................................................................................................................. 53

3.6.2.6 Shaft Generator Waiting Station Hold .............................................................................................. 53

3.6.2.7 RPM Setpoint Slope ......................................................................................................................... 54

3.6.2.8 Maintain Speed Function ................................................................................................................. 54

3.6.2.9 Critical Speed Protection ................................................................................................................. 54

3.6.2.10 Speed-Droop Compensation of Setpoint ......................................................................................... 54

3.6.2.11 Governor Output Scaling.................................................................................................................. 54

3.7 ME-ENGINE RUNNING MODE SELECTOR ............................................................................................ 55

3.7.1 ME-Engine Running Mode alarm ................................................................................................ 55

3.7.2 Serial communication to ECS stop working ................................................................................ 55

3.7.3 ME-Engine Running Mode selected at Power-Up....................................................................... 55

4. EMS PLATINUM-ME PANEL OPERATION DESCRIPTION .................................................................. 56

4.1 CONTROL RIGHT FOR EMS CONTROL FUNCTIONS .............................................................................. 56

4.2 BASIC MODE OVERVIEW DISPLAY ON EMS PANEL.............................................................................. 57

4.2.1 Setpoint System Alignment ......................................................................................................... 58

4.2.2 Other EMS Panel Indications ...................................................................................................... 58

4.3 OPERATION FROM EMS PANEL .......................................................................................................... 58

4.3.1 Select of Machine Control Groups .............................................................................................. 58

4.3.2 Main Engine Start/Stop Operation .............................................................................................. 59

4.3.2.1 Main Engine Start/Stop Status List .................................................................................................. 60

4.3.2.2 Main Engine Start/Stop Adjustments ............................................................................................... 60

4.3.3 Select Main Engine Control Functions ........................................................................................ 61

4.3.3.1 ME-Engine Running Mode Control................................................................................................... 61

4.3.3.2 ME-Engine Running Mode Status List ............................................................................................. 62

4.3.3.3 Main Engine Setpoint Fineadjust ..................................................................................................... 62

4.3.3.4 Main Engine Setpoint Fineadjust Status .......................................................................................... 63

4.3.3.5 Max RPM Limit Adjustment .............................................................................................................. 63

4.3.3.6 Max RPM Limit Adjustment Status ................................................................................................... 63

4.3.3.7 ME Tacho Selector........................................................................................................................... 64

4.3.3.8 ME Tacho System Status List .......................................................................................................... 64

4.3.4 Shaft Generator Interface ........................................................................................................... 65

4.3.5 EMS Panel Status Lists............................................................................................................... 66

4.3.5.1 ME Control Transfer Status List ....................................................................................................... 66

4.3.5.2 ECS Interface Status List ................................................................................................................. 67

4.3.5.3 Main Engine Governor Interface ...................................................................................................... 67

4.3.5.4 Main Engine Startblockings List ....................................................................................................... 68

4.3.5.5 Main Engine Shutdown List.............................................................................................................. 68

4.3.5.6 Main Engine Slowdown List ............................................................................................................. 69

4.3.5.7 ME Setpoint System Status List ....................................................................................................... 70

4.3.5.8 EMS Platinum-ME Sub-Telegraph Status List ................................................................................. 71

4.3.6 Input/Output Adjustments ........................................................................................................... 72

4.3.6.1 Adjustment of Governor Output ....................................................................................................... 72

4.3.6.2 Adjustment of RPM Telegraph Levers ............................................................................................. 73

4.3.6.3 RPM Setpoint Adjustment Status List .............................................................................................. 73

5. EMS PLATINUM-ME PANEL ALARM AND MAINTENANCE FUNCTIONS.......................................... 74

5.1 BASIC MODE ..................................................................................................................................... 74

5.2 HARD - AND SOFTKEY OVERVIEW ....................................................................................................... 75

5.3 ALARM LIST MODE ............................................................................................................................ 76

5.4 ADDITIONAL LIST MODE ..................................................................................................................... 78

810.001.751-01 Lyngsø Marine A/S

Engine Manoeuvring System, EMS Platinum-ME Page 3 of 116

User Manual for MAN Diesel ME/ME-C Engines 2010.06.28

5.4.1 Selecting the List Type ................................................................................................................ 79

5.4.2 At the List Level .......................................................................................................................... 80

5.5 DISPLAY CHANNEL MODE .................................................................................................................. 81

5.5.1 The Text Entry Screen ................................................................................................................ 81

5.5.2 The Stepping/status Screen........................................................................................................ 82

5.5.3 Channel Status Screen ............................................................................................................... 82

5.5.4 The Entry Selection Screen ........................................................................................................ 83

5.6 ADJUST CHANNEL MODE ................................................................................................................... 84

5.6.1 Entering of Numerical Data and Texts ........................................................................................ 86

5.7 MAINTENANCE MODE......................................................................................................................... 87

5.7.1 Display Time and Date ................................................................................................................ 88

5.7.2 View Program Version, Load Sequential Date and Number ....................................................... 88

5.7.3 Set Time and Date (priv. access level 1) .................................................................................... 89

5.7.4 Lamp Test ................................................................................................................................... 91

5.7.5 Select UTC or Local Time (priv. access level 1) ......................................................................... 92

5.7.6 Enter Commissioning Mode (priv. access level 4) ...................................................................... 92

5.7.7 Change Password - Level N (priv. access level N/N+1) ............................................................. 92

5.7.8 Enter System Password Level (priv. access level 4) .................................................................. 93

5.7.9 Select LOP-UCS Control ............................................................................................................ 93

5.7.10 Watch Dog Activation (priv. access level 4) ........................................................................... 94

5.7.11 Store Setup (priv. access level 4) ........................................................................................... 94

5.8 DIMMER MODE .................................................................................................................................. 95

6. EMS PLATINUM-ME ALARM INDICATION AND TROUBLE SHOOTING ........................................... 96

6.1 MONITORING CHANNELS FOR DISPLAY AND PRINTING PURPOSE ....................................................... 105

6.2 EMS MODBUS INTERFACE TO ME-ENGINE ECS SYSTEM.................................................................. 107

7. EMS PLATINUM-ME CUSTOMISING TOOL PRINT-OUT .................................................................. 110

7.1 INPUT/OUTPUT LIST TERMINAL BOARD REPORT................................................................................ 110

7.2 OUTPUT FUNCTIONS LIST REPORT ................................................................................................... 111

7.3 EMS PLATINUM-ME FUNCTION BLOCKS LIST REPORT ...................................................................... 112

8. EMS PLATINUM-ME COMPONENTS AND SPARE-PARTS............................................................... 113

8.1 HARDWARE COMPONENTS LIST ....................................................................................................... 113

8.2 HW MODULES LAYOUT AND JUMPER SETTINGS................................................................................ 115

8.3 SPARE-PART LIST ............................................................................................................................ 116

810.001.751-01 Lyngsø Marine A/S

Engine Manoeuvring System, EMS Platinum-ME Page 4 of 116

User Manual for MAN Diesel ME/ME-C Engines 2010.06.28

Subject Index

Many of the entries in the subject index are the exact EMS ALARM TEXT appearing at the

Operating Panels on the Bridge and in the ECR.

ECS Engine Blocked .........................................107

A

ECS Engine Bridge RPM Setpoint ....................109

Additional List ................................................ 18;78 ECS Engine ECR RPM Setpoint .......................109

Adjust Channel ......................................... 18;49;84 ECS Engine Fuel Index .....................................109

Adjustment ECS Engine Index Margin .................................109

Fineadjust RPM Setpoint ........................... 62;63 ECS Engine Line Alive Counter ........................109

Governor Output............................................. 72 ECS Engine Local RPM Setpoint ......................109

Max RPM Limit ............................................... 63 ECS Engine Not Ready.....................................107

RPM Telegraph Levers .................................. 73 ECS Engine Ready ...........................................107

Alarm Acknowledge .................................. 17;76;80 ECS Engine Running Mode ..............................109

Auxiliary Blower ............................................. 41;47 ECS Engine Starting air press ..........................109

Auxiliary Systems................................................ 47 ECS Hydraulic Pressure Low ............................108

ECS Limitations Increased................................107

B ECS Load Limitation .........................................107

Bridge Telegraph El-shaft fail ............................. 99 ECS Local Control.............................................109

ECS Local Forced Command Take-over ..........107

C ECS LOP Lamp Test Request ..........................108

Cancel ECS Main Starting Valve Block .........................108

Limits .................................................. 17;46;100 ECS Modbus LineAlive Handshake ..................108

Shutdown............................. 16;21;22;48;68;101 ECS near Limit ..................................................109

Slowdown .......................... 16;21;49;69;101;102 ECS Pitch Backup Control ................................108

Slowturn.......................................................... 46 ECS Pitch Not in ZERO Position.......................109

Start Blocking ............................................ 46;47 ECS Preparing Start..........................................107

Control Location ECS Repeated Start..........................................107

................... 13;14;15;17;28;48;49;56;60;66;104 ECS SG Disconnection Failed ..........................108

Control Transfer ECS Shaft Generator Permission .....................108

8;14;19;21;23;24;26;27;28;31;32;33;34;35;36;3 ECS Shaft Generator Request..........................108

7;38;66;107;108;109 ECS Slow Command ........................................108

Crash stop .......................................................... 44 ECS Spare Modbus Address 10071 .................109

Critical Speed ......................................... 54;57;100 ECS Start Blocked ............................................107

ECS Start Failed ...............................................107

D ECS Startair Distributor Block ...........................108

Dimmer ......................................... 14;18;74;95;107 ECS Starting Air Pressure Low .........................108

Display Channel ........................................ 18;49;81 ECS TC CutOut Load Limit Activ ......................108

DPU 40 ECS Turning Gear Engaged .............................108

Comm. To PCS Panel 1 ................................. 96 EMS Alarm Output to Alm.System ....................105

Comm. To PCS Panel 2 ................................. 96 EMS Line to EICU-A, ANA SuperV .....................97

EMS Line to EICU-A, BIN SuperV ......................97

E EMS Line to EICU-B, ANA SuperV .....................97

ECR Sub Panel ................................................... 19 EMS Line to EICU-B, BIN SuperV ......................97

ECS Actual Pitch Feedback.............................. 109 EMS SIO Channel 1, ECS EICU-A .....................97

ECS Ahead Command ..................................... 108 EMS SIO Channel 2, ECS EICU-B .....................97

ECS Astern Backup Mode ................................ 108 EMS1T01 Overspeed .........................................96

ECS Astern Command ..................................... 109 EMS1T01 Pickup 1 fail........................................96

ECS Aux. Blower Failure .................................. 108 EMS1T01 Pickup 2 fail........................................96

ECS Bridge Control .......................................... 109 EMS-Alarm Syst. Interface Fail ...........................96

ECS Control Air Vented .................................... 108 EPS Emergency Stop Supply F15 ......................98

ECS Delayed Start ............................................ 108 EPS Platinum 8;10;12;16;21;22;48;98;100;101;114

ECS ECR Control ............................................. 109 EPS Safety System Switched Off .......................98

ECS ECR Forced Command Take-over .......... 107 F

ECS Engine Actual RPM Setpoint .................... 109

ECS Engine Actual Speed ................................ 109 Fine Adjustment ..................................................53

Finished With Engine .................15;39;44;55;61;71

810.001.751-01 Lyngsø Marine A/S

Engine Manoeuvring System, EMS Platinum-ME Page 5 of 116

User Manual for MAN Diesel ME/ME-C Engines 2010.06.28

Forced Control Transfer ME Slowdown input 10 ......................................102

............................... 14;19;26;31;32;33;34;35;36 ME Slowdown input 11 ......................................102

ME Slowdown input 12 ......................................102

G

ME Slowdown input 13 ......................................102

Governor Setpoint.......................................... 52;67 ME Slowdown input 14 ......................................102

ME Slowdown input 15 ......................................102

L ME Slowdown input 16 ......................................102

Limits Cancel ................................ 17;46;54;67;100 ME Slowdown input 2 ........................................102

Local Control ME Slowdown input 3 ........................................102

10;12;20;27;28;29;30;32;33;34;35;36;37;39;42; ME Slowdown input 4 ........................................102

55;59;61;105;107;109 ME Slowdown input 5 ........................................102

Local Control Box .......................................... 12;20 ME Slowdown input 6 ........................................102

LOP Control ............................................ 15;45;105 ME Slowdown input 7 ........................................102

ME Slowdown input 8 ........................................102

M ME Slowdown input 9 ........................................102

Maintenance .............................. 18;49;74;87;93;94 ME Slowdown Prewarning ................................102

Manual Control ................................................... 42 ME Stand By .....................................................106

Manual Slowdown, Reduce RPM ....................... 98 ME Start Block Cancelled .................................102

Master DPU ME Start Blocked ..............................................102

Status of DPU 40............................................ 99 ME Stopped ......................................................106

MCS Platinum ........ 8;10;12;17;18;78;79;80;93;113 ME Subtelegraph Alarm ....................................102

ME Alarm Cut-Out in Stop ................................ 105 ME Tacho 1 Error ..............................................103

ME BRG TLG CMD ............................................ 99 ME Tacho 2 Error ..............................................103

ME BRG TLG CMD Failure ................................ 99 Module EMS1AI01 (AEM402) Error ..................103

ME BRG TLG El Shaft fail .................................. 99 Module EMS1C001 (SIO2010) Error ................103

ME BRG TLG Mis aligned .................................. 99 Module EMS1C002 (SIO) Error ........................103

ME BRG TLG Misaligned ................................... 99 Module EMS1C003 (DSN) Error .......................103

ME BRG TLG Setpoint ..................................... 105 Module EMS1M100 (IFM2200) Fuse ................103

ME Bridge Control ............................................ 105 Module EMS1M101 (BSM2200) Error ..............103

ME Control position fail ..................................... 100 Module EMS1M102 (BXM2200) Error ..............103

ME Critical Speed Range 1 .............................. 100 Module EMS1M103 (BXM2200) Error ..............103

ME Critical Speed Range 2 .............................. 100 Module EMS1M104 (AOM2200) Error ..............104

ME ECR Control ............................................... 105 MSB ..........................................................10;53;62

ME ECR TLG CMD........................................... 100 P

ME ECR TLG CMD Failure............................... 100

ME ECR TLG Mis aligned................................. 100 PTO ...........................................................11;52;65

ME ECR TLG Misaligned.................................. 100 R

ME ECR TLG Setpoint...................................... 105

ME Emergency Stop ......................................... 100 Reset

ME Emergency TLG CMD Failure .................... 100 Fine Adjustment RPM ................................53;62

ME Finished With Engine ................................. 105 Shutdown ...................................................21;48

ME Governor Load Lim Cancelled.................... 100 Slowdown ........................................16;21;49;50

ME Limit Status................................................. 105 Slowturn Timer ...............................................46

ME Local LOP Control ...................................... 105 Start Blocking..................................................46

ME LOP TLG Setpoint ...................................... 105

S

ME Malfunction Startblocking ........................... 105

ME NON Cancellable Slowdown ...................... 101 Sea Mode ............................15;39;41;42;55;71;106

ME Overspeed .................................................. 101 Shaftgenerator ..........11;12;52;53;58;62;65;70;108

ME RPM ................... 14;21;22;57;59;60;63;67;105 Shutdown 8;11;16;21;22;46;48;49;53;58;68;96;101

ME Running ........................................ 101;105;106 Slowdown

ME Running Failure .......................................... 101 .8;11;12;16;21;49;50;52;53;57;58;66;69;98;101;

ME Running Mode Fail ..................................... 101 102;108

ME Running Status for Display ......................... 106 Slowturn ..................................................21;46;107

ME Sea Mode ................................................... 106 Standby .........21;39;40;41;42;47;55;61;71;107;108

ME Shutdown Active ......................................... 101 Start blocking .......................................46;59;66;68

ME Shutdown Cancelled .................................. 101 Stop Horn ..................................................17;48;49

ME Shutdown Prewarning ................................ 101 Sub-Telegraph .......................................8;21;39;71

ME Slowdown Active ........................................ 101 System Description ...................................10;18;22

ME Slowdown Cancelled .................................. 101

ME Slowdown input 1 ....................................... 102

810.001.751-01 Lyngsø Marine A/S

Engine Manoeuvring System, EMS Platinum-ME Page 6 of 116

User Manual for MAN Diesel ME/ME-C Engines 2010.06.28

T Telegraph System ..................................8;12;23;24

Tacho Selector.................................................... 64 U

Telegraph Lever

UTC time .............................82;85;87;88;89;90;92

8;12;23;24;26;28;29;30;31;32;33;36;37;50;51;5

2;58;62;73;100;101;107

810.001.751-01 Lyngsø Marine A/S

Engine Manoeuvring System, EMS Platinum-ME Page 7 of 116

User Manual for MAN Diesel ME/ME-C Engines 2010.06.28

This page is intentionally left blank

810.001.751-01 Lyngsø Marine A/S

Engine Manoeuvring System, EMS Platinum-ME Page 8 of 116

User Manual for MAN Diesel ME/ME-C Engines 2010.06.28

1. EMS Platinum-ME Introduction

The Engine Manoeuvring System - EMS Platinum-ME is an Engine Manoeuvring System

used for remote control of a ship’s Propulsion Line, with a MAN Diesel two-stroke low speed

ME-Engine connected to a Fixed Pitch Propeller (FPP).

The EMS Platinum-ME is operated by means of Telegraph Levers and standard EMS Plati-

num-ME Panels with build in four-line display.

The EMS Platinum-ME is operated as a completely independent stand-alone system, with all

information and internal alarms displayed on the EMS Operator Panels.

When the EMS Platinum-ME are delivered as an integrated part of the Monitoring and Con-

trol System MCS Platinum, the systems can be interconnected by means of a communica-

tion network, so that alarms, indications and measurements values from the EMS Platinum-

ME can be displayed on the Graphical Operator Station (GOS) and alarm Panels in the

Alarm and Control System also.

The EMS Platinum-ME can be configured to provide complete control for:

• Main Engine Remote Start/Stop from Bridge

• Start Blocking indications

• Main Engine Setpoint System

• Main Engine Shutdown Indications from ME Safety System

• Main Engine Slowdown System

• Main Engine Speed Measurement and Indication

• Control Transfer for Bridge/ECR/Local Change-over

• Sub-telegraph Control with Finished With Engine (FWE), Stand-by and Sea-mode

• Main Engine Running Mode Selector (Economy mode, Emission Mode etc.)

• Dual Serial Interface to the ME-Engine Electronic Control System (ECS)

• Alarm Announcement and Indication

The EMS Platinum-ME can be extended with the following options:

• EPS Platinum Engine Safety System (independent system for Shutdowns and over-

speed)

• Communication Telegraph System for Bridge order communication to ECR/Local

• Bridge Wing Control (Wing Panels Optional) and Electric Shaft on Telegraph Levers

• Manoeuvring Order Printer integrated in the system

• Integration with Lyngsø Marine Alarm and Control System

• Serial interface (Modbus) to other types of ships alarm system

This User Manual gives an overview of the hardware and describes the functionality of the

EMS Platinum-ME Engine Manoeuvring System, and includes wiring diagrams etc.

Also the Monitoring and Control System, the Safety System, the Telegraph Lever System

with Electric Shaft for the Bridge Wings and other related system and options are described

to give a complete overview of the remote control system.

810.001.751-01 Lyngsø Marine A/S

Engine Manoeuvring System, EMS Platinum-ME Page 9 of 116

User Manual for MAN Diesel ME/ME-C Engines 2010.06.28

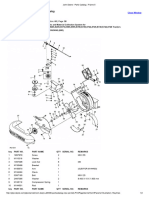

Br id g e Win g Po r t Br id g e Win g St a r b o a r d

Figure 1: Engine Manoeuvring System, EMS Platinum-ME layout.

810.001.751-01 Lyngsø Marine A/S

Engine Manoeuvring System, EMS Platinum-ME Page 10 of 116

User Manual for MAN Diesel ME/ME-C Engines 2010.06.28

1.1 References

[1] MAN Diesel ME-Engine Interface & Requirements to External Control Systems

[2] MAN Diesel ME-Engine Engine Control System – I/O Specification

[3] MAN Diesel ME-Engine Engine Control System – Available Options

[4] MAN Diesel ME-Engine Serial Interface – Requirement Specification

[5] Propulsion Control System, PCS2200, System Description

[6] Engine Protection System, EPS Platinum, System Description and User Manual

[7] Monitoring and Control System, MCS Platinum, System Description and User Manual

1.2 Definitions and Abbreviations

AEM Analog Input Module - type 402 (8 channel analog input)

AI Analog Input

AO Analog Output

AOM Analog Output Module - type 2200

BAP Basic Alarm Panel

BRG Bridge

BSM Binary Solid-state Input Output Module – type 2200

BXM Binary miXed input and relay output Module - type 2200

BT Bow Thruster

CPP Controllable Pitch Propeller

DG Diesel Generator

DI Digital Input

DNM Dual STELLA NET communication interface Module

DO Digital Output

DSN Dual STELLA NET communication interface

DZM DrehZahl relais Module - speed relay module type 402

ECR Engine Control Room

ECS Electronic Control System for MAN Diesel ME-Engine

EMG Emergency

EMS Engine Manoeuvring System - Bridge Manoeuvring System

ENT Enter key

EPS Engine Protection System - Engine Safety System

ER Engine Room

ESC Escape key

EXH Exhaust

FPP Fixed Pitch Propeller

GOS Graphic Operator Station

IFM InterFace Module adapter, DPU 2010 CPU to Input/Output module bus

I/O Input/Output

I/P Current to Pressure converter

LC Local Control

LCD Liquid Crystal Display

LED Light Emitting Diode

LOP Local Operator Panel

LP Low pass Filter

LM Lyngsø Marine

MCS Monitoring and Control System- ships alarm and control system

ME Main Engine

MEP Mean Effective Cylinder Pressure

MOP Main Operation Panel for ME-Engine ECS

MOS Monitoring System - ships alarm system

MSB Main Switch Board

MXM Multiplexer Module type 402 (16 channel analog input)

NA Not Applicable

810.001.751-01 Lyngsø Marine A/S

Engine Manoeuvring System, EMS Platinum-ME Page 11 of 116

User Manual for MAN Diesel ME/ME-C Engines 2010.06.28

PCC Propulsion Control Cabinet

PCS Propulsion Control System - Equivalent to EMS

PFM Power Filter Module for 24 Vdc Power Supply – type 2200

PLC Programmable Logic Controller - DPU 2010 PLC

PMS Power Management System - ships generator control system

PS Port Side

PTO Power Take Off

RPM Rotations per Minute

SB Star Board side

SG Shaft Generator

SHD Shutdown

SIM Serial Input/Output Interface Module

SIO Serial Input/Output Communication

SLD Slowdown

ST Stern Thruster

TAM Tacho Adapter Module - type 401

TC Turbo Charger

UCS Equivalent to MCS

UMS Equivalent to MOS

UPS Uninterruptible Power Supply

810.001.751-01 Lyngsø Marine A/S

Engine Manoeuvring System, EMS Platinum-ME Page 12 of 116

User Manual for MAN Diesel ME/ME-C Engines 2010.06.28

2. EMS Platinum-ME System Overview

The EMS Platinum-ME control functions for a Propulsion Line existing of a MAN Diesel two-

stroke low speed ME-Engine with Fixed Pitch Propeller are handled by one EMS Platinum-

ME DPU 2010 PLC mounted in the EMS control cabinet, together with the units for an EPS

Platinum Engine Safety System.

The Main Engine Safety System is completely independent of the EMS. The Main Engine

may be equipped with a standard Safety System from the Main Engine manufacturer. If the

Main Engine manufacturer supply does not include a Safety System, the EMS can be deliv-

ered together with an independent Engine Protection System, EPS Platinum Safety System.

Other DPU 2010 PLC's in the MCS Platinum Monitoring and Control System handles the

alarm and monitoring part of the machinery components controlled by the EMS Platinum-

ME. In case that alarms from the Main Engine are connected to the EMS DPU 2010 PLC, it

must be alarms relevant for the Main Engine controlled by that particular EMS DPU only, be-

cause they will be displayed as EMS alarms on the EMS Panels, such as e.g. alarms initiat-

ing a Slowdown/load reduction, startblockings etc.

The EMS Platinum-ME and the MCS Platinum Alarm and Control system are independent

systems, each with its own DPU 2010 PLC’s, only connected by a network to transfer alarms

and information to the GOS and printers (Manoeuvring Order Printer). The network will also

be used for automatic operation of the Power Management System (PMS) e.g. in case of

mode change to/from a mode where the SG is connected to a Bow Thruster (BT) and/or

Stern Thruster (ST).

Slowdowns for the Main Engine and optional RPM up/down signals from the Power Man-

agement System (for frequency control, load sharing and synchronising purposes) are trans-

ferred as hardwired signal lines for safety reasons. The Slowdown inputs to the EMS Plati-

num-ME are defined as supervised inputs, i.e. cable break can be detected.

All hardware component and logic circuitry of the EMS Platinum-ME and the MCS Platinum

Alarm and Control System is independent. That means it will still be possible to control the

propulsion machinery even in case of a total breakdown of the Alarm and Monitoring Sys-

tem.

The power supply for the EMS Platinum-ME as well as the EPS Platinum and MCS Platinum

must be Uninterruptible Power Supply (UPS) protected. There must be a separate fuse for

the EMS Platinum-ME DPU, the EPS PLC and the remaining hardware connected to this

system.

The following parts of the remote control system are described in this section:

• EMS Platinum-ME Main Cabinet (DPU 2010 PLC, I/O Modules etc.)

• EMS Platinum Panels for remote control of the propulsion machinery

• ECR Components for Manual ECR Control of the propulsion machinery

• Local Operator Panel for Local Control of the propulsion machinery

• EPS Platinum Engine Safety System

• Telegraph Lever System

• Electric Shaft for Bridge Wings control

• Communication Telegraph System

• Main Engine Speed Measurement

810.001.751-01 Lyngsø Marine A/S

Engine Manoeuvring System, EMS Platinum-ME Page 13 of 116

User Manual for MAN Diesel ME/ME-C Engines 2010.06.28

2.1 EMS Panels for Remote Control

For operation of a ship’s Propulsion Line, the EMS is connected with EMS operator panels

on all control locations, including instruments for RPM and Start air pressure indication and a

pushbutton for Emergency stop:

• one in the Engine Control Room (ECR)

• one on the Bridge

• two panels on the Bridge starboard and Port Wings (optional)

• a fifth panel can be mounted on an Aft Bridge (optional)

The EMS Panel is mounted together with a Setpoint Lever on all Control Locations with EMS

Control, i.e. normally Bridge and ECR, and optionally on the Bridge Wings.

Figure 2.1: EMS Panel, Telegraph and Instruments for Bridge and ECR Control Locations.

810.001.751-01 Lyngsø Marine A/S

Engine Manoeuvring System, EMS Platinum-ME Page 14 of 116

User Manual for MAN Diesel ME/ME-C Engines 2010.06.28

2.1.1 EMS Panel Functions

The following main functions are available on each control location for the Main En-

gine/Propulsion Line:

Analog instruments for indication of ME RPM

Analog instruments for indication of ME Start Air pressure

Dimmer potentiometer for illumination of the analog instruments (Bridge

only)

[ Emergency Stop ] push-button with cover

Forced [ Take Command ECR ] Control Transfer push-button with cover connected directly

to the ME-Engine ECS (ECR only)

[ Increase Limit ] with cover connected directly to the ME-Engine ECS

(ECR only)

EMS Platinum-ME Operator Panel with the following functions:

ME: <Runstat> 100.0 RPM, StAir 30.00 BAR

LIMITER:<Indic1>

TLG BC: ±120.0 ECR: ±120.0 ECS: 20.0 RPM

<Oldest unacknowledged alarm/Alarm stat>

Four lines display with 40 characters on each line

Softkeys [ S1 ] - [ S4 ] for operation of EMS functions

Six selection keys: [ ESC ], [ ENT ]

and four [ Arrow ] keys

[ Select ] of EMS control functions of

[ Status ], [ Control ] and [ Settings ]

810.001.751-01 Lyngsø Marine A/S

Engine Manoeuvring System, EMS Platinum-ME Page 15 of 116

User Manual for MAN Diesel ME/ME-C Engines 2010.06.28

Control location selection and indication for:

[ Bridge Ctrl. ] key for indication and Request / Acknowledge of Automatic

BRIDGE

CTRL.

Bridge.

References: Chapter 3.1.

[ E.C.R. Control ] key for indication and Request / Acknowledge of ECR

E.C.R.

CTRL.

Control Station (Automatic ECR or Manual ECR Control).

References: Chapter 3.1.

1 ABC

[ Local Ctrl. ] key for indication and Request / Acknowledge of Local

LOCAL (Emergency) Control Station. (Manual LOP Control)

CTRL.

References: Chapter 3.1.

SUB-Telegraph selection and indication for:

[ Sea Mode ] operation and indication key:

SEA Activation of this key commands Sea Mode and alarm for this is released.

MODE

Mode conditions: Control air on, Safety air on, Main start valve not blocked,

Starting air distributor not blocked and Turning gear not engaged.

When unacknowledged or conditions not fulfilled, the green LED is flashing.

When Sea Mode is present, the green LED is ON.

References: Chapter 3.2.3

[ Stand By ] operation and indication key:

STAND Activation of this key commands Stand By at the Main Engine and alarm for

BY

this is released.

Mode conditions: Control air on, Safety air on, Main start valve not blocked,

Starting air distributor not blocked and Turning gear not engaged.

When unacknowledged or conditions not fulfilled, the green LED is flashing.

When Stand By is present, the green LED is ON.

References: Chapter 3.2.2

7 STU

[ F.W.E. ] operation and indication key:

F.W.E. Activation of this key commands Finished With Engine and alarm for this is

released.

Mode conditions: Control air pressure off, Safety air pressure off

and Main start valve blocked.

When unacknowledged or conditions not fulfilled, the green LED is flashing.

When Finished With Engine is present, the green LED is ON.

References: Chapter 3.2.1

810.001.751-01 Lyngsø Marine A/S

Engine Manoeuvring System, EMS Platinum-ME Page 16 of 116

User Manual for MAN Diesel ME/ME-C Engines 2010.06.28

Slowdown operation and indication for:

[ Slow Down ] operation and indication key:

SLOW

DOWN

Activation of the key invokes the Slowdown status list at the LCD display.

When Slowdown is active, the red LED is ON.

References: Chapter 3.5.

2 DEF

[ Slowd. Cancel ] operation and indication key:

SLOWD. Slowdown may be cancelled, when in Automatic Bridge or Automatic ECR

CANCEL

control

When in Manual ECR Control, operation takes place from the EMS as well.

When Slowdown prewarning is present, the red LED is flashing.

When the Slowdown situation is cancelled, the red LED is ON.

References: Chapter 3.5.

8 VWX

[ Slowd. Reset ] operation and indication key:

SLOWD. Slowdown may be reset, when in Automatic Bridge or Automatic ECR con-

RESET

trol and the slowdown condition is neither present nor cancelled.

When in Manual ECR Control, operation takes place from the EMS as well.

When Slowdown may be reset due to Slowdown condition back to normal

or cancelled the red LED is flashing.

References: Chapter 3.5.

Shutdown operation and indication for:

[ Shut Down ] operation and indication key:

SHUT

DOWN

Activation of the key invokes the Shutdown status list at the LCD display.

When Shutdown is active, the red LED is ON.

References: Chapter 3.4 and EPS Platinum User Manual

3 GHI

[ Shutd. Cancel ] operation and indication key:

SHUTD. Shutdown may be cancelled, when in Automatic Bridge or Automatic ECR

CANCEL

control.

When not in Automatic EMS Control, operation takes place from the EPS

Platinum Operator Panel in ECR, or from the LOP.

When Shutdown prewarning is present, the red LED is flashing.

When the Shutdown situation is cancelled, the red LED is ON.

References: Chapter 3.4 and EPS Platinum User Manual

The [ RESET ] and [ CANCEL ] keys for Shutdown and Slow Down keys are only working

on the EMS Operator Panels which are in control, i.e. on anyone of the Bridge Operator

Panels in Bridge Control and on the ECR Operator Panel in Automatic ECR Control, how-

ever the Slowdown Reset can be configured to always require reset from the E.C.R. Opera-

tor Panel.

810.001.751-01 Lyngsø Marine A/S

Engine Manoeuvring System, EMS Platinum-ME Page 17 of 116

User Manual for MAN Diesel ME/ME-C Engines 2010.06.28

Startblock and Limits Cancel operation and indication for:

4 JKL

[ Start Block ] operation and indication key:

START Activation of the key invokes the Startblocking status list at the LCD dis-

BLOCK

play.

When Startblocking is present, the red LED is ON.

[ Limits Cancel ] operation and indication key:

6 PQR

LIMITS Activation of this key Cancels the RPM Max Limit and Load program of the

CANCEL

EMS Platinum-ME as well as raising the Index Limiters in the ME-Engine

ECS System.

When Cancellation is present, the red LED is ON.

The [ Limits Cancel ] key is only working on the EMS Operator Panels,

which are in control, i.e. on anyone of the Bridge Operator Panels in Bridge

Control and on the ECR Operator Panel in Automatic ECR Control.

EMS Platinum-ME keys for alarm functions:

[ Stop Horn ] operation key:

STOP

HORN

Activation of this key stops the buzzer in the EMS Operator Panel.

[ Alarm Acknowledge ] operation key:

ALARM

ACKN.

Activation of this key acknowledges the alarms present at the LCD display

of the EMS Operator Panel.

The [ Stop Horn ] and [ Alarm Ackn. ] keys can be configured to work on several different

conditions:

1. Both keys are always working in the ECR, e.g. when the Chief Engineer always wants

to be able to acknowledge alarms. Buzzer and [ Stop Horn ] are working on anyone of

the Bridge Operator Panels for all alarms announced on the bridge (configurable), but [

Alarm Ackn. ] will not be possible on the Bridge.

2. Both keys are working on the present EMS Control Location, i.e. working on anyone of

the Bridge Operator Panels in Bridge Control and on the ECR Operator Panel in ECR

Control.

In connection with an integrated MCS Platinum Monitoring and Control System, where the

Watch Station can be changed to the Bridge, the function of both keys is following the MCS

Watch Station.

810.001.751-01 Lyngsø Marine A/S

Engine Manoeuvring System, EMS Platinum-ME Page 18 of 116

User Manual for MAN Diesel ME/ME-C Engines 2010.06.28

[ Alarm List ] operation and indication key:

ALARM

LIST

References: Chapter 5.3.

[ Additional List ] operation and indication key:

ADD.

LIST

References: Chapter 0.

[Display Channel ] operation and indication key:

DISPLAY

CHANNEL

References: Chapter 5.5.

[ Adjust Channel ] operation and indication key:

ADJUST

CHANNEL References: Chapter 5.6.

[ Maintenance ] operation and indication key:

MAINTE- References: Chapter 5.7.

NANCE

[ Dimmer ] operation and indication key:

DIMMER

References: Chapter 5.8.

[ Alarm ] indication lamp for EMS Platinum-ME Alarm detected.

Any EMS Platinum-ME alarm in chapter 6 activates this indication.

[ Fault ] indication lamp for EMS Platinum-ME Operator Panel in Faulty

condition,

e.g. missing communication to the DPU 2010 PLC or missing EPROM

inside the panel.

Please refer to chapter 5 and the MCS Platinum System Description for further information

about the alarm system functions.

810.001.751-01 Lyngsø Marine A/S

Engine Manoeuvring System, EMS Platinum-ME Page 19 of 116

User Manual for MAN Diesel ME/ME-C Engines 2010.06.28

2.2 Manual ECR Control Equipment

All indications and operations, such as Aux. Blowers control and indication of Main Start

Valve position etc. in the ECR Control Console which used to take place on the ECR Sub

Panel are now included in the MAN Diesel supplied Main Operator Panel (MOP), please re-

fer to the MAN Diesel instruction manual.

Beside that the following facilities are available:

1. EMERGENCY STOP, i.e. when Emergency Stop is ordered from this pushbutton, then

the red lamp indication is ON. The pushbutton is protected with a plastic cover against

unwanted operation. The pushbutton is connected to the Safety System.

2. TAKE CONTROL, i.e. when this pushbutton is activated, the ME-Engine ECS Control

System makes a forced control transfer to Manual ECR Control. This button overrides all

other Control Transfer functions except the similar Take Control pushbutton on the LOP.

The pushbutton is connected directly to the ME-Engine ECS System.

3. INCREASE LIMITS, i.e. i.e. when this pushbutton is activated in Manual ECR Control,

the ME-Engine ECS will raise the limiters in the Governor System. The pushbutton is

connected directly to the ME-Engine ECS System.

4. For Manual ECR Control the ECR Telegraph supplied with the Engine Manoeuvring Sys-

tem is equipped with:

• Two 4 – 20mA set points connected directly to the ME-Engine ECS System

• Two Stop Switches connected directly to the ME-Engine ECS System

810.001.751-01 Lyngsø Marine A/S

Engine Manoeuvring System, EMS Platinum-ME Page 20 of 116

User Manual for MAN Diesel ME/ME-C Engines 2010.06.28

2.3 Local Operator Panel Functions

The ME-Engine Local Operator Panel (LOP), mounted locally at the ME-Engine is used for

fully electronic control from the Emergency Control Stand.

Figure 2.2: ME-Engine Local Operator Panel

810.001.751-01 Lyngsø Marine A/S

Engine Manoeuvring System, EMS Platinum-ME Page 21 of 116

User Manual for MAN Diesel ME/ME-C Engines 2010.06.28

The ME-Engine start/stop and setpoint signals are operated from the Emergency Telegraph

receiver mounted close to the LOP, with signals similar to the ECR Telegraph receiver:

• Two 4 – 20mA set points connected directly to the ME-Engine ECS System

• Two Stop Switches connected directly to the ME-Engine ECS System

The EMS Platinum-ME do however control the Sub-telegraph, the normal Control Transfer

and the Slowdown indications, and the EPS Platinum Safety System control the Shutdown

indications, but the ME-Engine ECS System will still be able to control the ME-Engine, even

in case of the EMS Platinum not functioning.

The following main functions are available on the ME-Engine Local Operator Panel:

• Analog instruments for indication of: Hydraulic Pressure

• Analog instruments for indication of: ME RPM

• Analog instruments for indication of: Starting Air Pressure

• EMS Subtelegraph [Finished With Engine], [Standby] and [At Sea] selection and indi-

cation

• EMS Control transfer [Bridge], [ECR] and [Local] control selection and indication

• [Forced take Control] selection and indication

• [Manual Slowdown Request] indication

• EMS [Slow Prewarning] and [Slow Down Active] indication, [Cancel Slow Down] and

[Reset Slow Down] operation and indication

• [Shutdown Prewarning] and [Shutdown] indication, [Cancel Shutdown] operation

and indication

• Start Conditions [Turning Gear Disengaged], [Start Air Distributor in Service], [Main

Start Valve in service], [Engine not ready] and [Start Blocked] indications

• EPS [Emergency stop] activation and indication

• [Aux Blowers running] and [Aux. Blowers Warning] indication

• [Fuel/Load Limitation Active] indication and [Increase Limitation] activation and indi-

cation

• [Start Failure] indication

• [Lamp Test] pushbutton

• [Air Run], [Slowturn] and [Auto] switch

• Shutdown Reset is done by putting the LOP Telegraph in stop position. The ME-Engine

ECS system will activate the reset signal to the Safety system by means of the LOP Tele-

graph setpoint and Stop switch.

810.001.751-01 Lyngsø Marine A/S

Engine Manoeuvring System, EMS Platinum-ME Page 22 of 116

User Manual for MAN Diesel ME/ME-C Engines 2010.06.28

2.4 Safety System for the Main Engine

The EMS Platinum-ME is normally delivered together with an independent EPS Platinum

(Engine Protection System) Safety System for Main Engine Emergency Stop, Overspeed

and Shutdown protection, which are interfaced to the EMS with hardware connections.

The system is based on a DZM 402 PLC with built-in functions for overspeed protection and

speed indication to instruments, and inputs for two speed pickups. The system is then ex-

tended with one, two or three BSM 2200 Input/Output Modules, with 16 DI (Digital Input)

channels and 12 DO (Digital Output) channels each for Shutdown inputs and Shutdown so-

lenoid valve outputs.

The Digital Input channels are all with cable supervision, i.e. the Shutdown sensor must be a

normally Open Contact (OC) contact, connected with an 8k2 Ohm resistor across the con-

tact, and a Closed Contact (CC) will then activate the Shutdown input.

The Digital Output channels are a solid-state relay output, with jumper selection of cable su-

pervision.

In the ECR, the EPS Platinum Safety System has its own EPS Panel, where it is possible to

see the relevant information for each Shutdown input channel, actual Main Engine RPM etc.

on the display, and it is also possible to make adjustments and cut-outs on the Shutdown in-

put channels.

Two keys with LED indication on the EPS Panel are used for Shutdown indication and Shut-

down Cancel function. At the Bridge, the corresponding functions are shown on two keys on

the EMS Panel.

The following functions are included in the EPS Platinum Safety System:

• Shutdown stop output for the ME-Engine ECU units (2 normally open outputs)

• Shutdown stop output for the ME-Engine Fuel Cut-off Valve (1 supervised output)

• Shutdown stop output for the ME-Engine CCU’s (n normally open outputs)

• Overspeed stop of the Main Engine (2 pickup inputs)

• Shutdown inputs (20 supervised inputs )

• Emergency stop of the Main Engine (5 supervised inputs)

• Alarm outputs to the alarm system (8 outputs)

• Tacho output for ME RPM to instruments (9 +/-10V instruments)

• Cancel and Reset inputs from EMS System, ME-Engine ECS and LOP (5 inputs)

• Local/Remote and EMS Control feedback (2 inputs)

For further information about the EPS Platinum Safety System, please refer to the EPS

Platinum System Description and User Manual.

810.001.751-01 Lyngsø Marine A/S

Engine Manoeuvring System, EMS Platinum-ME Page 23 of 116

User Manual for MAN Diesel ME/ME-C Engines 2010.06.28

2.5 Main Engine Speed Measurement

As standard the EMS Platinum-ME is only using the Tacho 1 signal received on the dual se-

rial interface from the ME-Engine ECS, and because it’s the ME-Engine ECS responsibility

of Start/Stop-Running detection and Repeated start as well as the Load Program, this tacho

signal is sufficient for the EMS.

Optional, the EMS Platinum-ME can use a Tacho Adapter Module (TAM401) to interface to

its own Tacho Pickups for Tacho 2.

The pickups are mounted close to the turning wheel on the main engine.

The TAM401 is connected to one of the CPU’s on the Serial Interface Board used for meas-

urement of the Main Engine speed.

2.6 Telegraph Transmitter and RPM Setpoint Control

The Bridge is equipped with a Telegraph Transmitter with built-in setpoint potentiometer on

the Bridge Centre Console, as the Bridge main operation station. As an option the Telegraph

Transmitter at the Bridge Centre can be interconnected by means of an Electric Shaft Sys-

tem to Bridge Wing Control at:

• Starboard Wing Panel

• Port Wing Panel

As standard the ECR is also equipped with a similar Telegraph Receiver and the LOP is

equipped with a watertight Telegraph Receiver.

Bridge Centre Telegraph Levers are equipped with potentiometer and stop switch with hard-

ware connection to the EMS System.

ECR and LOP Telegraph Levers are equipped with dual 4-20 mA Setpoint Transmitters and

Stop Switches connected directly to the ME-Engine ECS System.

The Bridge - and ECR Telegraph Levers are also used as engine telegraph system, when

running in manual ECR control.

The Bridge - and LOP Telegraph Levers are also used as engine telegraph system, when

running in local LOP control.

For alignment during control transfer and for printing on the manoeuvring order recorder

printer, the EMS receives the ECR and LOP Telegraph RPM Setpoint on the serial interface

from the ME-Engine ECS System.

2.6.1 Electrical Shaft System

Ships with Bridge Wing Control, can as an option be equipped with an electrical shaft system

interconnecting the Bridge Centre Telegraph with the Bridge Wing Control Telegraphs.

The electrical shaft system is an integrated part of the complete remote control system, but it

is based on components completely independent of the EMS DPU and all other items of the

overall system.

The Electric Shaft System is a so-called synchronising system, in which non-activated con-

trol levers are following the active control lever, chosen at random, i.e. when the Bridge Cen-

tre is master, then the two Bridge Wing levers automatically follows the master lever in the

Bridge Centre.

The system has been designed in such a way, that by means of a pushbutton switch, a cho-

sen control unit is activated as master.

810.001.751-01 Lyngsø Marine A/S

Engine Manoeuvring System, EMS Platinum-ME Page 24 of 116

User Manual for MAN Diesel ME/ME-C Engines 2010.06.28

2.6.1.1 Bridge Centre and Wings Control Transfer

Each Telegraph Transmitter on the Bridge’s Electrical Shaft System is equipped with three

indication lamps and one pushbutton for control transfer:

• Pushbutton selection of which position is the master control unit

• Lamp indication with dimmer for which one of the three control positions are the master

control unit

To change the control position between the three Control Units on the Bridge, press the

[ Take Over / ON Service ] pushbutton on the new master control position, and it will

change immediately, indicated with steady light in the [ Take Over / ON Service ]

lamp/pushbutton.

As the levers are already synchronised by the electrical shaft system, there are no need for

further alignments before pressing the [ Take Over / ON Service ] pushbutton.

2.6.2 Emergency Telegraph System

For backup communication of telegraph orders from the Bridge to ECR during ECR Control,

and/or to the engine side in the Engine Room during local control, the system can optionally

be extended with a separate Emergency Telegraph System, which is completely independ-

ent of the EMS Platinum-ME Engine Control System and the normal communication Tele-

graph Levers.

By means of a rotating switch or a pushbutton for each telegraph order, and lamps for each

telegraph order, the Communication Telegraph indicates the requested order.

On the Bridge, the switch is turned to the new order/the pushbutton for the new order is

pressed. The lamp for the new order will start flashing, and the buzzer on the Bridge and in

the ECR and/or a telegraph bell local on the engine side will start sounding.

To accept the new order, the switch on the receiver (ECR or local) must be turned to the po-

sition with the flashing lamp/the flashing lamp must be pressed, which will go into steady

light and the buzzer will stop.

By means of a pushbutton on each of the receivers; it is possible to select between the ECR

and the Local Communication Telegraph as the active receiver, i.e. the location from where

it is possible to acknowledge the telegraph order from the Bridge.

810.001.751-01 Lyngsø Marine A/S

Engine Manoeuvring System, EMS Platinum-ME Page 25 of 116

User Manual for MAN Diesel ME/ME-C Engines 2010.06.28

This page is intentionally left blank

810.001.751-01 Lyngsø Marine A/S

Engine Manoeuvring System, EMS Platinum-ME Page 26 of 116

User Manual for MAN Diesel ME/ME-C Engines 2010.06.28

3. EMS Platinum-ME Functional Description

3.1 Control Position Change-over

The electronically controlled ME-Engine can, when operated together with the EMS Plati-

num-ME for a Fixed Pitch Propeller (FPP), be operated in [BRIDGE CTRL.] directly from the

Bridge Panel, and Telegraph Levers with optional Bridge Wing Control operating in parallel

to the Bridge Centre. Please refer to section 2.6.1.1 for a description of the change over be-

tween Bridge Centre and the Bridge Wings.

When [BRIDGE CTRL.] is selected, the Main Engine's speed and direction is controlled by

the position of the Bridge Telegraph Lever. The DPU 2010 PLC located in the EMS Plati-

num-ME main cabinet convert the Bridge Telegraph Lever Setpoint into a speed setting sig-

nal which is sent to the ME-Engine ECS System via the serial line interface.

The ME-Engine ECS System then takes care of start and stop the engine and controlling the

engine speed by means of the build in Governor Functions.

Manual [E.C.R. CTRL.] from the ECR Telegraph Receiver is bypassing the EMS, i.e. the

start/stop and setpoint signals from the ECR Telegraph are hardwired directly from ECR to

the ME-Engine Control System.

[LOCAL CTRL.] from the Local Operator Panel (LOP) and Emergency Telegraph receiver is

bypassing the EMS, i.e. the start/stop and setpoint signals from the LOP and Telegraph are

hardwired directly from the LOP to the ME-Engine Control System.

The EMS is however responsible for the control transfer between all three control stations,

i.e. between [BRIDGE CTRL.], [E.C.R. CTRL] and [LOCAL CTRL.], and the active control

station is then informed to the ME-Engine ECS-system via the serial interface line between

the EMS and ECS. Please refer to section 4.0 showing the layout of the EMS operator panel.

For this purpose, the Local Operator Panel includes lamps and pushbuttons for [Bridge],

[E.C.R.] and [Local] Control Position indications similar to the EMS panels, but instead of

the serial interface to the EMS panels, they are hardwired directly to the EMS in order to be

able to make a request/acknowledge control transfer to/from Local control also. Please refer

to section 2.3 showing the layout of the local operator panel (LOP) for the ME-engine.

Beside the serial interface to the ME-Engine ECS system, the EMS also has hardware out-

puts to inform the Safety System about the active control station. In case the slowdown sys-

tem is not integrated in the EMS, this system must also be informed about the active control

station.

If there is no operator available on the old control station (Bridge or ECR) to acknowledge

the EMS request for Local control or if the EMS system is no longer operational, the ECS is

able to make a forced control transfer from EMS control to ECS control on the local control

stand by means of a [Forced Take Control] pushbutton on the LOP.

As the EMS Platinum-ME for FPP always has ECS control from ECR, the ECS will also be

able to make a forced control transfer from EMS control to ECS control in the ECR.

810.001.751-01 Lyngsø Marine A/S

Engine Manoeuvring System, EMS Platinum-ME Page 27 of 116

User Manual for MAN Diesel ME/ME-C Engines 2010.06.28

3.1.1 ECS Control Station Priority

The ME-Engine ECS control system has a priority of the control stations where the control

station closest to the engine has the highest priority:

1. Local ECS Control, highest priority

2. Manual ECR ECS Control

3. EMS Bridge Control, lowest priority

If the ECS loose the signal for the active control station, it will release an alarm and react as

follows:

• In case of lost signals, the last active control station will apply

• In case of disagreement between two or more signals, the control station will block so that

the last valid control station applies.

3.1.2 Operation of Control Station Transfer

The active control station can be transferred between the three control stations, Bridge, ECR

and Local Control on request from either the active control station, e.g. the Bridge Panel(s),

or on request from the new control station, e.g. the ECR or LOP panel without a previous re-

quest from the Bridge.

This means that the control station making the request for transfer does not have to be the

present control station.

The control station (Bridge, ECR or Local Control) requesting the new control station (ECR,

Bridge or Local Control), must first press the corresponding EMS Panel key:

• [BRIDGE CTRL.] if transfer from Local or ECR - to Bridge Control is requested

• [E.C.R. CTRL.] if transfer from Local or Bridge - to ECR Control is requested

• [LOCAL CTRL.] if transfer from ECR or Bridge - to Local Control is requested

As soon as the request for the control transfer is initiated from the Bridge, ECR or LOP, the

buzzer in the Panels involved will start beeping, and the LED indication in the key for the new

control station will start flashing, both on the Bridge Panel and in the corresponding LED in-

dication on the ECR Panel and in the LOP. The EMS panel buzzer sound for control transfer

is making two short beeps followed by a 5 sec pause.

If there is no buzzer available in the Local Operator Panel, the EMS has an optional output

for activation of the Telegraph Bells in the engine room, which will be activated during control

transfer to/from local control.

The LED indication for the present control station will remain in steady light, until all condi-

tions for the new control station are fulfilled, upon which it will be switched off.

When the control transfer is acknowledged by pressing the flashing key on the EMS Panel at

the acknowledge location:

• [BRIDGE CTRL.] if Local or ECR - to Bridge Control Transfer is acknowledged

• [E.C.R. CTRL.] if Local or Bridge - to ECR Control Transfer is acknowledged

• [LOCAL CTRL.] if ECR or Bridge - to Local Control Transfer is acknowledged

The control station will be changed, if the Setpoint Levers are aligned.

The flashing LED indication for the new control station will stop flashing and go into steady

light. The LED indication for the previous control station is switched off, and the buzzers will

stop beeping.

If the Setpoint Levers are not aligned, control transfer will not take place. The LED indication

for the new control station will continue flashing and the two-beep sound will continue until

810.001.751-01 Lyngsø Marine A/S

Engine Manoeuvring System, EMS Platinum-ME Page 28 of 116

User Manual for MAN Diesel ME/ME-C Engines 2010.06.28

the control transfer request is either cancelled, or the Setpoint Levers have been aligned.

If the Bridge and ECR setpoint levers are not aligned, a changeover display will show up on

the Bridge and ECR Panel with alignment barographs for the two set points, making it easier

to align the set points.

Note: the changeover display will only show up if the EMS Platinum-ME Basic mode over-

view display is active. If the Basic mode overview display is not active press the [ ESC ] key

several times until the outermost display level is reached.

If the request for control transfer is not acknowledged on the acknowledge location, the [Re-

quest] key or the old [Control Location] key at the request location can be pushed again to

cancel the control transfer request. If the control station has not changed (Setpoint Levers

not aligned), the flashing is stopped and the buzzer is silenced without further conse-

quences.

Transfer of control will not take place before the Setpoint Levers are aligned and acknowl-

edge is received from the acknowledge location.

3.1.2.1 From Bridge Control to ECR Control

The LED indication for Control station at transfer from Bridge Control to ECR Control is indi-

cating in the following way:

• [BRIDGE CTRL.] LED indication, i.e. the old control station LED indication on the Bridge,

ECR Panel and LOP are in steady light until transfer has taken place.

• [E.C.R. CTRL.] LED indication, i.e. the new control station LED indication on the Bridge,

ECR Panel and LOP are flashing, if the Setpoint Levers are aligned, until acknowledge

has taken place or the request is cancelled.

If the Setpoint Levers are not aligned, the [E.C.R. CTRL.] LED indication will continue flash-

ing until Setpoint Levers are aligned or the request is cancelled. During this alignment pro-

cedure, the EMS setpoint display will automatically show three barographs, with digital read-

ings of the telegraph lever set points, until the levers are aligned.

3.1.2.2 From Bridge Control to Local Control

The LED indication for Control station at transfer from Bridge Control to Local Control on the

engine is indicating in the following way:

• [BRIDGE CTRL.] LED indication, i.e. the old control station LED indication on the Bridge,

ECR Panel and LOP are in steady light until transfer has taken place.

• [LOCAL CTRL.] LED indication, i.e. the new control station LED indication on the Bridge,

ECR Panel and LOP are flashing, if the Setpoint Levers are aligned, until acknowledge

has taken place or the request is cancelled.

If the Setpoint Levers are not aligned, the [LOCAL CTRL.] LED indication will continue flash-

ing until Setpoint Levers are aligned or the request is cancelled. During this alignment pro-

cedure, the EMS setpoint display will automatically show three barographs, with digital read-

ings of the telegraph lever set points, until the levers are aligned.

810.001.751-01 Lyngsø Marine A/S

Engine Manoeuvring System, EMS Platinum-ME Page 29 of 116

User Manual for MAN Diesel ME/ME-C Engines 2010.06.28

3.1.2.3 From ECR Control to Bridge Control