Professional Documents

Culture Documents

Alquilacion Heptano Con Benceno y Preparacion de Montmorillonita

Uploaded by

Luis MartinezCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Alquilacion Heptano Con Benceno y Preparacion de Montmorillonita

Uploaded by

Luis MartinezCopyright:

Available Formats

Journal of the Japan Petroleum Institute, 63, (5), 289-296 (2020) 289

[Regular Paper]

Mechanistic Investigations of Liquid-phase Direct Alkylation of Benzene with

n-Heptane Using Proton-exchanged Montmorillonite Catalysts

Moe TAKABATAKE†1), Masayuki NAMBO†1), Yuichi MANAKA†1),†2), and Ken MOTOKURA†1)*,†3)

†1)

Dept. of Chemical Science and Engineering, School of Materials and Chemical Technology, Tokyo Institute of Technology,

4259 Nagatsuda, Midori-ku, Yokohama 226-8502, JAPAN

†2)

Renewable Energy Research Center, National Institute of Advanced Industrial Science and Technology (AIST),

2-2-9 Machiikedai, Koriyama, Fukushima 963-0298, JAPAN

†3)

PRESTO, Japan Science and Technology Agency (JST), 4-1-8 Hon-machi, Kawaguchi, Saitama 332-0012, JAPAN

(Received March 30, 2020)

The direct alkylation of benzene with n-heptane was investigated using noble-metal-free montmorillonite as a

solid acid catalyst. It was found that the catalytic activity of proton-exchanged montmorillonite increased after

pretreatments such as heating and ultrasonic irradiation. Aluminum-exchanged montmorillonite was also found

to be a good catalyst. Moreover, during the reaction using proton-exchanged montmorillonite, the product selec-

tivity depended on the interlayer distance of the catalyst. Detailed time-course analysis of the selectivity of the

alkylation product revealed that, in the case of the catalysts with smaller interlayer distances, the bimolecular

reaction occurred preferentially at the surface, resulting in higher selectivity with respect to the target C7 alkylated

products (Ph-C7). On the other hand, the monomolecular cracking of heptane in the interlayer spaces resulted in

a stable t-butyl cation, yielding t-butylbenzene. Monomolecular cracking also occurred when H-ZSM-5 was

used as the catalyst, and the main product was isopropylbenzene.

Keywords

Montmorillonite, Solid acid catalyst, Alkylation, Benzene, Heptane

1. Introduction or higher using Pt and Pd/H-ZSM-5 has been report-

ed12)∼18). There have also been reports on its alkyl-

The direct conversion of alkanes into raw materials ation with alkanes with relatively longer carbon chains,

for chemical products is important as it can result in such as hexane, using Pt/H-ZSM-5 and PtGa/

lower costs and fewer synthesis steps as compared with H-ZSM-519),20). In addition, a few noble-metal-free

the case for conventional processes, which use haloge- catalysts such as H-ZSM-5 have also been reported.

nated alkanes 1)∼3). On the other hand, alkanes are However, the selectivity of these catalysts with respect

composed only of C_C and C_H single bonds and there- to alkylated benzenes is low 19),20). Only HF-SbF 5,

fore have low reactivity. Hence, they are mostly used which is a homogeneous super strong acid, yields a

as fuels after industrial cracking, isomerization, and product with high selectivity at room temperature21).

steam reforming4). Many researchers have been work- On the other hand, there has been no report on the

ing on catalysts suitable for the direct conversion of synthesis of products with high selectivity using a

alkanes5)∼11). For example, selective alkane conver- noble-metal-free heterogeneous catalyst.

sion reactions, such as partial oxidation to alcohol or Montmorillonite is a cation-exchangeable clay com-

aldehydes6)∼8) and dehydrogenation to alkenes9)∼11), pound with a layered structure. The ion-exchange

have been reported. In this study, we focused on the ability of its interlayer spaces allows for the design and

direct alkylation of benzene using alkanes. The synthesis of several types of Brønsted and Lewis acid

alkylation of benzene with ethane or propane at 300 °C catalysts22)∼28). For example, Onaka and coworkers

reported Sn-exchanged montmorillonite catalysts for

liquid-phase organic synthesis through nucleophilic ad-

This paper was presented at the Yamagata Convention of JPI (49th dition reactions29)∼32). Sun and coworkers developed

Petroleum-Petrochemical Symposium of Jpn. Petrol. Inst.), Yamagata, Nb_montmorillonite for the synthesis of 5-hydroxy-

Japan, Oct. 31-Nov. 1, 2019.

DOI: doi.org/10.1627/jpi.63.289

methylfurfural from glucose33). Moreover, proton- and

*

To whom correspondence should be addressed. aluminum-exchanged montmorillonites have been

*

E-mail: motokura.k.ab@m.titech.ac.jp employed as solid acid catalysts for many carbon_carbon/

J. Jpn. Petrol. Inst., Vol. 63, No. 5, 2020

290

heteroatom bond-forming reactions such as the carbo- ture of the synthesized Na-mont (4.2 g), AlCl3・6H2O

silylation of olefins34)∼36). In addition, we had reported (6.5 mmol, 1.6 g), and 200 mL of water. The mixture

previously that aluminum-exchanged montmorillonite was stirred at 50 °C for 24 h, and the obtained slurry

(Al-mont) shows good catalytic performance during the was filtered and washed with 1 L of distilled water to

direct alkylation of benzene with heptane for the forma- ensure the removal of the chlorine present. This was

tion of alkylated products with a carbon chain of 7 car- followed by drying at 110 °C in air to afford Al-mont as

bon atoms (Ph-C7) at 150 °C37). Proton-exchanged a while-gray powder.

montmorillonite (H-mont) has also been found to be a 2. 4. Catalytic Reaction

good catalyst for the selective alkylation of benzene37). The reaction between n-heptane and benzene was

In this study, the relationship between the interlayer performed as follows. The catalyst (0.10 g), n-heptane

distance and product selectivity of montmorillonite as a (6.8 mmol), and benzene (1.2 mmol) were placed in a

catalyst was elucidated using H-mont catalysts that pressure tube with volume of 15 mL. The resulting

exhibited different interlayer distances through pretreat- mixture was then kept under stirring vigorously using a

ments. magnetic stir bar at 150 °C. After the completion of

the reaction, the catalyst was separated by filtration, and

2. Experimental quantitative and qualitative analyses were performed on

the products using GC-FID and GC-MS. During the

2. 1. General Method reaction, the pressure inside the reactor was approxi-

Shimadzu ICPS-8100 was used to perform inductively mately 4.5×102 kPa.

coupled plasma (ICP) emission spectroscopy for quan-

titative elemental analysis. The powder X-ray diffrac- 3. Results and Discussion

tion (XRD) patterns of the various catalysts were

recorded at room temperature using Rigaku Ultima IV 3. 1. Characterization of Prepared Montmorillonite

system with Cu-Kα radiation source. Analytical gas Catalysts

chromatography with flame-ionization detection (GC- The results of the elemental analysis indicated that

FID) was performed using Shimadzu GC-2025 with sodium was completely absent in H-mont and Al-mont

DB-1 columns. Further, analytical GC-mass spec- (Na: < 0.01 mmol g–1) after the ion-exchange treatment

trometry (MS) was performed with Shimadzu GC-2020 of Na-mont (Na: 0.86 mmol g–1). The amount of Al in

Plus system with QP2010SE and DB-1 columns. Al-mont was increased to 4.89 mmol g –1 from

2. 2. Material 4.40 mmol g–1 of aluminosilicate layer of Na-mont after

Unless otherwise noted, all materials were purchased the ion exchange. These indicate that almost all ion

from Kanto Chemical Co., Inc., FUJIFILM Wako Pure exchange sites of Al-mont are exchanged with Al cat-

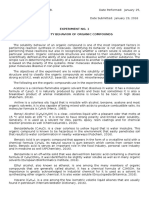

Chemical Corp., Tokyo Chemical Industry Co., Ltd. ion. XRD patterns confirmed that the layered struc-

and Sigma-Aldrich Co. LLC. Sodium-exchanged ture of montmorillonite was maintained after the ion

montmorillonite (Na-mont; Na0.33(OH)4Si8(Al3.34Mg0.66 exchange (Fig. 1). The shape of the XRD pattern of

Fe0.19)O20) was purchased from Kunimine Industry Co., H-mont as well as the relative intensities of the peaks

Ltd., Japan as Kunipia F. Finally, HSZ-820 (Si/Al2= present (b) did not change significantly after the ultra-

23.2, Tosoh Corp.) was used as H-ZSM-5. sonic irradiation process ((c) and (d)) or the heat treat-

2. 3. Catalyst Preparation ment (e), suggesting that the structural characteristics of

The cation-exchanged montmorillonite catalysts were H-mont were maintained after these treatments. On

prepared by the ion-exchange method. Proton- the other hand, the position of the d001 peak of H-mont

exchanged montmorillonite (H-mont) was prepared via (2θ=6-8°) shifted slightly after the ultrasonic irradia-

the cation-exchange method from Na-mont (3.0 g)

using 200 mL of aqueous HCl (1.1 wt%) solution.

The mixture was stirred at 90 °C for 24 h, and the

obtained slurry was filtered and washed with 1 L of dis-

tilled water to ensure the removal of chlorine. This

was followed by drying at 110 °C in air to obtain

H-mont. During the preparation of H-mont, the

obtained slurry containing H-mont and the aqueous HCl

solution was subjected to ultrasonic irradiation (38 kHz)

at room temperature for 0.5 h or 1 h, affording H-mont

(ui-0.5) and H-mont(ui-1.0), respectively. The H-mont

sample was heated at 150 °C for 1 h in an Ar atmo- Fig. 1●X R D P a t t e r n s o f ( a ) N a - m o n t , ( b ) H - m o n t , ( c )

sphere to obtain H-mont(150). Aluminum-exchanged H-mont(ui-0.5), (d) H-mon(ui-1.0), (e) H-mont(150), and (f)

montmorillonite (Al-mont) was prepared from a mix- Al-mont

J. Jpn. Petrol. Inst., Vol. 63, No. 5, 2020

291

tion process as well as the heat treatment. The inter- the ultrasonic irradiation process and heat treatment,

layer distances of the montmorillonite catalysts were and the Ph-C7 selectivity was maintained. The ben-

calculated by subtracting the c value of the silicate sheet zene conversion increased with the ultrasonic irradia-

(9.6 Å) from the d 001 value as determined from the tion time in the case of H-mont(ui), and the Ph-C7

XRD pattern (Table 1). The interlayer distance of selectivity was ca. 70 %. H-mont(150) exhibited a

H-mont (5.0 Å) decreased after the treatment at 150 °C benzene conversion of 0.91 %, and the Ph-C7 selectivity

(H-mont(150): 2.5 Å) and the ultrasonic irradiation pro- was 56 %. The benzene conversion improves by the

cess (H-mont(ui): 3.0-3.9 Å). In the XRD pattern, as heat treatment and ultrasonic irradiation of the parent

the d001 peak shifts, the d001 peak intensity also weakens. H-mont layers decreases. This is probably because the

In the case of H-mont(ui-1.0), d 001 peak shape was decrease of adsorbed water on the active site of the cat-

slightly changed with small amount of impurity peaks alyst. Similar phenomena were observed in Friedel-

around 15-18 degree. It is considered that a part of the Crafts alkylation with a styrene derivative 38). With

layered structure of H-mont was decomposed by ultra- respect to the other alkylation products, the t-butyl-

sonic irradiation, resulting the decrease of its interlayer benzene (Ph-t-C4) selectivity was 5 % in the case of

distance. The interlayer distance of Al-mont (6.0 Å) H-mont, while the main Ph-C4 product was 2-phenyl-

was slightly higher than those of the H-mont samples, butane in the case of H-mont(150). As mentioned in

suggesting the presence of hydrated Al species within our previous study37), Al-mont showed a high benzene

the montmorillonite interlayer in the case of the former. conversion (1.82 %) with a good selectivity of Ph-C7.

3. 2. Alkylation of Benzene with n-Heptane over When the reaction was performed using H-ZSM-5, the

Various Acid Catalysts selectivities for the Ph-C7 and Ph-C3 products were

The performances of the various catalysts were com- 29 % and 64 %, respectively. The higher acid strength

pared at 150 °C for 16 h using n-heptane and benzene of Al-mont and H-ZSM-5 compared to H-mont35),39),40)

(Table 2). While H-mont showed catalytic activity might be induced the higher benzene conversion of Al-

for the alkylation reaction, the reaction did not proceed mont and H-ZSM-5 because of the difficulties of alkane

when Na-mont was used, indicating that the acid sites activation. Regarding the byproduct, hydrogen was

generated by the ion-exchange process are involved in detected in the gas phase after the reaction. In addi-

the reaction. The benzene conversion increased after tion, when H-mont and Al-mont were reused, we have

confirmed the progress of the reaction although the cat-

Table 1●Interlayer Distance of Cation-exchanged Montmorillonite alytic activity was slightly reduced (H-mont: 0.24 %

Samples conv., 58 % selectivity to Ph-C7; Al-mont: 1.48 %

conv., 83 % selectivity to Ph-C7).

Sample 2θ [degree] Interlayer distance [Å]a)

The selectivities of the main products (Ph-C7, Ph-C3,

H-mont 6.0 5.0 and Ph-t-C4) were plotted against the benzene conver-

H-mont(ui-0.5) 6.5 3.9

sion to elucidate the reaction paths of the catalysts

H-mont(ui-1.0) 7.0 3.0

H-mont(150) 7.3 2.5 (Fig. 2). In the case of H-mont, the selectivity of Ph-t-

Al-mont 5.7 6.0 C4 was high initially. Further, the selectivity of the

Na-mont 7.2 2.7 target Ph-C7 product improved as the reaction pro-

a) Determined by subtracting c value of silicate sheet (9.6 Å) from gressed (Fig. 2(a)). The formation of Ph-t-C4 was

d001 value determined from XRD spectrum shown in Fig. 1. also detected initially in the cases of H-mont(ui-0.5)

Table 2●Solid-acid-catalyzed Alkylation of Benzene with n-Heptanea)

Catalyst (0.1 g) C7

+ + H2

150 °C, 16 h

6.8 mmol 1.2 mmol

Benzene conv. Selectivity [%]

Catalyst

[%] Ph-C7 Ph-C2 Ph-C3 Ph-t-C4 Other Ph-C4 Othersb)

H-mont 0.38 59 7 4 5 2 23

H-mont(ui-0.5) 0.75 71 8 4 1 1 15

H-mont(ui-1.0) 0.87 69 6 4 1 2 18

H-mont(150) 0.91 56 3 8 1 21 11

Al-mont 1.82 58 21 5 <1 2 14

H-ZSM-5 1.74 29 1 64 1 3 2

Na-mont 0.00 - - - - - -

a) Reaction conditions: n-heptane (6.8 mmol), benzene (1.2 mmol), 150 °C, 16 h.

b) Other alkylbenzenes and diphenylmethane were mainly formed as other products. Selectivity to coke formation was less than 1 %.

J. Jpn. Petrol. Inst., Vol. 63, No. 5, 2020

292

Reaction conditions: n-heptane (6.8 mmol), benzene (1.2 mmol), 150 °C.

Fig. 2●Product Selectivities vs. Benzene Conversion for Alkylation Reaction of n-Heptane over (a) H-mont, (b) H-mont(ui-0.5), (c)

H-mont(ui-1.0), (d) H-mont(150), (e) Al-mont, and (f) H-ZSM-5

and H-mont(ui-1.0) (Figs. 2(b) and 2(c)). However, decreased with an increase in the Ph-C7 selectivity, as

the selectivity of Ph-t-C4 was much lower than that of the reaction progressed. On the other hand, although

the parent, H-mont. In the case of H-mont(150), the Al-mont exhibited the same interlayer distance as

target, Ph-C7, was obtained with high selectivity right H-mont before the reaction, the target Ph-C7 product

from the start of the reaction (Fig. 2(d)). This phe- was obtained with high selectivity right from the begin-

nomenon was observed in the case of Al-mont as well, ning (Fig. 2(e)). This suggests that its selectivity did

which also showed high Ph-C7 selectivity (Fig. 2(e)). not depend on the interlayer distance of Al-mont, in

The H-ZSM-5 catalyst primarily afforded Ph-C3 and contrast to the case for H-mont. During the reaction,

Ph-C7, and the selectivities of these products during the the interlayer distance of Al-mont and H-mont(ui-0.5)

reaction maintained (Fig. 2(f)), suggesting that the cat- decreased to 2.6 Å and 3.2 Å, respectively, so it seems

alytic properties of H-ZSM-5 remained stable over the that the interlayer distance generally decreases after the

course of the reaction. reaction.

The sharp changes in the product selectivity in the In order to investigate the initial and secondary reac-

case of H-mont can be explained by the changes in the tions based on the products obtained, the product selec-

catalyst structure during the reaction. The initial Ph-t- tivities for a benzene conversion of approximately 1 %

C4 selectivity was correlated with the interlayer dis- were evaluated. Table 3 shows the isomer distribu-

tance of H-mont: the selectivity decreased with a de- tion for the Ph-C7 product for the different catalysts.

crease in the order of magnitude of the interlayer dis- Structures of main Ph-C7 isomers are shown in Fig. 3.

tance of H-mont, as shown in Table 1. For example, When montmorillonite was used as the catalyst, selec-

the Ph-t-C4 selectivity in the case of H-mont (interlayer tivity was observed in each isomer. On the other hand,

distance: 5.0 Å) for a conversion of 0.04 % was 37 % when H-ZSM-5 was used, the selectivity for 2-phenyl-

while for H-mont(ui-1.0; interlayer distance: 3.0 Å), it heptane was high, while 3-phenylheptane and 4-phenyl-

was 19 % for a conversion of 0.05 %. To investigate heptane were not detected. This was probably because

the structural changes induced in H-mont during the re- of the molecular sieving effect of the micropores of

action, the H-mont sample was recovered after each H-ZSM-5. Previous studies on the reaction between

conversion process and subjected to XRD measure- hexane and benzene over H-ZSM-5 have reported that

ment. The benzene conversion and the corresponding 1-phenylheptane is produced during the reaction19),20).

interlayer distances were as follows: 0.04 %, 2.4 Å; However, in the case of our reaction system investigated

0.07 %, 1.3 Å; and 0.38 %, 0.9 Å. From these results, in the present study, the formation of 1-phenylheptane

it can be surmised that the interlayer distance of H-mont was not confirmed. As shown in Fig. 4, the Ph-C7

J. Jpn. Petrol. Inst., Vol. 63, No. 5, 2020

293

Table 3●Distribution of Ph-C7 Isomer during Reaction of n-Heptane and Benzene for Benzene Conversion of 1 %

Catalyst (0.1 g) C7

+ + H2

150 °C, 16 h

6.8 mmol 1.2 mmol

Benzene conv. Ph-C7 selectivity Ph-C7 isomer distribution [%]

Catalyst

[%] [%] Ph-C7(2) Ph-C7(3) Ph-C7(4) Ph-C7(others)

b)

H-mont 1.16 59 29 22 13 36

H-mont(ui-0.5) 0.75 71 31 24 11 34

H-mont(ui-1.0) 0.87 69 32 26 12 30

H-mont(150) 0.91 55 31 16 7 46

H-ZSM-5c) 0.77 32 42 0 0 58d)

a) Reaction conditions: n-heptane (6.8 mmol), benzene (1.2 mmol), 150 °C. b) 64 h. c) 6 h. d) Other Ph-C7 products primarily

included (dimethylcyclopentyl)benzene.

(Ph-C2) and 2-phenylbutane increased after an increase

in the reaction time. These results indicate that the

main reason for the decrease in the Ph-C7 selectivity

for benzene conversion higher than 0.5 % was the sec-

ondary cracking reaction of Ph-C7. When the cata-

lysts that were not preheated before the reaction, namely,

Fig. 3●Structures of Ph-C7 Products

H-mont, H-mont(0.5), H-mont(1.0), and Al-mont, were

used, the selectivity of ethylbenzene increased as the

reaction progressed (Fig. 5(A), data for H-mont). On

the other hand, when H-mont(150), which was preheated

before the reaction, was used, the selectivity of 2-

phenylbutane (Ph-C4(2)) increased (Fig. 5(B)).

However, the reason for the observed differences in the

selectivities of the byproducts is not clear.

3. 3. Proposed Alkylation Reaction Mechanism

The isomer distribution of the Ph-C7 product

(Table 3) implies that a carbocation mechanism is

involved. The Ph-C7 product could be obtained by a

bimolecular reaction between the C7 alkyl cation and

benzene, while Ph-t-C4 and Ph-C3, the initial products

in the cases of H-mont and H-ZSM-5 (Figs. 2(a) and

2(f)), respectively, were formed after the mono-

molecular cracking of heptane. When the interlayer

distance is small (ca. 2-3 Å), owing to the progress of

the mont-catalyzed reaction, a heat-based drying pre-

treatment (H-mont(150)), or ultrasonic irradiation

(H-mont(ui)), the reaction primarily occurs at the edge

and/or surface of the montmorillonite particles because

both n-heptane and benzene cannot penetrate through

the small interlayer space. As a result, the bimolecular

reaction proceeds primarily because of the less-sterically

Fig. 4●Distribution of Ph-C7 Isomers vs. Benzene Conversion in hindered environment to selectively yield the Ph-C7

Case of H-mont(150) products ((A) in Scheme 1). In contrast, in the case

of the parent, that is, H-mont, the interlayer distance is

relatively large (5.0 Å), and the monomolecular cleav-

isomer distribution did not change significantly as the age of heptane occurs in the interlayers. This interlayer

reaction progressed. These results indicate that the re- distance is close to the molecular size of benzene, sug-

action proceeded because of carbocation and that the gesting the slow diffusion of benzene into the H-mont

initially generated Ph-C7 product did not undergo isom- interlayer. The generated stable tertiary carbocation

erization. subsequently reacts with benzene to produce Ph-t-C4

As shown in Fig. 5, the selectivities of ethylbenzene ((B) in Scheme 1). This hypothesis is supported by

J. Jpn. Petrol. Inst., Vol. 63, No. 5, 2020

294

Fig. 5●Selectivities of Ph-C7 (●), Ethylbenzene (Ph-C2) (▲), and 2-Phenylbutane (Ph-C4(2)) (■) vs. Benzene

Conversion: (a) H-mont and (b) H-mont(150)

Scheme 1●Proposed Alkylation Reaction Mechanism in Case of (A) Mont Surface, (B) H-mont with Large

Interlayer Distance, and (C) H-ZSM-5

the fact that the order of magnitude of the Ph-t-C4 selec- observed. The high selectivity of H-ZSM-5 toward

tivity in the initial stage of the reaction corresponds to Ph-C3 can be ascribed to the molecular sieving effect

the respective interlayer distances of H-mont, H-mont ((C) in Scheme 1). As shown in Table 3, 3-phenyl-

(ui-0.5), H-mont(ui-1.0), and H-mont(150) (Table 1 heptane and 4-phenylheptane were not formed during

and Figs. 2(a)-2(d)). The yield of Ph-t-C4 peaked at the H-ZSM-5-catalyzed reaction. This result also sup-

6 h and then decreased with the progress of the reac- ports the conclusion that a smaller pore size preferen-

tion. Olah and coworkers have reported that alkyl- tially affords small-molecular-diameter products and

benzene is also protonated by an acid catalyst and that that Ph-C3 is the other initial product formed along

the corresponding carbocation is formed, followed by with Ph-t-C4 in the case of H-ZSM-537).

hydride transfer from the other alkanes to the carboca- In the case of Al-mont, the target Ph-C7 product was

tion, yielding another alkylbenzene21). A few alkyl- obtained with high selectivity right from the beginning,

benzene products may be formed from Ph-t-C4 if the even though Al-mont has the same interlayer distance

reaction time is high. In the case of H-ZSM-5, the as H-mont. It is thought that, in the case of Al-mont,

monomolecular cracking of n-heptane was also the degree of steric hindrance and hydrophilicity of the

J. Jpn. Petrol. Inst., Vol. 63, No. 5, 2020

295

4. Conclusion

Proton-exchanged montmorillonite (H-mont) as cata-

lyst was prepared by an ion-exchange procedure.

After the H-mont catalyst had been subjected to heat-

based drying and ultrasonic irradiation, the activity and

selectivity of the Ph-C7 product during the reaction

between n-heptane and benzene increased. Detailed

time-course analysis of the H-mont-catalyzed alkylation

reaction helped to elucidate the reaction pathways,

which are affected by the mont interlayer spacing. It

was found that the bimolecular reaction occurs prefer-

entially on the catalyst surface when the interlayer

spacing is very small. On the other hand, monomolec-

ular cracking occurs to yield a tertiary cation when the

spacing is large. Aluminum-exchanged montmorillon-

ite (Al-mont) and H-ZSM-5 also showed catalytic

Fig. 6●Proposed Reaction Mechanism in Case of Al-mont activity during the direct alkylation of benzene to yield

Ph-C7 and Ph-C3, respectively. Thus, direct,

noble-metal-free mont-catalyzed alkylation would allow

interlayer are increased because of the presence of Al3+ for the efficient use of alkanes.

cations, which prevents the insertion of the substrate

into the interlayers. The almost complete ion ex- Acknowledgment

change ratio to Al from Na also support this hypothesis. This work was supported by PRESTO Grant (No.

Therefore, the bimolecular reaction occurs preferentially 11328) from the Japan Science and Technology Agency

at the surfaces or edges of the Al-mont particles, as (JST).

shown in Fig. 6.

When a mont-based catalyst was used, the cracking References

reaction of Ph-C7 resulted in a benzene conversion of

0.5 %, and ethylbenzene and 2-phenylbutane are formed 1) Labinger, J. A., Bercaw, J. E., Nature, 417, 507 (2002).

2) Tang, X., Jia, X., Huang, Z., Chem. Sci., 9, 288 (2018).

as the by-products (Fig. 5). On the other hand, when 3) Hartwig, J. F., J. Am. Chem. Soc., 138, 2 (2016).

ZSM-5 was used, the selectivity of the product did not 4) Weissermel, K., Arpel, H.-J., “Industrial Organic Chemistry,”

change even when the reaction time was prolonged till Wiley-VCH, Weinheim, Germany (2003), p. 59.

the benzene conversion was more than 1 %. This indi- 5) Tang, X., Jia, X., Huang, Z., J. Am. Chem. Soc., 140, 4157

cates that almost no secondary reaction involving the (2018).

6) Otsuka, K., Takahashi, R., Amakawa, K., Yamanaka, I., Catal.

product had occurred. This is presumably because the Today, 45, 23 (1998).

product barely diffused into the pores of the zeolite, 7) Kerler, B., Martin, A., Catal. Today, 61, 9 (2000).

because of which the secondary reaction was sup- 8) Forde, M. M., Armstrong, R. D., McVicker, R., Wells, P. P.,

pressed. Dimitratos, N., He, Q., Lu, L., Jenkins, R. L., Hammond, C.,

H-mont has a lower acid strength than those of Al- Lopez-Sanchez, J. A., Kielyc, C. J., Hutchingsa, G. J., Chem.

Sci., 5, 3603 (2014).

mont and H-ZSM-535),37)∼39), therefore, the bimolecular 9) Nakagawa, K., Okamura, M., Ikenaga, N., Suzuki, T.,

reaction affording Ph-C7 preferentially occurs com- Kobayashi, T., Chem. Commun., 1025 (1998).

pared to monomolecular cracking of n-heptane. On 10) Zangeneh, F. T., Sahebdelfar, S., Bahmani, M., Appl. Catal. A:

the other hand, carbocation from the desired product, Gen., 221, 397 (2001).

Ph-C7, is more stable than that from simple alkane, re- 11) Matveyeva, A. N., Wärnå, J., Pakhomov, N. A., Murzin, D. Yu.,

Chem. Eng. J., 381, 122741 (2020).

sulting the cracking reaction of Ph-C7 to ethylbenzene 12) Kato, S., Nakagawa, K., Ikenaga, N., Suzuki, T., Catal. Lett.,

and 2-phenylbutane at more than 1 % conversion of 73, 175 (2001).

benzene. Although Al-mont and H-ZSM-5 have com- 13) Alotaibi, A., Bayahia, H., Kozhevnikova, E. F., Kozhevnikov, I.

parable acid strengths35),37)∼39), the product selectivities V., ACS Catal., 5, 5512 (2015).

of these two catalysts were significantly different. 14) Sealy, S., Traa, Y., Appl. Catal. A: Gen., 284, 273 (2005).

15) Smirnov, A. V., Mazin, E. V., Yuschenko, V. V., Knyazeva, E. E.,

This fact strongly supports that the structure of the cata- Nesterenko, S. N., Ivanova, I. I., Galperin, L., Jensen, R.,

lyst, not the acid strength, determines the product selec- Bradley, S., J. Catal., 194, 266 (2000).

tivity. 16) Lukyanov, D. B., Vazhnova, T., J. Mol. Catal. A Chem., 279,

128 (2008).

17) Bressel, A., Donauer, T., Sealy, S., Traa, Y., Microporous

Mesoporous Mater., 109, 278 (2008).

J. Jpn. Petrol. Inst., Vol. 63, No. 5, 2020

296

18) Ordomskiy, V. V., Rodionova, L. I., Ivanova, I. I., Luck, F., 135 (2011).

ChemCatChem, 4, 681 (2012). 30) Wang, J., Masui, Y., Hattori, T., Onaka, M., Tetrahedron Lett.,

19) Danilina, N., Payrer, E. L., van Bokhoven, J. A., Chem. Commun., 53, 1978 (2012).

46, 1509 (2010). 31) Masui, Y., Wang, J., Teramura, K., Kogure, T., Tanaka, T.,

20) Danilina, N., Payrer, E. L., Troussard, E., van Bokhoven, J. A., Onaka, M., Microporous Mesoporous Mater., 198, 129 (2014).

Catal. Lett., 141, 391 (2011). 32) Tandiary, M. A., Asano, M., Hattori, T., Takehira, S., Masui, Y.,

21) Olah, G. A., Schilling, P., Staral, J. S., Halpern, Y., Olah, J. A., J. Onaka, M., Tetrahedron Lett., 58, 1925 (2017).

Am. Chem. Soc., 6807 (1975). 33) Qiu, G., Huang, C., Sun, X., Chen, B., Green Chem., 21, 3930

22) Onaka, M., Higuchi, K., Nanami, H., Izumi, Y., Bull. Chem. (2019).

Soc. Jpn., 66, 2638 (1993). 34) Motokura, K., Fujita, N., Mori, K., Mizugaki, T., Ebitani, K.,

23) Izumi, Y., Urabe, K., Onaka, M., Microporous Mesoporous Kaneda, K., Angew. Chem. Int. Ed., 45, 2605 (2006).

Mater., 21, 227 (1998). 35) Motokura, K., Nakagiri, N., Mizugaki, T., Ebitani, K., Kaneda,

24) Kaneda, K., Ebitani, K., Mizugaki, T., Mori, K., Bull. Chem. K., J. Org. Chem., 72, 6006 (2007).

Soc. Jpn., 79, 981 (2006). 36) Motokura, K., Matsunaga, S., Miyaji, A., Sakamoto, Y., Baba,

25) Motokura, K., Baba, T., Green Chem., 14, 565 (2012). T., Org. Lett., 12, 1508 (2010).

26) Kumar, B. S., Dhakshinamoorthy, A., Pitchumani, K., Catal. 37) Takabatake, M., Nambo, M., Manaka, Y., Motokura, K.,

Sci. Technol., 4, 2378 (2014). ChemPlusChem, 85, 450 (2020).

27) Dutta, D. K., Borah, B. J., Sarmah, P. P., Catal. Rev. Sci. Eng., 38) Motokura, K., Matsunaga, S., Noda, H., Miyaji, A., Baba, T.,

57, 257 (2015). ACS Catal., 2, 1942 (2012).

28) Hechelski, M., Ghinet, A., Louvel, B., Dufrénoy, P., Rigo, B., 39) Niwa, M., Katada, N., Sawa, M., Murakami, Y., J. Phys.

Daïch, A., Waterlot, C., ChemSusChem, 11, 1249 (2018). Chem., 99, 8812 (1995).

29) Wang, J., Masui, Y., Onaka, M., Appl. Catal. B: Environ., 107, 40) Niwa, M., Katada, N., Catal. Surv. Jpn., 1, 215 (1997).

要 旨

プロトン交換モンモリロナイト触媒を用いた n-ヘプタンによるベンゼンの液相直接アルキル化の反応機構

高畠 萌†1),南保 雅之†1),眞中 雄一†1,†2),本倉 健†1,†3)

†1)

東京工業大学物質理工学院応用化学系,226-8502 横浜市緑区長津田町4259 G1-19

†2)

(国研)産業技術総合研究所 再生可能エネルギー研究センター,963-0298 福島県郡山市待池台2-2-9

†3)

(国研)科学技術振興機構 さきがけ,332-0012 埼玉県川口市本町4-1-8

固体酸触媒であるモンモリロナイトを用いたときの n-ヘプ 高い選択率で目的の炭素鎖 7 のアルキル化生成物が得られるこ

タンによるベンゼンの直接アルキル化における反応機構を調査 とが明らかになった。一方,前処理を行っていない層間が広い

した。プロトン交換モンモリロナイトやアルミニウム交換モン プロトン交換モンモリロナイトでは,層間における n-ヘプタ

モリロナイトが本反応に活性を示すことが分かった。また,プ ンの単分子クラッキングにより,t-ブチルカチオンが生じ,t-

ロトン交換モンモリロナイトの触媒活性は,加熱や超音波照射 ブチルベンゼンが生成した。H-ZSM-5 を触媒として使用した

などの前処理によって増加し,反応初期の生成物の選択性も変 場合も n-ヘプタンの単分子クラッキングが起きるが,主生成

化した。生成物選択性の詳細な経時変化の測定によって,層間 物はイソプロピルベンゼンとなった。

がより狭い触媒の場合,表面で二分子反応が優先的に起こり,

J. Jpn. Petrol. Inst., Vol. 63, No. 5, 2020

You might also like

- Iso 25239-5-2011 PDFDocument16 pagesIso 25239-5-2011 PDFJorgeNo ratings yet

- Light Alkane (Mixed Feed) Selective Dehydrogenation Using Bi-Metallic Zeolite Supported CatalystDocument8 pagesLight Alkane (Mixed Feed) Selective Dehydrogenation Using Bi-Metallic Zeolite Supported Catalystbinapaniki6520No ratings yet

- Applied Catalysis A: General: Sukriti Singh, Anjali Patel, Pravya PrakashanDocument10 pagesApplied Catalysis A: General: Sukriti Singh, Anjali Patel, Pravya PrakashanValentina Vargas VargasNo ratings yet

- Catalytic Ethanol Dehydration To Ethylene Over Nanocrystalline O CatalystsDocument11 pagesCatalytic Ethanol Dehydration To Ethylene Over Nanocrystalline O CatalystsSebastián Zúñiga RojasNo ratings yet

- Methane Transformation Using Light Gasoline As Co-Reactant Over Zn/H-ZSM11Document6 pagesMethane Transformation Using Light Gasoline As Co-Reactant Over Zn/H-ZSM11Everyday Lentzery HogarNo ratings yet

- 451 JMSE 2595 ArhzafDocument11 pages451 JMSE 2595 ArhzafamineNo ratings yet

- Enhanced Performance of Non-PGM Catalysts in Air Operated PEM-Fuel Cells 2016Document7 pagesEnhanced Performance of Non-PGM Catalysts in Air Operated PEM-Fuel Cells 2016Nikolay KorneevNo ratings yet

- Enhanced Performance of Zn-Sn/HZSM-5 Catalyst For The Conversion of Methanol To AromaticsDocument9 pagesEnhanced Performance of Zn-Sn/HZSM-5 Catalyst For The Conversion of Methanol To AromaticsArash AbbasiNo ratings yet

- Catalytic Activation of Methane Using N-Pentane As Co-Reactant Over Zn/H-ZSM-11 ZeoliteDocument5 pagesCatalytic Activation of Methane Using N-Pentane As Co-Reactant Over Zn/H-ZSM-11 ZeoliteEveryday Lentzery HogarNo ratings yet

- Methanol OxidationDocument7 pagesMethanol OxidationJohndannNo ratings yet

- Applied Catalysis A: General: P. Sangeetha, K. Shanthi, K.S. Rama Rao, B. Viswanathan, P. SelvamDocument6 pagesApplied Catalysis A: General: P. Sangeetha, K. Shanthi, K.S. Rama Rao, B. Viswanathan, P. SelvamJoha BetancurNo ratings yet

- Highly Dispersed SevillaDocument19 pagesHighly Dispersed SevillaRuben FelipeNo ratings yet

- MgO-WO3/SiO2 Catalysts for Propylene ProductionDocument16 pagesMgO-WO3/SiO2 Catalysts for Propylene ProductionAnoopNo ratings yet

- (Vários Exemplos, Ler Melhor) 1-s2.0-S156673670800544X-mainDocument6 pages(Vários Exemplos, Ler Melhor) 1-s2.0-S156673670800544X-mainAislan LemeNo ratings yet

- CVD Graphene Supported Cobalt (II) Phthalocyanine As Cathode Electrocatalyst For PEM Fuel CellsDocument8 pagesCVD Graphene Supported Cobalt (II) Phthalocyanine As Cathode Electrocatalyst For PEM Fuel CellsAndres Carmona OsorioNo ratings yet

- Electrolytic Activity of Carbon-supportedPt-Au Nano Particles ForDocument7 pagesElectrolytic Activity of Carbon-supportedPt-Au Nano Particles ForAmitvikram DubeyNo ratings yet

- Subhedar 2018Document10 pagesSubhedar 2018Angélica Andrea SalinasNo ratings yet

- The Dehydrogenation of 2-Butanol Over Copper-Based Catalysts-Optimising Catalyst Composition and Determining Kinetic Parameters PDFDocument10 pagesThe Dehydrogenation of 2-Butanol Over Copper-Based Catalysts-Optimising Catalyst Composition and Determining Kinetic Parameters PDFYohana MelianthaNo ratings yet

- Kinetics of Acetone Hydrogenation For Synthesis of Isopropyl Alcohol Over Cu-Al Mixed Oxide CatalystsDocument9 pagesKinetics of Acetone Hydrogenation For Synthesis of Isopropyl Alcohol Over Cu-Al Mixed Oxide Catalysts李国俊No ratings yet

- Role of Calcination Temperature OnDocument9 pagesRole of Calcination Temperature OnThiago FagundesNo ratings yet

- Reaccion 2 PDFDocument8 pagesReaccion 2 PDFAleja LaraNo ratings yet

- Carbon Dioxide Reforming of Methane Over NiAl2O3 Treated With Glow Discharge PlasmaDocument6 pagesCarbon Dioxide Reforming of Methane Over NiAl2O3 Treated With Glow Discharge PlasmaViệtDũng TôNo ratings yet

- Carbon Dioxide Reforming of Methane Over NiAl2O3 Treated With Glow Discharge PlasmaDocument6 pagesCarbon Dioxide Reforming of Methane Over NiAl2O3 Treated With Glow Discharge PlasmaViệtDũng TôNo ratings yet

- Synthesis of Anisole by Vapor Phase Methylation of Phenol With Methanol Over Catalysts Supported On Activated AluminaDocument3 pagesSynthesis of Anisole by Vapor Phase Methylation of Phenol With Methanol Over Catalysts Supported On Activated AluminaNitish Singh SengarNo ratings yet

- N - Pentane Isomerization Over PTDocument9 pagesN - Pentane Isomerization Over PTNguyen Viet HungNo ratings yet

- Presentation by GopalDocument19 pagesPresentation by GopalSherlock BakshiNo ratings yet

- 10 1016@j Ijhydene 2016 07 072Document13 pages10 1016@j Ijhydene 2016 07 072peymanNo ratings yet

- Engineering Pt-Mn2O3 Interface To Boost Selective Oxidation of Ethylene Glycol To Glycolic AcidDocument11 pagesEngineering Pt-Mn2O3 Interface To Boost Selective Oxidation of Ethylene Glycol To Glycolic Acid63011373No ratings yet

- 10.1016@S0926 860X9900477 9Document7 pages10.1016@S0926 860X9900477 9baizidiNo ratings yet

- Fly Ash Supported Ni Fe Solid Acid Catalyst For Efficient Production of Diesel Additive: Intensi Fication Through Far-Infrared RadiationDocument10 pagesFly Ash Supported Ni Fe Solid Acid Catalyst For Efficient Production of Diesel Additive: Intensi Fication Through Far-Infrared RadiationSriArthiNo ratings yet

- 24IJAERS 06202012 Cheapzeolite PDFDocument5 pages24IJAERS 06202012 Cheapzeolite PDFIJAERS JOURNALNo ratings yet

- Cheap Zeolite Catalyst (Na3PO4/NaX) For Toluene/methanol Side Chain AlkylationDocument5 pagesCheap Zeolite Catalyst (Na3PO4/NaX) For Toluene/methanol Side Chain AlkylationIJAERS JOURNALNo ratings yet

- 156 Indoles ElectroanalysisDocument8 pages156 Indoles Electroanalysiswora123potNo ratings yet

- 2005 Electrochemcomm ZhaoDocument6 pages2005 Electrochemcomm ZhaoGuerrero OmarNo ratings yet

- Production of Hydrogen Over Bimetallic Pt-Ni/d-Al O I. Indirect Partial Oxidation of PropaneDocument8 pagesProduction of Hydrogen Over Bimetallic Pt-Ni/d-Al O I. Indirect Partial Oxidation of PropaneleylaNo ratings yet

- Gong 2010Document5 pagesGong 2010mettyanaNo ratings yet

- Jurnal Perancangan AlatDocument6 pagesJurnal Perancangan AlatFreeQueenNo ratings yet

- Applied Surface Science: Full Length ArticleDocument7 pagesApplied Surface Science: Full Length ArticleermiasNo ratings yet

- Nano-Scale ZSM-5 Zeolite Effectively Cracks HydrocarbonsDocument9 pagesNano-Scale ZSM-5 Zeolite Effectively Cracks HydrocarbonsIka SulistyaningtiyasNo ratings yet

- A New Trend For Preparating Polymeric CalciumDocument11 pagesA New Trend For Preparating Polymeric CalciumNicolae LucaNo ratings yet

- Catalysts for simultaneous isomerization and dehydrogenation of n-butaneDocument6 pagesCatalysts for simultaneous isomerization and dehydrogenation of n-butanesmalathipriyacse1987No ratings yet

- A Kinetic Study of The Thermal Degradation of Chitosan-Metal ComplexesDocument10 pagesA Kinetic Study of The Thermal Degradation of Chitosan-Metal ComplexesFernanda Stuani PereiraNo ratings yet

- Zhao 2004Document7 pagesZhao 200463011273No ratings yet

- An Efficient Cufunctionalized Graphene Oxide Catalyst For Synthesis of 5-Substituted 1H-TetrazolesDocument9 pagesAn Efficient Cufunctionalized Graphene Oxide Catalyst For Synthesis of 5-Substituted 1H-TetrazolesT MaiyalaganNo ratings yet

- Coking Kinetics On The Catalyst During Alkylation of FCC Off-Gas With Benzene To EthylbenzeneDocument7 pagesCoking Kinetics On The Catalyst During Alkylation of FCC Off-Gas With Benzene To EthylbenzeneAndres PeñaNo ratings yet

- Oxidation of Cyclohexane and Ethylbenzene by Hydrogen Peroxide Over Co-Substituted Heteropolytungstate CatalystDocument6 pagesOxidation of Cyclohexane and Ethylbenzene by Hydrogen Peroxide Over Co-Substituted Heteropolytungstate Catalystrungrawin ngamkhumNo ratings yet

- Ruta 7Document9 pagesRuta 7DORIS HELENA GUTIÉRREZ LONDOÑONo ratings yet

- Autothermal Reforming ProcessDocument9 pagesAutothermal Reforming ProcessOliver Everett EspinoNo ratings yet

- Thermochemistry and Kinetics of The Reactions of Apatite Phosphates With Acid SolutionsDocument27 pagesThermochemistry and Kinetics of The Reactions of Apatite Phosphates With Acid SolutionsDizzixxNo ratings yet

- Multiwalled Carbon Nanotube Supported PT - SN-M (M Ru, Ni, and Ir) Catalysts For Ethanol ElectrooxidationDocument11 pagesMultiwalled Carbon Nanotube Supported PT - SN-M (M Ru, Ni, and Ir) Catalysts For Ethanol ElectrooxidationFabricio CarrilloNo ratings yet

- Catalytic Cracking of Paraffins On Zeolite Catalysts For The Production of Light OlefinsDocument10 pagesCatalytic Cracking of Paraffins On Zeolite Catalysts For The Production of Light Olefinskzc_07No ratings yet

- Active Sites of Ni2PSiO2 Catalyst For Hydrodeoxygenation of Guaiacol A Joint XAFS and DFT Study PDFDocument9 pagesActive Sites of Ni2PSiO2 Catalyst For Hydrodeoxygenation of Guaiacol A Joint XAFS and DFT Study PDFblackjack_027No ratings yet

- Thermal Decomposition of MgO NanoparticlesDocument6 pagesThermal Decomposition of MgO NanoparticlesIvy JoyceNo ratings yet

- 2013-Hydrogen Rich Gas Production From Etanol Steam Reaction - Energy ResearchDocument12 pages2013-Hydrogen Rich Gas Production From Etanol Steam Reaction - Energy ResearchDanCosminNo ratings yet

- One-Pot Hydrothermal Synthesis, Characterization, and Electrochemical Properties of Rgo/Mnfe2O4 NanocompositesDocument8 pagesOne-Pot Hydrothermal Synthesis, Characterization, and Electrochemical Properties of Rgo/Mnfe2O4 NanocompositesjhenyNo ratings yet

- HT - Efect Memorie - 1 - 2004Document5 pagesHT - Efect Memorie - 1 - 2004seby_antalNo ratings yet

- 835 1809 1 SMDocument8 pages835 1809 1 SMJkcnkdnkdknd JodjdidjNo ratings yet

- For Paper - 12Document13 pagesFor Paper - 12AlisaNo ratings yet

- 10.1007/s12039 015 0795 0Document11 pages10.1007/s12039 015 0795 0AnaGomezNo ratings yet

- Full TextDocument8 pagesFull TextAbril FgNo ratings yet

- Transition Metal-Catalyzed Pyridine Synthesis: Transition Metal-Catalyzed Heterocycle Synthesis SeriesFrom EverandTransition Metal-Catalyzed Pyridine Synthesis: Transition Metal-Catalyzed Heterocycle Synthesis SeriesNo ratings yet

- Synthesis and Antihypertensive Activity DHP and PirimidinasDocument8 pagesSynthesis and Antihypertensive Activity DHP and PirimidinasLuis MartinezNo ratings yet

- Hoshin Kanri A Study of Practice in The UKDocument8 pagesHoshin Kanri A Study of Practice in The UKrh4500No ratings yet

- Cavidad PrediccionDocument9 pagesCavidad PrediccionLuis MartinezNo ratings yet

- Structure Based Virtual Screening, in Silico Docking, ADME PropertiesDocument17 pagesStructure Based Virtual Screening, in Silico Docking, ADME PropertiesLuis MartinezNo ratings yet

- Apertura EpoxidoDocument6 pagesApertura EpoxidoLuis MartinezNo ratings yet

- Inhibition of The SARS-CoV-2 RNA-Dependent RNA Polymerase by Natural BioactiveDocument13 pagesInhibition of The SARS-CoV-2 RNA-Dependent RNA Polymerase by Natural BioactiveLuis MartinezNo ratings yet

- Therapeutic Development by Repurposing Drugs Targeting SARS-CoV-2Document9 pagesTherapeutic Development by Repurposing Drugs Targeting SARS-CoV-2Luis MartinezNo ratings yet

- Review Actividad Bilogica PirimidinasDocument25 pagesReview Actividad Bilogica PirimidinasLuis MartinezNo ratings yet

- In silico evaluation of flavonoids as potential antiviral agents against SARS-CoV-2 spike glycoproteinDocument12 pagesIn silico evaluation of flavonoids as potential antiviral agents against SARS-CoV-2 spike glycoproteinLuis MartinezNo ratings yet

- 3D-QSAR and Docking Studies On PyrimidineDocument15 pages3D-QSAR and Docking Studies On PyrimidineLuis MartinezNo ratings yet

- Phytotherapy Research - 2020 - Tutunchi - Naringenin A Flavanone With Antiviral and Anti Inflammatory Effects A PromisingDocument11 pagesPhytotherapy Research - 2020 - Tutunchi - Naringenin A Flavanone With Antiviral and Anti Inflammatory Effects A PromisingLuis MartinezNo ratings yet

- Leeerrrrr Posible Articulo Flavonoids As Potential Anti-MRSA Sitio AlostericoDocument16 pagesLeeerrrrr Posible Articulo Flavonoids As Potential Anti-MRSA Sitio AlostericoLuis MartinezNo ratings yet

- Identification of Alkaloids From Justicia Adhatoda As Potent SARS CoV-2Document8 pagesIdentification of Alkaloids From Justicia Adhatoda As Potent SARS CoV-2Luis MartinezNo ratings yet

- Unsymmetrical Aromatic Disulfides As SARS-CoV-2 Mpro InhibitorsDocument10 pagesUnsymmetrical Aromatic Disulfides As SARS-CoV-2 Mpro InhibitorsLuis MartinezNo ratings yet

- COVID-19 and Flavonoids in Silico Molecular Dynamics Docking To The Active Catalytic SiteDocument27 pagesCOVID-19 and Flavonoids in Silico Molecular Dynamics Docking To The Active Catalytic SiteLuis MartinezNo ratings yet

- 2020 Potential Inhibitor of Covid-19 Main Protease From Several Medicinal Plant CompoundsDocument15 pages2020 Potential Inhibitor of Covid-19 Main Protease From Several Medicinal Plant CompoundsLuis MartinezNo ratings yet

- Docking Study of Naringin Binding With COVID-19 Main ProteaseDocument8 pagesDocking Study of Naringin Binding With COVID-19 Main ProteaseLuis MartinezNo ratings yet

- PBP2a Talon de AquilesDocument20 pagesPBP2a Talon de AquilesLuis MartinezNo ratings yet

- Interacciones Pi Electron Indol en ChalconasDocument15 pagesInteracciones Pi Electron Indol en ChalconasLuis MartinezNo ratings yet

- Lerr Sitio Alosterico Proteina DimmsDocument6 pagesLerr Sitio Alosterico Proteina DimmsLuis MartinezNo ratings yet

- Interacciones Pi Electron Indol en ChalconasDocument15 pagesInteracciones Pi Electron Indol en ChalconasLuis MartinezNo ratings yet

- Distancia Entre Sitio Catalitico y AlostericoDocument6 pagesDistancia Entre Sitio Catalitico y AlostericoLuis MartinezNo ratings yet

- Drug Design: Functional Groups / Pharmacological ActivityDocument24 pagesDrug Design: Functional Groups / Pharmacological ActivityIoana Mirela VasincuNo ratings yet

- Leerr Autodoc Vina ManualDocument6 pagesLeerr Autodoc Vina ManualLuis MartinezNo ratings yet

- Estudio Sitio Catalitico RatasDocument9 pagesEstudio Sitio Catalitico RatasLuis MartinezNo ratings yet

- Eftekhari Sis2013Document86 pagesEftekhari Sis2013Luis MartinezNo ratings yet

- Estudio Sitio Catalitico RatasDocument9 pagesEstudio Sitio Catalitico RatasLuis MartinezNo ratings yet

- Handouts Heterocycles2005 06 PDFDocument45 pagesHandouts Heterocycles2005 06 PDFlosblancos1No ratings yet

- Interacciones Pi Electron Indol en ChalconasDocument15 pagesInteracciones Pi Electron Indol en ChalconasLuis MartinezNo ratings yet

- Drug Design: Functional Groups / Pharmacological ActivityDocument24 pagesDrug Design: Functional Groups / Pharmacological ActivityIoana Mirela VasincuNo ratings yet

- Properties of Water - Its Chemistry and Some PhysicsDocument44 pagesProperties of Water - Its Chemistry and Some PhysicsjohnosborneNo ratings yet

- Gastric Juice (Autosaved)Document15 pagesGastric Juice (Autosaved)ZahidKhanNo ratings yet

- RK-200 Steam Reforming CatalystsDocument2 pagesRK-200 Steam Reforming CatalystsJhimmy TercerosNo ratings yet

- Ship Stability Yuk BilgisiDocument342 pagesShip Stability Yuk BilgisiHasan CosalevNo ratings yet

- Sampling Wrought Nonferrous Metals and Alloys For Determination of Chemical CompositionDocument2 pagesSampling Wrought Nonferrous Metals and Alloys For Determination of Chemical Compositionaiurea92No ratings yet

- Hnology and Livelihood Education: Quarter 1 - Module 2: CookeryDocument27 pagesHnology and Livelihood Education: Quarter 1 - Module 2: CookeryDomeng Karo100% (5)

- Paraffin Test ActivityDocument2 pagesParaffin Test ActivityCapal Anna MarieNo ratings yet

- Chem 33.1 Exp 1 Lab ReportDocument4 pagesChem 33.1 Exp 1 Lab ReportLucile BronzalNo ratings yet

- Gr5 Wk5 Active Passive TransportDocument1 pageGr5 Wk5 Active Passive TransportFum AbdullahNo ratings yet

- Project Report On Manures and Chemical FertilizersDocument5 pagesProject Report On Manures and Chemical FertilizersAvishekNo ratings yet

- Y11A Cycle Test 9.2.23Document16 pagesY11A Cycle Test 9.2.23sharkeesha sharkeeshaNo ratings yet

- Product 62494 DatasheetDocument7 pagesProduct 62494 DatasheetAaron GeogreNo ratings yet

- Sodiumcarbonate 180826152936Document31 pagesSodiumcarbonate 180826152936Aliha AzmatNo ratings yet

- Udemy AComplete Guideto Pharmaceutical Organic Chemistry IIDocument5 pagesUdemy AComplete Guideto Pharmaceutical Organic Chemistry IIcbnnoon1111No ratings yet

- 22602-Sample-Question-Paper (Msbte Study Resources) Maintenance and Repairs of Structures (MRS)Document4 pages22602-Sample-Question-Paper (Msbte Study Resources) Maintenance and Repairs of Structures (MRS)Roshan Kinholkar100% (1)

- 9chem Ch1,2 PDFDocument4 pages9chem Ch1,2 PDFMohammad AshfaqNo ratings yet

- Food Packaging and Shelf Life: A. Nor Adilah, B. Jamilah, M.A. Noranizan, Z.A. Nur HananiDocument7 pagesFood Packaging and Shelf Life: A. Nor Adilah, B. Jamilah, M.A. Noranizan, Z.A. Nur HananiDharmPalNo ratings yet

- Grade 11th Chemistry Annual PlanDocument4 pagesGrade 11th Chemistry Annual PlanAbdi Mohammed100% (1)

- Aws D14.4 2005Document178 pagesAws D14.4 2005luisNo ratings yet

- CXS - 200 - PeanutsDocument3 pagesCXS - 200 - PeanutsDr. Polixenia UdubasaNo ratings yet

- Components of FoodDocument37 pagesComponents of FoodSunil KumarNo ratings yet

- 6-Week Industrial Training Report at National Fertilizers LimitedDocument31 pages6-Week Industrial Training Report at National Fertilizers LimitedKaran KaushalNo ratings yet

- Ies60 020Document19 pagesIes60 020Humberto RodriguezNo ratings yet

- Povidone Iodine Based Antimicrobial Foam Soap Scrub Formulation and Manufacturing ProcessDocument7 pagesPovidone Iodine Based Antimicrobial Foam Soap Scrub Formulation and Manufacturing ProcessVivekPatilNo ratings yet

- Etulay Online Tutorial: Physical ScienceDocument39 pagesEtulay Online Tutorial: Physical ScienceTara SantosNo ratings yet

- Technical Guide PALADEXDocument38 pagesTechnical Guide PALADEXÖmer Faruk GÜLNo ratings yet

- Lab 11 Nucleic Acid PDFDocument10 pagesLab 11 Nucleic Acid PDFprincessfarah hussinNo ratings yet

- Department of Biochemical Engineering: (1) - However, It Is PossibleDocument9 pagesDepartment of Biochemical Engineering: (1) - However, It Is PossibleMarcelo ParraNo ratings yet

- Hydrogen Generation During In-Situ CombustionDocument15 pagesHydrogen Generation During In-Situ CombustionRoobinRZamirNo ratings yet