Professional Documents

Culture Documents

ASME BPVC VIII div.1-2019-MANDATORY APPENDIX 12-UT

ASME BPVC VIII div.1-2019-MANDATORY APPENDIX 12-UT

Uploaded by

Sanat Moshaver0 ratings0% found this document useful (0 votes)

13 views1 pageUltrasonic Testing

ASME BPVC VIII div.1-2019-MANDATORY APPENDIX 12-UT

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentUltrasonic Testing

ASME BPVC VIII div.1-2019-MANDATORY APPENDIX 12-UT

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

13 views1 pageASME BPVC VIII div.1-2019-MANDATORY APPENDIX 12-UT

ASME BPVC VIII div.1-2019-MANDATORY APPENDIX 12-UT

Uploaded by

Sanat MoshaverUltrasonic Testing

ASME BPVC VIII div.1-2019-MANDATORY APPENDIX 12-UT

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

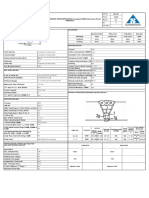

12-1 – 12-4 ASME BPVC.VIII.

1-2019

MANDATORY APPENDIX 12

ULTRASONIC EXAMINATION OF WELDS (UT)

12-1 SCOPE (a) Indications characterized as cracks, lack of fusion,

or incomplete penetration are unacceptable regardless

(a) This Appendix describes methods which shall be of length.

employed when ultrasonic examination of welds is speci- (b) Other imperfections are unacceptable if the indica-

fied in this Division. tions exceed the reference level amplitude and have

(b) Section V, Article 4 shall be applied for detail re- lengths which exceed:

quirements in methods and procedures, unless otherwise (1) 1/4 in. (6 mm) for t up to 3/4 in. (19 mm);

specified in this Appendix. (2) 1/3t for t from 3/4 in. to 21/4 in. (19 mm to 57 mm);

(c) Ultrasonic examination shall be performed in accor- (3) 3/4 in. (19 mm) for t over 21/4 in. (57 mm).

dance with a written procedure, certified by the Manufac-

turer to be in accordance with the requirements of where t is the thickness of the weld excluding any allow-

Section V, Article 1, T-150. able reinforcement. For a butt weld joining two members

having different thicknesses at the weld, t is the thinner of

these two thicknesses. If a full penetration weld includes a

12-2 CERTIFICATION OF COMPETENCE OF fillet weld, the thickness of the throat of the fillet shall be

NONDESTRUCTIVE EXAMINER included in t.

Personnel performing and evaluating ultrasonic exam-

inations required by this Division shall meet the require- 12-4 REPORT OF EXAMINATION

ments of UW-54.

The Manufacturer shall prepare a report of the ultraso-

nic examination and a copy of this report shall be retained

12-3 ACCEPTANCE–REJECTION STANDARDS by the Manufacturer as required by this Division (10-13).

The report shall contain the information required by Sec-

These Standards shall apply unless other standards are

tion V. In addition, a record of repaired areas shall be

specified for specific applications within this Division.

noted as well as the results of the reexamination of the re-

Imperfections which produce a response greater than

paired areas. The Manufacturer shall also maintain a re-

20% of the reference level shall be investigated to the ex-

cord of all reflections from uncorrected areas having

tent that the operator can determine the shape, identity,

responses that exceed 50% of the reference level. This re-

and location of all such imperfections and evaluate them

cord shall locate each area, the response level, the dimen-

in terms of the acceptance standards given in (a) and (b)

sions, the depth below the surface, and the classification.

below.

452

www.sanatmoshaver.com

You might also like

- Flaw Manufacturing TechnologyDocument31 pagesFlaw Manufacturing Technologyツ ツNo ratings yet

- Visual Inspection ProcedureDocument8 pagesVisual Inspection ProcedureTouil Houssem100% (3)

- ASME V Article 7 Magnetic Particle ExaminationDocument1 pageASME V Article 7 Magnetic Particle ExaminationAmanda Ariesta Aprilia100% (4)

- AWS CWI Training Program PDFDocument22 pagesAWS CWI Training Program PDFDjamelNo ratings yet

- Company ProfileTradingDocument19 pagesCompany ProfileTradingmanugeorge100% (1)

- Eddy-Current Examination of Steel Tubular Products Using Magnetic SaturationDocument5 pagesEddy-Current Examination of Steel Tubular Products Using Magnetic SaturationROHITNo ratings yet

- Aws d1.1 WQT ThicknessDocument2 pagesAws d1.1 WQT ThicknessArul Edwin VijayNo ratings yet

- PA Probe Catalog en 201308Document24 pagesPA Probe Catalog en 201308Alvaro Alexis Mendoza PradaNo ratings yet

- PART-C MokpDocument13 pagesPART-C MokpSamuel Hugos100% (2)

- Silverwing RMS2 01Document4 pagesSilverwing RMS2 01rubiodegoNo ratings yet

- RWPL TG Capital Overhauling Scope of JobDocument8 pagesRWPL TG Capital Overhauling Scope of JobSreekanthMylavarapuNo ratings yet

- Code, Standard, Specification and ProcedureDocument13 pagesCode, Standard, Specification and Proceduremangsuresh100% (1)

- Procedimiento IT-ET - UT-014 Rev 02 API 1104 - 2013 InglesDocument10 pagesProcedimiento IT-ET - UT-014 Rev 02 API 1104 - 2013 InglesJonathan Espinoza MejiaNo ratings yet

- Paut Checklist AuditDocument1 pagePaut Checklist Auditaakash0% (1)

- Welding Defects and Implications On Welded Assemblies PDFDocument10 pagesWelding Defects and Implications On Welded Assemblies PDFM.Jasim MoNo ratings yet

- Profile RadiogarphyDocument24 pagesProfile RadiogarphySantosh Kumar100% (1)

- 020-NDT - TSE - UT - ASME B31.3 - 20 - Ultrasonic, REV 00 (1) - CompressedDocument35 pages020-NDT - TSE - UT - ASME B31.3 - 20 - Ultrasonic, REV 00 (1) - CompressedPT PUTRA SETIAWAN PRIMANo ratings yet

- Ut Proceduregeneral 141118232235 Conversion Gate02Document24 pagesUt Proceduregeneral 141118232235 Conversion Gate02Danem HalasNo ratings yet

- Radiography AcceptanceDocument1 pageRadiography Acceptanceagus sukmanaNo ratings yet

- Sa 578 UltrasonidoDocument6 pagesSa 578 UltrasonidoDavid EstradaNo ratings yet

- Classification Notes: Extended Dry-Docking SchemeDocument11 pagesClassification Notes: Extended Dry-Docking SchemeSagar GoyalNo ratings yet

- Insp 2017 999 8700 0301 Inspection Test Plan For A Piping WorkDocument14 pagesInsp 2017 999 8700 0301 Inspection Test Plan For A Piping Workestephan82No ratings yet

- Phased Array UT Application For Boiler Tube Inspection in Manufacturing Anandamurugan S, Siva Sankar YDocument10 pagesPhased Array UT Application For Boiler Tube Inspection in Manufacturing Anandamurugan S, Siva Sankar YmuhdmsohNo ratings yet

- LPT As Per Asme & IsoDocument2 pagesLPT As Per Asme & Isosbmmla100% (1)

- ASME Sec V Calibration BlockDocument1 pageASME Sec V Calibration BlockwalitedisonNo ratings yet

- I&TP Piping WorksDocument11 pagesI&TP Piping Worksmesmerize59100% (1)

- UT Formula SheetDocument2 pagesUT Formula SheetOktayKul100% (1)

- WPS Resrvoire Sous Pression Smaw SawDocument6 pagesWPS Resrvoire Sous Pression Smaw SawDanem HalasNo ratings yet

- Report 1 Paut Sts 409Document12 pagesReport 1 Paut Sts 409DEBJYOTI SENGUPTA100% (2)

- Api RP 2x-Acceptance CriteriaDocument6 pagesApi RP 2x-Acceptance CriteriaAllwynNo ratings yet

- Astm Se-273Document5 pagesAstm Se-273Deyci Yamile Peña SantosNo ratings yet

- Measuring Ultrasonic Velocity in Materials by Comparative Pulse-Echo MethodDocument14 pagesMeasuring Ultrasonic Velocity in Materials by Comparative Pulse-Echo MethodRoman D100% (1)

- HTHA Module Rev 7Document14 pagesHTHA Module Rev 7judicejrNo ratings yet

- ASME B31.3 - 2014 - Table 341.3.2 - AcceptanceDocument4 pagesASME B31.3 - 2014 - Table 341.3.2 - AcceptanceDjamel100% (5)

- Integrity Management of CRA Pipelines Technical ReportDocument27 pagesIntegrity Management of CRA Pipelines Technical ReportMiqdad100% (1)

- Phased Array Probes - DopplerDocument10 pagesPhased Array Probes - DopplerJ.Carrasco0% (1)

- Post Weld Heat TreatmentDocument1 pagePost Weld Heat Treatmentthho84No ratings yet

- Ferrite Content Measurement ProcedureDocument5 pagesFerrite Content Measurement ProcedureSenthil Periyasamy0% (1)

- Ultrasonic Testing Report Format Based On IACSDocument1 pageUltrasonic Testing Report Format Based On IACSDeepak100% (6)

- Aws Application of Phased Array UltrasonicDocument7 pagesAws Application of Phased Array UltrasonicDileep KumarNo ratings yet

- Demo SUMDocument27 pagesDemo SUMRudolph RednoseNo ratings yet

- Scan Plan Paut-Mc-02-Corregido PDFDocument5 pagesScan Plan Paut-Mc-02-Corregido PDFCarlos TijerinaNo ratings yet

- Approved Structural Steel-Welding Procedures - Double V-Groove With Back Gouge PDFDocument3 pagesApproved Structural Steel-Welding Procedures - Double V-Groove With Back Gouge PDFBhavani PrasadNo ratings yet

- Sa 388.sa 388MDocument8 pagesSa 388.sa 388MWagner Renato AraújoNo ratings yet

- Proc. For Radiographic Profile Thk. MeasurementDocument7 pagesProc. For Radiographic Profile Thk. MeasurementSergey KichenkoNo ratings yet

- Wps-01 C.S. GtawDocument2 pagesWps-01 C.S. GtawMohamed Tarek HamamNo ratings yet

- Aws d1.5 PQRDocument2 pagesAws d1.5 PQRjacquesmayolNo ratings yet

- API 6A RadiographyDocument4 pagesAPI 6A RadiographyminakshissawantNo ratings yet

- Asme PQR DemoDocument3 pagesAsme PQR DemoMuthusamy AyyanapillaiNo ratings yet

- Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document8 pagesQw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Muhammad HannanNo ratings yet

- Chapter 1: "Phased Array Introduction and Principles": Practice QuestionsDocument5 pagesChapter 1: "Phased Array Introduction and Principles": Practice QuestionsMarcus Antonius100% (1)

- PAUT Procedure EEISDocument13 pagesPAUT Procedure EEISZakirUllahNo ratings yet

- Procedure For Ferrit TestingDocument11 pagesProcedure For Ferrit TestingKarrar TalibNo ratings yet

- Zzze) I (ZFRP: QW-163 Acceptance Criteria - Bend Tests QW-163 Acceptance Criteria - Bend TestsDocument1 pageZzze) I (ZFRP: QW-163 Acceptance Criteria - Bend Tests QW-163 Acceptance Criteria - Bend TestsSARSAN NDTNo ratings yet

- ASME Section IX Appendix-4 (Rounded Indicaion) For RTDocument9 pagesASME Section IX Appendix-4 (Rounded Indicaion) For RTGoutam Kumar DebNo ratings yet

- Article 4 Metodo UltrasonidoDocument24 pagesArticle 4 Metodo UltrasonidoLessly Lorena Apala RamirezNo ratings yet

- Se 273Document4 pagesSe 273solrac4371No ratings yet

- Astm E110Document2 pagesAstm E110nandorg27No ratings yet

- Astm e 1158Document5 pagesAstm e 1158KEN KNo ratings yet

- Ultrasonic Examination Based Acceptance CriteriaDocument2 pagesUltrasonic Examination Based Acceptance CriteriaAngelTinocoNo ratings yet

- Astm E747Document3 pagesAstm E747AmithNo ratings yet

- Section II A SA-435 - SA-435MDocument3 pagesSection II A SA-435 - SA-435MSocrates MoralesNo ratings yet

- Zapata Siui Phased ArrayDocument3 pagesZapata Siui Phased ArrayEdgar Javier Cepeda AmadoNo ratings yet

- E390-11 Standard Reference Radiographs For Steel Fusion WeldsDocument4 pagesE390-11 Standard Reference Radiographs For Steel Fusion WeldsAhmed Shaban KotbNo ratings yet

- DAC Block Details PDFDocument2 pagesDAC Block Details PDFShrikant UtekarNo ratings yet

- Saferad ProcedureDocument19 pagesSaferad ProcedureExsan OthmanNo ratings yet

- Tubular Heat ExchangerDocument4 pagesTubular Heat Exchangerprashant_dc_inNo ratings yet

- Welding Procedure Welding Procedure Specification SpecificationDocument2 pagesWelding Procedure Welding Procedure Specification SpecificationHamid MansouriNo ratings yet

- Olympus ECT CatalogDocument62 pagesOlympus ECT CatalogMahesh Raja100% (1)

- Ut 4 PDFDocument42 pagesUt 4 PDFtusharNo ratings yet

- WPS Ernicu 7 R1 3 6 PDFDocument4 pagesWPS Ernicu 7 R1 3 6 PDFandresNo ratings yet

- Mandatory Appendix 12 Ultrasonic Examination of Welds (Ut) : 12-1 SCOPEDocument1 pageMandatory Appendix 12 Ultrasonic Examination of Welds (Ut) : 12-1 SCOPESefa yıldızNo ratings yet

- Asme Viii - Mandatoryappendix 6 - MTDocument2 pagesAsme Viii - Mandatoryappendix 6 - MTDjamelNo ratings yet

- Book Collection List1Document7 pagesBook Collection List1DjamelNo ratings yet

- 21st Century Pie Chart1Document1 page21st Century Pie Chart1DjamelNo ratings yet

- PHR-PP-QC-GG-003 Inspection and Test Plan at ShopDocument103 pagesPHR-PP-QC-GG-003 Inspection and Test Plan at Shopmashari budiNo ratings yet

- OPSS 906 - Nov12Document20 pagesOPSS 906 - Nov12umerfr2No ratings yet

- Australian/New Zealand StandardDocument21 pagesAustralian/New Zealand StandardJoel MennieNo ratings yet

- WeldEye Value Impct of Welding+Management Software Over The Welding Value Chain White Paper PDFDocument12 pagesWeldEye Value Impct of Welding+Management Software Over The Welding Value Chain White Paper PDFPrakash RajNo ratings yet

- Inspection and Test Plan Rotating Equipment:: LPG PumpDocument4 pagesInspection and Test Plan Rotating Equipment:: LPG PumpErico Haryanto LumbanrajaNo ratings yet

- Hydrophilic Emulsifier: Product Data SheetDocument3 pagesHydrophilic Emulsifier: Product Data SheetMiguelNo ratings yet

- Astm E1606 20Document5 pagesAstm E1606 20faruk öztürkNo ratings yet

- 1169 2014-BOK Rev-071014Document9 pages1169 2014-BOK Rev-071014Siva KumarNo ratings yet

- Siemens SW Industrial Quality Testing EBDocument12 pagesSiemens SW Industrial Quality Testing EBAnkurNo ratings yet

- Optimization Algorithms For Ultrasonic Array Imaging in Homogeneous Anisotropic Steel Components With Unknown PropertiesDocument14 pagesOptimization Algorithms For Ultrasonic Array Imaging in Homogeneous Anisotropic Steel Components With Unknown PropertiespjhollowNo ratings yet

- NDT of Waterproofing MembranesDocument5 pagesNDT of Waterproofing MembranesSazali KhamsanNo ratings yet

- PW-11 Volumetric Examination of Welded Butt JointsDocument1 pagePW-11 Volumetric Examination of Welded Butt JointsARNOLDONo ratings yet

- NDT Non Distructive TestsDocument18 pagesNDT Non Distructive TestsOmar MamdouhNo ratings yet

- Pt. Cemindo Gemilang Rotary Kiln MaterialDocument3 pagesPt. Cemindo Gemilang Rotary Kiln Materialfauzan tarmiziNo ratings yet

- DNV-OS-F101 2000 Submarine Pipeline System PDFDocument168 pagesDNV-OS-F101 2000 Submarine Pipeline System PDFMichael MooreNo ratings yet

- Weld Inspection PaparazziDocument3 pagesWeld Inspection PaparazziIqfal ZulhendriNo ratings yet