Professional Documents

Culture Documents

1 ST

Uploaded by

RenuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1 ST

Uploaded by

RenuCopyright:

Available Formats

Special Issue - 2017 International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

VIMPACT - 2017 Conference Proceedings

A Review Paper on an Overview of Organic Light

Emitting Diode

Paras Raj Birwa

Department of Electronics & Communication

Vivekananda Institute of Technology, Jaipur

Jaipur, India

Abstract: Organic light emitting diode is a solid device whether the LCD uses cold cathode fluorescent lamps or an

containing thin films of organic molecules that create light with LED backlight.

the application of electricity. Organic LED can supplied

brighter ,crisper displays on electronic devices and it uses less HISTORY:

power than conventional light emitting diodes use today. An

The first observations of electroluminescence in organic

organic LED is a solid state semiconductor device and it is 100

to 500 nanometers thick or 200 times smaller than a human materials were in the early 1950 by André Bernanos and co-

hair. OLEDs can have two layers or three layers of organic workers at the Nancy-University in France. They applied

material. Organic displays use a material with self-luminous high alternating voltages in air to materials such as acridine

property .This self-luminous property remove the need of back orange. In 1960, Martin Pope and some of his co-workers at

light in displays. OLED are lighter, thinner and more flexible New York University developed ohmic dark-injecting

than LED and LCD electrode contacts to organic crystals .They further

INTRODUCTION: described the necessary energetic requirements for hole and

An organic light emitting diode is normally light emitting electron injecting electrode contacts. These contacts are the

diode which has electro luminescent layer is made of a film basis of charge injection in all modern OLED devices. Pope

of organic compounds. The layers are made up of small group also first discovered direct current

organic molecules or macro polymers that conduct electroluminescence under vacuum on a single pure crystal

electricity. They have conductivity levels ranging from of anthracene and on anthracene crystals doped with

insulators to conductors, so OLEDs are well thought out as tetracene in 1963 using a small area silver electrode at 400

organic semiconductors. The layer of organic semiconductor volts. The projected mechanism was field-accelerated

material is formed between two electrodes, where at least electron excitation of molecular fluorescence. Pope group

one of the layers is transparent. Material with self- luminous described in 1965 that in the absence of an external electric

property that eliminates the involve of a back light. These field, the electroluminescence in anthracene crystals is

result in a thin and compact display. caused by the recombination of a thermalized electron and

hole, and that the conducting level of anthracene is higher in

LITERATURE SURVEY : energy than the exciting energy level. Also in 1965, W.

An organic light emitting diode is a light emitting diode in Helfrich and W. G. Schneider of the National Research

which the emissive electroluminescent layer is a film of Council in Canada developed double injection

organic compound which emits light in reaction to an recombination electroluminescence for the first time in an

electric current. This layer of organic semiconductor is anthracene single crystal using hole and electron injecting

located between two electrodes typically at least one of electrodes, the forerunner of modern double injection driven

these electrodes is transparent. OLED are used to create (100–3000 Hz) electrically insulated one millimeter thin

digital displays in devices such as television screens, layers of a melted phosphor consisting of ground anthracene

computer monitors, portable systems such as mobile phones, powder, tetracene, and graphite

handheld game consoles and PDA. A major field of research

is the development of white OLED devices for use in solid

state lighting applications. There are two main families of

OLED those based on small particle and those employing

polymers. Adding mobile ions to an OLED produces a light-

emitting electrochemical cell which has a slightly different

mode of operation. OLED displays can use either passive-

matrix or active-matrix addressing system. Active matrix

OLED require a thin film transistor backplane to switch

each separate pixel on or off, but allow for higher resolution

and larger display sizes. An OLED display works without a

backlight thus it can show deep black levels and can be

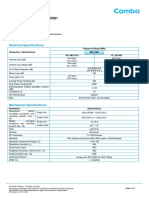

thinner and lighter than a liquid crystal display. In low Schematic of a bilayer OLED: 1. Cathode (−), 2. Emissive Layer, 3.

ambient light status such as a dark room an OLED screen Emission of radiation, 4. Conductive Layer, 5. Anode (+)

can attain a higher contrast ratio than an LCD, regardless of

Volume 5, Issue 23 Published by, www.ijert.org 1

Special Issue - 2017 International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

VIMPACT - 2017 Conference Proceedings

A typical OLED is composed of a layer of organic materials organic light-emitting diodes make use of spinorbit

located between two electrodes, the anode and cathode, all interactions to facilitate intersystem marking between

deposited on a substrate. The organic molecules are singlet and triplet states thus obtaining emission from both

electrically conductive as a result of delocalization of pi singlet and triplet states and improving the internal

electrons caused by pairing over part or all of the molecule. efficiency. Indium tin oxide is mostly used as the anode

These materials have conductivity levels ranging from material. It is transparent to visible light and has a high work

insulators to conductors, and are therefore well thought out procedure which promotes injection of holes into the

organic semiconductors. The highest occupied and lowest HOMO level of the organic layer. A typical conductive

untenanted molecular orbitals of organic semiconductors are layer may consist of PEDOT:PSS as the HOMO level of this

analogous to the valence and conduction bands of inorganic material mostly lies between the work function of ITO and

semiconductors. Originally, the most basic polymer OLED the HOMO of other commonly Metals such as barium and

comprised of a single organic layer. One example was the calcium are often used for the cathode as they have low

first light-emitting device synthesized by J. H. Burroughes work functions which boost injection of electrons into the

et al., which need a single layer of poly (p-phenylene LUMO of the organic layer. Such metals are reactive so they

vinylene). However multilayer OLEDs can be fabricated involve a capping layer of aluminum to avoid degradation.

with two or more layers in order to better device efficiency. Experimental research has proven that the properties of the

As well as conductive properties, different materials anode specifically the anode/hole transport layer interface

devices. In the same year, Dow Chemical researchers topography plays a major role in the efficiency,

patented a method of preparing electroluminescent cells performance, and lifetime of organic light emitting diodes.

using high voltage 500–1500 V AC- may be chosen to aid Imperfections in the surface of the anode reduction anode-

charge injection at electrodes by allowing a more gradual organic film interface adhesion, increase electrical

electronic profile, or block a charge from reaching the resistance, and allow for more frequent formation of non-

opposite electrode and being wasted. Many modern OLED emissive dark spots in the OLED material adversely

contain a simple bilayer structure consisting of a conductive affecting lifetime. barrier too large for efficient electron

layer and an emissive layer. More recent developments in injection.

OLED architecture better quantum efficiency up to 19% by ADVANTAGES:

using a graded heterojunction. In the graded heterojunction Roll-to-roll vapour deposition methods for organic devices

architecture the composition of hole and electron-transport do provide mass production of thousands of devices per

materials change continuously within the emissive layer minute for minimal cost, although this technique also

with a dopant emitter. The graded heterojunction induces problems in that devices with multiple layers can be

architecture merge the benefits of both conventional challenging to make because of registration lining up the

architectures by improving charge injection while different printed layers to the required degree of accuracy.

simultaneously balancing charge transport within the

emissive region. During operation a voltage is implement CONCLUSION:

across the OLED such that the anode is positive with respect Organic light emitting diode induces electronic viewing

to the cathode. Anodes are picked based upon the quality of more convenient as they are more energy efficient. OLED is

their optical transparency, electrical conductivity, and so revolutionary that in the field of elucidation it is being

chemical stability .A current of electrons flows through the hailed as “the first discovery since Edison”. Today OLED

device from cathode to anode as electrons are shooted into technology is extensively seen as a next generation

the LUMO of the organic layer at the cathode and component for flat panel displays and is expected to become

withdrawn from the HOMO at the anode. This latter action a key technology in the development of flexible displays.

may also be described as the injection of electron holes into They are thinner and more flexible than the crystalline

the HOMO. Electrostatic forces contribute the electrons and layers in an LED or LCD. They have large fields of view as

the holes towards each other and they recombine forming an they induced their own light.

exciton a bound state of the electron and hole. This happens

closer to the emissive layer because in organic FUTURE SCOPE:

semiconductors holes are mostly more mobile than Video images could be much more realistic and constantly

electrons. The decay of this excited state results in a easiness upgrade. OLED have large fields of view as they induced

of the energy levels of the electron, accompanied by their own light. OLED have wide viewing angle than LCD

emission of radiation whose frequency is in the visible and can replace LCD in future. It is a key technology in the

region. The frequency of this radiation calculated on the development of flexible displays.

band gap of the material, in this case the difference in

energy between the HOMO and LUMO. As electrons and REFERENCES:

holes are fermions with half integer spin an exciton may

[1] International Journal of Engineering Sciences & Research

either be in a singlet state or a triplet state calculating on

Technology (IJESRT)

how the spins of the electron and hole have been combined. [2] IJEEE-EFES-P106.pdf : The benefits and applications of solar tree

Statistically three triplet excitons will be framed for each with natural beauty of trees

singlet exciton. Decay from triplet states is spin forbidden [3] IJSETR-VOL-4-ISSUE-6-1982- 1985.pdf : Economy Electrification

increasing the timescale of the transition and bounding the Using Solar Tree

[4] IJSRP-p2490.pdf : Idea to design a solar tree using nanowire

internal efficiency of fluorescent devices. Phosphorescent technology

Volume 5, Issue 23 Published by, www.ijert.org 2

You might also like

- Power Factor CorrectionDocument8 pagesPower Factor CorrectionMourtadaAshraf100% (2)

- NL 49Document23 pagesNL 49teomondoNo ratings yet

- Verification Thevenin's Theorem and Maximum Power TransfeDocument5 pagesVerification Thevenin's Theorem and Maximum Power Transfeabdullah8680% (5)

- Organic Semiconductor-Based Plastic Solar CellsDocument73 pagesOrganic Semiconductor-Based Plastic Solar CellsPiyush Raj SaxenaNo ratings yet

- Wheel Speed SensorsDocument7 pagesWheel Speed SensorsJude MakobaNo ratings yet

- Questions On TransformersDocument22 pagesQuestions On Transformerskibrom atsbha100% (1)

- Organic Light-Emitting DiodesDocument17 pagesOrganic Light-Emitting DiodesSuresh KumarNo ratings yet

- IEEE PaperDocument6 pagesIEEE PaperShayer Jaleel0% (1)

- Organic LED: From Wikipedia, The Free EncyclopediaDocument14 pagesOrganic LED: From Wikipedia, The Free Encyclopediaswati131987mishraNo ratings yet

- Motor Technical Brochure PDFDocument24 pagesMotor Technical Brochure PDFvinodk335100% (1)

- International Symposium on Selective Ion-Sensitive Electrodes: International Union of Pure and Applied ChemistryFrom EverandInternational Symposium on Selective Ion-Sensitive Electrodes: International Union of Pure and Applied ChemistryG. J. MoodyNo ratings yet

- SupercapacitorsDocument20 pagesSupercapacitorsMohamed DRISSI100% (1)

- Module 9 - Advanced Transmission Analysis and PlanningDocument518 pagesModule 9 - Advanced Transmission Analysis and PlanningDhapaDan100% (1)

- Motorola-SeminarsandApplicationBooksRF Device Data Vol2 1998-DLDocument818 pagesMotorola-SeminarsandApplicationBooksRF Device Data Vol2 1998-DLjm1503_772868557No ratings yet

- Lab Report Solayman Ewu - CompressDocument12 pagesLab Report Solayman Ewu - CompressVic100% (1)

- Seminar Report Organic Light Emitting DiodeDocument23 pagesSeminar Report Organic Light Emitting DiodesaRAth asgaRdian100% (3)

- OLED: Organic Light Emitting Diode Technology ExplainedDocument15 pagesOLED: Organic Light Emitting Diode Technology ExplainedpraneethNo ratings yet

- Report OledDocument33 pagesReport OledRamnani RockyNo ratings yet

- OLED Technology GuideDocument7 pagesOLED Technology Guidesurendra parlaNo ratings yet

- OLED Technology ExplainedDocument3 pagesOLED Technology ExplainedRicha GargNo ratings yet

- Seminar ReprtcpyDocument33 pagesSeminar Reprtcpysimonrock72No ratings yet

- Dept of EceDocument38 pagesDept of EceBakiesaliyaNo ratings yet

- Organic Light Emitting DiodeDocument16 pagesOrganic Light Emitting DiodeBhargavi DoddaNo ratings yet

- Organic LightDocument16 pagesOrganic LightxchoisrasputinNo ratings yet

- Oled TechnologyDocument28 pagesOled TechnologyMonishkumarNo ratings yet

- OLEDs ReportDocument6 pagesOLEDs Reportphiwayinkosi PwaNo ratings yet

- OLED ReportDocument28 pagesOLED Reportajaylp8722No ratings yet

- Oled Seminar ReportDocument25 pagesOled Seminar ReportVarun Pathak100% (8)

- Seminar (FOLED) PDFDocument22 pagesSeminar (FOLED) PDFShruthi MudaliarNo ratings yet

- Introduction To Organic Light Emitting DiodesDocument10 pagesIntroduction To Organic Light Emitting DiodesananthadigaNo ratings yet

- OLED Study: Organic Light-Emitting Diode TechnologyDocument17 pagesOLED Study: Organic Light-Emitting Diode Technologybabu4527No ratings yet

- Seminar (FOLED)Document38 pagesSeminar (FOLED)Shruthi MudaliarNo ratings yet

- Seminar (FOLED) PDFDocument38 pagesSeminar (FOLED) PDFShruthi MudaliarNo ratings yet

- OLED: A New Display TechnologyDocument10 pagesOLED: A New Display TechnologyArpit Singh BhutaniNo ratings yet

- Final Document DastaDocument14 pagesFinal Document Dastabedadala akhilNo ratings yet

- OLED2Document19 pagesOLED2Saurabh MishraNo ratings yet

- PolyLED PresentationDocument26 pagesPolyLED PresentationDilip MathuriaNo ratings yet

- AMOLED: An Emerging Trends in LED: Abstract-This Paper Presents The Concept of Active MatrixDocument4 pagesAMOLED: An Emerging Trends in LED: Abstract-This Paper Presents The Concept of Active MatrixDheeraj KakaraparthiNo ratings yet

- Seminar Report 2021-22 OledDocument25 pagesSeminar Report 2021-22 OledClassic PrintersNo ratings yet

- 1 JMES 607 2014 Karzazi PDFDocument12 pages1 JMES 607 2014 Karzazi PDFVirgiNo ratings yet

- Organic Light Emitting DiodesDocument15 pagesOrganic Light Emitting DiodesvmulamuriNo ratings yet

- 1 Oled For StuydentsDocument9 pages1 Oled For StuydentsHEMANTH BATTULANo ratings yet

- Organic Light Emitting Diode: B. Tech. Seminar ReportDocument19 pagesOrganic Light Emitting Diode: B. Tech. Seminar Reportasif_javedNo ratings yet

- Organic Electronics: A Field of Material ScienceDocument13 pagesOrganic Electronics: A Field of Material ScienceRahul KoraveniNo ratings yet

- Evolution of AMOLED AND SUPER AMOLED Display Technology: A Seminar Report ONDocument23 pagesEvolution of AMOLED AND SUPER AMOLED Display Technology: A Seminar Report ONBhupendra SinghNo ratings yet

- CS & E Dept, AIT ChikmagalurDocument22 pagesCS & E Dept, AIT ChikmagalurMayank ParasharNo ratings yet

- A Seminar Report On Organic Led or Environmental Effective LedDocument17 pagesA Seminar Report On Organic Led or Environmental Effective LedVasu JainNo ratings yet

- OLED Seminar Report on Organic Light Emitting Diode TechnologyDocument18 pagesOLED Seminar Report on Organic Light Emitting Diode TechnologysyedbashaNo ratings yet

- OLED - An Imminent Technology: AbstractDocument6 pagesOLED - An Imminent Technology: AbstractJoren BustamanteNo ratings yet

- Organic Light-Emitting Diodes (OLED) : Presented BY ManvithDocument34 pagesOrganic Light-Emitting Diodes (OLED) : Presented BY ManvithMukeshPatelNo ratings yet

- A Review On The Light Extraction TechniqDocument13 pagesA Review On The Light Extraction TechniqOscarito VázquezNo ratings yet

- OLEDsDocument2 pagesOLEDsMerita DemaNo ratings yet

- Organic Light Emitting Diode 11601 2q5WbPIDocument11 pagesOrganic Light Emitting Diode 11601 2q5WbPIVishnupriya GanapathineniNo ratings yet

- Seminar Report On Amoled TechnologyDocument22 pagesSeminar Report On Amoled TechnologyRanjana Upadhayay88% (8)

- OLED Seminar Covers Types Like Active-Matrix & Benefits Of Thinner DesignsDocument12 pagesOLED Seminar Covers Types Like Active-Matrix & Benefits Of Thinner DesignsIshan UpadhyayNo ratings yet

- Oled (Organic Light Emitting Diode) : Pavithra C 4JN07EC031Document32 pagesOled (Organic Light Emitting Diode) : Pavithra C 4JN07EC031Shashi KiranNo ratings yet

- Devabhaktuni2009 PDFDocument8 pagesDevabhaktuni2009 PDFsandeep devabhaktuniNo ratings yet

- Lecture 1Document22 pagesLecture 1Sameer HussainNo ratings yet

- Samskruti College of Engineering and TechnologyDocument16 pagesSamskruti College of Engineering and TechnologyHemanth TejaNo ratings yet

- Organic Light Emitting DiodesDocument39 pagesOrganic Light Emitting DiodesAbhijith GaneshNo ratings yet

- Organic Light Emitting DiodesDocument3 pagesOrganic Light Emitting DiodesshravanNo ratings yet

- Seminar on Light Emitting PolymersDocument14 pagesSeminar on Light Emitting PolymersSiddyNo ratings yet

- Module 3Document36 pagesModule 3Sridhar C.SNo ratings yet

- Organic Light Emitting Diode ThesisDocument7 pagesOrganic Light Emitting Diode Thesissusanmigliacciostamford100% (1)

- What is OLED? The Revolutionary Organic Light Emitting Diode Display Technology ExplainedDocument2 pagesWhat is OLED? The Revolutionary Organic Light Emitting Diode Display Technology ExplainedharishkavraniNo ratings yet

- U3 L1 Introduction LEDsDocument14 pagesU3 L1 Introduction LEDsThennarasu RamachandranNo ratings yet

- Seminar Report On OLEDDocument26 pagesSeminar Report On OLEDsaicharan1990100% (2)

- CANQUE - Optical PropertiesDocument5 pagesCANQUE - Optical PropertiesAvelyn Mary Canque ClarionNo ratings yet

- Light Emitting PolymersDocument17 pagesLight Emitting PolymersAshim K SNo ratings yet

- 2013 Biometrics Security Based On Face RecognitionDocument118 pages2013 Biometrics Security Based On Face RecognitionmariakristadelacruzNo ratings yet

- PEA306 WorkbookDocument85 pagesPEA306 WorkbookRenuNo ratings yet

- PEA306 WorkbookDocument85 pagesPEA306 WorkbookRenuNo ratings yet

- Ies Syllabus For Electrical Engineering (EE) : APTITUDE PAPER (Stage-I, Paper-I)Document4 pagesIes Syllabus For Electrical Engineering (EE) : APTITUDE PAPER (Stage-I, Paper-I)LeonardoXanMNo ratings yet

- 20 Baking With Electromagnetic WavesDocument4 pages20 Baking With Electromagnetic WavesMallikarjun SutarNo ratings yet

- Lecture - 25 Time Dependent Perturbation Stanford UniversityDocument39 pagesLecture - 25 Time Dependent Perturbation Stanford UniversityGarima TanwarNo ratings yet

- Laser Surgery in Veterinary MedicineDocument389 pagesLaser Surgery in Veterinary MedicineDetian WangNo ratings yet

- Cable Fault Locators SPG40 Cable Fault Location Cable Fault LocatorsDocument1 pageCable Fault Locators SPG40 Cable Fault Location Cable Fault LocatorsKrishan Kumar SharmaNo ratings yet

- BJT (P - 4)Document60 pagesBJT (P - 4)Samshul islamNo ratings yet

- BXE LAB MANUAL STUDY ACTIVE & PASSIVE COMPONENTSDocument79 pagesBXE LAB MANUAL STUDY ACTIVE & PASSIVE COMPONENTSAnkita WankhadeNo ratings yet

- 3WL12252CB321AA2 Datasheet enDocument7 pages3WL12252CB321AA2 Datasheet enWladimir RomeroNo ratings yet

- Eror Code 144Document24 pagesEror Code 144DamatNo ratings yet

- Surface Mount Devices For Hybrid ApplicationsDocument2 pagesSurface Mount Devices For Hybrid Applicationsjulian andres lopezNo ratings yet

- 7.12 NYK Engine Cadet Course Handouts (FEIon)Document6 pages7.12 NYK Engine Cadet Course Handouts (FEIon)TowfiqNo ratings yet

- Technical Information AVRDocument57 pagesTechnical Information AVRPAWAR PRAFULLNo ratings yet

- Experiment-No 2Document5 pagesExperiment-No 2carloNo ratings yet

- PCD 01003 0H CAT5eDocument1 pagePCD 01003 0H CAT5ev6656No ratings yet

- Band Pass Filter: FP-E80-OD01, FP-E80D-OD01Document3 pagesBand Pass Filter: FP-E80-OD01, FP-E80D-OD01Muh IkramNo ratings yet

- HCF4015B: Dual 4-Stage Static Shift Register With Serial Input/Parallel OutputDocument10 pagesHCF4015B: Dual 4-Stage Static Shift Register With Serial Input/Parallel OutputchinnathambijNo ratings yet

- Programmable Precision References Technical Data SheetDocument6 pagesProgrammable Precision References Technical Data Sheet81968No ratings yet

- CMN422 RW3Document9 pagesCMN422 RW3Sean Matthew L. OcampoNo ratings yet

- Signal Conditioning Op-AmpsDocument41 pagesSignal Conditioning Op-AmpsSaleem Haddad100% (1)

- Ir 2136Document36 pagesIr 2136Viet VietNo ratings yet

- Nexans Cable Catalogue QICC - Part4Document19 pagesNexans Cable Catalogue QICC - Part4test examNo ratings yet