Professional Documents

Culture Documents

AMOLED: An Emerging Trends in LED: Abstract-This Paper Presents The Concept of Active Matrix

Uploaded by

Dheeraj KakaraparthiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AMOLED: An Emerging Trends in LED: Abstract-This Paper Presents The Concept of Active Matrix

Uploaded by

Dheeraj KakaraparthiCopyright:

Available Formats

International Journal of Scientific & Engineering Research, Volume 3, Issue 10, October-2012 1

ISSN 2229-5518

AMOLED : An Emerging Trends

in LED

Vivek Purohit#1, Tasneem Banu#2, Komal Daiya#3

1

B.TECH., Third Year, ECE, S.I.T.E. Nathdwara , Rajasthan, India

2

B.TECH., Third Year, ECE, S.I.T.E. Nathdwara , Rajasthan, India

3

B.TECH., Third Year, ECE, S.I.T.E. Nathdwara , Rajasthan, India

1

Vivekpurohit@hotmail.com, 09001444388

2

tasbanu52@yahoo.com, 09784161439

3

k.daiya@yahoo.com, 07568634545

OLED, it can emit light usable in a variety of devices, from

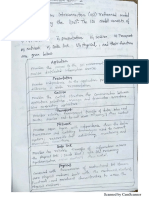

Abstract—This paper presents the concept of Active Matrix flashlights to computers.

Organic Light Emitting Diodes as a modern trend in Light

Emitting Devices. This paper introduces AMOLED device The basic principle behind the working of AMOLED is

structure and operation, AMOLED materials, Evolution of

Electroluminescence. Electroluminescence (EL) is an optical

AMOLED. AMOLED are used in television screens, computer

monitors, small, portable system screens such as mobile phones phenomenon and electrical phenomenon in which a material

and PDA, watches, advertising, information, and indication. emits light in response to the passage of an electric current or

AMOLED are also used in light sources for space illumination to a strong electric field. This is distinct from black body light

and in large-area light-emitting elements. Due to their early stage emission resulting from heat, from a chemical reaction, sound,

of development, they typically emit less light per unit area than or other mechanical action.

inorganic solid-state based LED point-light sources. Different

fabrication processes and technologies are covered. Also Passive-

Matrix OLED driving schemes are outlined. This paper also Electroluminescence is the result of excitation of electrons

describes the market potential of AMOLED by taking modern which releases their energy as photons - light. Prior to

trends in technology into account. recombination, electrons and holes may be separated either by

doping the material to form a p-n junction (in semiconductor

Index Terms—AMOLED, Luminescence, Light Emission, electroluminescent devices such as light-emitting diodes) or

OLED, Energy Efficiency. through excitation by impact of high-energy electrons

accelerated by a strong electric field (as with the phosphors in

electroluminescent displays). Regarding creation of color

I. INTRODUCTION

AMOLED has more control over colour expression because it

A CTIVE Matrix Light Emitting diode is a display

technology for use in mobile devices and televisions.

OLED describes a specific type of thin-film display

only expresses pure colours when electric current stimulates

the relevant pixels. The primary colour matrix is arranged in

red, green and blue pixels which are mounted directly to a

technology in which organic compounds form the printed circuited board. Each individual AMOLED element is

electroluminescent material, and active matrix refers to the housed in a special micro cavity structure designed to greatly

technology behind the addressing of pixels. Since it is an reduce ambient light interference that also improves overall

advancement of OLED technology, AMOLED features a colour contrast. The thickness of the organic layer is adjusted

great deal of the same characteristics as its predecessor. In to produce the strongest light to give a colour picture. Further,

fact, the similarities far the colours are refined with a filter and purified without using

outnumber the differences. a polarizer to give outstanding colour purity.

OLED, at its core, is a

simple light-emitting diode

whose luminescence is II. HISTORY

provided by a film made of

The first observations of electroluminescence in organic

organic components, as

materials were in the early 1950s by A. Bernanose and co-

opposed to traditional

workers at the Nancy-University, France. They applied high-

inorganic materials. By

voltage alternating current (AC) fields in air to materials such

running an electric current

as acridine orange, either deposited on or dissolved in

Fig. 1. Basic Molecule of AMOLED through the electrodes in an

cellulose or cellophane thin films. The proposed mechanism

was either direct excitation of the dye molecules or excitation

IJSER © 2012

http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 3, Issue 10, October-2012 2

ISSN 2229-5518

of electrons. Research into polymer electroluminescence culminated in

1990 with J. H. Burroughes at the Cavendish Laboratory in

In 1960, Martin Pope and co-workers at New York Cambridge reporting a high efficiency green light-emitting

University developed ohmic dark-injecting electrode contacts polymer based device using 100 nm thick films of poly (p-

to organic crystals. They further described the necessary phenylene vinylene).

energetic requirements (work functions) for hole and electron

injecting electrode contacts. These contacts are the basis of III. CONSTRUCTION

charge injection in all modern AMOLED devices. Pope's It consists of an emissive layer, a conductive layer, a

group also first observed direct current (DC) substrate, and both anode and cathode terminals. The emissive

electroluminescence under vacuum on a pure single crystal of layer, where light is made by the emission of radiation whose

anthracene and on anthracene crystals doped with tetracene in frequency is in the visible region is made up of organic plastic

1963 using a small area silver electrode at 400 V. The molecules that transport electrons from the cathode and the

proposed mechanism was field-accelerated electron excitation polymer used is polyfluorene. The conductive layer is made

of molecular fluorescence. up of organic plastic molecules that transport holes from the

anode and the conducting polymer used is polyaniline. The

Pope's group reported in 1965 that in the absence of an substrate that supports AMOLED is made up of flexible

external electric field, the electroluminescence in anthracene plastic, inexpensive glass or metal foil. Anode, that removes

crystals is caused by the recombination of a thermalized electrons when a current flows through the device, is generally

electron and hole, and that the conducting level of anthracene made up of Indium tin oxide and it is transparent and cathode

is higher in energy than the excited energy level. Also in 1965, that injects electrons when a current flows through the device

W. Helfrich and W. G. Schneider of the National Research is made up of metals like aluminium and calcium, which may

Council in Canada produced double injection recombination or may not be transparent depending on the type of AMOLED.

electroluminescence for the first time in an anthracene single

crystal using hole and electron injecting electrodes, the

forerunner of modern double injection devices. In the same

year, Dow Chemical researchers patented a method of

preparing electroluminescent cells using high voltage (500–

1500 V) AC-driven (100–3000 Hz) electrically insulated one

millimetre thin layers of a melted phosphor consisting of

ground anthracene powder, tetracene, and graphite powder.

Their proposed mechanism involved electronic excitation at Fig. 2. Physical Structure of an active-

the contacts between the graphite particles and the anthracene matrix OLED cell

molecules.

IV. WORKING

Device performance was limited by the poor electrical

conductivity of contemporary organic materials. This was A typical AMOLED is composed of a layer of organic

overcome by the discovery and development of highly materials situated between two electrodes, the anode and

conductive polymers. cathode, all deposited on a substrate. The organic molecules

are electrically conductive as a result of delocalization of pi

Electroluminescence from polymer films was first observed electrons caused by conjugation over all or part of the

by Roger Partridge at the National Physical Laboratory in the molecule. These materials have conductivity levels ranging

United Kingdom. The device consisted of a film of poly (n- from insulators to conductors, and therefore are considered

vinyl carbazole) up to 2.2 micro metres thick located between organic semiconductors. The highest occupied and lowest

two charge injecting electrodes. The results of the project were unoccupied molecular orbitals (HOMO and LUMO) of

patented in 1975 and published in 1983. organic semiconductors are analogous to the valence and

conduction bands of inorganic semiconductors.

The first diode device was reported at Eastman Kodak by

Ching W. Tang and Steven Van Slyke in 1987. This device Originally, the most basic AMOLEDs consisted of a single

organic layer. One example was the first light-emitting device

used a novel two-layer structure with separate hole

transporting and electron transporting layers such that synthesised by J. H. Burroughes et al., which involved a single

layer of poly (p-phenylene vinylene). However multilayer

recombination and light emission occurred in the middle of the

organic layer. AMOLEDs can be fabricated with two or more layers in order

to improve device efficiency. As well as conductive

This resulted in a reduction in operating voltage and properties, different materials may be chosen to aid charge

improvements in efficiency and led to the current era of injection at electrodes by providing a more gradual electronic

AMOLED research and device production. profile, or block a charge from reaching the opposite electrode

and being wasted. Many modern AMOLEDs incorporate a

IJSER © 2012

http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 3, Issue 10, October-2012 3

ISSN 2229-5518

simple bilayer structure, consisting of a conductive layer and material and can be useful when trying to study energy

an emissive layer. More recent developments in OLED transfer processes. As current through the device is composed

architecture improves quantum efficiency (up to 19%) by of only one type of charge carrier, either electrons or holes,

using a graded heterojunction. In the graded heterojunction recombination does not occur and no light is emitted. For

architecture, the composition of hole and electron-transport example, electron only devices can be obtained by replacing

materials varies continuously within the emissive layer with a ITO with a lower work function metal which increases the

dopant emitter. The graded heterojunction architecture energy barrier of hole injection. Similarly, hole only devices

combines the benefits of both conventional architectures by can be made by using a cathode comprised solely of

improving charge injection while simultaneously balancing aluminium, resulting in an energy barrier too large for

charge transport within the emissive region. efficient electron injection.

During operation, a voltage is applied across the AMOLED

such that the anode is positive with respect to the cathode. A V. ADVANTAGES

current of electrons flows through the device from cathode to 1) AMOLED are thinner, lighter and more flexible than the

anode, as electrons are injected into the LUMO of the organic crystalline layers in an LED or LCD. The plastic, organic

layer at the cathode and withdrawn from the HOMO at the layers of an OLED are 100 to 500 nanometres thick or about

anode. This latter process may also be described as the 200 times smaller than a human hair.

injection of electron holes into the HOMO. Electrostatic forces 2)They are brighter than LEDs because the organic layers of

bring the electrons and the holes towards each other and they an AMOLED are much thinner than the corresponding

recombine forming an exciton, a bound state of the electron inorganic crystal layers of an LED. Also they do not require

and hole. This happens closer to the emissive layer, because in glass for support which absorbs some light.

organic semiconductors holes are generally more mobile than 3)It has ability to emit light from a surface, low heat

electrons. The decay of this excited state results in a relaxation generation, and environmentally sound compared to

of the energy levels of the electron, accompanied by emission fluorescent lamps.

of radiation whose frequency is in the visible region. The 4)They do not require backlighting like LCDs as they generate

frequency of this radiation depends on the band gap of the light themselves, so they consume much less power than

material, in this case the difference in energy between the LCDs.

HOMO and LUMO. 5)They are easier to produce and can be made to large sizes

because they are essentially plastics, which can be made into

As electrons and holes are fermions with half integer spin, large, thin sheets.

an exciton may either be in a singlet state or a triplet state 6)They can enable a greater artificial contrast ratio that is

depending on how the spins of the electron and hole have been measured in purely dark conditions and have better viewing

combined. Statistically three triplet excitons will be formed for angle compared to LCDs because AMOLED pixels directly

each singlet exciton. Decay from triplet states emit light.

(phosphorescence) is spin forbidden, increasing the timescale 7)They have a faster time response than standard LCD

of the transition and limiting the internal efficiency of screens.

fluorescent devices. Phosphorescent organic light-emitting 8)AMOLED is the most eco-friendly display structure

diodes make use of spin–orbit interactions to facilitate requiring a low amount of energy consumption that only a

intersystem crossing between singlet and triplet states, thus specific spot in need of the light flow represents the image.

obtaining emission from both singlet and triplet states and 9)AMOLEDs can also have a faster response time than

improving the internal efficiency. standard LCD screens. Whereas LCD displays are capable of

between 2 and 16 ms response time offering a refresh rate of

Indium tin oxide (ITO) is commonly used as the anode 60 to 480 Hz, an AMOLED can theoretically have less than

material. It is transparent to visible light and has a high work 0.01 ms response time, enabling up to 100,000 Hz refresh rate.

function which promotes injection of holes into the HOMO 10)The efficiency of AMOLED is 20cd/A to 40cd/A with a

level of the organic layer. A typical conductive layer may lifetime of 50,000 hours and power consumption is 62W

consist of PEDOT:PSS as the HOMO level of this material

generally lies between the work function of ITO and the VI. DISADVANTAGES

HOMO of other commonly used polymers, reducing the

1)Limited lifetime of the organic materials. While red and

energy barriers for hole injection. Metals such as barium and

green OLED films have longer lifetimes, blue organics

calcium are often used for the cathode as they have low work

currently have much shorter lifetimes. However, the lifespan

functions which promote injection of electrons into the LUMO

of AMOLED displays can be increased by improving light

of the organic layer. Such metals are reactive, so require a

outcoupling.

capping layer of aluminium to avoid degradation.

2)The intrusion of water into displays can damage the organic

materials and limit the longevity of more flexible displays.

Single carrier devices are typically used to study the

Therefore, improved sealing processes are important for

kinetics and charge transport mechanisms of an organic

IJSER © 2012

http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 3, Issue 10, October-2012 4

ISSN 2229-5518

practical manufacturing. REFERENCES

3)The fabrication of the substrate is complex and expensive [1] Lin, Chih-Lung; Chen, Yung-Chih. "A Novel LTPS-TFT

process in the production of TFT LCD, so flexible substrates Pixel Circuit Compensating for TFT Threshold-Voltage Shift

such as roll-up displays and displays embedded in fabrics or and OLED Degradation for AMOLED". IEEE Electron

clothing can be used. Device Letters 28: 129. DOI:10.1109/LED.2006.889523

4) It can be easily damaged by water. [2] Hamer, John W.; Arnold, Andrew D.; Boroson, Michael

5)AMOLED have much more expensive manufacturing L.; Itoh, Masahiro; Hatwar, Tukaram K.; Helber, Margaret J.;

process. Miwa, Koichi; Levey, Charles I. et al. (2008). "System design

for a wide-color-gamut TV-sized AMOLED display". Journal

VII. APPLICATIONS of the Society for Information Display 16: 3.

DOI:10.1889/1.2835033

1)The AMOLED are basically used in the touch screens of

[3] Mian Dong; Choi, Y.-S.K; Lin Zhong (July 2009).

mobile phones, at the same time it is also used in computers,

"Power modeling of graphical user interfaces on OLED

netbooks, tablet pc.

displays". Design Automation Conference, 2009. DAC '09.

2)AMOLED displays are used in a growing numbers of 46th ACM/IEEE (IEEE): 652–657.

applications supporting dismounted soldiers and commanders [4] Ashtiani, Shahin J.; Reza Chaji, G.; Nathan, Arokia.

in situational awareness, thermal imaging, simulation and "AMOLED Pixel Circuit With Electronic Compensation of

training. This technology is being integrated in more military Luminance Degradation". Journal of Display Technology 38:

systems and on the long run is expected to replace most small 36. DOI:10.1109/JDT.2006.890711

form-factor LCD displays. Among the applications where

AMOLED technology is already maturing are near-eye

displays of “virtual images” When projected on a head

mounted, helmet mounted or visor (see-through) display, such

image appears like an image in a movie theater or on a

computer monitor, but is created using magnifying optics from

a very small display near to the eye. Such an image displayed

with very high resolution, can appear solid and real, or made

see-through depending on the type optics used.

VIII. FUTURE ASPECTS

Combining a transparent AMOLED display panel with a Solar

Panel at the back. As we know, these transparent AMOLED

panels are made out of all transparent materials, so they

transmit high amounts of light through them. A high

efficiency( 40% or more) Solar panel placed at the back can

help increase the battery life of Smartphones, so they charge

fast(because of smaller battery), but last long(due to charge

from Solar panel). Some calibration might be needed to

acheive color accuracy like that of normal AMOLED display.

This type of setting will in no away affect the aesthetics of the

device as it's completely placed inside the device. The cost of

very high efficiency solar panels may be very high too, but it

should be very less for sizes as small as smartphone display.

IX. CONCLUSION

Active matrix Organic light emitting diodes promise to

make electronic viewing more convenient and ubiquitous as

they are more energy efficient. OLED is so revolutionary that

in the field of illumination it is being hailed as “the first

discovery since Edison”. Today, OLED technology is widely

seen as a next generation component for flat panel displays

and is expected to become a key technology in the

development of flexible displays view the main points of the

paper, do not replicate the abstract as the conclusion. A

conclusion might elaborate on the importance of the work or

suggest applications and extensions.

IJSER © 2012

http://www.ijser.org

You might also like

- Circuits: HobbyDocument372 pagesCircuits: HobbyLeonel rugamaNo ratings yet

- Electronics 27Document34 pagesElectronics 27Diego García MedinaNo ratings yet

- Organic Light-Emitting DiodesDocument17 pagesOrganic Light-Emitting DiodesSuresh KumarNo ratings yet

- IEEE PaperDocument6 pagesIEEE PaperShayer Jaleel0% (1)

- Organic LED: From Wikipedia, The Free EncyclopediaDocument14 pagesOrganic LED: From Wikipedia, The Free Encyclopediaswati131987mishraNo ratings yet

- Report OledDocument33 pagesReport OledRamnani RockyNo ratings yet

- Organic Light Emitting Diode: B. Tech. Seminar ReportDocument19 pagesOrganic Light Emitting Diode: B. Tech. Seminar Reportasif_javedNo ratings yet

- Seminar ReprtcpyDocument33 pagesSeminar Reprtcpysimonrock72No ratings yet

- 1 STDocument2 pages1 STRenuNo ratings yet

- Oled TechnologyDocument28 pagesOled TechnologyMonishkumarNo ratings yet

- Seminar Report Organic Light Emitting DiodeDocument23 pagesSeminar Report Organic Light Emitting DiodesaRAth asgaRdian100% (3)

- A Seminar Report On Organic Led or Environmental Effective LedDocument17 pagesA Seminar Report On Organic Led or Environmental Effective LedVasu JainNo ratings yet

- OLED: A New Display TechnologyDocument10 pagesOLED: A New Display TechnologyArpit Singh BhutaniNo ratings yet

- Dept of EceDocument38 pagesDept of EceBakiesaliyaNo ratings yet

- CS & E Dept, AIT ChikmagalurDocument22 pagesCS & E Dept, AIT ChikmagalurMayank ParasharNo ratings yet

- OLED Technology GuideDocument7 pagesOLED Technology Guidesurendra parlaNo ratings yet

- OLED Seminar Report on Organic Light Emitting Diode TechnologyDocument18 pagesOLED Seminar Report on Organic Light Emitting Diode TechnologysyedbashaNo ratings yet

- 10.1038@s41565 019 0588 6Document2 pages10.1038@s41565 019 0588 6Saurabh ChoudharyNo ratings yet

- Seminar Report 2021-22 OledDocument25 pagesSeminar Report 2021-22 OledClassic PrintersNo ratings yet

- Final Document DastaDocument14 pagesFinal Document Dastabedadala akhilNo ratings yet

- Seminar (FOLED) PDFDocument22 pagesSeminar (FOLED) PDFShruthi MudaliarNo ratings yet

- Seminar (FOLED) PDFDocument38 pagesSeminar (FOLED) PDFShruthi MudaliarNo ratings yet

- Seminar (FOLED)Document38 pagesSeminar (FOLED)Shruthi MudaliarNo ratings yet

- Organic Light Emitting DiodeDocument16 pagesOrganic Light Emitting DiodeBhargavi DoddaNo ratings yet

- OLEDs ReportDocument6 pagesOLEDs Reportphiwayinkosi PwaNo ratings yet

- 1 JMES 607 2014 Karzazi PDFDocument12 pages1 JMES 607 2014 Karzazi PDFVirgiNo ratings yet

- PolyLED PresentationDocument26 pagesPolyLED PresentationDilip MathuriaNo ratings yet

- OLED: Organic Light Emitting Diode Technology ExplainedDocument15 pagesOLED: Organic Light Emitting Diode Technology ExplainedpraneethNo ratings yet

- Evolution of AMOLED AND SUPER AMOLED Display Technology: A Seminar Report ONDocument23 pagesEvolution of AMOLED AND SUPER AMOLED Display Technology: A Seminar Report ONBhupendra SinghNo ratings yet

- Amoled: (Active-Matrix Organic Light Emitting Diode)Document23 pagesAmoled: (Active-Matrix Organic Light Emitting Diode)Pratham KhandelwalNo ratings yet

- Organic LightDocument16 pagesOrganic LightxchoisrasputinNo ratings yet

- 1 Oled For StuydentsDocument9 pages1 Oled For StuydentsHEMANTH BATTULANo ratings yet

- Introduction To Organic Light Emitting DiodesDocument10 pagesIntroduction To Organic Light Emitting DiodesananthadigaNo ratings yet

- Seminar Report On Amoled TechnologyDocument22 pagesSeminar Report On Amoled TechnologyRanjana Upadhayay88% (8)

- OLED - An Imminent Technology: AbstractDocument6 pagesOLED - An Imminent Technology: AbstractJoren BustamanteNo ratings yet

- Devabhaktuni2009 PDFDocument8 pagesDevabhaktuni2009 PDFsandeep devabhaktuniNo ratings yet

- oledDocument9 pagesoleddfr6p9c5h4No ratings yet

- Samskruti College of Engineering and TechnologyDocument16 pagesSamskruti College of Engineering and TechnologyHemanth TejaNo ratings yet

- OLED Technology ExplainedDocument3 pagesOLED Technology ExplainedRicha GargNo ratings yet

- Organic Light Emitting Diode 11601 2q5WbPIDocument11 pagesOrganic Light Emitting Diode 11601 2q5WbPIVishnupriya GanapathineniNo ratings yet

- Organic Led: A Novel Light SourceDocument13 pagesOrganic Led: A Novel Light SourcevineelaviswanathNo ratings yet

- A Review On The Light Extraction TechniqDocument13 pagesA Review On The Light Extraction TechniqOscarito VázquezNo ratings yet

- Oled Seminar ReportDocument25 pagesOled Seminar ReportVarun Pathak100% (8)

- OLEDsDocument2 pagesOLEDsMerita DemaNo ratings yet

- AmoledDocument29 pagesAmoledShariq StreakNo ratings yet

- CANQUE - Optical PropertiesDocument5 pagesCANQUE - Optical PropertiesAvelyn Mary Canque ClarionNo ratings yet

- What is OLED? The Revolutionary Organic Light Emitting Diode Display Technology ExplainedDocument2 pagesWhat is OLED? The Revolutionary Organic Light Emitting Diode Display Technology ExplainedharishkavraniNo ratings yet

- Organic Light Emitting Diode ThesisDocument7 pagesOrganic Light Emitting Diode Thesissusanmigliacciostamford100% (1)

- OLED Study: Organic Light-Emitting Diode TechnologyDocument17 pagesOLED Study: Organic Light-Emitting Diode Technologybabu4527No ratings yet

- 234 SeminorDocument21 pages234 Seminornagaraju jujuriNo ratings yet

- Organic Light Emitting Diode (Oled) : January 2015Document8 pagesOrganic Light Emitting Diode (Oled) : January 2015sforinewsNo ratings yet

- Term Paper - Solid State LightingDocument12 pagesTerm Paper - Solid State LightingFranco LimNo ratings yet

- OLED Display Technology ExplainedDocument11 pagesOLED Display Technology ExplainedtintinchanNo ratings yet

- OLED2Document19 pagesOLED2Saurabh MishraNo ratings yet

- Lecture 1Document22 pagesLecture 1Sameer HussainNo ratings yet

- Anthocyanins Compound As Natural Sensitizers Dyesensitized Solar CellsDocument8 pagesAnthocyanins Compound As Natural Sensitizers Dyesensitized Solar CellsIJAMTESNo ratings yet

- Oleds: Organic Light Emitting DiodesDocument17 pagesOleds: Organic Light Emitting DiodesAbhijitj100% (1)

- OLED: A Modern Display Technology: Mr. Bhrijesh N. Patel, Mr. Mrugesh M. PrajapatiDocument5 pagesOLED: A Modern Display Technology: Mr. Bhrijesh N. Patel, Mr. Mrugesh M. PrajapatiArpit Singh BhutaniNo ratings yet

- Interior Lighting: Fundamentals, Technology and ApplicationFrom EverandInterior Lighting: Fundamentals, Technology and ApplicationNo ratings yet

- Reliability, Robustness and Failure Mechanisms of LED Devices: Methodology and EvaluationFrom EverandReliability, Robustness and Failure Mechanisms of LED Devices: Methodology and EvaluationNo ratings yet

- Color Science and Photometry for Lighting with LEDs and Semiconductor NanocrystalsFrom EverandColor Science and Photometry for Lighting with LEDs and Semiconductor NanocrystalsNo ratings yet

- Pecp: Scanned by CamscannerDocument4 pagesPecp: Scanned by CamscannerDheeraj KakaraparthiNo ratings yet

- Notification APPSC Asst Statistical Officer PostsDocument26 pagesNotification APPSC Asst Statistical Officer PostsHemanth KumarNo ratings yet

- DCCNDocument17 pagesDCCNDheeraj KakaraparthiNo ratings yet

- AbsDocument1 pageAbsDheeraj KakaraparthiNo ratings yet

- Levelling and Differentiating SolventsDocument7 pagesLevelling and Differentiating SolventsChibuike CharlesNo ratings yet

- Tp-1s72a-El-0002-Dtl-0006 - 04-C - Operation and Maintenance Spare Parts For CP System - Approved Code - 03Document9 pagesTp-1s72a-El-0002-Dtl-0006 - 04-C - Operation and Maintenance Spare Parts For CP System - Approved Code - 03Gopalakris AlagarNo ratings yet

- Coeficiente de Difusión Ferricianuro FerrocianuroDocument6 pagesCoeficiente de Difusión Ferricianuro Ferrocianurocaanmaro17No ratings yet

- Diode: Miguel Luis R. Binaday MEE31 ECET320k Engr. Katrina AcapulcoDocument5 pagesDiode: Miguel Luis R. Binaday MEE31 ECET320k Engr. Katrina AcapulcoMiguel BinadayNo ratings yet

- Class 12 CH - 14Document12 pagesClass 12 CH - 14Kumaran100% (1)

- Assignment ECETDocument3 pagesAssignment ECETJohn Joselle MacaspacNo ratings yet

- Oxidation Reduction Past PaperDocument8 pagesOxidation Reduction Past Paperrainbow100% (1)

- 11138.0997 Cathodic Protection of Surface Storage Tank BottomsDocument7 pages11138.0997 Cathodic Protection of Surface Storage Tank Bottomsoussama somraniNo ratings yet

- Daimler Ir Mercedes Benz Strategy Update 2020 PresentationDocument79 pagesDaimler Ir Mercedes Benz Strategy Update 2020 PresentationabcdNo ratings yet

- Chemistry Investigatory Project 1Document16 pagesChemistry Investigatory Project 1Shubhankar Oad100% (1)

- Atomic Structure and PropertiesDocument2 pagesAtomic Structure and PropertiesAnmol TwickleyNo ratings yet

- NTNU TSA SprayingDocument89 pagesNTNU TSA SprayingAnnNo ratings yet

- Fun With ElectroplatingDocument4 pagesFun With ElectroplatingJeffrey PiggottNo ratings yet

- ChemistryDocument240 pagesChemistrymeno.mqiNo ratings yet

- LD3361BS PDFDocument51 pagesLD3361BS PDFPrincess Dainne Fontanilla DahiligNo ratings yet

- Electrolytic Silver Recovery From Fixing Baths in UseDocument11 pagesElectrolytic Silver Recovery From Fixing Baths in Usemuftah76No ratings yet

- General Information: Checks & RepairsDocument24 pagesGeneral Information: Checks & RepairsChristian BedoyaNo ratings yet

- Question Bank Class Xii ChemistryDocument75 pagesQuestion Bank Class Xii ChemistryArvindNarayanNo ratings yet

- Electrodes For Generation of Hydrogen and Oxygen From SeawaterDocument8 pagesElectrodes For Generation of Hydrogen and Oxygen From Seawaterarnab chattopadhyayNo ratings yet

- Docsity Respostas Exercicios Atkins Cap 12Document38 pagesDocsity Respostas Exercicios Atkins Cap 12JOÃO PEDRO BEZERRA OLIVEIRANo ratings yet

- B.Tech First Year: Course Name: Engineering ChemistryDocument29 pagesB.Tech First Year: Course Name: Engineering ChemistryHemant Singh JadounNo ratings yet

- Battery Life Cycle Testing Fiber Optic Temperature SensorsDocument9 pagesBattery Life Cycle Testing Fiber Optic Temperature SensorsRugged MonitoringNo ratings yet

- ICAF Comissioning Check List - MPE Catodic ASDocument4 pagesICAF Comissioning Check List - MPE Catodic ASBùi Công Lộc100% (1)

- Resolving TimeDocument2 pagesResolving TimeEthan PollNo ratings yet

- Chemistry 30AP Electrochemistry Workbook: Net Ionic EquationsDocument27 pagesChemistry 30AP Electrochemistry Workbook: Net Ionic EquationsDayanul AlamNo ratings yet

- Experiment 2 Electrolytic Cell Nurul Husna Binti IbrahimDocument4 pagesExperiment 2 Electrolytic Cell Nurul Husna Binti IbrahimNurul HusnaNo ratings yet

- Chemi G 10 Chap 3 HanoutDocument5 pagesChemi G 10 Chap 3 HanoutYISHAK ABRHAMNo ratings yet

- James Blake Westgard (Auth.) - Electrodynamics - A Concise Introduction-springer-Verlag New York (1996)Document438 pagesJames Blake Westgard (Auth.) - Electrodynamics - A Concise Introduction-springer-Verlag New York (1996)bogus idNo ratings yet