Professional Documents

Culture Documents

Scope of The HACCP Plan

Uploaded by

raja0 ratings0% found this document useful (0 votes)

5 views2 pagesOriginal Title

Scope of the HACCP Plan

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views2 pagesScope of The HACCP Plan

Uploaded by

rajaCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

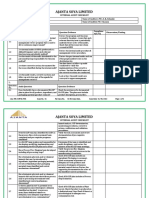

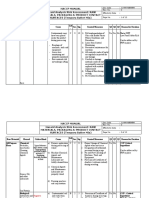

HACCP Plan Form

(1) (2) (3) (4) (5) (6) (7)

Critical Significant Critical Limits for Monitoring Corrective Actions Verification Records

Control Hazards each Preventive

Point Measure

What How Frequency Who

CCP1:

CCP2:

CCP3:

Signature of Company Official: Date:

Example:

(1) (2) (3) (4) (5) (6) (7)

Critical Significant Critical Limits for Monitoring Corrective Actions Verification Records

Control Hazards each Preventive

Point Measure

What How Frequency Who

Biological: 1) No unqualified 1) Check 1) Discard Every time Production Change supplier or Conduct internal Temperature log

CCP1: Cross- product to be used the damaged or before salting manager brand audits report

Prepare and contamination condition of spoiled process begins

salt cabbage pathogen 2) presence of vegetables vegetables Retrain incompetent Records of third-party

growth high salt content employees audits

2) Check 2) Measure

(>5%)

salt content ingredients

accurately

Biological: 1) pH < 4.6 (for Brine pH 1) Check the 1) Every 12 Production Recall food that is Conduct internal Yearly audit:

CCP2: Pathogen room temperature pH level of hours for 2 days manager suspected to have audits Results of

Fermentatio growth fermentation) the brine for room undeclared allergens. laboratory analysis

n temperature Records of third-party

2) pH < 4.6 for 2) Use food Dispose of food that audits pH level log sheet

fermentation under grade pH 2) Every day for has been exposed to

refrigeration meter 4 days for cross-contact during

fermentation storage

under

refrigeration

Biological: Temperature ≤5°C Storage unit Check Everyday Production Dispose of food that Conduct internal Temperature log

CCP3: Cross- must be temperature of manager was not stored in audits report

Refrigerated contamination refrigerated storage unit properly at ≤5°C

storage Records of third-party

audits

Signature of Company Official: Date:

You might also like

- Section 5-2 HACCP PLANDocument3 pagesSection 5-2 HACCP PLANshamroz khanNo ratings yet

- SAMPLEHACCPPLANFORM Sous Vide or Cook ChillDocument2 pagesSAMPLEHACCPPLANFORM Sous Vide or Cook ChillJoeNo ratings yet

- Process Step HACCPDocument2 pagesProcess Step HACCPMeha RajNo ratings yet

- HACCPExample1 PDFDocument6 pagesHACCPExample1 PDFSaraa HusainNo ratings yet

- Haccp PlanDocument3 pagesHaccp PlanResya Andita PutriNo ratings yet

- Example HACCP StudyDocument10 pagesExample HACCP StudyAdnan MeghaniNo ratings yet

- Hazard Analysis - FinalDocument3 pagesHazard Analysis - FinalPrasad D VishnuNo ratings yet

- Yogurt HACCP Plan PDFDocument38 pagesYogurt HACCP Plan PDFserenela100% (2)

- NCC-IMS-FM-05-02 - OPRP Control Chart Is7.0Document9 pagesNCC-IMS-FM-05-02 - OPRP Control Chart Is7.0baseimNo ratings yet

- HACCP Review GuideDocument14 pagesHACCP Review Guideahmad mahmoodNo ratings yet

- HACCP Plan For The Production of Squid BallDocument1 pageHACCP Plan For The Production of Squid BallCallisto Regulus100% (1)

- Hazard Analysis Critical Control Point (HACCP)Document4 pagesHazard Analysis Critical Control Point (HACCP)Paul LVNo ratings yet

- Hazard Analysis & HACCP WorksheetsDocument3 pagesHazard Analysis & HACCP WorksheetsJohn Cedric DullaNo ratings yet

- D - dms2000 - QMS - Active - FSMS - Standard Operating Procedures - Abattoir - SOP010...Document3 pagesD - dms2000 - QMS - Active - FSMS - Standard Operating Procedures - Abattoir - SOP010...Vimbainashe ChigumbuNo ratings yet

- LC HAGroundBeefDocument2 pagesLC HAGroundBeefAnar MahmudovNo ratings yet

- Status FSSC 22000 Final Audit (Updated)Document4 pagesStatus FSSC 22000 Final Audit (Updated)sajid waqasNo ratings yet

- HACCP ImplementationDocument25 pagesHACCP ImplementationAronn SiamNo ratings yet

- Ame of Control Measure(s) To Be Verified Verification Procedure When Who RecordsDocument3 pagesAme of Control Measure(s) To Be Verified Verification Procedure When Who RecordsAnggoro AntonoNo ratings yet

- HACCP Plan Fruit YoghurtDocument8 pagesHACCP Plan Fruit YoghurtJaynie Lee VillaranNo ratings yet

- Haccp Manual Presentation: By: Foodacy IndustriesDocument19 pagesHaccp Manual Presentation: By: Foodacy Industrieseizat abasNo ratings yet

- Supplier Pre-Assessment AuditDocument8 pagesSupplier Pre-Assessment AuditNor Idayu IsmailNo ratings yet

- HACCP Plan Template Cook ChillDocument21 pagesHACCP Plan Template Cook ChillAnastasia IonasNo ratings yet

- Internal Audit Checklist Food Safety-MRDocument5 pagesInternal Audit Checklist Food Safety-MRRavi BaghelNo ratings yet

- Part IV Food SafetyDocument9 pagesPart IV Food Safetyapi-606957005No ratings yet

- Establish Critical Limits Principle # 3Document4 pagesEstablish Critical Limits Principle # 3kolita kamalNo ratings yet

- Submitted By: Lantape, Ryan Luis P. RISK 111 Balandang, Jymel Gabriel Submitted To: Mrs. Mylene Dela Cruz Palmares, Vincent RileyDocument3 pagesSubmitted By: Lantape, Ryan Luis P. RISK 111 Balandang, Jymel Gabriel Submitted To: Mrs. Mylene Dela Cruz Palmares, Vincent RileyJhon Rommel Dela Cruz-OdiamanNo ratings yet

- هاسب تصنيع الشيكولاتةDocument20 pagesهاسب تصنيع الشيكولاتةMuhammed aNo ratings yet

- Audit Checklist - ISO 22000 Food Safety ManagementDocument18 pagesAudit Checklist - ISO 22000 Food Safety ManagementChoirul HudaNo ratings yet

- Rii Hazards Blank FormDocument13 pagesRii Hazards Blank FormArsalan PervezNo ratings yet

- HACCP Plan ExampleDocument20 pagesHACCP Plan ExampleMenna WahedNo ratings yet

- HACCP Guide 1705316356Document57 pagesHACCP Guide 1705316356ahmed.tomakNo ratings yet

- 5.2 Internal Insp200705Document13 pages5.2 Internal Insp200705John D. BalyaNo ratings yet

- Validation - Pathogen - Reduction StepsDocument17 pagesValidation - Pathogen - Reduction StepsCHERWINNo ratings yet

- Would A Loss of Control Lead To Risk of Illness or Injury: Decision TreeDocument3 pagesWould A Loss of Control Lead To Risk of Illness or Injury: Decision Tree20125320No ratings yet

- FSMS - Advance PlanningDocument28 pagesFSMS - Advance PlanningSidNo ratings yet

- INDIV PERFORMANCE COMMITMENT AND REVIEWDocument12 pagesINDIV PERFORMANCE COMMITMENT AND REVIEWEdgar DumagpiNo ratings yet

- 4.0 Food Safety and Quality SystemDocument44 pages4.0 Food Safety and Quality SystemSiti Aisyah MahamudNo ratings yet

- OPRP 4 Management of Cleaning ValidationDocument1 pageOPRP 4 Management of Cleaning ValidationAngger100% (1)

- CIP Checklist: CIP Unit Preparation (In CIP Room)Document1 pageCIP Checklist: CIP Unit Preparation (In CIP Room)Rizwan SultanNo ratings yet

- Internal Training on Record Keeping and Monitoring Critical Control Points at Platinium Marine ProductsDocument23 pagesInternal Training on Record Keeping and Monitoring Critical Control Points at Platinium Marine ProductsHas platiniumNo ratings yet

- Kiem Soat Hoa Chat Xu Ly Con TrungDocument5 pagesKiem Soat Hoa Chat Xu Ly Con TrungDung NguyenNo ratings yet

- HACCP ModuleDocument31 pagesHACCP ModuleAsu AsuNo ratings yet

- REC326 FSSC Auditor Training/ Sign Off SheetDocument14 pagesREC326 FSSC Auditor Training/ Sign Off SheetFabricio NoriegaNo ratings yet

- Fish Haccp Model 2 - enDocument14 pagesFish Haccp Model 2 - enTRANDAFNo ratings yet

- HACCP Manual Hazard Analysis and Risk Assessment for Tempura Batter Mix Raw MaterialsDocument10 pagesHACCP Manual Hazard Analysis and Risk Assessment for Tempura Batter Mix Raw Materialsclarisa martinezNo ratings yet

- Super Sani Cloth Tech Data Bulletin - 0619 UPDATE - 07168610Document4 pagesSuper Sani Cloth Tech Data Bulletin - 0619 UPDATE - 07168610Alexandra' LuqueNo ratings yet

- Validate HACCP SystemsDocument45 pagesValidate HACCP SystemsSartika MutiarasaniNo ratings yet

- Salt FishDocument21 pagesSalt FishFayed100% (1)

- HACCP Plan WorksheetDocument2 pagesHACCP Plan WorksheetzhonglulogisticsNo ratings yet

- 13.2 HACCP Plans ExamplesDocument10 pages13.2 HACCP Plans ExamplesRodgers MtongaNo ratings yet

- HACCP OverviewDocument21 pagesHACCP OverviewSherylleneAguileraNo ratings yet

- 238464354-Template-Traceability-Audit-Checklist-ExampleDocument2 pages238464354-Template-Traceability-Audit-Checklist-ExampleTrinh DuNo ratings yet

- Marriott's Global HACCP Food Safety PlanDocument65 pagesMarriott's Global HACCP Food Safety Plansyed zia ul hassan100% (3)

- HACCP Study 3Document7 pagesHACCP Study 3Karissa Evangelista33% (3)

- NSF Audit CHK ListDocument15 pagesNSF Audit CHK Listmueen khanNo ratings yet

- Vendor Audit Checklist PDFDocument3 pagesVendor Audit Checklist PDFMaria Magdalena Palacios HernandezNo ratings yet

- FTECH4426 - Lab Act 2 HACCPDocument2 pagesFTECH4426 - Lab Act 2 HACCPTuts ValdezNo ratings yet

- Mushrooms as Functional FoodsFrom EverandMushrooms as Functional FoodsPeter C. CheungNo ratings yet

- UNDERSTANDING FOOD HYGIENEDocument22 pagesUNDERSTANDING FOOD HYGIENESahilDalalNo ratings yet

- Designing An LLC ResonantDocument30 pagesDesigning An LLC Resonant劉品賢No ratings yet

- Marking Scheme Bio Paper 3 07Document16 pagesMarking Scheme Bio Paper 3 07genga100% (1)

- Calculus (Solution To Assignment Iv) : February 12, 2012Document4 pagesCalculus (Solution To Assignment Iv) : February 12, 2012Mawuena MelomeyNo ratings yet

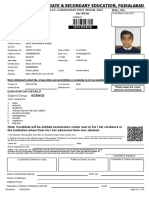

- Roll No. Form No.: Private Admission Form S.S.C. Examination First Annual 2023 9th FRESHDocument3 pagesRoll No. Form No.: Private Admission Form S.S.C. Examination First Annual 2023 9th FRESHBeenish MirzaNo ratings yet

- Campus Event ReflectionDocument2 pagesCampus Event ReflectiondntbenfordNo ratings yet

- IPv4 - IPv4 Header - IPv4 Header Format - Gate VidyalayDocument15 pagesIPv4 - IPv4 Header - IPv4 Header Format - Gate VidyalaySakshi TapaseNo ratings yet

- ADU4518R7v06: Antenna SpecificationsDocument1 pageADU4518R7v06: Antenna SpecificationsAndrewNo ratings yet

- Core Java AdvancedDocument103 pagesCore Java AdvancedRavi Chandra Reddy MuliNo ratings yet

- Resume Ked 2 1Document2 pagesResume Ked 2 1api-273985023No ratings yet

- Beteq2010 Part 1Document198 pagesBeteq2010 Part 1Zilmar JustiNo ratings yet

- REST API For Oracle Fusion Cloud HCMDocument19 pagesREST API For Oracle Fusion Cloud HCMerick landaverdeNo ratings yet

- Understanding and Applying The ANSI/ ISA 18.2 Alarm Management StandardDocument260 pagesUnderstanding and Applying The ANSI/ ISA 18.2 Alarm Management StandardHeri Fadli SinagaNo ratings yet

- SATR-W-2007 Rev 7Document4 pagesSATR-W-2007 Rev 7QA QCNo ratings yet

- Plummer Blocks 2500-E LowresDocument66 pagesPlummer Blocks 2500-E LowresChintamani VeerrajuNo ratings yet

- Critical Factors Influencing Infrastructure ProvisionDocument6 pagesCritical Factors Influencing Infrastructure Provisionlulut falaNo ratings yet

- GCC Lab ManualDocument61 pagesGCC Lab ManualMadhu BalaNo ratings yet

- Product Information: Automotive Sensor UMRR-96 TYPE 153Document18 pagesProduct Information: Automotive Sensor UMRR-96 TYPE 153CORAL ALONSONo ratings yet

- What is Strategic Human Resource ManagementDocument8 pagesWhat is Strategic Human Resource ManagementYashasvi ParsaiNo ratings yet

- Install 13 SEER condensing unitDocument9 pagesInstall 13 SEER condensing unitalfredoNo ratings yet

- Bridal Boutique Business Plan SummaryDocument35 pagesBridal Boutique Business Plan Summarykira5729No ratings yet

- Aluminum Wire Data and PropertiesDocument31 pagesAluminum Wire Data and PropertiesMaria SNo ratings yet

- Satelec X Mind DC Brochure enDocument133 pagesSatelec X Mind DC Brochure enAndres Alberto Sanchez LaraNo ratings yet

- Strings: - A String Is A Sequence of Characters Treated As A Group - We Have Already Used Some String LiteralsDocument48 pagesStrings: - A String Is A Sequence of Characters Treated As A Group - We Have Already Used Some String LiteralsJNUNo ratings yet

- Answer Sheet ToeicDocument2 pagesAnswer Sheet ToeicNgọc PhanNo ratings yet

- Geospatial Assessment of Climatic Variability and Aridity in Katsina State, NigeriaDocument11 pagesGeospatial Assessment of Climatic Variability and Aridity in Katsina State, NigeriaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Transfer Taxes and Basic SuccessionDocument59 pagesTransfer Taxes and Basic SuccessionARC SVIORNo ratings yet

- CLSI M100-S20 (2010) Cephalosporin and Aztreonam Breakpoint Revisions Fact Sheet I. Terminology / ProcessesDocument10 pagesCLSI M100-S20 (2010) Cephalosporin and Aztreonam Breakpoint Revisions Fact Sheet I. Terminology / ProcessesCarol TieppoNo ratings yet

- Emmanuel Oneka - CV-3Document3 pagesEmmanuel Oneka - CV-3Emmanuel OnekaNo ratings yet

- Sonic sdw45Document2 pagesSonic sdw45Alonso InostrozaNo ratings yet