Professional Documents

Culture Documents

D DS 01 Smard M Series 2019 06 en

Uploaded by

Joost PostOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

D DS 01 Smard M Series 2019 06 en

Uploaded by

Joost PostCopyright:

Available Formats

COM PR E SS E D AI R

T E C H N O LO GY

Refridgeration dryers

S M A R D M S E R I E S - M A R I N E A P P L I CAT I O N

B E N E F I T S A N D F E AT U R E S

• Corrosion-free air circuit, made of copper and stainless steel

• Powder-coated housing

• Halogen-free cables

• Potential-free alarm contact

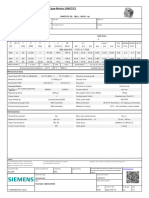

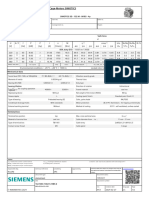

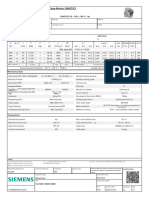

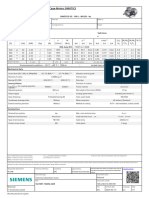

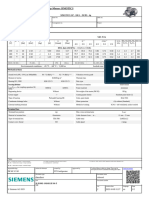

Technical Data 18 - 83 98 - 266 300 - 1000

Inlet / Outlet On rear Flanges top position

Bypass – –

Refrigerant R134a R407A

Air cooling –

Water cooling –

Heat Exchanger Stainless steel plate Stainless steel plate

IP rating IP 44 IP 44

Dew point indication Colour change LED Digital

Potential free alarm contact

Time-controlled condensate drain

Electronic level-controlled drain

General Data

Medium Compressed Air

Housing Steel

Colour - Panels M 18 – M 266 7,5 BG 7/2 (Munsell), M 300 – M 1000: RAL 7016 (Anthracite-grey)

Location Indoors

standard optional – not available

Dimensions Power

Model Flow Rate* Connection Weight el. Connection

A B C Consumption

m3/h mm kg V/Ph/Hz kW

Smard M 18 37 394 368 568 30 0.34

3/4"

Smard M 50 92 483 526 510 42 0.55

Smard M 60 111 46 0.60

Smard M 83 154 1" 336 763 525 51 0.65

Smard M 98 182 55 230/1/60

1.20

Smard M 133 246 73

440 917 718

Smard M 166 308 1 1/2“ 1.50

86

Smard M 201 372 2.00

520 966 760

Smard M 266 492 2" 95 2.70

Smard M 300 1,000 3.40

560

Smard M 400 1,200 3.70

1,190 869

Smard M 500 1,500 DN 80 580 4.90

400/3/50

Smard M 600 1,800 1,942 600 5.50

460/3/60

Smard M 700 2,400 890 7.20

Smard M 900 3,000 1,213 1,369 980 8.90

DN 100

Smard M 1000 3,200 1,050 9.20

* ISO 7183, based on the intake volume of the compressor at +20°C and 1 bar (a), operating pressure 7 bar (g), inlet temperature +45°C, ambient temperature +45°C, pressure dew point +3°C

Technical data and specification are subject to change without prior notice

C C

B B

A A

M 18 - 266 M 300 - 1000

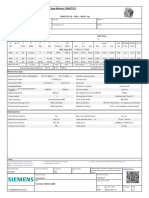

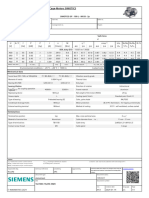

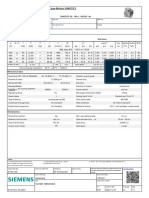

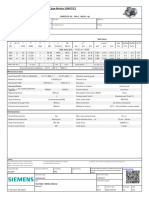

Design Data* Min. Nom. Max.

Operating pressure 3 bar (g) 7 bar (g) 16 bar (g)

Inlet temperature +4 °C +45 °C +55 °C

Ambient temperature +4 °C +45 °C +50 °C

* The following correction factors need to be used to select the correct unit for other operating conditions.

Deltech® refrigerant compressed air dryers are best used with a Deltech® PF pre-filter and a HF after-filter.

Correction factors for different operating pressures in bar (g) (F1)

bar (g) 3 4 5 6 7 8 9 10 11 12 13 14

Smard M 18 - 266 0.72 0.85 0.92 0.96 1.00 1.04 1.10 1.13 1.15 1.18 1.21 1.24

Smard M 300 - 1000 – – 0.91 0.95 1.00 1.03 1.09 1.11 1.14 1.17 1.20 –

Correction factors for different inlet temperatures in °C (F2)

°C +45 °C +50 °C +55 °C

Smard M 18 - 266 1.00 0.89 0.61

Smard M 300 - 1000 1.00 0.89 0.60

Selection example Calculation

Compressor capacity (V1) 900 m3/h

V1 900

Operating pressure (F1) 6 bar (g) V2 = = = 1,064 m3/h

Inlet temperature (F2) +50 °C F1 · F2 · F3 0.95 · 0.89 · 1

Ambient temperature (F3) +45 °C Selection: Smard M 400

V2 Required dryer capacity

Correction factors for different ambient temperatures in °C (F3)

°C +45 °C +50 °C

Smard M 18 - 266 1.00 0.94

Smard M 300 - 1000 1.00 1.00

SPX Flow Technology Germany GmbH

Konrad-Zuse-Straße 25 | D-47445 Moers

Tel.: +49 (0) 28 41 / 8 19-0 | Fax: +49 (0) 28 41 / 8 19 83

E-Mail: info@spx-deltech.de

www.spx-deltech.de | www.spxflow.com

SPX FLOW, Inc. reserves the right to incorporate our latest design and material changes without notice or obligation.

Design features, materials of construction and dimensional data, as described in this bulletin, are provided for your information only and should not be relied upon unless confirmed in writing. Please contact your

local sales representative for product availability in your region. For more information visit www.spxflow.com.

The green “ ” and “ ” are trademarks of SPX FLOW, Inc.

DT_Smard-M-Series_GB Version_06/2019 COPYRIGHT © 2019 SPX FLOW INC.

You might also like

- ZAMIL PY Series Installation, Operation & Maintenance ManualDocument33 pagesZAMIL PY Series Installation, Operation & Maintenance Manualambuenaflor67% (9)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Revenue Process: Customer Master File MaintenanceDocument1 pageRevenue Process: Customer Master File MaintenanceRiza Mae Alce100% (1)

- BOOST ExamplesDocument128 pagesBOOST Examplesiturcic9No ratings yet

- MTDSilent LEA089Document6 pagesMTDSilent LEA089Alan TanNo ratings yet

- 1LE1002-1DB43-4FB4 Datasheet enDocument1 page1LE1002-1DB43-4FB4 Datasheet enshashibagewadiNo ratings yet

- Domestic - MTD SilentDocument6 pagesDomestic - MTD SilentVan Vinh NguyenNo ratings yet

- 1LE1503-1DB43-4FK4 Datasheet enDocument1 page1LE1503-1DB43-4FK4 Datasheet enNicolas RossettoNo ratings yet

- 1le1523 1eb43 4FB4Document2 pages1le1523 1eb43 4FB4pmf engineering limitedNo ratings yet

- 1le1523 1eb43 4ab4Document2 pages1le1523 1eb43 4ab4pmf engineering limitedNo ratings yet

- 0.18KW4P Gad-200 PDFDocument1 page0.18KW4P Gad-200 PDFprasadNo ratings yet

- Baumer MTA3 EN DSBaumer MTA3 EN DSDocument3 pagesBaumer MTA3 EN DSBaumer MTA3 EN DSMilan JovicicNo ratings yet

- Siemens Motors DatasheetDocument2 pagesSiemens Motors DatasheetFar DesignNo ratings yet

- 1LE1601-1AB53-4FB4-Z F01+F11+F50+L05 Datasheet enDocument2 pages1LE1601-1AB53-4FB4-Z F01+F11+F50+L05 Datasheet enTien NguyenNo ratings yet

- 1le1503 0CB22 2ka4 Z - H22+L25Document3 pages1le1503 0CB22 2ka4 Z - H22+L2501666754614No ratings yet

- 1LE1503-2AA43-4AA4 Datasheet enDocument1 page1LE1503-2AA43-4AA4 Datasheet enAndrei LupuNo ratings yet

- 3827-E10-063 - Modulating Control Valve - EDocument6 pages3827-E10-063 - Modulating Control Valve - EMohamed Elsaid El ShallNo ratings yet

- 1LE1503-1CB21-7AB4-Z B02+D22+L22+Y82 Datasheet enDocument2 pages1LE1503-1CB21-7AB4-Z B02+D22+L22+Y82 Datasheet enMostafaElrakhawyNo ratings yet

- HDL-PSG3442-300 Filtro Solberg - Filtro de Descarga de Equipo PDFDocument1 pageHDL-PSG3442-300 Filtro Solberg - Filtro de Descarga de Equipo PDFYacila AlvaradoNo ratings yet

- 1LE1503-1DB21-7AB4-Z B02+D22+L22+Y82 Datasheet enDocument2 pages1LE1503-1DB21-7AB4-Z B02+D22+L22+Y82 Datasheet enMostafaElrakhawyNo ratings yet

- Data Sheet For SIMOTICS GP 1LE0143 Low-Voltage MotorDocument1 pageData Sheet For SIMOTICS GP 1LE0143 Low-Voltage MotorkayakurbanoNo ratings yet

- 1LE1503-1EB21-7AB4-Z B02+D22+L22+Y82 Datasheet enDocument2 pages1LE1503-1EB21-7AB4-Z B02+D22+L22+Y82 Datasheet enMostafaElrakhawyNo ratings yet

- Automig 80S-B2 / Tigfil 80S-B2: Classification: ApprovalsDocument1 pageAutomig 80S-B2 / Tigfil 80S-B2: Classification: ApprovalssatnamNo ratings yet

- 1le1002 1ca13 4aa4Document3 pages1le1002 1ca13 4aa4Atlanta BoliviaNo ratings yet

- 1LE1003-1AA43-4AB4 Datasheet enDocument1 page1LE1003-1AA43-4AB4 Datasheet enAhmed Mahmoud AliNo ratings yet

- 1LE1604 1DB43 4GB4 Datasheet enDocument1 page1LE1604 1DB43 4GB4 Datasheet ennarminaNo ratings yet

- JCB ZTS 8025-8030 MINI ExcavatorDocument3 pagesJCB ZTS 8025-8030 MINI ExcavatorJohnny Zhang100% (1)

- Aac 500, Aac 1267, Acsr 60Document5 pagesAac 500, Aac 1267, Acsr 60Rahmat IzaiziNo ratings yet

- RK1B7 A193b7m - A193b7 A193b7m EngDocument1 pageRK1B7 A193b7m - A193b7 A193b7m EngNarimane BentyNo ratings yet

- RM50DA/CA/C1A-XXF: Insulated TypeDocument3 pagesRM50DA/CA/C1A-XXF: Insulated TypevasquezbencomoNo ratings yet

- 1LE1502 1EB23 4AA4 Datasheet enDocument1 page1LE1502 1EB23 4AA4 Datasheet enRasool SabeghiNo ratings yet

- 1LE1501-1EB43-4JA4 Datasheet enDocument1 page1LE1501-1EB43-4JA4 Datasheet enIbraheem AlfalahatNo ratings yet

- 1LE1502-1EA23-4AA4-Z D22+D47 Datasheet enDocument2 pages1LE1502-1EA23-4AA4-Z D22+D47 Datasheet enmohamed gomaaNo ratings yet

- Specifications: Indoor UnitDocument2 pagesSpecifications: Indoor UnitJohan FloresNo ratings yet

- 1LE1001-1AB42-2JA4 Datasheet enDocument1 page1LE1001-1AB42-2JA4 Datasheet enMulyanto Abinya Farras-IzyanNo ratings yet

- Aire Ventana r32 110v Mwrut18br TGMDocument2 pagesAire Ventana r32 110v Mwrut18br TGMdanielbarbosagoncalvNo ratings yet

- 1LE1523-1EB43-4AA4 Datasheet enDocument1 page1LE1523-1EB43-4AA4 Datasheet enmuhammad nazmiNo ratings yet

- 1LE1003-1AA43-4FA4-Z B02 Datasheet enDocument2 pages1LE1003-1AA43-4FA4-Z B02 Datasheet enRefresh DrNo ratings yet

- 1LE1003-0EB42-2FA4-Z F01+F11 Datasheet enDocument2 pages1LE1003-0EB42-2FA4-Z F01+F11 Datasheet enUmair MirzaNo ratings yet

- 1LE1003-0EB42-2FA4-Z F01+F11 Datasheet enDocument2 pages1LE1003-0EB42-2FA4-Z F01+F11 Datasheet enUmair MirzaNo ratings yet

- 3827-E10-062 - Two Position Valve - DDocument4 pages3827-E10-062 - Two Position Valve - DMohamed Elsaid El ShallNo ratings yet

- 1LE1503-2BB03-4AA4 Datasheet enDocument1 page1LE1503-2BB03-4AA4 Datasheet enAnil Kumar KnNo ratings yet

- Spec He Urea P-4Document144 pagesSpec He Urea P-4M Aditya Regisyah PNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1AV1164B Simotics GP - 160 L - Im B3 - 4PDocument3 pagesData Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1AV1164B Simotics GP - 160 L - Im B3 - 4PMeky Bima TokoNo ratings yet

- Electrical Turrets: Instruction For Use and MaintenanceDocument14 pagesElectrical Turrets: Instruction For Use and MaintenanceАлександр ЕвграфовNo ratings yet

- VB 536 Ag DR: TypeDocument1 pageVB 536 Ag DR: TypeMaffone NumerounoNo ratings yet

- Mve 500 - 3Document2 pagesMve 500 - 3Amol SarinNo ratings yet

- Silnik - Karta Katalogowa 1LE1002 1AB42 2FA4 Z Y99Document2 pagesSilnik - Karta Katalogowa 1LE1002 1AB42 2FA4 Z Y99artur.sowaNo ratings yet

- 3 Phase Motor DetailDocument1 page3 Phase Motor Detailhashir zamanNo ratings yet

- Nexans - Medium Hard Drawn Copper Cabl...Document1 pageNexans - Medium Hard Drawn Copper Cabl...hamza salamiNo ratings yet

- 1le1502 2BB03 4aa4Document3 pages1le1502 2BB03 4aa4Atlanta Bolivia100% (1)

- MIN FLOW CalculationDocument6 pagesMIN FLOW Calculationdilip matalNo ratings yet

- After-Coolers Air Belt GuardDocument2 pagesAfter-Coolers Air Belt GuardMauricioNo ratings yet

- 8 5-MM85DHDocument3 pages8 5-MM85DHnappyNo ratings yet

- 国际39M混凝土泵车卖点介绍Specification & Advantages of SYG39Document30 pages国际39M混凝土泵车卖点介绍Specification & Advantages of SYG39Alex MazaNo ratings yet

- Mve 500 - 3Document1 pageMve 500 - 3Fethi ChabaneNo ratings yet

- Barhi Plant Grid-13 Cold FormDocument6 pagesBarhi Plant Grid-13 Cold FormRakesh SharmaNo ratings yet

- Motovibrator OLI MVE 500/3E-40A0 - SpecsDocument2 pagesMotovibrator OLI MVE 500/3E-40A0 - SpecsfernandoalvesvnbNo ratings yet

- Selfeeder ElectricDocument32 pagesSelfeeder Electricasta seikiNo ratings yet

- Anglo–American Microelectronics Data 1968–69: Manufacturers A–PFrom EverandAnglo–American Microelectronics Data 1968–69: Manufacturers A–PNo ratings yet

- Master of Library and Information ScienceDocument5 pagesMaster of Library and Information ScienceGaurav NavaleNo ratings yet

- Stotram Digitalized byDocument3 pagesStotram Digitalized bymanchiraju raj kumarNo ratings yet

- File 4Document5 pagesFile 4Sri NehaNo ratings yet

- Boot Magazine - Issue 04 - Lust List 96 - December 1996Document124 pagesBoot Magazine - Issue 04 - Lust List 96 - December 1996José ArceNo ratings yet

- Sri Mittapalli College of EngineeringDocument41 pagesSri Mittapalli College of EngineeringbrsreddyNo ratings yet

- SDLC ModelDocument11 pagesSDLC Modeladititech724No ratings yet

- Practical Research 2 Module 1Document11 pagesPractical Research 2 Module 1Charry CervantesNo ratings yet

- Detailed Lesson Plan - LMVGDocument10 pagesDetailed Lesson Plan - LMVGangel caoNo ratings yet

- AP Computer Science Principles Course OverviewDocument2 pagesAP Computer Science Principles Course OverviewMohamed AliNo ratings yet

- Ark2Tech Consultants For Ship Design Maritime Oil & Gas OffshoreDocument4 pagesArk2Tech Consultants For Ship Design Maritime Oil & Gas Offshorerohitf117No ratings yet

- Briefing-Note-9---Soft-LandingsDocument6 pagesBriefing-Note-9---Soft-LandingsIDEAL DRAGONSNo ratings yet

- PC - Print - 11-15-24 AmDocument4 pagesPC - Print - 11-15-24 AmTheo AnggaraNo ratings yet

- ElectricalDocument40 pagesElectricalAkash SNo ratings yet

- Statistics AssignmentDocument13 pagesStatistics AssignmentBishal BanikNo ratings yet

- Literature Review On BpoDocument8 pagesLiterature Review On Bpoafmzwlpopdufat100% (1)

- Harman Kardon HK 3380 - Mk2 Service ManualDocument54 pagesHarman Kardon HK 3380 - Mk2 Service ManualDimceStereophileski100% (2)

- DM 246 Division Research TrainingDocument7 pagesDM 246 Division Research Traininglsh AshNo ratings yet

- NC252MP: High Efficiency Self Contained Amplifier ModuleDocument19 pagesNC252MP: High Efficiency Self Contained Amplifier ModuleMeego TestsNo ratings yet

- Basic Electronic ComponentsDocument5 pagesBasic Electronic ComponentsHa FaiazNo ratings yet

- C Variables: Declaration & Initialization of C VariablesDocument3 pagesC Variables: Declaration & Initialization of C VariablesPrinting CorporateNo ratings yet

- Eco-244 Course-Outline Spring2012Document2 pagesEco-244 Course-Outline Spring2012Madiha Kabir ChowdhuryNo ratings yet

- Dc6Cautp4P3X: Product DatasheetDocument3 pagesDc6Cautp4P3X: Product DatasheetKailash KumarNo ratings yet

- Depth (M) Soil Description Depth (M) Soil Description: Subsurface Exploration (SPT) Geoforma Engenharia LtdaDocument9 pagesDepth (M) Soil Description Depth (M) Soil Description: Subsurface Exploration (SPT) Geoforma Engenharia LtdaJAVIER ADRIANNo ratings yet

- SQL QuizDocument8 pagesSQL QuizMazaher Mohamedali0% (3)

- Map Design: 1) ImaginationDocument10 pagesMap Design: 1) ImaginationDavid KitaviNo ratings yet

- Factors Affecting Internal ResistanceDocument23 pagesFactors Affecting Internal Resistancethisisaaqib62% (29)

- Plasma Ion NitridingDocument2 pagesPlasma Ion Nitridingyadu kumar singhNo ratings yet

- Io ListDocument4 pagesIo ListsswahyudiNo ratings yet