Professional Documents

Culture Documents

Specs

Specs

Uploaded by

Mathieu AlekeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Specs

Specs

Uploaded by

Mathieu AlekeCopyright:

Available Formats

Pre-Engineered Buildings

Standard Product Specifications

Standard Product Specifications

Index

1. General

1.1 Definition

1.2 Standard Structural Framing Systems

1.3 Standard Framing Features

1.4 Building Components

2. Design

2.1 Codes

2.2 Loads

3. Material Specifications

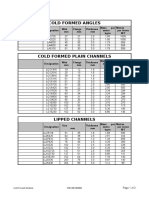

3.1 Structural Members

3.2 Panels

3.3 Trims & Gutters

3.4 Bolts

3.5 Fasteners

3.6 Other Items

4. Shop Paint

4.1 Structural Members

5. Building Accessories

5.1 Heavy Duty Personnel Doors

5.2 Steel Sliding Doors

5.3 Steel Roll Up Doors

5.4 Windows

5.5 Adjustable Steel Louvers

5.6 Gravity Ventilators

6. Structural Sub-Systems

6.1 Roof Extensions

6.2 Canopies

6.3 Fascias and Parapets

7. Foundations and Anchorage

8. Submittals

8.1 Approval Drawings

8.2 Erection Drawings

8.3 Design Calculations

8.4 Design Certification

Standard Product Specifications Pre-Engineered Buildings

1. General 1.1.11 The building clear height is the distance from

finished floor level (FFL) to the bottom of the end

plate of the rafter at the knee.

1.1 Definition

1.1.1 The building, as specified herein, consists of 1.2 Standard Structural Framing Systems

columns, rafters, bracing, connection clips, roof

purlins, wall girters, roof and wall sheeting, 1.2.1 Clear Span (CS) buildings have a gable roof with

anchor bolts, flashing, trims, etc., or as specified. vertical sidewalls and endwalls. Interior bay

All materials shall be new and free from defects. frames are clear span rigid frames without

interior columns.

1.1.2 The main building structure comprises single or

multiple gable interior rigid frames with either 1.2.2 Multi-Span (MS) buildings have a gable roof with

rigid or “post-and-beam” frames at the endwalls. vertical sidewalls and endwalls. Interior bay

frames are rigid frames, typically with tapered

1.1.3 The standard roof slopes are 0.5 or 1.0 unit of exterior columns, tapered rafters and square tube

vertical rise to 10 units of horizontal run. Other or built-up interior columns.

slopes are available upon request.

1.2.3 Space Saver (SV) buildings have a gable roof

1.1.4 The sidewall steel line is the plane of the inside with vertical sidewalls and endwalls. Interior bay

vertical surface of the sidewall sheeting. It is also frames are clear span rigid frames having

the plane of the outside vertical surface of the constant depth columns and tapered rafters

eave strut. typically with horizontal bottom flanges.

1.1.5 The endwall steel line is the plane of the inside 1.2.4 Lean-To (LT) buildings consist of outer sidewall

vertical surface of the endwall sheeting. It is also columns and simple span rafters attached to the

the plane of the outside vertical surface of the sidewall columns or the endwall posts of the main

outer flange of the endwall girters. building. Lean-To columns are of constant depth.

Lean-To rafters may be tapered or of constant

1.1.6 The building width is the distance between the depth.

steel lines of opposite sidewalls. Building width

does not include the width of Lean-To buildings or 1.2.5 Multi-Gable (MG) buildings have a roof with two

roof extensions. or more gables and vertical sidewalls and

endwalls. Interior bay frames are rigid frames

The width of a Lean-To building is the distance typically having tapered exterior columns,

from the steel line of the exterior sidewalls of the tapered rafters and built-up interior columns.

Lean-To building to the (sidewalls or endwalls)

steel line of the main building to which the Lean-To

building is attached. 1.3 Standard Framing Features

1.1.7 The building length is the distance between the 1.3.1 Main frames are typically constructed from

steel lines of opposite endwalls. Building length tapered or constant depth columns and rafters.

is a combination of several bay lengths.

1.3.2 Rigid frames for Clear Span (CS) and Multi-Span

Building length does not include the width of (MS) buildings are most commonly spaced from

endwall Lean-To buildings or roof extensions. 6000 mm to 10000 mm, center line to center line.

1.1.8 End bay length is the distance from the outside of 1.3.3 Outside flanges of Clear Span (CS) and Multi-Span

the outer flange of endwall columns to the center (MS) rigid frame columns are inset 200 mm from

line of the first interior frame. the sidewall steel line to allow for by-pass girts.

1.1.9 Interior bay length is the distance between the 1.3.4 Outside flanges of Space Saver (SV) rigid frame

center lines of two adjacent interior rigid frame columns shall be placed flush with the sidewalls

columns. steel line.

1.1.10 The building eave height is the distance from 1.3.5 The top flanges of all rigid frame rafters are 200 mm

finished floor level (FFL) to the top of the eave strut below the bottom of the roof sheeting.

at the sidewalls steel line.

1.3.6 End frames are “post-and-beam” (P&B) load

Pre-Engineered Buildings Standard Product Specifications 1

bearing frames with endwall girts flush framed into addition to acting as a transition point for walls

the webs of the endwall posts so that the outer and roof sheeting.

flanges of the girts are in the same vertical plane as 1.4.6 Panels (roof and walls) are roll formed to the

the outer flanges of the posts. Optional rigid frames maximum practical length (generally 9000 mm) to

may be used at the building ends. The center line of minimize end laps in the field.

the endwalls rigid frame shall be 385 mm from the

endwalls steel line. 1.4.7 The standard roof and walls panel is Profile “S”.

It is a roll formed panel having 4 major high ribs

1.3.7 Endwall posts are typically spaced at 6000 mm. and 4 minor ribs. The panel covers a width of 1000

Depending on the width of the building and mm. The lapped major rib has a siphon break to

endwall openings, other spacing may also be used. prevent capillaric intrusion of water at the side

lap. The panel has an extended bearing leg to

When the building width is not evenly divisible by provide stiffening during installation.

6000 mm, the interior spacing of the endwall posts is

typically kept at 6000 mm with two equal end 1.4.8 Roof panels have a minimum end lap of 150 mm

spacings smaller or larger than 6000 mm. over purlins and are fully protected from siphon

action by an end lap mastic.

1.3.8 For Clear Span (CS) and Multi-Span (MS)

buildings, the sidewall girts are attached 1.4.9 Wall panels have the same side lapping as the

(by-passed) to the outer flanges of exterior columns. roof panels. End lap is 100 mm over the girts.

Sidewall girts are lapped at all interior frames. Generally no side or end lap mastic is required.

For Space Saver (SV) and Lean-To (LT) buildings,

the sidewall girts are flush connected (flush framed) 1.4.10 Sandwich panels are factory-injected insulated

so that the outer flange of the girters is in the same panels. They are constructed of a hard

vertical plane as the outer flange of the polyurethane foam core between two single skin

exterior columns. panels. The rigid foam core has a density of

approximately 40 kg/m3.

1.3.9 The bottom flanges of roof purlins are attached to The standard roof sandwich panel is the Tempcon

the outer (top) flanges of the rafters. Purlins are (TC) panel. The outer panel is the

lapped at all interior frames in all structural standard Profile “S” panel, described in section

framing systems. 1.4.7. The inner panel is a flat panel.

The standard wall sandwich panel is the Tem-

1.4 Building Components parch (TA) panel. Both the outer and inner panels

are flat panels.

1.4.1 Columns and rafters of rigid frames are tapered All sandwich panels cover a width of 1000 mm.

built-up “I” sections. Interior columns of multi-span

frames may be square tube sections. 1.4.11 Profiled ridge panels are provided at the ridge of

all buildings with single skin roof panels.

1.4.2 All rigid frame connections are bolted. Columns

and rafters are provided with welded end plates for 1.4.12 Eave gutters are supplied in lengths of 6000 mm.

anchoring to foundations and for member-to- They are cold-formed to a profiled cross-section

member attachment. Pre-punched holes or welded that is about 180 mm wide x 168 mm high.

clips are provided for attachment of purlins and

girters, bracing, and other components. 1.4.13 Downspouts for eave gutters are supplied in

lengths of up to 9000 mm to minimize splicing.

1.4.3 Load bearing “post-and-beam” (P&B) end frames They are cold-formed to a ribbed rectangular

may be constructed from cold-formed channels, hot cross section 105 mm wide x 73 mm deep.

rolled sections or built-up welded plate sections, as

required. 1.4.14 Valley gutters are supplied in maximum lengths

of 4500 mm. They are cold-formed in two standard

1.4.4 Purlins and girts are pre-punched cold-formed “Z” size classifications; 400 mm wide x 190 mm high

shaped sections, 200 mm in depth with stiffened and 354 mm wide x 190 mm high.

flanges.

1.4.15 Downspouts for valley gutters in Multi-Gable

1.4.5 Eave struts are pre-punched cold-formed “C” (MG) buildings are PVC pipes supplied in three

shaped sections, 180 mm in depth with 85 mm sizes; 110 mm, 160 mm and 200 mm (outside

stiffened flanges. The eave strut serves as a diameter). Fiberglass or PVC outlets connecting

longitudinal structural bracing member in the valley gutter to the downspouts are also supplied.

2 Standard Product Specifications Pre-Engineered Buildings

for quotation.

1.4.16 Diagonal bracing, providing longitudinal stability

against wind, seismic or other forces, is attached 2.2.3 When snow load is of concern, the customer will

to the web of the rigid frame near the outer flange specify the snow load where applicable, in

of columns and rafters. The standard diagonal accordance with local codes.

bracing is a galvanized steel 7-wire strand cable

with an eye bolt with an adjusting nut and hillside 2.2.4 Load combinations shall be in accordance with

washer at each end. Solid round bars or hot rolled the requirements of the “Low Rise Building

angles may be used as required by design. Systems Manual” published by MBMA.

1.4.17 Flange braces, in the form of angles, are provided 2.2.5 Other loads and load combinations can be

to stabilize the interior flanges of rigid frame rafters accommodated and must be specified at the time

and columns at certain purlin and girter locations. of request for quotation.

1.4.18 Base angles are provided in fully sheeted walls 2.2.6 Zamil Steel will not be responsible for any static

6000 mm in length for attachment of the wall panel or dynamic loads that are transferred to its

to the concrete slab. The concrete floor slab must building from the plant machinery and equipment,

have a 40 mm x 40 mm notch at the perimeter unless the loads are specifically requested at the

(below the finished floor level) to accommodate time of request for quotation.

the bottom of the wall panel to prevent ingress of

dust and water. The base angle is a light gauge

bent plate.

3. Material Specifications

2. Design 3.1 Structural Members

3.1.1 Built-up sections are fabricated from hot rolled

2.1 Codes steel plates conforming to ASTM A 572M Grade

345 Type 1 (or equivalent), with a minimum yield

2.1.1 Frame members (hot rolled or built-up) are strength of 34.5 kN/cm2 (50 ksi). Flanges are

designed in accordance with the American welded to the web by a continuous single side

Institute of Steel Construction (AISC): “Manual of fillet weld deposited by an automatic submerged

Steel Construction, Allowable Stress Design.” arc welding process.

2.1.2 Cold-formed members are designed in 3.1.2 Hot rolled sections are mill produced according

accordance with the American Iron and Steel to EN 10025-2 Grade S355JR (or equivalent) with a

Institute (AISI): “Cold-formed Steel Design minimum yield strength of 34.5 kN/cm2 (50 ksi).

Manual.”

3.1.3 Tube sections, (used as interior columns in some

2.1.3 All welds are designed in accordance with the Multi-Span buildings) are mill formed steel sections

American Welding Society (AWS): “Structural conforming to EN 10210-1 S355J2H or JIS 3466 STKR

Welding Code - Steel”. 490 (or equivalent), with a minimum yield strength of

32.5 kN/cm2 (47 ksi).

2.1.4 Loads are applied in accordance with the

requirements of the Metal Building Manufacturers 3.1.4 Secondary members (comprised mostly of purlins

Association (MBMA) of the USA: “Low Rise Building & girts) are cold-formed from hot rolled steel coils

Systems Manual”. ranging in thickness from 1.5 mm to 3.0 mm for “Z”

shapes, and in 2.0 mm and 2.5 mm for “C” shapes

(lipped channels).

2.1.5 Other codes can be accommodated if specified.

3.1.4.1 Painted secondary members are cold-formed from

2.2 Loads hot rolled steel coils conforming to ASTM A 607

Grade 50 or ASTM A 1011M HSLAS Grade 340

2.2.1 The building is designed to withstand the dead Class 1 Type 1 (or equivalent) having a minimum

load (DL) of the structure plus a specified live load yield strength of 34.0 kN/cm2; and then factory

(LL) and wind load (WL). painted with Zamil Steel standard primer.

2.2.2 Auxiliary (Collateral) loads, if any, must be 3.1.4.2 Galvanized secondary members are cold-formed

specified by the customer at the time of request from steel coils conforming to ASTM A 653M Grade

Pre-Engineered Buildings Standard Product Specifications 3

SS 340 Class 1 (or equivalent), with zinc coating to 3.2.4 Standard colors for pre-painted wall panels are

Z275 (G 90) designation (275 g/m2), having a those standard colors mentioned in Zamil Steel’s

minimum yield strength of 34.0 kN/cm2 (50 ksi). product brochure and panel chart.

3.1.5 Bracing cables are 12 mm diameter, zinc coated 3.2.5 Mezzanine deck panels are roll-formed from 0.7 mm

thick cold-rolled galvanized steel. The material

7-wire strand steel cables of extra high strength. The

conforms to ASTM A 653M SS Grade 550, zinc

strand wires conform to ASTM A 475 (or equivalent) coating Z180 (G60), and has a minimum yield strength

with a minimum breaking load of 119.7 kN. of 55.0 kN/cm2 (80 ksi).

3.1.6 Bracing rods, used in sidewalls of buildings 3.2.6 Roof and walls panel upgrades.

supporting cranes, are solid plain round steel bars Other premium durability paint finishes are avail-

conforming to ASTM A 36M (or equivalent) with a able upon request, such as Polyvinylidene Fluoride

minimum tensile strength of 40 kN/cm2 (58 ksi). finish (ZPF)

3.1.7 Sag rods, used to brace purlins and girts in bays lon- Roof and wall panels may be upgraded to 0.7 mm

ger than 8500 mm or in buildings with slopes larger (nominal) thickness as follows:

than 2.5 to 10, are 12 mm or 16 mm solid threaded, Thickness

round steel bars conforming to ASTM A 36M (or Base Metal Paint Finish

(mm)

equivalent) with a minimum tensile strength of 40 kN/

cm2 (58 ksi). Bare Zincalume

Steel ZSP

3.1.8 Flange braces used to stabilize the inner flanges of 0.7

main frame columns and rafters are 50 mm x 50 ZPF

mm x 4 mm steel angles conforming to ASTM A 36M Plain

(or equivalent) with a minimum yield strength of 25 Aluminum

kN/cm2 (36 ksi). ZSP

3.1.9 Base / gable angles are 45 mm x 73 mm x 1.5 mm

3.2.7 Sandwich panels are available in two types:

thick angles supplied in 6000 mm long pieces,

cold-formed from galvanized steel and conforming (a) Tempcon Panels:

to ASTM A 653M SS Grade 340 Class 1 (or equivalent), Tempcon sandwich panels are produced

with zinc coating to Z275 (G90) designation (275 g/ using rigid polyurethane foam core with

m2) having a minimum yield strength of 34.0 kN/ external and internal sheets in steel or

cm2 (50 ksi). aluminum of varying thickness, coatings

and colors. Tempcon is a durable sand

3.2 Panels wich panel, particularly in industrial build

ings and are suitable for roof and wall for

3.2.1 Roof Panels are roll formed from 0.5 mm (nominal) all building applications.

thick cold-rolled steel coated with an aluminum /

zinc alloy (Zincalume). The material conforms to (b) Temparch Panel:

ASTM A 792M Grade 340 Class 2, with alloy (Alumi- Temparch sandwich panels are produced

num / Zinc) coating AZM150 (or equivalent), having using rigid polyurethane foam core with

a minimum yield strength of 34 kN/cm2 (50 ksi). The external and internal sheets in steel or

coating is achieved through a hot dip process, which aluminum of varying thickness, and are

is 55% aluminum and the balance zinc, by weight. suitable for walls for all building

Pre-painted roof panels are optional. applications, interior partition and

cold stores.

3.2.2 Wall Panels have the same specifications as the roof

panels (as described in section 3.2.1 above), but they All the outer skins of Tempcon and Temparch pan-

are mill painted. Paint finish film thickness shall be 25 els are Zincalume coated steel conforming to ASTM

microns of high durability polyester (ZSP) on the A 792M Grade 340 Class 2, with zinc alloy coating

exterior (weather) face and 12 microns of plain AZM150 and are available in all Zamil Steel stan-

polyester on the interior face. dard colors.

3.2.3 Interior liner panels have the same specifications as All the inner skins of Tempcon and Temparch pan-

the wall panels (as described in section 3.2.2 above). els are Zincalume coated steel conforming to ASTM

A 792M Grade 340 Class 2, with zinc alloy coating

4 Standard Product Specifications Pre-Engineered Buildings

AZM150, and are available in Frost White color. (or equivalent). They are 5.5 mm diameter, hex-head,

Tempcon and Temparch skins may be upgraded as self-drilling screws, assembled with galvanized steel

per section 3.2.6. washers bonded with EPDM seals.

3.5.2 Wall fasteners are metallic-polyester coated,

heat-treated carbon steel, conforming to AS 3566

3.3 Trims & Gutters Class 3 (or equivalent). They are 5.5 mm diameter,

hex-head, self-drilling screws with integral

3.3.1 Walls flashing and trims (gable, corner, framed washers bonded with EPDM seals. The heads of

opening, accessories, etc.) are cold-formed from wall fasteners are painted to match the color of the

the same material (color & finish) as wall panels. wall panels (as per section 3.2.4).

3.3.2 Roof flashing and trims (parapet flashing, 3.5.3 Sandwich panel fasteners

transition trims, expansion joint trims and ridge same as 3.5.2.

caps) are cold-formed from the same material

(color & finish) as roof panels. 3.5.4 Stitch fasteners for the roof are metallic-polyester

coated, heat-treated carbon steel, conforming to

3.3.3 Eave gutters and downspouts are cold-formed AS 3566 Class 3 (or equivalent). They are 4.8 mm

from the same material as wall panels. diameter, hex-head, self-drilling screws,

assembled with galvanized steel washers bonded

3.3.4 Valley gutters (used in parapet fascias and valley with EPDM seals. They are used on the side laps

conditions) are cold-formed from a 1.0 mm (minimum) of roof panels, and in trim-to-trim and trim-to-

thick (nominal) bare Zincalume coated cold-rolled panel fixing applications.

steel coil, conforming to ASTM A 792M Grade 340

Class 2, with zinc alloy coating AZM150 or bare 3.5.5 Stitch fasteners for the walls are metallic-polyester

Galvanized/Zinc coated cold rolled steel coil con- coated, heat-treated carbon steel, conforming

forming to ASTM A 653M SS Grade 340 Class 1, to AS 3566 Class 3 (or equivalent). They are 4.8

with Z275 coating (or equivalent) having a mm diameter, hex-head, self-drilling screws with

minimum yield strength of 34.0 kN/cm2 (50 ksi). hex-head integral washers bonded with EPDM

seals. The heads of stitch fasteners for the walls

A protective zinc phosphate pigmented epoxy are painted to match the color of the wall panels

coating system is applied to the exposed surface, (per section 3.2.4). They are used on the side laps

having a total average dry film thickness of 150 of panels, and in trim-to-trim and trim-to-panel

microns on the exterior side and 50 microns on the fixing applications.

interior side.

3.5.6 Mezzanine deck fasteners are 5.5 mm diameter,

3.4 Bolts metallic-polyester coated, heat-treated carbon

steel, self-drilling screws, with hex head, capable

3.4.1 High strength bolts are hot-dip galvanized and of drilling through steel up to 12 mm thick. They

conform to ASTM A 325M (full thread), Type 1 (or conform to AS 3566 Class 3 (or equivalent).

equivalent). They are used to connect primary

members. 3.5.7 Rivets are 4.0 mm diameter and made from

Aluminum. They are used in gutter splicing,

3.4.2 Machine bolts are electro-galvanized with a fixing trim-to-trim, or trim-to-panel, and fastening

yellow chromate color conversion coating and accessories to roof or wall claddings. They are

conform to DIN 933 Class 4.6 (or equivalent). They available in all standard colors.

are used to connect secondary members (mainly

purlins and girts). 3.5.8 Stainless steel fasteners, for Aluminum panels,

are 5.5 mm diameter, hex-head, self-drilling,

3.4.3 Anchor bolts are manufactured from rods stainless steel screws, assembled with stainless

conforming to ASTM F1554 grade 55 or ISO 898-1 steel washers bonded with EPDM seals. Material

Class 5.8 (or equivalent) with a minimum yield grade is AISI 304 (or equivalent).

strength of 38.0 kN/cm2 and an ultimate strength of

51.7 - 65.5 kN/cm2. 3.6 Other Items

3.5 Fasteners 3.6.1 Skylights and wall lights are made of translucent

white acrylic modified, ultra violet stabilized,

3.5.1 Roof fasteners are metallic-polyester coated, heat fiberglass with a tensile strength of 8.7 kN/cm2

treated carbon steel, conforming to AS 3566 Class 3 (using ASTM D 638 test method) with a flexural

Pre-Engineered Buildings Standard Product Specifications 5

strength of 13.83 kN/cm2 (using ASTM D 790 test film thickness of not less than 40 microns.

method). Translucent panels weigh 2.4 kg/m2

(nominal) and provide the same coverage as the 4.1.2 Primer paint conforms to the performance

panel width with a maximum length of 3600 mm. requirements of Steel Structures Painting Council

The profile of the translucent panels matches that SSPC Paint 15 Type 1.

of the adjoining roof/wall panels so that weather 4.1.3 Shop primer is intended to provide temporary

tightness is achieved through the same lapping protection against weathering during transport

technique used for the panels themselves. The and erection. It is not intended to provide

translucent panels meet the light transmission permanent corrosion protection, especially in the

value of 75% (+5%) according to ASTM D 1494. case of exposed steel.

3.6.2 Fall Shield (Skylight Fall Protection) is a fall pro- 4.1.4 When special paint supplier is specified by the

tection system to safeguard people from tripping, consultant / client, and paint is found to have

stepping and falling accidentally through skylights application problems and (or) extended drying

on the roof. It is fabricated from hot-dip galvanized times, Zamil Steel will recommend to substitute it

wiremesh and rigidly supported by hat sections with an equivalent and suitable supplier, subject

and clips which are fixed directly on top of the pan- to final approval by the consultant / client.

el-purlin area on the roof with covering size/dimen-

sion conforming to the surface area of the skylight

panel. 5. Building Accessories

3.6.3 Foam closures match the panel profile. They are

made of expanded polyethylene or similar 5.1 Personnel Doors

material.

5.1.1 Personnel doors are flush-finished and 44 mm

3.6.4 Bead mastic is an extruded elastomeric butyl thick. Single leaf doors are 915 mm wide x 2135

rubber based sealant supplied in rolls on silicon mm high. Double leaf doors are 1830 mm wide x

release paper conforming to Federal Specification 2135 mm high.

TT-C-1796 A Type II Class B (or equivalent).

5.1.2 Door leaves are reinforced, stiffened and

3.6.5 Flowable mastic (caulking sealant) is a neutral soundproofed with an expanded polystyrene core,

cure silicone rubber sealant that is chemically laminated to the inside faces of door panels,

inert and non-corrosive. It is UV resistant and suitable completely filling the inside cavity of the door leaf.

for exterior applications against weathering and

rainwater. When cured, it is non-toxic and will 5.1.3 Steel door panels are 0.9 mm (nominal) thick, hot

accommodate high thermal and shrinkage dip galvanized, 180 g/m2, as per ASTM A 653M

changes in structural movement joints. (Z180) cold-rolled steel, thoroughly cleaned,

phosphated and painted with a white finish to

3.6.6 Fiberglass insulation meets UL 25/50 fire rating ensure optimal corrosion protection.

and is supplied in 50 mm, 75 mm, 100 mm and 150

mm thicknesses with a factory laminated Rein- 5.1.4 A white or galvanized finished “Z” shaped

forced White Metalized film Scrim Kraft (WMSK) astragal is field attached to the inactive leaf of all

or Foil Reinforced Kraft (FRK) faced vapor barrier. double doors.

The fiberglass density is 10 kg\m3. Other facings,

densities and thicknesses are 5.1.5 Doors are factory prepared for a cylindrical lockset.

available upon request.

5.1.6 Door frames are 1.5 mm (nominal) thick hot-dip

Fiberglass insulation is supplied with double face galvanized steel, prepared to ASTM A 653M (Z180)

tape, patching tape, stapler and staples. classification (or equivalent), thoroughly cleaned,

phosphated and painted with a modified alkyd

primer, plus a white finish coat.

4. Shop Paint

5.1.7 Door frames are delivered knocked-down. Mitered

corners have brackets with pre-drilled holes for

4.1 Structural Members field assembly and are supplied with all fasteners

necessary for assembly.

4.1.1 Primary and secondary steel is cleaned and prime

painted according to the Steel Structures Painting 5.1.8 The lockset is a keyed cylindrical type with satin

Council SSPC-PS Guide 7.00 specification to a dry chrome finish. Optional panic devices and auto

6 Standard Product Specifications Pre-Engineered Buildings

closer are available. paint in Frost White color. The bottom rail of the

door curtain is an extruded Aluminum angle.

5.1.9 Each door leaf has three mortise 115 mm x 115 mm

ball bearing hinges with a security set screw in 5.3.3 Guides are 95 mm deep channels roll formed from

the barrel to prevent removal of the hinge pin with 2.5 mm (nominal) thick hot-dip galvanized steel.

the door in a closed position.

5.3.4 The door drum (supporting the door curtain) is a

165 mm (nominal) diameter and 3.2 mm (nominal)

5.2 Steel Sliding Doors thick pipe. The drum houses safety springs, end

shafts, collars and bearings and conforms to

5.2.1 The frames of horizontal steel sliding doors are Australian Standard AS 1905 for safety.

manufactured from 2 mm (nominal) thick, cold

formed channels and girts and are delivered 5.3.5 Doors are supplied complete with guides, axle,

knocked-down for field assembly. All clips, curtain and a manual chain and reduction gear

fasteners, etc., necessary for assembly are operating mechanism. Electric operators are

provided. available as an option.

5.2.2 The exterior face of the door leaf is sheeted with

5.4 Sectional Doors

0.5 mm (nominal) thick, pre-painted profiled

panels. The panel ribs run vertically. The door

5.4.1 Sectional doors are available in normal/regular

panel profile matches the profile and material of

sizes of 5000 mm Width x 5000 mm Height and be-

the wall panels.

low. (Other and bigger door sizes can also be made

upon request.)

5.2.3 Door leaves are either suspended from an exterior

mounted trolley rail attached to a structural header

beam or bottom, supported by rollers on a fixed track Width (mm) Height (mm)

anchored on the ground. The door hood trim, de- 3000 3000

signed to conceal and protect the header and rail, 3000 4000

is supplied with same material as the wall pan-

els. 4000 4000

4000 5000

5.2.4 Doors are bottom or top guided by a specially 5000 5000

designed steel rail track.

5.4.2 The sectional door’s panel or leaf is composed of

5.2.5 Door widths range from 1500 mm to 3000 mm, for 42 mm thick, double-skin and hot-dip galvanized

single sliding doors, and from 3000 mm to 6000 steel section, insulated with polyurethane core and

mm, for double sliding doors. The height of the painted with primer-polyester coating.

sliding doors range from 3000 mm to 6000 mm.

5.4.3 Track (or Door Guide) use 52 mm rail width/depth

5.2.6 Sliding doors may also be provided with for door sizes of 5000 mm Width x 5000 mm Height

flush-hinged pilot doors. A pilot door is a and below. (For bigger door sizes, 91 mm rail width/

personnel door within a leaf of the sliding door. depth is used.)

5.4.4 Sectional doors can be manually operated or elec-

5.3 Steel Roll Up Doors trically operated using industrial duty motor with

manual override/operation in case power is off.

5.3.1 Roll-up door sizes conform to the following table:

5.4.5 Sectional doors can be supplied with optional ac-

Width (mm) Length (mm) cessories such as Ventilation Grills, Glazing and

3000 3000 Wicket Doors.

3000 4000

4000 4000 5.5 Windows

4000 5000

Window frames are made of anodized Aluminum

5000 5000

extrusions with natural color finish conforming to

ASTM B 221M Alloy 6063-T5 tempered aluminum

5.3.2 The door curtain is cold-formed from hot-dip alloy (or equivalent). Windows are horizontal

galvanized steel and painted with a polyester

Pre-Engineered Buildings Standard Product Specifications 7

double slide type, 1000 mm high and 1000 mm wide, sidewalls.

specifically designed for installation in profiled 6.2 Canopies

exterior wall panels. Windows are factory glazed with

minimum 6 mm thick clear glass and are equipped 6.2.1 Sidewall canopies are cantilevered rafters

with latches and a removable insect screen. attached to the sidewall columns at any point

below the eave and support 200 mm deep by-pass

“Z” purlins supporting the canopy roof panels.

5.6 Adjustable / Fixed Steel Louvers

6.2.2 End wall canopies are cantilevered rafters along

Adjustable steel louvers are 1000 mm wide x 1000

a uniform elevation attached to the end wall posts

mm high. They are supplied complete with a

below the roof line and support by-passed 200 mm

galvanized steel mesh, blades and framing. They

deep “Z” purlins supporting the canopy roof panels.

are made from the same material, finish and color

as wall panels. Fixed steel louvers are available

6.2.3 Optional canopy soffits conceal only the canopy

in 1000 mm wide x 1000 mm high, 1000 mm wide x

purlins, leaving rafters exposed, unless otherwise

1500 mm high and 1500 mm wide x 1000 mm high.

specified.

5.7 Gravity Ventilators 6.2.4 Unless otherwise specified, the roof panels of the

canopies shall match the color and profile of the

Gravity flow ridge ventilators are 3000 mm long main building roof panels.

with a throat opening of 300 mm or 600 mm. They

are installed as either individual units or as 6.2.5 The width of a canopy depends on the size of the

continuous (i.e. joined) units. The outer skin of sidewall columns or end wall posts supporting it.

the ventilators is pre-painted Zincalume steel that Practical widths range from 1500 mm to 3000 mm.

matches the color of roof panels. The ventilators Wider canopies are possible but require heavier

are supplied complete with bird screens. A damp- sidewall columns or end wall posts.

er system to close the throat opening is optional on

300 mm throat ventilators. 6.2.6 The length of a canopy is ideally a multiple of bay

lengths of the sidewalls or a multiple of column

For export shipments, ventilators are shipped

spacings of the end walls.

knocked-down to be field assembled by the

erector before installation.

6.3 Fascias and Parapets

6.3.1 Vertical fascias consist of 200 mm deep vertical posts

6. Structural Sub-systems supported by brackets from sidewall columns or

endwall posts. Cold-formed 200 mm deep “C”

section top and bottom girts are flush-framed to the

6.1 Roof Extensions vertical fascia posts. An intermediate “C” girt

positioned vertically is supplied to support a valley

6.1.1 Sidewall roof extensions extend beyond the

gutter, when required.

defined building width and are generally a

continuation of the main building roof slope.

Standard vertical fascias project 600 mm from the

building sidewall or end wall steel lines. Projections

6.1.2 End wall roof extensions extend beyond the defined

exceeding 600 mm are possible but may require

building length and are constructed by extending

the end bay purlins and eave struts of the main heavier sidewall columns and end wall posts. The

building past the endwall rafters. height of the fascia varies depending on actual

requirements. Typical heights range between 1000

6.1.3 Standard widths for roof extensions range from 900 mm to 1600 mm.

mm to 1500 mm. Wider roof extensions can be used

Fascia sheeting is supplied in 0.5 mm (nominal) thick,

but may require heavier or additional framing.

pre-painted panels matching the sidewalls profile.

Soffit panels and back-up panels are

6.1.4 Soffit panels for roof extensions are optional.

provided only when specified.

6.1.5 Main building eave gutters are normally relocated

to the edge of the roof extensions. Gutter drainage 6.3.2 Curveline fascias are of the same type of

is achieved by downspouts located at the building construction as vertical fascias but are sheeted with

8 Standard Product Specifications Pre-Engineered Buildings

curved profiled panels and are available in three foundation work, etc. Zamil Steel shall not be

types: responsible for any consequences arising from the

Bottom curved fascias that have a curved panel at premature use of information provided in

the bottom of the fascia only. drawings that are not issued for construction.

Top and bottom curved fascias that have a curved

panel at the top and bottom of the fascia. 8.2 Erection Drawings

Center curved fascias that haave a single panel 8.2.1 Erection Drawings, “Issued For Construction”,

curved at the mid height of the fascia. are provided for the assembly of the building(s)

and consist of an anchor bolt setting plan, a frame

6.3.3 A parapet fascia is an extension of the sidewalls and cross-section, a roof framing plan, walls framing

endwalls above the roof line. The wall sheeting of the details and roof and wall sheeting details. Part

building will continue to the top of the parapet. designations for all Bill of Materials (BOM)

components are shown on erection drawings.

6.3.4 Standard eave gutters and downspouts are used

in buildings with sidewall vertical fascias. 8.2.2 Bolt schedules identifying the required bolt

Valley gutters are used in buildings having diameter and length for specific connections are

sidewall parapet fascias. shown on erection drawings.

8.3 Design Calculations

7. Foundation and Anchorage Structural calculations may be provided upon

7.1.1 Foundations, tie beams and concrete floor slabs request, duly certified by the Engineering

should be designed by a licensed engineer. Manager.

Zamil Steel does not provide this service.

8.4 Design Certification

7.1.2 The design should be based on the building

column specifications stated on “Issued For A letter of certification, in lieu of design

Construction” anchor bolt setting Plans. calculations, may be provided upon request, duly

certified by the Engineering Manager.

7.1.3 Anchor bolts must be set in strict accordance with

Zamil Steel anchor bolt setting plans. Zamil Steel is

not be responsible for incorrectly set anchor bolts.

8. Submittals

8.1 Approval Drawings

8.1.1 Approval drawings are submitted upon request.

If approval drawings are requested, fabrication

will not start until one set of the approval drawings

has been signed by the buyer or his representative

as “Approved As Is” or “Approved As Noted” and

returned to Zamil Steel.

Statements, descriptions, specifications and dimensions

8.1.2 Approval drawings are issued as “Not For contained herein are in effect as of the date of this issue.

Construction” drawings; the contractor is Zamil Steel reserves the right to make material substitutions,

enhencement and changes in specifications and construction

specifically instructed not to use dimensions methodology as and when deemed necessary.

shown on approval drawings for his civil work,

Pre-Engineered Buildings Standard Product Specifications 9

HEAD OFFICE AREA OFFICES

Saudi Arabia (Dammam, Riyadh & Jeddah) Kuwait (Kuwait City) Bahrain (Manama) Qatar (Doha)

PO Box 877

UAE (Dubai & Abu Dhabi) Oman (Muscat) Yemen (Sanaa) Jordan (Amman) Syria (Damascus) Iraq (Basra)

Dammam 31421 Bangladesh (Dhaka) Pakistan (Lahore) Sri Lanka (Colombo) India (Chennai & Bangalore) Greece (Athens)

Romania (Bucharest) Hungary (Budapest) Poland (Warsaw) Czech Rep. (Prague) Spain (Madrid) Luxembourg

Saudi Arabia

Egypt (Cairo) Sudan (Khartoum) Libya (Tripoli) Algeria (Algiers) Senagal (Dakar) Ethiopia (Addis Ababa)

Phone (966 3) 847 1840 Tanzania (Dar-es-Salaam) Nigeria (Lagos) Vietnam (Ho Chi Minh City, Hanoi, Haiphong & Da Nang)

Thailand (Bangkok) Malaysia (Kuala Lumpur, Johor & Kota Kinabalu) Singapore Philippines (Manila)

Fax (966 3) 847 1291

Myanmar (Yangon, Mandalay & Pyinmana) Indonesia (Jakarta & Batam) Philippines (Manila) Laos (Vientiane)

E-Mail pebmarketing@zamilsteel.com Cambodia (Phnompenh) China (Shanghai, Qingdao & Dalian) Japan (Tokyo)

Standard Product Specifications Pre-Engineered Buildings

www.zamilsteel.com January 2012

You might also like

- Ware House Purlin DesignDocument4 pagesWare House Purlin DesignSuhail Ahamed100% (1)

- Agricultural Buildings Designed To BS 5502-22Document3 pagesAgricultural Buildings Designed To BS 5502-22fNo ratings yet

- Solutions To Design of Weldments - BlodgettDocument80 pagesSolutions To Design of Weldments - Blodgettstudent_bl94% (17)

- Concrete Cone FailureDocument16 pagesConcrete Cone FailurePrakash SinghNo ratings yet

- Prokon - Base Plate Design To EurocodeDocument7 pagesProkon - Base Plate Design To EurocodeArnold TunduliNo ratings yet

- MBMA 2010 Supplement To 2006 - Free Download PDFDocument73 pagesMBMA 2010 Supplement To 2006 - Free Download PDFsurendra sharma100% (1)

- Z PurlinDocument4 pagesZ Purlinsachinapkar100% (1)

- Example Design of A Cold-Formed Steel Lipped Channel Wall Stud in CompressionDocument4 pagesExample Design of A Cold-Formed Steel Lipped Channel Wall Stud in CompressionOprisor Costin100% (1)

- Corle Architect ManualDocument81 pagesCorle Architect Manualw_christopher_miller@gmail_comNo ratings yet

- Technical Bulletin - Timber Frame StructuresDocument24 pagesTechnical Bulletin - Timber Frame Structuresrexo100% (1)

- AISC SDM-SCBF Connection ExampleDocument48 pagesAISC SDM-SCBF Connection Examplekashyap_structuralNo ratings yet

- Zamil Steel PDFDocument12 pagesZamil Steel PDFAshishNo ratings yet

- Specs - Zamil SteelDocument12 pagesSpecs - Zamil SteelKhizer. A.No ratings yet

- Zamil Steel Panel Chart PDFDocument1 pageZamil Steel Panel Chart PDFFerdie TolosaNo ratings yet

- METSEC Purlins SystemsDocument84 pagesMETSEC Purlins SystemsIvan KlyuchkaNo ratings yet

- Manual of Purlin and Girt DesignDocument64 pagesManual of Purlin and Girt DesigntitlesaengNo ratings yet

- Load Calculation For Mbma Loading - EnclosedDocument1 pageLoad Calculation For Mbma Loading - EnclosedRavi GuptaNo ratings yet

- Z PurlinDocument2 pagesZ PurlinAddrien DanielNo ratings yet

- Kirby Corporate BrochureDocument48 pagesKirby Corporate Brochurecpersels001No ratings yet

- Longterm Deflection Comparison With EtabsDocument6 pagesLongterm Deflection Comparison With EtabsArnel Dodong100% (1)

- Peb BrochureDocument26 pagesPeb BrochureAbdul MaminNo ratings yet

- V2 I8 39 PDFDocument6 pagesV2 I8 39 PDFRamachandra Sahu100% (1)

- Peb Division ManualDocument8 pagesPeb Division ManualGeorgeEdwardNo ratings yet

- Dubai Municipality RequirementsDocument1 pageDubai Municipality RequirementsmaheshbandhamNo ratings yet

- Z Purlins TigerDocument9 pagesZ Purlins TigerabuthahirNo ratings yet

- Windloads On Building CanopyDocument5 pagesWindloads On Building CanopyMaryNo ratings yet

- C & Zed Purlins Design Manual and Catalogue BC783d01Document31 pagesC & Zed Purlins Design Manual and Catalogue BC783d01GnabBangNo ratings yet

- Aci318-08 Moment Shear Torsion DesignDocument7 pagesAci318-08 Moment Shear Torsion DesignMohammed HanafiNo ratings yet

- Shear KeyDocument14 pagesShear KeyMbalekelwa MpembeNo ratings yet

- Composite SlabDocument13 pagesComposite Slabkosithuag50% (2)

- Zamil Steel ManualDocument469 pagesZamil Steel ManualDhanu Padhu80% (5)

- Anchor Systems.: Hilti. Outperform. OutlastDocument54 pagesAnchor Systems.: Hilti. Outperform. Outlasturos_kostic1980No ratings yet

- ACI 318M-11 RC Bracket and Corbel Design - v0.03 - 2017!04!10Document2 pagesACI 318M-11 RC Bracket and Corbel Design - v0.03 - 2017!04!10Diana RamosNo ratings yet

- Pennar Decking ProfileDocument4 pagesPennar Decking ProfileMohamed IsmailNo ratings yet

- Canadian Seismic Design of Steel Structures An Organized OverviewDocument25 pagesCanadian Seismic Design of Steel Structures An Organized OverviewJamal Muhammad BahajajNo ratings yet

- Mbs PartitionwallDocument91 pagesMbs PartitionwallRamsey RasmeyNo ratings yet

- Main Pole Wind Load On TIA 222G: QZ 0.613 (KZ) (KZT) (KD) (V2) (I)Document29 pagesMain Pole Wind Load On TIA 222G: QZ 0.613 (KZ) (KZT) (KD) (V2) (I)boypardede3552No ratings yet

- Serviceability MBMADocument2 pagesServiceability MBMAabdulloh_99100% (1)

- Design PDFDocument26 pagesDesign PDFLingkaNo ratings yet

- Design of Purlin & Runner-Ro-Final-Rev-0Document8 pagesDesign of Purlin & Runner-Ro-Final-Rev-0Sabrina ImloulNo ratings yet

- NA To Sls en 1991-1-1Document12 pagesNA To Sls en 1991-1-1Shan Sandaruwan AbeywardeneNo ratings yet

- Peb Shed StaadDocument22 pagesPeb Shed StaadShashank PatoleNo ratings yet

- RC Design Aci318m 19 v4.3Document72 pagesRC Design Aci318m 19 v4.3mohammed alebiedNo ratings yet

- Calculation 1.0 Design Information 1.1 Building DescriptionDocument20 pagesCalculation 1.0 Design Information 1.1 Building Descriptionerkapil1120No ratings yet

- Specs PDFDocument12 pagesSpecs PDFjoy7898No ratings yet

- Pre-Engineered BuildingsDocument10 pagesPre-Engineered BuildingsAhmed Khan100% (4)

- Specs PDFDocument12 pagesSpecs PDFmohammed_almostyNo ratings yet

- Components of Industrial BuildingsDocument9 pagesComponents of Industrial BuildingsSharon Shine100% (1)

- Brochure MetalDocument28 pagesBrochure Metalonkar_kashyapNo ratings yet

- Pre Engineered Materials StructuresDocument10 pagesPre Engineered Materials StructuresDenise EstrellaNo ratings yet

- Components of PEBDocument28 pagesComponents of PEBAjitesh YelisettyNo ratings yet

- Adrian Rollo Toisa: Portal Frame Construction & Pre Engineered Building SystemDocument31 pagesAdrian Rollo Toisa: Portal Frame Construction & Pre Engineered Building SystemdamandadinoNo ratings yet

- NNNDocument3 pagesNNNjhonlloydtipon2No ratings yet

- 003 Bt5 Pre-Engineered BuildingDocument31 pages003 Bt5 Pre-Engineered BuildingNicole VerosilNo ratings yet

- ScaffoldingDocument6 pagesScaffoldingUmar Bello NuhuNo ratings yet

- BLD 212 Lecture 2Document9 pagesBLD 212 Lecture 2Umar Bello NuhuNo ratings yet

- Pre-Engineered Structure ResearchDocument9 pagesPre-Engineered Structure Researchya gurl shainnaNo ratings yet

- Shed ProfileDocument16 pagesShed ProfilesuganthiNo ratings yet

- Unit - 5 Portal FrameDocument12 pagesUnit - 5 Portal FrameRajiv Reddy100% (2)

- Portal Frame SampleDocument70 pagesPortal Frame SampleVincent 202050% (2)

- PrecastDocument35 pagesPrecastalyssa0% (1)

- The Visit To Hindustan Steel Structural Works and PrefabricationsDocument9 pagesThe Visit To Hindustan Steel Structural Works and PrefabricationsPranali DevthanekarNo ratings yet

- Chowka BaraDocument1 pageChowka Barakashyap_structuralNo ratings yet

- Moment ConnectionDocument7 pagesMoment Connectionkashyap_structuralNo ratings yet

- AISC SDM-OCBF Connection ExampleDocument29 pagesAISC SDM-OCBF Connection Examplekashyap_structuralNo ratings yet

- Calculation Sheet For Flares: User Supplied Inputs (Grey Cells)Document1 pageCalculation Sheet For Flares: User Supplied Inputs (Grey Cells)kashyap_structuralNo ratings yet

- PIER Input GuideDocument21 pagesPIER Input Guidekashyap_structuralNo ratings yet

- PIER Readme PDFDocument2 pagesPIER Readme PDFkashyap_structuralNo ratings yet

- Solar RoofDocument1 pageSolar Roofkashyap_structuralNo ratings yet

- Mcneilus Steel CatalogDocument108 pagesMcneilus Steel Catalogkashyap_structuralNo ratings yet

- Condition ASD LRFD Related Info: W-Shapes - S-Shapes - C-And MC-ShapesDocument4 pagesCondition ASD LRFD Related Info: W-Shapes - S-Shapes - C-And MC-Shapesanand77ininNo ratings yet

- Cold Formed Section-NewDocument2 pagesCold Formed Section-Newkashyap_structuralNo ratings yet

- Wilsons LTD Aluminium Alloy QQ A 25011 T6 Sheet 200Document2 pagesWilsons LTD Aluminium Alloy QQ A 25011 T6 Sheet 200kashyap_structuralNo ratings yet

- As 1170.2 and ASME STS-1 Wind Sensitive Structures Like ChimneyDocument7 pagesAs 1170.2 and ASME STS-1 Wind Sensitive Structures Like Chimneysam_antony2005No ratings yet

- Reinforced Concrete Pipe DimensionsDocument3 pagesReinforced Concrete Pipe DimensionsHans Hans SadzNo ratings yet

- Norma Jis A5525Document10 pagesNorma Jis A5525Gerardo Emmanuel Romana BrianoNo ratings yet

- Seismic Analysis of 3d Sandwich Panel Wall Building With Varying Soil Strata in Different Zon IJERTV6IS060268 PDFDocument5 pagesSeismic Analysis of 3d Sandwich Panel Wall Building With Varying Soil Strata in Different Zon IJERTV6IS060268 PDFVirat DesaiNo ratings yet

- City Square Mall ImpDocument19 pagesCity Square Mall ImpBhuvanaNo ratings yet

- Construction of 02 Nos. Hostel Blocsk and Nursing College Hostel at MGIMS, KHS, Sevagra-Mahatma Gandhi Institute of Medical Sciences, MaharashtrDocument29 pagesConstruction of 02 Nos. Hostel Blocsk and Nursing College Hostel at MGIMS, KHS, Sevagra-Mahatma Gandhi Institute of Medical Sciences, MaharashtrSachin MoryaNo ratings yet

- Bison Hollow Core Floors March 2007Document15 pagesBison Hollow Core Floors March 2007walshceNo ratings yet

- Granite RateDocument1 pageGranite RateBamila EliezarNo ratings yet

- Project 02 SpecificationDocument16 pagesProject 02 SpecificationDUMLAO, ANGELIE M.No ratings yet

- Mud ArchDocument36 pagesMud ArchGunjan Dogra100% (1)

- PDF Perhitungan Neraca Panas Boiler DLDocument10 pagesPDF Perhitungan Neraca Panas Boiler DLRizki MuhardanaNo ratings yet

- Energy SavingDocument34 pagesEnergy SavingSankaran_Nair_3051100% (1)

- Sr. No. Description of Sub-Estimate Amount (RS.) Abstract of CostDocument34 pagesSr. No. Description of Sub-Estimate Amount (RS.) Abstract of CostVIJAYNo ratings yet

- Material ListDocument8 pagesMaterial ListDinda RinaldyNo ratings yet

- GLOBAL TEKNO PROJECT EXPERIENCE LIST - OptimizeDocument2 pagesGLOBAL TEKNO PROJECT EXPERIENCE LIST - Optimizegd sutawijayaNo ratings yet

- Asahi India Glass Ltd.Document3 pagesAsahi India Glass Ltd.Anisha BerryNo ratings yet

- HVAC AcroymnsDocument6 pagesHVAC AcroymnsglenlcyNo ratings yet

- Improving Quality and Durability of Bitumen and Asphalt ConcreteDocument9 pagesImproving Quality and Durability of Bitumen and Asphalt ConcreteKristophe WatsonNo ratings yet

- 3.3 Catalogo Tem3Document18 pages3.3 Catalogo Tem3Deison F. Arango A.No ratings yet

- Repair Guard - F (M55)Document3 pagesRepair Guard - F (M55)Santosh Kumar PatnaikNo ratings yet

- New Voltas AC - Tech - SpecsDocument1 pageNew Voltas AC - Tech - Specsmohamad chaudhariNo ratings yet

- Piping System Design Part - 1Document28 pagesPiping System Design Part - 1Ij OooNo ratings yet

- National Institute of Fashion Technology, New DelhiDocument8 pagesNational Institute of Fashion Technology, New DelhiHimangi VermaNo ratings yet

- Portland Cement Plaster Over Foam: NWCB Technical DocumentDocument1 pagePortland Cement Plaster Over Foam: NWCB Technical Documentmy dlNo ratings yet

- Gujarat Technological University Civil EngineeringDocument3 pagesGujarat Technological University Civil EngineeringSheezan KhanNo ratings yet

- Unpriced BOQDocument57 pagesUnpriced BOQCobbinah MarkNo ratings yet

- Final Report On WordDocument15 pagesFinal Report On WordBheemm Bomjan Professional TrainerNo ratings yet

- Case Study Suzlon One Earth PuneDocument44 pagesCase Study Suzlon One Earth PuneamlaNo ratings yet

- Code of Practice For Waterproofing of Underground WaterreservoirsandswimmingpoolsDocument9 pagesCode of Practice For Waterproofing of Underground WaterreservoirsandswimmingpoolsAnvit GadkarNo ratings yet

- Stairwel and Lobby Pressurization CalculationDocument4 pagesStairwel and Lobby Pressurization CalculationLarry Bea67% (3)