Professional Documents

Culture Documents

HPD L15a7

Uploaded by

pachara0032Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HPD L15a7

Uploaded by

pachara0032Copyright:

Available Formats

HPD

D L15

5A7

Eng allation Manu

gine Insta M al

DB-1 and

a DB-6

D 6 Cha

assis

s

8//2010

Downloaded from www.Manualslib.com manuals search engine

Swift Chassis DB-1 & DB-6

L15A7 Engine Installation Manual

Table of Contents

1. Safety Consideration and Warnings ..................................................... Page 2

2. Title Page ............................................................................................. Page 3

3. Bell Housing Adapter Preparation ........................................................ Page 4

4. Install Slave Cylinder ............................................................................ Page 6

5. Modify Shifter Rod ................................................................................ Page 8

6. Bell Housing / Oil Tank Preparation ..................................................... Page 9

7. Install Fuel System ............................................................................. Page 10

8. Engine Installation .............................................................................. Page 17

9. Oil System .......................................................................................... Page 20

10. Install Modified Shifter Rod ................................................................ Page 22

11. Miscellaneous ..................................................................................... Page 24

12. Completed Install ................................................................................ Page 25

13. Engine Side Cover Blister Installation. ................................................ Page 27

14. Contact Information ............................................................................. Page 30

1

8/2010

Downloaded from www.Manualslib.com manuals search engine

Swift Chassis DB-1 & DB-6

L15A7 Engine Installation Manual

Safety Precautions

The service information in this manual is intended for use by qualified, professional

technicians. Attempting service or repairs without the proper training, tools and

equipment could cause injury or death to you and others. It could also cause damage to

the engine / vehicle or create an unsafe condition.

This manual describes the proper methods and procedures for the race kit installation

related to your chassis, in addition to service and repair procedures described in the

Honda Fit service manual. Some procedures require the use of specifically designed

tools and dedicated equipment. Any person who intends to use a replacement part, a

service procedure, or a tool that is not recommended by Honda or the race sanctioning

body, must determine the risk to their personal safety, and the safe operation of the

vehicle. Any error or oversight while performing this conversion or service can result in

faulty operation, damage to the vehicle, or injury to yourself, or others.

Proper service and maintenance are essential to the racer‟s safety and the reliability of

the race car. If you need to replace any parts, always use the correct parts supplied by

Honda Performance Development or American Honda Motor Co., Inc. Do not use

inferior quality or unapproved parts.

Because this manual is intended for professional technicians, we do not provide

warnings for basic shop safety practices – for example, hot parts = wear gloves. If you

have not received shop safety training or do not feel confident about your knowledge

about safe servicing practices, we recommend that you do not attempt the procedures

described in this manual. We cannot warn you of every conceivable hazard that can

arise in doing service and repair procedures. Only you can decide whether or not you

should do a given task.

Improper service or repairs can create an Failure to properly follow instructions and

unsafe condition that can cause your precautions can cause you to be seriously

customer or others to be seriously hurt or hurt or killed.

killed.

Carefully follow the procedures and

Carefully follow the procedures and precautions in this manual.

precautions in this manual and other

service material.

2

8/2010

Downloaded from www.Manualslib.com manuals search engine

Swift Chassis DB-1 & DB-6

L15A7 Engine Installation Manual

This manual details the steps necessary to install the Honda L15A7 engine

with the HPD engine kit into a Swift DB-1 / DB-6 chassis. The converted

L15A7 engine is designed to be installed utilizing the existing mounting

points of your chassis without modification.

For the purpose of this manual, all photos are of a DB-1 chassis. Specific

parts and procedures unique to the DB-6 are explained when necessary.

3

8/2010

Downloaded from www.Manualslib.com manuals search engine

Swift Chassis DB-1 & DB-6

L15A7 Engine Installation Manual

Bell Housing Adapter Preparation

12

10 3 1. Adaptor plate.

2. Internal hex bolt 3/8-24 x 1-3/4”

8 (2x)

3 3. Internal hex bolt 3/8-24 x 1-1/2”

(2x)

11

2 4. Dowel - 12 x 10mm (2x)

7 9 5. Dowel – 14 x 20mm (2x)

6. Spherical Bearing (DB-1)

6 7. Circlip, Internal – 1.06” (DB-1)

8. Flange Bolt – 10 x 25mm

10 9. Flange Bolt – 10 x 40mm

2 10. Flange Bolt – 12 x 60mm (2x)

1 11. Flange Bolt – 12 x 65mm

12. 12 x 28mm stud

Polish the circlip groove to remove

the sharp edge.

Circlip Groove.

Heat the adapter plate.

Install the spherical bearing. A light to

moderate press is normal.

Install the internal circlip.

4

8/2010

Downloaded from www.Manualslib.com manuals search engine

Swift Chassis DB-1 & DB-6

L15A7 Engine Installation Manual

Bell Housing Adapter Preparation cont’d

Install the locating dowels.

Dowels

Mock up the adapter plate to the

engine.

Note the area where the shifter rod

passes through. This area will need to

be tapered towards the bearing. Mark

the area of the engine block for

material removal. Remove only

enough material to allow the rod to

move freely, leaving enough material

to maintain a mating surface.

5

8/2010

Downloaded from www.Manualslib.com manuals search engine

Swift Chassis DB-1 & DB-6

L15A7 Engine Installation Manual

Install Slave Cylinder

For the DB-1

Install the HPD supplied slave

cylinder using the same procedure

used for the Swift slave cylinder.

NOTE: Use new seals and backing

rings.

Install a new release bearing onto the

slave cylinder.

Install the HPD chassis kit input shaft

using the same procedure as the

Swift unit.

Refer to the appropriate manual for

your type of gearbox for proper

installation.

It is suggested that the input shaft

seals be upgraded / replaced at this

time.

6

8/2010

Downloaded from www.Manualslib.com manuals search engine

Swift Chassis DB-1 & DB-6

L15A7 Engine Installation Manual

Install Slave Cylinder cont’d

For the DB-6

Remove the release bearing from the

Swift assembly.

Press on the HPD supplied adapter.

Install the new release bearing.

Clutch Slave Cylinder Placement

1. Measure distance from the back of the engine block to the end of the clutch fingers. This is dimension

“A”

2. Place a straight edge across the front of the bell housing and measure from the straight edge to to the

mounting surface of the slave cylinder. This is dimension “B”.

3. With the slave cylinder compressed into the bore, measure the installed height of the slave cylinder.

Add 4.0mm to this dimension for freeplay. This will be dimension “C”.

4. Use the following equation to determine the proper slave cylinder spacer length. B – C – A = XX

Spacer Length.

7

8/2010

Downloaded from www.Manualslib.com manuals search engine

Swift Chassis DB-1 & DB-6

L15A7 Engine Installation Manual

Modify Shifter Rod DB-1 Only

The middle shifter rod will need to be

modified to clear the C.V. joint flange.

HPD has supplied the rod for the rear

shifter link.

C.V. Joint Flange

Clearanced Area

The middle Apex joint will need to be

moved forward by 4 inches.

Cut the Apex joint from the rear shifter

rod, and the rear Apex joint of the

middle shifter rod. Weld one joint onto

the new rear rod (gearbox side).

Lay your, and HPD‟s, rod next to each

other and measure the difference in

length (approximately 4 inches). This

will be the amount to remove from the

middle rod.

Cut the middle rod.

Weld the second Apex joint onto the

middle rod.

Drill the bolt hole, being careful to line

up the linkage properly.

NOTE: It is suggested to wait until the

engine and gearbox are properly

installed before drilling the bolt hole.

This will better ensure that the linkage

is clocked properly.

8

8/2010

Downloaded from www.Manualslib.com manuals search engine

Swift Chassis DB-1 & DB-6

L15A7 Engine Installation Manual

Bell Housing / Oil Tank Preparation – DB-1 & DB-6

Using Hondalock 2, or its equivalent,

install the AN -10 plug in the upper

left oil return port. This is now an

engine mounting point.

Install oil tank cover using existing

bolts and an RTV-type sealant.

9

8/2010

Downloaded from www.Manualslib.com manuals search engine

Swift Chassis DB-1 & DB-6

L15A7 Engine Installation Manual

Install Fuel System – DB-1 & DB-6

The Fit Fuel system consists of the fuel pump, fuel filter, regulator, assorted fittings and hoses.

If you are using your own hose supply, ensure that it is rated for high pressure fuel injection systems. The

HPD-kitted fuel system runs at 50-60 PSI. The feed hose needs to be rated at a minimum of 150 psi.

Remove the regulator from the kit.

Discard the ring, the small O-ring and

the small clip.

Modify the fuel cell cover by using the

drawing provided to add a third outlet.

This will become the fuel out.

The AN-6 center hole (previously the

fuel out) will be for fuel pump harness.

The right side AN-4 will become the

fuel cell vent.

The left side AN-4 is the main fuel

feed out.

10

8/2010

Downloaded from www.Manualslib.com manuals search engine

Swift Chassis DB-1 & DB-6

L15A7 Engine Installation Manual

Install Fuel System – DB-1 & DB-6 cont’d

Regulator Housing

Install the regulator into the housing

using a light oil or silicone lubricant on

the O-rings.

Make sure to insert the regulator

square, as it will be easy to cut the

O-rings.

It will take some force by hand to

install the regulator.

Install the clip in the housing.

Pressure Regulator

Position the housing so the return fuel

port faces toward the bottom of the

Fuel Return Port fuel cell.

Using a pipe thread sealant, install

the AN-4 to 1/8 NPT adaptor into the

housing, on the cover (top) side. This

will connect to the AN-4 bulkhead

feed fitting.

11

8/2010

Downloaded from www.Manualslib.com manuals search engine

Swift Chassis DB-1 & DB-6

L15A7 Engine Installation Manual

Install Fuel System – DB-1 & DB-6 cont’d

Using the pipe thread sealant, install

the 5/16‟ Barb to AN-4 ORB adaptor

into the housing, on the fuel cell

(bottom) side. This will connect to the

fuel pump.

NOTE: Be sure the regulator is

sending excess fuel back into the tank

(down) and not into the cover (up).

Install the fuel pump harness into the

AN-6 hole. Ensure the O-ring is in

place.

Snug down the connector.

Loosely install both 90° AN-4

bulkhead fittings in to their respective

positions.

Use the AN-4 crush washers between

the flange and the jam nuts.

12

8/2010

Downloaded from www.Manualslib.com manuals search engine

Swift Chassis DB-1 & DB-6

L15A7 Engine Installation Manual

Install Fuel System – DB-1 & DB-6 cont’d

Find the depth of your fuel cell.

Depending on your fuel cell configuration, you may need to remove the two middle sections of fuel cell

foam.

From the top of the cover retainer ring, measure to the bottom of the cell.

Subtract 1/8” – 1/4” from your measurement. This number is the target length for your fuel pump location.

Ensure the fuel pump does not rest on the bottom of the fuel cell.

NOTE: Be sure the cell is not collapsed; you may have to lift up on the retainer ring for an accurate

measurement.

Pressure Regulator Housing Calculate the length of the

connector hose.

Install the pressure regulator housing

assembly onto the bulkhead fitting in

the cover. Snug the fitting.

Measure from the bottom of the cover

to the bottom of the hose nipple on

the housing, record this number.

Measure the length of the fuel pump

Bulkhead Fitting

from the bottom of the hose nipple to

the bottom of the pick up screen -

record this number.

Add these two numbers together and

subtract from the overall fuel cell

depth measurement. The final number

will be the length of the connector

hose.

Install the hose with the clamps.

13

8/2010

Downloaded from www.Manualslib.com manuals search engine

Swift Chassis DB-1 & DB-6

L15A7 Engine Installation Manual

Install Fuel System – DB-1 & DB-6 cont’d

Clock the fuel pump pick up towards

the rear of the cell.

Clock the regulator housing so fuel is

returned over the pickup.

Tighten all of the connections.

Clock the bulkhead fitting correctly on

the top of the fuel cell cover, so

access to the retainer bolts is possible

and supply and vent hoses are not

overly twisted.

Connect the fuel pump harness to the

pump.

Bulkhead Fittings

Pigtail the harness around the hose

Harness

being careful that the harness does

not chafe on the regulator housing.

You will need to cut out some of the

fuel cell foam from the left side piece.

Only remove enough to be able to

install the cover/pump assembly

easily.

Install the assembly.

14

8/2010

Downloaded from www.Manualslib.com manuals search engine

Swift Chassis DB-1 & DB-6

L15A7 Engine Installation Manual

Install Fuel System – DB-1 & DB-6 cont’d

Fuel hose routing

There are 4 cushion clamps supplied

with the kit to mount the fuel filter.

Using the adaptors and reducers

connect the fuel test port to the „out‟

side of the fuel filter.

Mount this assembly using the

cushion clamps about 4-5 inches from

the mid bulkhead (this is only a

suggested location).

Install the 45° push-loc fittings onto

the supplied hose.

Install the fuel feed line onto the fuel

cell cover and route the same as the

original. This will connect to the fuel

filter with another 45° degree push-

loc.

Cut the hose to length and install.

15

8/2010

Downloaded from www.Manualslib.com manuals search engine

Swift Chassis DB-1 & DB-6

L15A7 Engine Installation Manual

Install Fuel System – DB-1 & DB-6 cont’d

Install the third 45° push-loc onto the

supplied hose.

Connect this to the „vent‟ fitting on the

fuel cell cover, route it the same as

the fuel feed line.

NOTE: You will need to supply your

own vent check valve.

Route the hose as normal.

16

8/2010

Downloaded from www.Manualslib.com manuals search engine

Swift Chassis DB-1 & DB-6

L15A7 Engine Installation Manual

Engine Installation

Install the lower rear mounting studs.

This engine will install in the same

manner as your previous engine.

Be sure the water lines are installed

on the engine per the engine race kit

manual.

Install the gearbox adaptor with the

supplied dowels and socket head

bolts to the bell housing.

The spacers in the chassis for the

lower front mounting studs need to be

a minimum length of 30mm, to

prevent the flange nut from bottoming

on the shank of the stud. (1.18”).

Four 3mm thick washers are included

in the kit to help adjust this dimension.

If needed, they are to be placed

between the flange nut and frame

member, indicated by the arrow.

17

8/2010

Downloaded from www.Manualslib.com manuals search engine

Swift Chassis DB-1 & DB-6

L15A7 Engine Installation Manual

Engine Installation cont’d

Loosely install the upper front mount.

Be sure the top hat is in the flange on

the head from the bottom.

(From Engine Kit Installation Manual –

Pg 17).

Slide the engine into position; thread

the nuts onto the front studs. Loosely

install the upper mount bolts into the

head.

Apply a small amount of anti-seize to

the splines of the input shaft.

Ensure the lower rear mount studs are

in position and not binding.

Introduce the bell housing assembly

onto the engine.

18

8/2010

Downloaded from www.Manualslib.com manuals search engine

Swift Chassis DB-1 & DB-6

L15A7 Engine Installation Manual

Engine Installation cont’d

Align the input shaft splines with the

clutch and mate the bell housing to

the engine.

When you have the dowels engaged,

you can thread in the four bolts and

snug up the bell housing.

Where the bell housing and the

adaptor meet on the underside, it may

be necessary to install shims before

tightening the bottom studs.

Shims are included in the kit (0.01mm

and 0.02mm thickness).

Install the main chassis bolts into the

bell housing. Install the 10mm flange

nut onto the engine stud.

Check the shim dimension on the

bottom of the engine/adaptor plate.

Install the k-nuts onto the studs and

tighten.

Tighten all studs and bolts.

19

8/2010

Downloaded from www.Manualslib.com manuals search engine

Swift Chassis DB-1 & DB-6

L15A7 Engine Installation Manual

Oil System

Layout all the hose and fittings before

assembly to understand how the

hoses are to be placed.

NOTE: If you are cutting the braided

hose to length and installing the

fittings yourself be sure you are

familiar with the proper procedures. If

not done correctly you could cause

damage or harm to yourself or others.

The oil feed for both chassis is on the

lower right side of the oil pan. This is

an AN-10 fitting.

There is an in line filter included in the

kit. This should be incorporated into

the oil feed line. Be sure it is installed

in the correct direction.

In-line Filter

The oil return line is a AN-12 at the

bottom of the scavenge pump.

Route the return line up between the

engine and bell housing.

20

8/2010

Downloaded from www.Manualslib.com manuals search engine

Swift Chassis DB-1 & DB-6

L15A7 Engine Installation Manual

Oil System cont’d

Route the breather lines, being sure to

check the following items:

1. That the 2mm breather

restrictor is in the valve cover.

2. That the valve cover breather

is not interfering with the

operation of the rear anti roll

bar.

3. That the DB-1 kit has AN-8

hose end fittings and adaptor

fittings for the breather lines.

4. That the DB-6 kit has push loc

fittings for all breather lines.

DB-6 owners may need to grind the

indicated area on the bell housing

adapter to prevent chafing of the oil

feed line.

Area to be clearanced

21

8/2010

Downloaded from www.Manualslib.com manuals search engine

Swift Chassis DB-1 & DB-6

L15A7 Engine Installation Manual

Install Modified Shifter Rod

Install the HPD supplied rear shifter

rod.

Install the bolt to the shaft and

selector fork at the gearbox.

Line up the shifter lever in the cockpit

and mark through the middle Apex

joint to place the new bolt hole.

Remove the shaft and drill new bolt

hole.

22

8/2010

Downloaded from www.Manualslib.com manuals search engine

Swift Chassis DB-1 & DB-6

L15A7 Engine Installation Manual

Install Modified Shifter Rod cont’d

Install the middle shifter rod; tighten

all bolts securing the shifter rod and

check that you can select all the

gears.

Make fine adjustments at the lever-

end in the cockpit if necessary.

23

8/2010

Downloaded from www.Manualslib.com manuals search engine

Swift Chassis DB-1 & DB-6

L15A7 Engine Installation Manual

Miscellaneous

Install the throttle cable.

Use the method described in the Race

Engine Assembly manual (pg 48) to

set full throttle.

Performance Tip:

Be sure your throttle pedal stop is

strong enough to withstand the force

of your foot.

The pedal should not be able to rock

side-to-side on its pivot point, as this

will lead to premature cable wear and

inconsistent full throttle applications.

Install the exhaust system. Depending

on your previous system you will need

to adjust the height of the tail pipe

support.

Install the Lambda sensor per the

Honda Fit service manual. Plug into

the engine harness.

24

8/2010

Downloaded from www.Manualslib.com manuals search engine

Swift Chassis DB-1 & DB-6

L15A7 Engine Installation Manual

Completed Install

Left Side View

Right Side View

25

8/2010

Downloaded from www.Manualslib.com manuals search engine

Swift Chassis DB-1 & DB-6

L15A7 Engine Installation Manual

Completed Install cont’d

Top View

Installing fluids:

The oil system will hold the same volume as your previous engine did.

The coolant bleed procedure is the same as your previous engine.

We recommend you prime the oil and fuel systems before starting your L15A7 engine for the first time.

See „Operating Parameters‟ section of your L15A7 Engine Kit Assembly Manual.

NOTE: HPD recommends installing a 19-20psi radiator cap.

Follow the Honda Fit Service manual guidelines for all fluid recommendations.

Connect the brake and clutch lines. Bleed the systems as normal.

26

8/2010

Downloaded from www.Manualslib.com manuals search engine

Swift Chassis DB-1 & DB-6

L15A7 Engine Installation Manual

Engine Side Cover Blister Installation

By Stan Clayton

Dauntless Racing Cars, February 2010

Safety Precautions

Personnel undertaking this procedure should read and understand all relevant MSDS documents before

using resins, hardeners, catalysts and solvents, as they can be hazardous to one's health. Use

appropriate safety equipment at all times while working with these materials, with a minimum of long

sleeves, protective gloves, respirator and eye protection.

This set of instructions presumes the reader is familiar with basic composites work. Read and understand

all steps of this procedure before starting it. If you doubt that you can correctly complete the task, do not

hesitate to have an experienced composites shop complete it for you.

Warning

Improper service or repairs can create an Failure to properly follow instructions and

unsafe condition that can cause your precautions can cause you to be seriously

customer or others to be seriously hurt or hurt or killed.

killed.

Follow the procedures and precautions in

Follow the procedures and precautions in this manual carefully.

this manual and other service materials

carefully.

27

8/2010

Downloaded from www.Manualslib.com manuals search engine

Swift Chassis DB-1 & DB-6

L15A7 Engine Installation Manual

Engine Side Cover Blister Installation cont’d

1. The blisters are made approximately one inch oversize to give the installer maximum flexibility to

match the body lines of the engine side covers. Feel free to trim the pieces during installation to

best match your car's side cover body lines. A pneumatic cut-off tool with a 3" x 3/64" narrow kerf

metal cutting wheel works well to make the holes, as well as to trim the blisters. A sanding block,

dremel or die grinder is also handy for making fine adjustments during fitting.

2. Before attempting to match the blister to each side cover, fit the side cover to the chassis with the

Honda Fit engine fully installed and mark the inside of the side cover where the obstruction

strikes it. Remove the side cover from the chassis and carefully cut away a minimum of material

to clear the obstruction. Several fittings may be needed to cut away just enough. Once the hole is

large enough to clear the obstruction, ensure the side cover can be fully installed and uninstalled

without the side cover hitting the obstruction. Measure and record how much clearance is needed

on either side to clear the obstruction.

3. With the trimmed side cover installed on the chassis, place the appropriate blister over the

opening and slide it around on the side cover to best match the side cover body lines, as well as

clear the obstruction. The flanges are left over sized, so the installer may need to trim them to

ensure a good fit. If trimming is needed, go slowly and trim just a little at a time to prevent

trimming too much from the blister. Once the blister is trimmed to best match the body lines, trace

the outline of the trimmed blister on the side cover and set the blister aside.

4. Remove the side cover from the chassis and carefully cut slightly inside the marked outline of the

trimmed blister with the cut-off wheel. Work slowly to ensure you don't remove too much material.

When the hole is roughly cut out inside the line a pneumatic die grinder with a porting stone or

flap wheel works well for final trimming. Or use sand paper held in the hand. Do not use a disc as

it can easily remove too much material. Once satisfied that trimming is complete and that there is

a close fit between the side cover and the blister, set the blister aside and invert the side cover so

that the inner surface (the surface facing the engine) is facing upwards, and support the side

cover on a work bench.

5. Trace a line around the opening approximately 2" outside the trimmed edge of the hole. Scrub the

area with acetone to remove all traces of dirt, grease and oil. It is critical to a successful

installation that all traces of dirt, oil and grease be removed from this area, or the new resin will

not properly adhere. Next, using a sanding block with medium grit paper or a die grinder and flap

wheel, abrade the surface inside the 2" line down to raw resin and/or glass. Remove just enough

material to get clean resin/glass. Don't grind through to the surface! Once the sanding is

complete, vacuum the area to remove the dust. Lightly abrade the inner face of the blister to

ensure a fresh bonding surface.

6. Place the trimmed blister on the fiberglass cloth you will use to make the bonding patch. Trace a

line approximately 1.5" outside the blister's outline and cut the fabric to match the line, then cut

out a matching outline approximately 1.5" inside the outline of the blister. You will now have a

roughly donut shaped piece of fiberglass cloth approximately 3" wide. Repeat the process to

produce two more donuts, approximately 2" wide and 1.5" wide. All three layers can be the full

width, but narrower strips will save a little weight. Three layers should do the job, but you may

add additional layers if you wish, so long as they do not conflict with the chassis tubes or engine

installation. Alternatively, if there is internal clearance, you may wish to use 3 solid patches

covering out to approximately 1.5" outside the blister outline. Cutting out the inside of the patches

(the "donut hole") is not critical...it just saves a little weight.

28

8/2010

Downloaded from www.Manualslib.com manuals search engine

Swift Chassis DB-1 & DB-6

L15A7 Engine Installation Manual

Engine Side Cover Blister Installation cont’d

7. It is now time to fit the blister to the side cover and tape the outside with 2" masking tape. Ensure

the entire outside outline of the opening is covered with masking tape, or resin may leak out onto

the outer surface of the side cover. You may also wish to tape the blister in place with additional

pieces of tape running fore and aft and up and down on the outside of the side cover.

8. With the blister securely taped in place (tape ONLY on the OUTSIDE surface!), place the side

cover inner surface up on a soft mount that will support the side cover without distorting it. You

are now ready to bond the blister in place.

9. Ensure the resin and hardener/catalyst and side cover are at or above the minimum working

temperature of the resin. Wear all appropriate safety gear and measure out the resin and

hardener. The blisters are made with epoxy resin, but satisfactory patches can be had with

vinylester or polyester resins, as well. Resin dye may be added to match the color of the patch to

the color of the side cover resin. Resin dyes suitable for all resin types may be purchased at:

Tap Plastics: http://www.tapplastics.com/shop/product.php?pid=50&

10. Once again clean the sanded inner surfaces of the side cover and blister with acetone on a paper

towel and let it dry while mixing the resin and hardener thoroughly. When the acetone is

evaporated and the resin and hardener are thoroughly mixed, brush a light layer of resin over the

sanded and cleaned surfaces, allowing the resin to fill the gap between the side cover and the

blister. Place the widest patching layer carefully in place, distributing it evenly inside and outside

the outline of the blister. Using the brush, gently wet it out with resin and work out any air bubbles

or creases in the fabric so it lies flat to the surface. When the widest layer is wetted out, carefully

place the next smaller layer on top of it and wet that layer out. Alternatively, you may start with

the narrowest layer; it is not critical. Repeat until all layers are in place and wetted out. Allow to

fully cure before proceeding.

11. Once the resin is fully cured (appropriately 24 hours for epoxy, or 12 hours for vinylester or

polyester), carefully remove the masking tape. Using a small sanding block and medium grit

paper, or a dremel or die grinder with a small stone, carefully sand down any resin bubbles that

are standing proud of the outer surface of the side cover.

12. If there are any unsightly transitions between the outer surface of the side cover and the blister,

sand the outer surfaces of the blister and side cover with medium grit paper and apply a thin layer

of body filler to smooth the transitions. Shape and sand the body filler to a smooth line. Repeat

thin layers of body filler as needed to get the desired smooth transition line, then sand and prep

for painting.

13. Prime and paint as desired.

29

8/2010

Downloaded from www.Manualslib.com manuals search engine

Swift Chassis DB-1 & DB-6

L15A7 Engine Installation Manual

Contact Information

Honda Performance Development, Inc.

25145 Anza Drive

Santa Clarita, CA. 91355

661-294-7300

Honda Racing Line

grmsadmin@hra.com

Phone: 661-702-7777

Fax: 661-294-7367

30

8/2010

Downloaded from www.Manualslib.com manuals search engine

You might also like

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualFrom EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualNo ratings yet

- Downloaded From Manuals Search EngineDocument50 pagesDownloaded From Manuals Search EngineVENTAS DIESEL DE EL SALVADORNo ratings yet

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualFrom EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualRating: 3.5 out of 5 stars3.5/5 (2)

- 2008 Softail Models Service Manual: ©2008 H-D. All Rights Reserved 99482-08ADocument29 pages2008 Softail Models Service Manual: ©2008 H-D. All Rights Reserved 99482-08AIgor RiveraNo ratings yet

- 2013 HD Softail FXSBSE SupplementDocument390 pages2013 HD Softail FXSBSE Supplementveteandando100% (7)

- Cubo 793Document67 pagesCubo 793wemersonsrNo ratings yet

- VW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004From EverandVW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004Rating: 3 out of 5 stars3/5 (1)

- DocuPrint 3055,2065 SM (E) 1st EditionDocument622 pagesDocuPrint 3055,2065 SM (E) 1st EditionQuang Thành Phạm75% (4)

- VW Transporter T4 (Petrol and Diesel - 1990-1995) Workshop Manual: Owners Edition (Owners' Workshop Manuals)From EverandVW Transporter T4 (Petrol and Diesel - 1990-1995) Workshop Manual: Owners Edition (Owners' Workshop Manuals)No ratings yet

- Introduction To RAPID - Operating Manual - ABB RoboticsDocument58 pagesIntroduction To RAPID - Operating Manual - ABB RoboticsPrabhu100% (2)

- Operator’S Guide to Centrifugal Pumps: What Every Reliability-Minded Operator Needs to KnowFrom EverandOperator’S Guide to Centrifugal Pumps: What Every Reliability-Minded Operator Needs to KnowRating: 2 out of 5 stars2/5 (1)

- Harley Davidson 2013 Sportster Electrical Diagnostic ManualDocument346 pagesHarley Davidson 2013 Sportster Electrical Diagnostic ManualYael Rodriguez100% (4)

- Dinli 901Document136 pagesDinli 901zaracuscaNo ratings yet

- 2013 Dyna Electrical DiagnosisDocument416 pages2013 Dyna Electrical DiagnosisDmitrolv Dmitrolv100% (1)

- Liebherr l506 776 Operating Manual SN From 12800Document251 pagesLiebherr l506 776 Operating Manual SN From 12800Ivan100% (1)

- Pautas de Reutilizacion y Recuperacion Tren DelanteroDocument30 pagesPautas de Reutilizacion y Recuperacion Tren Delanterojvm982No ratings yet

- Operation Manual BVM 640Document588 pagesOperation Manual BVM 640TariqMaqsood100% (1)

- Touring 2011 Electrical Diagnostic ManualDocument556 pagesTouring 2011 Electrical Diagnostic ManualVu Trinh100% (1)

- Sds Operation M Ver6Document106 pagesSds Operation M Ver6Roberto Vertel RomeroNo ratings yet

- Wheel Loader Liebherr L 504-L 522 - Service ManualDocument510 pagesWheel Loader Liebherr L 504-L 522 - Service Manualdim4erema91% (23)

- Service Manual 2014 HD Dyna Service Manual 99481-14 (Preview)Document6 pagesService Manual 2014 HD Dyna Service Manual 99481-14 (Preview)Amip FolkNo ratings yet

- Service and Repair Manual: Z - 45 XC Z - 45 HFDocument197 pagesService and Repair Manual: Z - 45 XC Z - 45 HFabdelhanin bouziane100% (1)

- S5 Ys05e06aDocument155 pagesS5 Ys05e06aNelson FurtadoNo ratings yet

- P 7 Ada 54 BDocument18 pagesP 7 Ada 54 Bzvonkomihajlovic4891No ratings yet

- 2013 VRSC Models Service ManualDocument515 pages2013 VRSC Models Service ManualCaio A Alves60% (15)

- Z45:25Document121 pagesZ45:25Kardec SanchezNo ratings yet

- USB Disk Drive Replacement Kit: Product ManualDocument30 pagesUSB Disk Drive Replacement Kit: Product Manualkanokchanok promsanNo ratings yet

- Weld Repair Procedure For The Rear Axle A-Frame On 776 & 777 Off-Highway Trucks (0679, 3260, 3268)Document25 pagesWeld Repair Procedure For The Rear Axle A-Frame On 776 & 777 Off-Highway Trucks (0679, 3260, 3268)Israel MirandaNo ratings yet

- E58fb CX-60 8KF4-EE-22A Edition1 WebDocument754 pagesE58fb CX-60 8KF4-EE-22A Edition1 WebspineckiNo ratings yet

- DCP-9040CN, DCP-9042CDN 9440CN 9450CDNDocument450 pagesDCP-9040CN, DCP-9042CDN 9440CN 9450CDNLone WolfNo ratings yet

- Dimensiones de WheelsDocument117 pagesDimensiones de Wheelsariel avalos100% (2)

- Reusage and Salvage of Water PumpsDocument61 pagesReusage and Salvage of Water Pumpsharikrishnanpd3327No ratings yet

- Doosan DL06, D110s-5, D130s-5, D160s-5, Dl06k Operation ManualDocument211 pagesDoosan DL06, D110s-5, D130s-5, D160s-5, Dl06k Operation ManualJose Henrique GuimarãesNo ratings yet

- Service Manual: Diesel Engine 5.8 Liter (DB58S)Document152 pagesService Manual: Diesel Engine 5.8 Liter (DB58S)rodrigoborges10No ratings yet

- IEC To Modbus Converter - Saitel SchneiderDocument116 pagesIEC To Modbus Converter - Saitel SchneiderMohit Yadav Mohit YadavNo ratings yet

- 2014 HDXDocument192 pages2014 HDXVincent Roy100% (1)

- Operating Manual: Wheel Loader L538 - 432 From 13100Document284 pagesOperating Manual: Wheel Loader L538 - 432 From 13100Jacques Van Niekerk100% (4)

- Service Manual: International HS 2.8LDocument130 pagesService Manual: International HS 2.8LIssac NegreteNo ratings yet

- Roadliner Stratoliner Service ManualDocument444 pagesRoadliner Stratoliner Service ManualBorborean Andrei TiberiuNo ratings yet

- En OmsmDocument127 pagesEn OmsmValentinNo ratings yet

- Brother Service Manual - 5240,5250D, 5270DNDocument323 pagesBrother Service Manual - 5240,5250D, 5270DNCosmin CurticapeanNo ratings yet

- Freightliner s2 Chassis Workshop ManualDocument20 pagesFreightliner s2 Chassis Workshop Manualrobert98% (46)

- Kawasaki Jet Ski Watercraft 1100 STX D.I. '03 (JT1100-G1) - Service ManualDocument288 pagesKawasaki Jet Ski Watercraft 1100 STX D.I. '03 (JT1100-G1) - Service Manualdale123850167% (3)

- 2013 HD Softail Electrical DiagnosticsDocument486 pages2013 HD Softail Electrical Diagnosticsveteandando95% (20)

- 2008 XB Electronics Manual 99493-08YDocument288 pages2008 XB Electronics Manual 99493-08YAnthony WindomNo ratings yet

- Xerox® Phaser® 6510 Color Printer/ Workcentre® 6515 Color MFP Service Manual - Revised Bus Update: July 2020Document774 pagesXerox® Phaser® 6510 Color Printer/ Workcentre® 6515 Color MFP Service Manual - Revised Bus Update: July 2020MarcosNo ratings yet

- SF5xxx Userguide EnglishDocument132 pagesSF5xxx Userguide Englishshamsudin yassinNo ratings yet

- z45-25j Mantenimiento 2Document255 pagesz45-25j Mantenimiento 2jonny david martinez perezNo ratings yet

- Foreword: Manual Name Pub. No. DUTRO Chassis Workshop Manual Supplement S1ïYXZE10ADocument137 pagesForeword: Manual Name Pub. No. DUTRO Chassis Workshop Manual Supplement S1ïYXZE10AJerwin Jay MaderasNo ratings yet

- Manual 3HAC038751-En RevBNDocument32 pagesManual 3HAC038751-En RevBNtatequietoneneNo ratings yet

- c7 1 PDFDocument34 pagesc7 1 PDFTASHKEELNo ratings yet

- Suzuki 2005 DF15 20 Service ManualDocument320 pagesSuzuki 2005 DF15 20 Service ManualLjubo GlusacNo ratings yet

- Mb900 Trouble GuideDocument427 pagesMb900 Trouble GuideCarlos Chzs100% (10)

- 2007-421-Yamaha - VStar - 1300 Manual 2 PDFDocument421 pages2007-421-Yamaha - VStar - 1300 Manual 2 PDFRory Neilson100% (2)

- S5 Yw04e06aDocument130 pagesS5 Yw04e06aNelson FurtadoNo ratings yet

- Service Manual 2010 HD Sportster Service Manual 99484-10 (Preview)Document6 pagesService Manual 2010 HD Sportster Service Manual 99484-10 (Preview)Amip Folk0% (1)

- Colorqube 9203 Family ServiceDocument1,942 pagesColorqube 9203 Family ServiceKalai Chelvan S RamiahNo ratings yet

- DP DP CouplerDocument104 pagesDP DP Couplerpercu_mwNo ratings yet

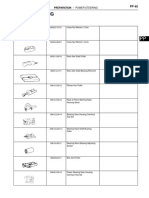

- Preparation - Power SteeringDocument4 pagesPreparation - Power Steeringpachara0032No ratings yet

- 1GR-FE Exhaust - 00200610Document1 page1GR-FE Exhaust - 00200610Raf SNo ratings yet

- ZF TboxDocument2 pagesZF Tboxpachara0032No ratings yet

- Revo IoDocument2 pagesRevo Iopachara0032No ratings yet

- Toyota RevoDocument1 pageToyota Revopachara0032No ratings yet

- Catch Me If You Can WorksheetDocument4 pagesCatch Me If You Can WorksheetHurleyHugoNo ratings yet

- Palm Kernel Reinforced Composites for Brake Pad ApplicationsDocument18 pagesPalm Kernel Reinforced Composites for Brake Pad ApplicationsSachin SukumaranNo ratings yet

- Types of FlowersDocument3 pagesTypes of FlowersAurea Jasmine DacuycuyNo ratings yet

- Mahatma Gandhi Institute of Pharmacy, LucknowDocument1 pageMahatma Gandhi Institute of Pharmacy, LucknowMukesh TiwariNo ratings yet

- BS 0812-114 - 1989Document12 pagesBS 0812-114 - 1989عمر عمرNo ratings yet

- StressesDocument61 pagesStressesMuhammad MusaNo ratings yet

- Rhythm MP - The Music Page - Theory Made Easy For Little Children Level 1Document9 pagesRhythm MP - The Music Page - Theory Made Easy For Little Children Level 1AmilacicNo ratings yet

- Splices: S100 S100 S101 S101 S101 S102Document3 pagesSplices: S100 S100 S101 S101 S101 S102Albert BriceñoNo ratings yet

- Approximate Methods For The Estimation of Muskingum Flood Routing ParametersDocument12 pagesApproximate Methods For The Estimation of Muskingum Flood Routing Parameterssherif ashrafNo ratings yet

- Colossians 1Document1 pageColossians 1aries john mendrezNo ratings yet

- Digital Media TYBMM (Advertising & Journalism) Semester VIDocument5 pagesDigital Media TYBMM (Advertising & Journalism) Semester VIKartavya JainNo ratings yet

- Daftar Obat Alkes Trolley EmergencyDocument10 pagesDaftar Obat Alkes Trolley EmergencyMaya AyuNo ratings yet

- Train LapbookDocument34 pagesTrain LapbookSebõk KatalinNo ratings yet

- Demolition and excavation worksDocument30 pagesDemolition and excavation worksHafizan Hanafiah100% (3)

- Eriopon R LiqDocument4 pagesEriopon R LiqsaskoNo ratings yet

- 14-01 Lista de Laptops - DistribuidoresDocument29 pages14-01 Lista de Laptops - DistribuidoresInkil Orellana TorresNo ratings yet

- History All Pictures QuestionsDocument7 pagesHistory All Pictures QuestionsDivyansh RajoriaNo ratings yet

- Philippine School Action Plan for Scouting ProgramDocument1 pagePhilippine School Action Plan for Scouting ProgramLaira Joy Salvador - ViernesNo ratings yet

- Coding deCoding class insightsDocument18 pagesCoding deCoding class insightsShalabh Vikram SahuNo ratings yet

- Haven, Quantum Social ScienceDocument306 pagesHaven, Quantum Social ScienceMichael H. HejaziNo ratings yet

- Social Responsibility and Managerial Ethics (Principles of Management)Document35 pagesSocial Responsibility and Managerial Ethics (Principles of Management)Reader94% (16)

- LMV Tyre SafetyDocument19 pagesLMV Tyre SafetykarvadNo ratings yet

- Republic OF THE Philippines Department OF Budget AND Manageme 589 May 25, 2022Document14 pagesRepublic OF THE Philippines Department OF Budget AND Manageme 589 May 25, 2022Juvy BustamanteNo ratings yet

- Southwest Globe Times - Sep 8, 2011Document16 pagesSouthwest Globe Times - Sep 8, 2011swglobetimesNo ratings yet

- Hsslive Xii History All in One Notes 2023 by SujithDocument72 pagesHsslive Xii History All in One Notes 2023 by SujithKanupriya AgnihotriNo ratings yet

- Biopharma SolutionDocument7 pagesBiopharma SolutionLili O Varela100% (1)

- Attendance: Umut KurtoğluDocument2 pagesAttendance: Umut KurtoğluHavvaNo ratings yet

- Visual Communication, Summary WritingDocument8 pagesVisual Communication, Summary WritingAsumpta MainaNo ratings yet

- Logistic Growth Rate Functions Blumberg1968Document3 pagesLogistic Growth Rate Functions Blumberg1968Jonnathan RamirezNo ratings yet

- Creative 2nd QuarterDocument6 pagesCreative 2nd QuarterJanice CordovaNo ratings yet

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseFrom EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseRating: 4.5 out of 5 stars4.5/5 (50)

- The Laws of Thermodynamics: A Very Short IntroductionFrom EverandThe Laws of Thermodynamics: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (10)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedFrom EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedRating: 5 out of 5 stars5/5 (1)

- Waves and Beaches: The Powerful Dynamics of Sea and CoastFrom EverandWaves and Beaches: The Powerful Dynamics of Sea and CoastRating: 4 out of 5 stars4/5 (1)

- Rolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsFrom EverandRolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsNo ratings yet

- Handbook of Mechanical and Materials EngineeringFrom EverandHandbook of Mechanical and Materials EngineeringRating: 5 out of 5 stars5/5 (4)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionFrom EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionRating: 4.5 out of 5 stars4.5/5 (3)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Introduction to the Explicit Finite Element Method for Nonlinear Transient DynamicsFrom EverandIntroduction to the Explicit Finite Element Method for Nonlinear Transient DynamicsNo ratings yet

- Three Laws of Nature: A Little Book on ThermodynamicsFrom EverandThree Laws of Nature: A Little Book on ThermodynamicsRating: 4.5 out of 5 stars4.5/5 (10)

- Machinery Failure Analysis Handbook: Sustain Your Operations and Maximize UptimeFrom EverandMachinery Failure Analysis Handbook: Sustain Your Operations and Maximize UptimeRating: 3.5 out of 5 stars3.5/5 (4)

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNo ratings yet

![VW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004](https://imgv2-1-f.scribdassets.com/img/word_document/282876773/149x198/5fb74bd6e1/1675169638?v=1)