Professional Documents

Culture Documents

1124-Es-803 Out of Date

1124-Es-803 Out of Date

Uploaded by

sreeagile.es0 ratings0% found this document useful (0 votes)

40 views189 pagesOriginal Title

1124-ES-803_OUT_OF_DATE

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

40 views189 pages1124-Es-803 Out of Date

1124-Es-803 Out of Date

Uploaded by

sreeagile.esCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 189

‘TENDER No CNE/005/2006

DUBAI ELECTRICITY AND WATER AUTHORITY (DEWA)

SUPPLY, INSTALLATION, TESTING AND.

INING OF 400/132kV GARDENS

SUBSTATION AND ASSOCIATED WORKS

COMMIS:

FIRE FIGHTING

TENDER ENQUIRY SPECIFICATION

REVISION

a. MITSUBISHI ELECTRIC

‘SUPPLY, INSTALLATION, TESTING & COMMISSIONING

‘OF 400/132kV GARDENS SUBSTATION &

"ASSOCIATED WORKS

‘SCALE

DATE

March 2008

FIRE FIGHTING

TENDER ENQUIRY SPECIFICATION

DESIGNED,

DRAWN

‘APPROVED CED.

rt

CHECKED

1108- ES - 802

FIRE FIGHTING

SECTION 1

SECTION 2

SECTION 3

SECTION 4

SECTION 5

SECTION 6

SECTION 7

SECTION 8

SECTION 9

SECTION 10

SECTION 11

SECTION 12

SECTION 13

SECTION 14

SECTION 15

SECTION 16

SECTION 17

SECTION 18

INDEX

Scope of Works & Introductory Description

Fire Protection Specification & Associated

Information

Details of Works

General Requirements & Design Criteria

Project Execution Programme

Pricing Schedule - A

ISO Accredition - Schedule B

Manufacture & Place of Manufacture Schedule-D1

List of Subcontractors - Schedule-D2

Optional Spare Parts - Schedule H1 & H1-II

Training at Manufacturers Works - Schedule H2-I

Special Tools & Equipment - Schedule H2-IT

Training at Site (optional works) Schedule H2-VIII

List of Deviation from Specification - Schedule K

Price Variation Formulae - Schedule J

Date of Inspection & Delivery Schedule

Guaranteed Technical Particulars- Schedule 16

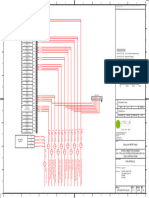

Drawings

1. SCOPE OF WORK & INTRODUCTORY DESCRIPTION

iD WATER. IORITY,

SIGN, MANUFACTURE

DESIGN, MANUFACTURE SUPPLY, SHIPPING & DELIVERY TO SITE,

INSTALLATION, TESTING, COMMISSIONING & HANDING OVER OF THE FIRE

1G, FIRE PROTECTION, Fil

NS 400/132kV SUBSTATI

AND ASSOCIATED WORKS

FIRE FIGHTING TENDER ENQUIRY SPECIFICATION

1.0 Introduction

Mitsubishi Electric invites firm fixed pricing for the fire fighting works associated with

the Supply, Installation, Testing, Commissioning & Handing Over of Garden

400/132kV Substation (Dubai) and Associated Works. Which shall comprise but not

be limited to the following works.

2.0 Programme

All Fire Fighting work shall be completed within the time scales indicated in the

Project execution programme, in section 5 of this document. Tenderers are

requested to submit an outline Installation Schedule consistent with a realistic time

frame within the overall completion periods.

3.0 Outline Scope of Works

The works shall include Fire Fighting Supply, Installation, Testing, Commissioning &

Handing Over associated with the items described in section 2 of this document plus

any other such items as shown or implied as necessary by the attached

Specifications, Schedules and Drawings.

4.0 All Schedules

To be completed & retumed with your quotation.

5.0 Quotation Return Date

Please return your quotation for review on or before the 22 of March 2006.

»AR’ SCOPE OF WORKS

Mitsubishi will be offering an alternative Substation layout in addition to the compliant offer

(Gee alternative layout drawing in section 18 of this document). Please provide two

quotations; one quotation for the compliant offer & a second quotation for the alternative

offer. Where schedule information for the alternative offer varies from the compliant offer;

please take a copy of the schedule & mark the schedule for alternative offer only,

‘The scope of works shall cover the design, manufacture, supply, shipping and delivery to

site, installation, testing and commissioning and handing over of fire fighting, fire protection,

fire detection and alarm schemes for the following, 400/132kV Sub Station:

Gardens Sub Stations and Associated Works, whiich shall comprise but not be limited to the

following works.

Please Note: All transformer enclosures will have blast walls,

Hurtecene Frorsscnsc Doc

EXTENT

1.01

1.02

1.04

1.05

1.06

1.07

1.08

1.09

1.10

4441

4.12

1.13

1.14

115

1.16

‘The preparation and submission of design files for approval.

The design of the entire fire fighting, fire protection, fire detection and alarm

systems in accordance with the specifications, schedules, appropriate

standards and regulations.

‘The system consists of fire detection & alarm system, water spray systems

(inclusive of test & refil water), hand held fire extinguishers, fire sealing and

cable coating for each Sub Station.

‘The preparation and submission of detailed drawings for approval (to comply

with the Client programme).

Co-ordination of design with other disciplines.

‘The preparation and submission of construction drawings

‘The manufacture and/or procurement of all necessary fire fighting and fire

detection equipment in accordance with the specifications, appropriate

standards and regulations.

Any necessary Co-ordination with the panel manufacturers to supply all fire

detectors, so as to avoid any delay in pane! manufacture.

‘The supply of shop test procedures 8 weeks before factory testing is due.

Making arrangements for the Contractor to carry out factory inspections of

fire fighting and fire detection equipment (in accordance with the terms of

subcontract).

Making appropriate arrangements for the Client to witness shop tests of fire

fighting and detection equipment in accordance with the requirements of the

specifications and terms of subcontract.

‘The preparation and submission of builders work drawings in accordance with

the specifications and subcontract drawings.

‘The preparation & submission of drawings required for building permit if

applicable.

‘Submission of fire fighting equipment test certificates.

‘The supply and delivery on a tum key basis (including the necessary

documentation) of all necessary materials for the fire fighting, fire protection,

fire detection and alarm scheme in accordance with the specifications and

terms of subcontract.

The complete installation of all fire fighting, fire protection, fire detection &

‘alarm materials in accordance with the construction drawings, s

and the Contractors programme of works.

‘Submission of manpower schedules and programme of works for approval.

Details of which shall follow the Contractors overall construction programme.

evtoncenr_rravesecnsc 000

4aT

1.18

1.19

1.20

1.21

1.22

‘Testing and commissioning in accordance with the specifications

‘Supply and installation of a suitable number of operation and maintenance

wall charts.

‘The preparation and submission of operation and maintenance manuals in

accordance with the specifications.

‘Supply and delivery of spare parts and catalogues.

Preparation and submission of as-built drawings in accordance with the

specifications.

Guarantee all fire fighting, fire protection, fire detection and alarm equipment

‘supplied in accordance with the specifications.

venioncenw_Frovrsscnsc.00c

BLANK PAGE

Supply, Installation, Testing and Commissioning of

400/132kV Gardens Substation and Associated TENDER NO. CNEV005/2006

400KV OHL Works

1. Introduction

DUBAI ELECTRICITY & WATER AUTHORITY (DEWA) intends to implement additions and

alterations to the existing DEWA High Voltage Transmission System, specifically to cater for

the power supply requirements due to the rapid expansion of Dubai. The part A portion of

the 'M’ Station project involves the construction of new 400KV ‘M' substation, new 400/132kV

Gardens substation, some modification of remote ends substations, new double circuit

400kV OH line from ‘M’ station to 'H’ Station new with LILO at Gardens substation,

Conversion of the existing 400kV single circuit lines (G station-Najma & DRED-NAJMA) to

double circuit lines to have ‘M’ Station-Najma and ‘L’ Station-Najma, some diversion of

existing 400kV lines as per drawing: 'M' Station - Proposed 400kV Connection Scheme.

Substation Works included in this Tender document is construction of 400/132kV Gardens

substation

2. Scope of Works for 400/132kV Gardens Substation

‘Scope of the works shall consist of the following:

1. A new indoor 400kV GIS substation is to be supplied, installed and

commissioned. This shall provide 14 circuit-breaker bays in a double busbar

configuration, arranged as follows:

Four 400/132kV Transformer bays each rated at 1250 A

Two Bus Coupler bays each rated at 4000 A

‘Two Bus Section bays each rated at 4000 A.

Six Feeder bays each rated at 2500 A

‘Two sections of main/reserve busbars, each rated at 4000A.

Provision shall be made for extension by one additional bay at each side of

GIS at a later date. Local control panels (LCP) for 400KV GIS bays shall be

included in the scope.

The single line diagram is shown in the Tender drawing referent number:

CE/005/06/S/01/D/DI0055

The scope of work also includes additional 400kV Gas Insulated Busbar (GIB)

as indicated in the layout drawings referent number:

‘CE/005/06/S/04/D/D/0052

2. A new indoor 132kV GIS substation is to be supplied, installed and

commissioned. This shall provide 28 circuit-breaker bays in a double busbar

configuration, arranged as follows:

Four 400/132 kV ICT Transformer bays each rated at 2500 A

Two Bus Coupler bays each rated at 3000 A

Two Bus Section bays each rated at 3000 A

Eighteen Feeder bays each rated at 1500 A

‘Two Reactor Bays each rated at 1500 A

‘Two sections of mainvreserve busbars, each rated at 3000A.

Provision shall be made for extension by two additional bays at each side of

GIS ata later date, Local control panels (LCP) for 132kV GIS bays shall be

included in the scope.

1 FICHTNER

‘Supply, Installation, Testing and Commissioning of

‘400/132kV Gardens Substation and Associated TENDER NO. CNE/005/2006

400kV OHL Works

The single line diagram is shown in the Tender drawing referent number:

CE/005/06/S/01/D/D/0056

Four Interbus 400/132kV 450MVA transformers shall be supplied and

installed to interconnect the 400 KV and 132 kV substations.

These transformers shall be three phase oil immersed units, suitable for

installation outdoors and shall be of the auto-transformer type with a delta

connected tertiary winding brought out to external terminals.

‘Two 40 MVAr shunt reactors rated shall be supplied and installed to provide

reactive compensation at the 132kV busbars, each connected via an

individual switchgear bay. The reactors shall be of the three phase, oil

immersed type.

132KV XLPE cables for connection between interbus transformers and 132kV

GIS, as well as between shunt reactors and 132kV GIS as shown in the

single fine diagram, including cable supporting system and cable

terminations.

Substation Control, Supervision / Monitoring and Protection shall be provided

to be consistent and compatible with DEWA's current standards, philosophy

and arrangements.

‘Telecommunication system shall provide the following services:

. Power line Teleprotection,

. SCS Communication with SCC/ECC,

. DFR Communication,

. SCADA Telephone system.

Substation services shall provide the following:

© LVAC Supplies (11/0.4KV Auxiliary transformer, main supply cable,

RMUs as well as main LV cables for connection with LVAG

switchboard will be installed by others.),

. DC Supplies including 110V and 48 V systems,

* Fire alarm and fire fighting system,

+ HVAC system,

* Lighting and small power system,

+ Earthing and lightning protection system,

* Set of LV power, control, instrumentation and telecommunication

cables including cable supporting system,

* Electrical system installation works including cabling system

installation works,

* Overhead traveling cranes for 400kV GIS building and 132kV GIS

building

2 FICHTNER

Supply, Installation, Testing and Commissioning of

400/132kV Gardens Substation and Associated TENDER NO. CNEJ005/2006

400kV OHL Works.

9.

Substation Civil Works comprising the following:

The works shall comprise all necessary design and construction for all civil,

structural, architectural works and services, required for the complete project

including inter-linking of services with existing systems where deemed

appropriate.

The Contractor is bound to provide complete works, even if the equipment or

services to be provided are not specifically mentioned in the specification,

The Scope of Work for substation shall include, but not be limited to the

following

. Site survey and subsoil investigation work,

. Site preparation, grading and landscaping,

. Road works, hard standing, paths, surfacing to suit architectural

requirements,

‘Substation buildings as well as auxiliary buildings and structures,

. Foul and storm water drainage systems,

. Permanent water supply to buildings and plumbing installations,

. Outdoor equipment supporting structures, foundations, gantries,

fencing and ete.

. Cable/GIB ways, duct banks and concrete cable trenches/tunnels,

. Transformer and Shunt Reactor compounds complete with firewalls,

: Relevant civil work provisions for 11kV RMUs, auxiliary transformers

and cable trenches.

10. Spare parts and tools shall be provided as per relevant Technical

Specifications and Prices Schedules.

The scope of work shall include the design, manufacture, factory testing, packing

and marking, shipment, insurance, delivery to site, loading and unloading,

erection, site testing, start up, commissioning, initial operation, reliability run,

performance testing, putting into commercial operation and maintenance support

for the defects liability period.

The Specification shall in any case be understood to comprise all equipment,

materials, services etc. even if not specifically mentioned, that would be required

or desirable to make the plant operational, safe and complete in every respect.

The Tenderer shall ascertain for himself the exact scope of work including all

material/equipment to be supplied such that the installation is complete and in

working order on completion of the contract. All the works and equipment/material,

including all extensions and modifications to existing plant/systems are deemed to

be included in the price quoted in the schedule.

Plant layout included in the tender documents is just a standard one and intended

only to guide the Tenderer. The Contractor may offer alternative arrangement that

would better suit the equipment offered or will provide a more practical or safer

design.

3 FICHTNER

‘Supply, Installation, Testing and Commissioning of

400/132kV Gardens Substation and Associated TENDER NO. CNE/005/2008

400KV OHL Works

However the plant layout and design shall satisfy the following requirements:

a) In developing the sites, the Contractor shail ensure that satisfactory

and safe access for maintenance, inspection and operation is

provided to all equipment and measurement points.

b) The plant shall be finished to produce a coherent and coordinated

design. All equipment shall be finished in the same colour regardless

of the manufacturer except when specified otherwise or to be

compatible with the existing equipment.

©) The Contractor shall include provisions in his tender for any work

necessary to locate buried services and rerouting of cables, pipes and

associated equipment to avoid previously unidentified hazards.

d) Where practicable, the Contractor should supply similar equipment to

that already existing to minimize the future spares requirement.

4 FICHTNER

BLANK PAGE

2. FIRE PROTECTION SPECIFICATION & ASSOCIATED

INFORMATION

‘Supply, Installation, Testing and Commissioning

of 400/132kV Gardens Substation and

Associated 400kV OHL Works.

VOLUME III

SECTION IV

TENDER NO. CNE/005/2006

Technical Specifications for 400/132kV Gardens Substation

CHAPTER 16

FIRE PROTECTION

TABLE OF CONTENTS

Clause Description Page No.

16.1 FIRE FIGHTING PHILOSOPHY 16-4

16.2 GENERAL 16-1

16.3 FIRE DETECTION AND ALARM SYSTEM 16-2

16.4 AUTOMATIC HEAT/SMOKE DETECTORS 16-4

16.5 ADDRESSABLE LOOP ISOLATORS 16-5

16.6 ADDRESSABLE MANUAL CALL POINTS 16-5

16.7 FIRE ALARM SOUNDERS/STROBES: 16-5

16.8 FIRE ALARM CONTROL PANEL 16-6

16.8.1 General Function 16-6

16.8.2 Zone Indication 16-6

16.8.3 Control and Alarm Equipment 166

16.8.4 Fault Waming 16-7

16.8.5 Alarm Sequence and Lamp Test 16-7

16.8.6 Ait Conditioning and Ventilation Equipment 16-7

16.9 PORTABLE FIRE EXTINGUISHERS 16-7

16.10 WATER SPRAY SYSTEMS 16-8

16.10.1 Deluge System for Transformers and Reactors 16-9

16.10.11 | General 16-9

16.10.12 Operation and Control 16-9

16.10.2 Cable BasementGallery and Tunnel Fire Protection 16-9

16.10.21 General 169

16.10.22 Operation and Control 16-10

16.11 WATER STORAGE TANK FOR FIRE FIGHTING 16-10

16.41.1 Tank 16-10

16.12 PUMPED WATER SYSTEM 16-11

16.13 VALVES PIPEWORK AND GENERAL ITEMS 16-13

16.13.1 Valves — General Requirements 16-13

16.13.2 Valve Types 16-13

16.13.3 Drain Valves 16-13

16.13.4 Non-Return Valves, 16-14

16.135 Nameplates 16-14

16.136 Pressure Relief Valves 16-14

16.13.7 Control Valve Sets (Deluge and Alarm Valves) 16-45

16.13.8 Strainers 16-45

16.13.9 Pressure Swithches 16-15

16.13.10 Pipe Work General Requiremets 16-15

16.13.11 Template Pipes 16-16

16.13.12 Pipe Joints _ _ 16-16

i FICHTNER

ENERGOPROJEKT ENTEL

16 Fire Protection

‘Supply, installation, Testing and Commissioning of

400/132kV Gardens Substation and Associated

400KV OHL Works TENDER NO. CNE/O05/2006

CHAPTER 16

FIRE PROTECTION

16.1 FIRE FIGHTING PHILOSOPHY

‘The substation shall be designed to provide a safe operating environment for equipment and

personnel. This shall be achieved by laying equipment out with sufficent separ:

segregation to minimise the risks from fire and explosion, and by selection or

equipment and materials.

The fire fighting and detection equipment to be supplied and installed under this contract

‘shall comprise the following:

(2) Automatic Fire detection and alarm system complete with manual call points,

(©) Portable and wheeled fire extinguishers for various rooms of the substation,

(©) Automatic water spray system for transformers and reactors.

(@) Automatic water spray system for the cable galleries and basements

(©) Fire water main with outdoor hydrants/hose equipment

A manual and automatic fire detection and alarm system shall be Provided, with detection

devices selected to suit particular risks, and with a control system designed to provide

Automatic and manual extinguishing systems will be provided to limit the consequences of

fires in major items of plant and minimise power shut dewn,

The fire fighting installations shall be designed to prevent the spread of fire, and buildings

shall incorporate fire resistant materials, fire dampers for air-conditioning and ventilation

ducting, fire stoppers for cable entries, and other faciltice Necessary to complete the

installations.

All openings in fire zone such as doors, windows, cable openings, PVC pipes and AC ducts

shall have the same rating of the fire zone.

Buildings are to be sub-divided into fire zones, as defined inthis specification

16.2 GENERAL

The Fire Detection and Alarm ‘systems shall be Analogue Addressable type and should be in

accordance with NFPA72 fire Codes. Fire fighting system design shall also be as per

relevant NFPA Fire codes e. g. NFPA-13, NFPA-15, NFPA-20, NFPA-24 etc.

rare fighting, fre detection and alarm, fire extinguishers, re pumps, diesel engine, electric

Groton: fire pump controllers shall have Listing or Approval from one or mone of the following

organisations (FM,UL),

16 Fire Protection

16-1 FICHTNER

ENERGOPROJEKT ENTEL

‘Supply, Installation, Testing and Commissioning of

400/132KV Gardens Substation and Associated

‘AQ0KV OHL Works: ‘TENDER NO, CNE/005/2008

All proposed fire fighting and fire detection and alarm systems shall be proven in DEWA or

installed in other power utilities in GCC minimum last three years. All equipment/devices

and accessories shall be subjected to DEWA’s approval

In this specification where DEWA requirement exceeds the requirement of Fire Codes and

Standards, DEWA requirements shall be considered as final.

The installation shall comply with local regulations of the United Arab Emirates Ministry of

Interior, Dubai Civil Defence, in respect of suppliers, installers, etc. and the Contractor shall

obtain the approval of Dubai Civil Defence Department for designs and installation as

appropriate.

Design parameters shall be as per relevant NFPA, fire codes and standards. In addition, the

1.E.C. Recommendations and Codes of Practice for Electrical Equipment shall apply to

equipment supplied under this contract as appropriate.

All electrical devices shall be type tested, conform to EMC and proved to be free from mal-

‘operation due to switching surges, voltage fluctuations, lightning and other electrical noises,

which may be expected in electrical substation environment.

Fire Protection System design, supply and installation shall be carried out by a fully

experienced and responsible contractor. Contractor shall submit, their ISO certification,

NFPA membership certification, Civil Defence approval, copy of Trade licence, Organization

chart, CVs of Design & Commissioning engineers copies along with their offer. Before a

system is installed, complete working plans, Specifications and drawings shall be prepared

and made available.

Design submissions shall clearly indicate the brief description of the total scheme of FPS

‘e.g. number of deluge valves considered for Transformers, for basement, number of fire

hydrants with location, number of repeater and mimic panels with locations, type and

number of detectors, manual call points, sounder/beacons, extinguishers, exit signs, safety

signs, provision of LHS, location of interface modules with weatherproof boxes, types of fire

pumps, type and number of water tanks etc.

16.3 FIRE DETECTION AND ALARM SYSTEM

The system shall comprise automatic fire detection and alarm system including manual

alarm initiating points to provide early warning of the outbreak of fire in any part of the

substation. Fire Detection and Alarm System shall be of Analogue Addressable type. In

addition the substations shall be divided up into zones for identifying the location of the

‘outbreak of fire. Generally the buildings within the substation shall be zoned as follows for

the software programming purpose and detecting fire, deluge operation, fire pump and water

tank status monitoring:

132kV/400 kV Switchgear Room (each room as one zone)

LCC & BCU Room

400kV Relay Room

432kV Relay Room

Battery Rooms

Battery Charger Rooms.

DC Distribution Room

AC Distribution Room

Control Room

Telecom Room

‘Store & Workshop Room

age@nogsena

28

16-2 FICHTNER

ENERGOPROJEKT ENTEL

Supply, Installation, Testing and Commissioning of

400/132kV Gardens Substation and Associated

aoouv onsen TENDER NO. CNE/008/2006

12, Corridor

13, Office & Pantry

1& Each Main Transformer (one zone for detection and one for deluge operation)

15. Each Auxiliary Transformer

16. Each Shunt Reactor

17. Each Cable Basement Rooms, Gallery Rooms (one zone for detection and

one for deluge operation).

18. DG Set Room

19. Gate House

20. Fire Pump House

21. Cable riser

22, HVAC shaft.

‘Supervisory Alarms for the followings:

Jockey pump controller fault

Jockey pump running.

Electric pump on demand.

Electric pump running.

Electric pump controller fault.

Diesel pump on demand.

Diesel pump running.

Diese! pump controller fault.

Fire pump room sprinkler operated.

Firewater tank level high alarm,

Firewater tank level low alarm.

Sprinkler isolation valve closed.

Fireman delivery isolating valve closed.

Fire pump junction isolating valvej closed.

Diesel enginer initling fuel ine closed.

Diesel enginer cooling line is closed.

Seeger se eromaone

saxapsss oes Fi

‘The Fire Detection and Alarm System shall be designed, manufactured and installed to the

highest standard of reliability by a specialist contractor/manufacturer complying to NFPAT®,

The number of fire detectors in any room shall be con:

fecommendation for the particular size of room and purpose for which the room is used but

shall not be less than two.

[The Fire Protection equipment shall have its own self contained 24V DC power supply with

batteries (two nos) and charger system. The control and indicating equipment shall comply

with the requirements of NFPA 72 and shall incorporate indicators to identify the zone in

Panel Batteries are to be submitted for DEWA approval. Fire Alarm Control Panel batterice

are to be installed in a separate cabinet adjacent to the panel

Following signals shall be transmitted to substation DCS:

Fire in substation.

132kV basement deluge operated,

400kV gallery deluge operated.

ICT Deluge Operated (One zone for each ICT)

Reactor Deluge Operated (One zone for each Reactor).

Cable riser basement tunnel deluge operated.

Fire pump running.

Fire protection faulty.

PNOMAONA

16-3 FICHTNER

ENERGOPROJEKT ENTEL

16 Fire Protection

Supply, Installation, Testing and Commissioning of

‘400/132kV Gardens Substation and Associated

400KV OHL Works. TENDER NO. CNE/005/2008,

9. Firewater tank level low alarm,

‘The fire detecting devices and manual call points shall initiate the following:~

(a) All sounders/strobes with flashing beacons mounted externally on the four

sides of substation buildings.

(b) Visual alarm on the Main Fire Alarm Panel at Control Room, Mimic/Repeater

Panels located near the main entrance of 400kV and 132kV Switchgear room,

and at Gate house.

(c) Audio-visual alarm at Control Room, Gate House and all building entrance.

{d) __Interposing relays and other equipment necessary to shutdown HVAC

System, Transformer Cooling fans, exhaust fans efc. and annunciation at

Transformer controlirelay panel/DCS.

(©) __Interposing relays and other equipment necessary to initiate a remote

supervisory alarm, which shall be connected to the SCADA marshalling kiosk

or DCS,

Continuous fault monitoring of the system is to be included so that an alarm is initiated in the

event of the system being out of service due to faulty detecting devices/modules/circuits,

alarm circuits, failure of power supply unit/batteries etc. Audio-visual alarm shall be available

at all Fire Alarm Control, Mimic/Repeater panels.

An appropriate number of auxiliary volt free contacts (but not less than four) shall be

provided for controlling the air conditioning and ventilation plant and other equipment.

16.4 AUTOMATIC HEAT/SMOKE DETECTORS

‘Automatic Analogue Addressable Smoke and Heat detectors shall be of approved and well-

tested types from reputable manufacturers. The detector elements and associated wiring

shall be encased in rugged, fire resistant containers, which shall protect the detector element

from accidental damage and ingress of moisture or dust. Address coding of the detectors

shall be either by software programming or, by dipswitches. X-pert card address coding

shall not be accepted.

The design and selection of Fire Detectors shall be in accordance with the environmental

conditions and likely combustion products, which can reasonably be anticipated. Generally,

Optical smoke Detectors will be suitable for the majority of areas, except Battery/ Fire Pump

rooms, where analogue addressable Rate of Rise/Fixed Temperature Heat Detectors are

required as appropriate.

If conventional rate-Anticipation/Rod type Heat Detectors is used in Main Transformer,

Reactors Rooms and Auxiliary Transformers Rooms (if required by DEWA), weather proof

(1P67) zone monitor units/interface modules are to be used for interfaceing the same with the

Analogue Addressable Fire Alarm and Detection System. All such detectors shall be

provided with heat collector plate of size 300mmX300mmX2mm.

All Interface modules shall be installed in weatherproof (IP55) boxes in an Air-Conditioned

room (near by).

Detectors shall be installed within all false ceilings, floor voids, cable trenches and cable

risers. All these detectors and any other devices shall be located in easily accessible

locations. Detectors inside the132kV/400kV switchgear room shall be accessible from the

EOT crane. Fixed type access ladders are to be provided to reach the detectors at cable

riser ceiling where there is no other access facilities.

Where detectors are installed in hidden voids, independent remote indicator lights shall be

provided for each void detector.

= 16-4 FICHTNER

a ENERGOPROJEKT ENTEL

16 Fire Protection

‘Supply installation, Testing and Commissioning of

400/132KV Gardens Substation and Associated

400KV OHL Works. TENDER NO. CNE/005/2006

Detectors fixed to false ceilings tiles shall be installed in a neat and symmetrical pattern

aesthetically orientated to the ceiling panel arrangement, coordinated with other equipment

and shall be in obstruction free locations. The tiles in the false celling where ceiling

detectors are to be fixed shali have reinforcement with wooden frame or any strong and

durable hard sheet.

All special equipment (hot air blowers, Smoke gun, detector removal tools with extension

Poles, etc.) that is necessary to facilitate the proper testing and maintenance of detectors

shall be provided under the same contract before commissioning,

Number of Detectors in each room shall be as per the recommendations of the

manufacturer, as per Fire Codes/Standards but shall be a minimum of two. Beam depth is

to be considered as per fire codes to determine the number of detectors in each

room/compartment.

Al detection cabling shall be of MIGC cable. Termination of MICC cables shall comprise of

a Seal to provide a means of electrical connection and a gland to secure the cable Into the

appropriate apparatus. Glands are to be covered with PVC shrouds. The maximum number

of cores per cable shall be two, except where specifically approved by the Engineer. In all

instances where the cables cross building or other movement joints the cable shall be

Suitably curved or looped to provide for expansion, contraction, or other movement. Where

cable Is run in areas where mechanical damage is possible additional protection shall be

provided.

16.5 ADDRESSABLE LOOP ISOLATORS

Loop isolators compatible with the main fire alarm panel shall be provided between each

floor, between each building, between each basement, but the maximum number of devices

between two isolators shall not be more than twenty or as per the manufacturer's

recommendation which ever is less. Loop isolator in basementigallery and fire pump room

shall be inside weatherproof box with IP65 protection,

16.6 ADDRESSABLE MANUAL CALL POINTS

Addressable Manual call points shall be provided at strategic locations in and around the

substation, specially near to each corridor and every exit. The location of each manual call

Point shall be subject to approval of DEWA & Civil Defence. Basement/gallery partition wall

shall be provided with manual call point (WP) near each doors on both sides.

{Al outdoor and deluge zone area Manual Call Points shall be of waterproof type(IP65) and

to be provided with transparent protective cover.

16.7 FIRE ALARM SOUNDERS/STROBES

Only Sounder/Strobe combined unit shall be provided inside the substation at strategic

locations. All sounders used inside the substation shall be of a similar type and tone Ail

Sounders/strobes should be waterproof (IP65) for deluge zone and external’ use,

Sounder/Strobes shall be provided in all rooms corridors and surrounding all buildings.

he, sound level of the soundersistrobes at any point in the building shall be 65 dB(A) or

5 dB(A) above any other noise likely to persist for longer than 30 seconds, whichever is the

greater. If necessary, additional sounder shall be installed to meet this requirement,

16-5 FICHTNER

ENERGOPROJEKT ENTEL,

16 Fite Protection

supply, Installation, Testing and Commissiring of

400/132KV Gardens Substation and Associates

400KV OHL Works TENDER NO. CNE/005/2006

16.8 FIRE ALARM MAIN CONTROL PANEL

16.8.1 General Function

Fire Alarm Control Panel shall be of Analogue Addressable type with LCD display and

keypad and other facilities required for programming, event history checking, operation etc.

‘The fire alarm control panel (FACP) shall consist of a number of individual units for

accepting and initiating alarms and identification of fire alarms originating from the protected

premises and for monitoring the status of all associated equipment. The panel shall be of

minimum of four loops. The actual number shall be conversant with the panel

manufacturer's rack size. The fire alarm main control panel shall comply with the

requirements of relevant NFPA fire codes. Panel must have FM approval and UL listing.

Each separate building other than that where the main FACP is located shall have a

standard Repeater panel. A mimic panel only is required near the FACP and Repeater panel

in Gate House. This mimic panels shall have LEDs indicators/buzzerlacknowledge and

silence button and LEDs test facility,

All fire detection system wiring shall be of MICC cables within buildings, outside the buildings

and between different buildings.

MICC cabling in the Control room and in corridors shall be concealed in wall but should be

serviceable by laying them in Gl trunkings with covers on the surface of the wall. Devices

within these areas also should be recessed in walls.

Alll outgoing wiring from the FACP to plant shutdown (transformer cooling fan shutdown, A/C

ventilation trip) should have linkable terminals. Panel shall have provision for manual

isolation of output groups operated due to the operation of particular device.

Desktop printer shall be provided with proper table for printing the events from FACP.

16.8.2 Zone Indication

The protected premises are to be split into zones as per DEWA requirement. All the

detection devices within one zone shall initiate one common indication, which shall clearly

identify the zone and indicate the zone on a plan or mimic of the premises. Normally RED

LEDs shall indicate fire detection and GREEN LEDs shall indicate deluge operation.

Repeater Panels shall also have LCD display as like as main panel. Provision for lamp test,

silence and reset shall also be available. Minimum three number of repeater panel shall be

provided at the approved locations.

16.8.3 Control and Alarm Equipment

‘The FACP and repeater panels shall be equipped with an audible alarm functioning on

initiation of any of the detector devices.

Each zone monitor shall be equipped with the following: -

(a) Avolt free contact for repeat common alarm to the system control centre.

(b) A volt free contact for repeat common alarm to the standby control panel.

(©) Avolt free contact to initiate external loud ringing bells.

16 Fie Protection

166 FICHTNER

ENERGOPROJEKT ENTEL

‘Supply, Installation, Testing and Commissioning of

400/132kV Gardens Substation and Associated

400kV OHL Works TENDER NO. CNE/005/2006

(4) Two spare volt free contacts.

(©) Complete detector circuit monitoring, initiating a visual and audible warning

(on occurrence of a fault condition.

() Zone fire protection it tiating device for initiating functions such as control of

HVAC, Transformer cooling fans etc. and separate volt free contacts as

above for initiation of repeat common alarms and external loud ringing bells.

16.8.4 Fault Warning

Equipment faults or advisory warming alarms such as water level low pressure, Power

supplies, etc. shall initiate local visual and audible alarms via a fault monitor.

Internal faults shall initiate local visual and audible alarms via a fault monitor.

The audible alarm shall be distinctive and different to the audible fire alarm.

Each fault monitor shall be equipped with the following:

(@)__Avvolt free contact for repeat common alarm to the system control centre.

(b) A volt free contact for repeat common alarm to ‘the standby control centre.

(©) Two spare volt free contacts.

16.8.5 Alarm Sequence and Lamp Test

All alarm circuits shall be provided with an approved scheme for accept, silence, reset and

test.

All lamps, including indication lamps, shall be provided with an approved scheme for lamp

test.

16.8.6 Air Conditioning and Ventilation Equipment

On the occurrence of any zone fire alarm, automatic shutdown shall be initiated of any air

conditioning and ventilation plant supplying the affected zone with the exception of the

battery room extract fans. The same shall start automatically after resetting of Fire Alarms

Shutdown scheme shall be designed in such a way that fire detection in any area of the

building or floor shall shutdown the HVAC system of that building or floor only. However, the

final scheme of HVAC shutdown is to be coordinated with Civil Department,

16.9 PORTABLE FIRE EXTINGUISHERS

All apparatus shall be suitable for operation by one person alone and shall be easily

recharged. The discharge shall be non-corrosive and free of chemicals prone to give off

toxic gases when heated. The extinguishers shall be of the nitrogen stored pressure type

dry powder and of S~6 kg charged weight apart from those in rooms containing electrical

apparatus such as control panels, etc., in which case the extinguisher shall be carbon

dioxide type of 5~6 kg charged weight. All indoor extinguishers shall be provided with

Fecess(wall flush) type steel cabinet with stainless steel facia and front door with wired glass

and MS powder coated back box. A schedule of fire extinguishers shall be provided, 25~30

Kg Trolley Type DCP/CO2(as approved by the engineer or Civil Defence) Extinguisher shall

be provided at switchgear room (400KV, 132kV & 11kV) and 5~6 Kg CO2 extinguisher at

16-7 FICHTNER

ENERGOPROJEKT ENTEL

16 Fire Protection

‘Supply, Installation, Testing and Commissioning of

400/132kV Gardens Substation and Associated

‘400kV OHL Works. TENDER NO. CNE/005/2008,

each ICT and Reactor room. Extinguishers installed outside of the building shall be supplied

with weatherproof steel boxes painted red. All extinguishers and their cabinets are to be

provided with photoluminous safety signs and proper labeling. 45 liter AFFF (3%) trolley

mounted foam fire extinguisher shall be provided in fire pump room and generator room

(Minimum two number each room).

‘The Contract shall include for the supply and installation of all wall brackets and fittings etc

required for mounting the extinguishers.

Operating instructions shall be clearly printed on each unit (or adjacent to each unit in Arabic

cor English). Sticker type label will not be accepted. All fire extinguishers shall be UL Listed

and FM approved.

Fire Fighting equipment should not contain any ozone depleting gases.

The arrangement of the portable fire extinguishers, quantities, locations and types shall be to

‘the approval of the U.AE., Ministry of Interior, Dubai Civil Defence and the Engineer. A

separate drawing is to be submitted indicating the location of all extinguishers, exit signs and

exit route.

All indoor safety signs shall be of photo luminous type. All final EXIT signs shall be

illuminated type, the wiring shall be done with fire/shock/water resistant MICC cables.

Breathing apparatus of 45-minute duration are to be provided in the main entrance or

corridor(2. nos) and gate house (2nos). The cylinder shall be of composite lightweight

aluminum and shall be installed in a recess type mild steel cabinet with stainless steel fascia.

The cabinets are to be provided with photo luminous safety signs and proper labelling.

16.10 | WATER SPRAY SYSTEMS

Water spray systems are to be in accordance with the NFPA 15 code and are to be fully

automatic in operation.

Each transformer shall have an independent detection and operating system. The following

features shall be incorporated:

(a) _ Effective water spray shall be discharged from the nozzles within 30 seconds

of the initiation to the Deluge Valve.

(b) Readily accessible deluge valve just outside the protected area.

(c) __Allpipework shall be sized on the basis of flow from firewater tank.

(d) All water storage requirements shall be provided,

(9) Strainers at the deluge valves shall be provided to prevent blockage of the

nozzle heads.

(h) All pipework and nozzle heads shall be designed to enable maintenance on

the transformers to take place without need for removal of the pipework and

to the approval of the Engineer.

() All metal pipe works at road crossing shall pass through trenches. Pipe flange

edges shall have 150mm clearance at the bottom and 150mm above the

valve stem or, the flanges edges. Trenches are to be provided with heavy-

ee 16-8 FICHTNER

= ENERGOPROJEKT ENTEL

‘Supply, Installation, Testing and Commissioning of

400/132kV Gardens Substation and Associated

Hood Ono TENDER NO, CNEV008/2006

duty lightweight covers. Proper protection is to be provided against corrosion

from the soil conditions.

All fitings and futures for pipe work shall be of Carbon Steel schedule40, hot

dipped galvanized and painted to colour red,

16.10.1 Deluge System for Transformers and Reactors

16.10.1.1 General

Water coverage and application should be in accordance with N.F.P.A. 15. Article 4-4.3.4

(10.2 Iitresiminim2), “Water storage should be sufficient to maintain a 20-minute design

discharge to the two largest single hazards hazards whichever is the greater Minimeen

number of wet pilot ring in transformer and reactor rooms shalll be two.

16.10.1.2 Operation and Control

The fire protection system for the transformers and reactors shall be fully automatic in

operation. Using fixed temperature and rate of rise detection for detecting fire and for

actuating the audio-visual Fire Alarms System. The initiation to the Deluge Valve should be

Plug. All glass bulb sprinklers inside the room shall be provided with heat collector plate of

size 300mmX300mmx2mm.

The heat responsive devices shall be so placed in order to detect fire in any part of the

Protected area and to activate Fire Alarm System.

Manual release devices (box type) shall be Provided for all deluge valves. Such devices

shall be controlled from feadily accessible locations in the event of fire. Control shall be

DeWAn al or other approved means as per Civil Defence Authority and as approved by

DEWA. Manual release devices are to be fitted with a wire seal,

1610.2 CABLE BASEMENT/GALLERY AND TUNNEL FIRE PROTECTION

16.10.21 General

The completed installation shall provide total fire protection for all cables and equipment in

the basement area and in cable tunnels/risers. Provision shall be made for al futtne cable

installations,

16-9 FICHTNER

ENERGOPROJEKT ENTEL

16 Fie Protection

‘Supply, tnstallation, Testing and Commissioning of

‘4O0/132KV Gardens Substation and Associated

400kV OHL Works ‘TENDER NO. CNE/005/2008

protected by a system of water sprayers at ceiling level, both systems to be controlled and

‘operated by a common valve and detection system.

Water storage shall be sufficient to supply two largest zones simultaneously for 60 minutes

(Ref. also N.F.P.A. 15 Appendix A 3-2.1 and 3-3.1)

16.10.2.2 Operation and Control

Each zone of operation shall be controlled from a deluge valve. Linear heat detectors and/or

point heat detectors in the cable trays and combined point heat/smoke detectors at ceiling

level shall initiate the Fire Alarm and detection system in each zone. Initiation of Deluge

Valve in each zone shall be from wet pilot sprinkler system to the approval of Civil Defence

Authority of Dubai. Each deluge valve shall also have the facility for manual operation from

a box type manual pull station.

In area of the basement where suspended linear heat detectors would be prone to damage

the single point heat detectors shall be installed.

Upon operation of any zone of protection, a signal shall be provided to initiate audible and

visual alarms.

Combination of Heat and Smoke detectors shall be arranged into matching zones. The

Heat/Smoke detectors shall not initiate the fire protection system but will give audible and

visual alarm, so that the system may be operated manually if deemed necessary.

Linear heat detectors shall be installed in a zigzag fashion above and below all cable trays

and cable risers to cover the full width and length of the trays. Where trays are stacked one

above the other the intermediate spaces between them will need only one linear heat

detector to cover the tray above and the tray below. LHS cables for floor-mounted cables

are to be provided in spiral fashion. In all cases turn-to-turn distance shall be a maximum of

500mm. The linear heat detector shall be "DIGITAL" type and should not operate due to

‘switching or fluctuation. Each basement zone shall be provided with interface module for

LHD and shall be considered as a separate zone.

Heat Sensor Cables are to be provided for all control, Power Cables on the floor, cable trays

and cable risers. Minimum 4 nos interface module should be provided for the LHS cables in

each basement. Minimum 2 nos of interface modules shall be provided as spare in each

basementigallery.

46.11 | WATER STORAGE TANK FOR FIRE FIGHTING

16.114 Tank

‘The capacity of Fire Water Storage Tanks is to be decided as per the requirement based on

detailed calculations but total capacity should not be less than 500 cu meters and there shall

be two compartments (each having half the total capacity. Both tanks shall be inter-

connected to each other with suitable piping/vaive arrangements to facilitate isolation for the

purpose of maintenance/repairs. These Tanks can either be overground or on the roofs of

Pump House, Gate House, staff accommodation or Independent Towers depending on

planning/availabilty of space at site.

Tanks shall be of RCC/Aluminium construction with water proofing inside. Contractor must

ensure the positive head at the fire water pump suction all the times.

& 1640 FICHTNER

ENERGOPROJEKT ENTEL

‘Supply, Installation, Testing and Commissioning of

400/132kV Gardens Substation and Associated 7

400kV OHL Works. TENDER NO. CNE/005/2006

The tank shall include the following: -

Internal ladder (To be of stainless steel! and to be so constructed as not to be

directly affected by water pressure on to the Tanks’ walls and

bottom)

High-level float switch

Ball valve

Pipe test return nozzle

Contents gauge/Level gauge

300mm outlet with lockable valve

65mm drain connection

Sump for pumping out

‘U' tube vent with bird/insect screen

Level alarm switches/high & low

Fire services outlet of a standard pattern approved by the United Arab Emirates

Ministry of Civil Defence.

All metal parts and external ladder shall be stainless steel of grade 316 or higher.

Float Valve inspection pit with hinge type cover including lock & key arrangement.

Float valve inspection pit with hinge type cover including lock and key arrangement.

Fire pump test return line is to be connected to both the tanks, each branch shalll be

provided with isolation valves.

16.12 PUMPED WATER SYSTEM

Two pump sets with all ancillary equipment required and all complying with the requirements

of NFPA-20. The design and the equipment shall include all pipework, jockey pumps,

pressure gauges/switches and automatic starting equipment etc. Pumps shail be installed in

a readily accessible position in a sprinkler protected building. Contractor shall provide the

mono-rail minimum of 1 ton capacity electrically operated inside the fire pump room.

Pressure shall be generated by one electric and one diesel driven pumps, each capable of

supplying the water as per requirement and to maintain the trunk main and the associated

pipework at adequate pressure. All pressure gauges inside the fire pump room are to be

provided with anti vibration fluid. The pumpsets shall be arranged as main and standby, the

electric pumpset shall be the main pumpset.

All pumps, motors, diesel engines and controllers shall have individual FM approval and UL

listing

Electric Motor shall be of totally enclosed fan ventilated (TEFV) and of IP55.

All controllers, DBs, junction boxes inside the fire pump room shall also be of IPSS rating or

equivalent NEMA.

Pumps shall have long coupling, stainless steel shaft and bronze impeller with split casing.

Each fire pump(with 100% capacity) shall be capable of providing the pressure and flow

requirements of the two largest hazards operating simultaneously.

A jockey pump shall be installed to restore any small losses in the trunk main, which do not

necessitate the starting of the main pump set. Hour-run-counter is to be provided for the

Jockey Pump to monitor the amount of leakage in the system. Jockey pump controller shall

be provided with over run timer, Supply Healthy/Control circuit healthy/Pump Running/Pump

Tripped indications, A/C Power isolation Switch etc.

ae 16-11 FICHTNER

ENERGOPROJEKT ENTEL

‘Supply, Installation, Testing and Commissioning of

400/132kV Gardens Substation and Associated

400kV OHL Works TENDER NO. CNE/005/2006

Sufficient clearance is to be provided in between the foundation level of Diesel-Pump set

and the bottom of Diesel engine to facilitate easy drainage of Engine oil. A half or three-

fourth inch drainpipe is to be provided from the drain port at the bottom of the engine and to

be extended beyond the engine base with isolation valve and plug.

Pressure switches on the small bore pipework at delivery side of the pumps shall cause the

jockey and the main pumps to start up in a predetermined and correct sequence to meet the

demand for water.

‘When the start up pressure for the main pump has been attained, due to operation of the fire

protection system, a pressure switch shall initiate the start up sequence. A second pressure

‘switch shall initiate an alarm of "Pump on Demand’ at the main fire alarm panel. When the

pump is running a pressure switch on the top of the pump casing shall initiate an alarm of

“Pump Running" at Main Fire Alarm Control Panel at Control room and all other repeater

panels.

‘Should the water demand be too great for the main pump set, should the main pumpset fail

to operate, the standby pump shall start when a predetermined pressure is attained. Start

up of the standby pump shall also be alarmed at the main and repeater panels as above.

Drainpipes shall be provided at delivery head of the electric/diesel pumps with drain valves

to maintain the minimum required flow of the pump at closed head to avoid overheating,

Pressure gauges with anti vibration fluid shall also be provided at pump delivery. Contractor

shall indicate the minimum required flow with closed head during the design stage.

The system shall be provided with all local and remote control indications and alarms, which

shall be subject to approval. All pumps and their control panels should be monitored for

power supply facility (A/C supply fail, DC supply fail, battery disconnected) and audio-visual

alarm should be initiated at Fire Alarm Control Panel at Control room, Scada and all

Mimic/Repeater Panels.

Pump House shall be provided with splitiwindow type A/C in addition to ventilation system

with louvers. Wall mounted thermometer, Hydrometer, Battery filler are to be provided in the

Fire Pump room.

‘A multi-rack, double door wall mounted cabinet shall be provided inside the pump room for

keeping FPS testing tools and emergency spares.

Diesel fuel pump & connection shall be provided outside the pump room. Diesel fuel should

be electric motor (explosion proof) driven with controller and suitable for fuel system.

Shade should be provided for controller. Fuel filing pump, motor and controller should be

suitable for diesel fuel and outdoor use.

Trench cover lifting tools, valve-operating keys are also to be provided and fixed inside the

pump room wall.

16-12 FICHTNER

ENERGOPROJEKT ENTEL

16 Fife Protection

‘Supply, Installation, Testing and Commissioning of

400/132KV Gardens Substation and Associated

400kV OHL Works ‘TENDER NO. CNE/005/2006

16.13 VALVES PIPEWORK AND GENERAL ITEMS

16.13.1 Valves - General Requirements

All valves shall be of approved design and those of similar make, size and type shall be

interchangeable with one another unless otherwise approved. All valves, fitting and

accessories shall be of FM approved and UL listed.

16.13.2 Valve Types

All valves shall be of the full way gate type unless approved to the contrary. The internal

diameter of all valves at the end adjacent to the pipes shall be the same as the internal

diameter of the pipes to which they are joined. All valves shall have flanged pipe joints as

may be required and the cover joints shall also be to approval. All valves shall be flanged

type. All valves shall be OS & Y & resilient seated type.

All valves hand wheels shall be of metal. Plastic or Bakelite will not be accepted. The outer

rim of all hand wheels shall be radiused to prevent any sharp or angled edges.

Valves shall be provided with locking facilities to approval, which shall include any necessary

leather straps/chains, and locks,

Alll valves shall be closed by rotating the hand wheels in a clockwise direction when looking

at the face of the hand wheel. The face of each hand wheel shall be clearly marked with the

words "Open" and "Shut/Close”, with arrows adjacent to indicate the direction of rotation to

which each refers. All valves shall be fitted with indicators so that it may readily be seen

whether the valves are open or shut.

Where valves are exposed to the weather protective covers to approval, shall be provided on

the spindles.

All valves shall be easily accessible and provided with plate form for operation and

maintainance purpose,

Globe valve flange type at the fire pump test return line at the downstream of flow meter

shall be provided,

Valves shall not be fitted in an inverted position.

Light pattern valves, valves with screwed glands and lever operated gate valves are not

acceptable for any service. Valves with screwed connections will not be accepted for any

system containing oil

16.13.3 Drain Valves

Alll drain valves shall be of approved type and unless otherwise specified or approved shall

have cast or forged steel bodies with covers and glands of approved construction minimum

PN20 rating. Spindles shall be of stainless steel and the materials of internal parts shall be

to approval and suitable for operation at the maximum working pressure and temperature of

the piping to which they are connected. Valves shall be designed for continuous operation

partially open without erosion of the valve seats or faces. Where valve seats are shrouded

the design of the shroud shall be such as to prevent foreign matter lodging in the valve seat.

Alll drain valves shall be readily accessible.

16 Fire Protection

16-13 FICHTNER

ENERGOPROJEKT ENTEL

‘Supply, Installation, Testing and Commissioning of

400/132KV Gardens Substation and Associated

face Onan TENDER NO. CNE/005/2006

All Deluge manifolds shall be welded type and shall be provided with flanges at both ends.

Mechanical alarm shall be provided for each deluge valve separately. One inch diameter

drain valve with plug shall be provided with each manifold. Common priming line shall be

tapped from the manifold with an isolation valve with drain plug,

16.3.4 Non-Return Valves

All non-return valves shall be of approved type, make and loss of head.

The bodies shall be provided with removable access to enable the internal parts to be

examined or renewed without removing the vaives from the pipeline. NRV seat shall be of

gunmetal or brass.

NRV shall be flange type. Valve bodies shall be stamped with an arrow to indicate the

correct direction of flow.

Non-return valves in vertical pipes shall be provided with bypass or drain valves as may be

approved by the Engineer.

16.13.5 Nameplates

Each valve hand wheel shall be fitted with a nameplate indicating the following, in an

approved manner in Arabic and English: -

(2) The duty or service for which the valve is intended.

(bt) Avalve schedule reference number.

(©) __ Its normal operational status, ie. "normally open as NO" or “normally closed

as NC"

All the cable basementgallery zones should be labeled with aluminum nameplates with red

background and white text in an approved manner in Arabic and English to differentiate from

the neighboring zones as may be approved by DEWA.

Alll the Detectors, manual call points, audio-visual alarm warning devices, fire extinguisher

etc. should be labeled with address code or, identification numbers as applicable in English

and Arabic as may be approved by DEWA.

Fire action boards mentioning the sequence of action to be taken in case of fire are to be

provided at control room,security gate house, manifold area, near to each fire alarm panel,

Repeater/Mimic panels and in any other places as approved by Civil Defence Authority or as

by Employer /Engineer.

Procedure for testing and resetting of deluge valve, water motor alarm should be provided

near the deluge valve station on a board as approved by DEWA.

1613.6 Pressure Reliof Valves

Pressure relief valves shall be fitted as necessary to all pipe services (fire main, deluge valve

trim line,etc.) to protect pipework or other items of plant against pressures above the normal

working conditions of the system.

ee 16-14 FICHTNER

and ENERGOPROJEKT ENTEL

18 Fite Protection

‘Supply, Installation, Testing and Commissioning of

400/132kV Gardens Substation and Associated

400kV OHL Works. TENDER NO. CNE/005/2006

46.13.7 Control Valve Sets (Deluge and Alarm Valves)

Each control valve set shall include: -

i (@) Stop valve of approved construction with an indicator showing "OPEN" and

"CLOSED" positions, complete with padiocked securing straps. The valve

shall be mounted on the incoming side of the alarm or deluge valve.

(6) Control valve fixed above the main stop valve on the main supply pipe and

before any connection is taken off. Alarm Test line may be connected before

| main stop valve if necessary to fulfill condition(g) below.

(©) Auxiliary contacts/devices for alarm annunciation.

(4) Facilities for testing including any necessary valves, pipe work and drains.

(©) Dial pressure gauges(with anti-vibration fluid) arranged to monitor the water

pressures above and below the deluge valve set that means each deluge

valve should have two dial pressure gauges. Each gauge shall be provided

with a three-way isolating valve so that it can be easily isolated and removed

for testing and checking without shutting down the water supply.

' () Easy test facilities,

(9) Arrangement should be provided for testing the operation of water-motor-

: alarm while keeping deluge isolation valve closed.

All such valves and valve seats shall be leak tight under all pressure up to the test pressure

of the system. Each control valve station shall be provided with individual mechanical alarm.

‘Adequate testing arrangement shall be provided without spray the fire water to hazard.

{ Deluge vaive with trim assembly shall be FM approved and UL listed.

1613.8 Strainers

Strainers shall be provided on the supply line to each deluge system. Strainers shall be

capable of removing from the water all solids of sizes likely to obstruct the spray or sprinkler

nozzles. Main strainers should be installed with a bypass for use during cleaning. Strainer

mesh material shall be of stainless steel. Strainer shall be flange type.

16.13.9 Pressure Switches

Each pressure(alarm) switch shall have two separate operating switches. Range of alarm

pressure switches shall be 0 ~ 20 psi(factory sel) and for Pump start pressure switches

pressure range shall be shall be 0 ~ 11 bar(field adjustable). All pressure switch shall be IP

65 and FM approved & UL Listed.

16.13.10 Pipe work General Requirement

Fireman pipe shall be of ring type around the substation with both side isolation valves near

the T-junction for each manifold. All pipe work shall be of Seamless Carbon Steel,

Schedule40 with hot dipped galvanization after fabrication and shall be designed for the

appropriate conditions and shall comply with the requirements of the latest issue of the

S&S 16-15, FICHTNER

ENERGOPROJEKT ENTEL

‘Supply, Installation, Testing and Commissioning of

400/132kV Gardens Substation and Associated

400kV OHL Works ‘TENDER NO. CNE/005/2006

relevant National, NFPA codes. All pipes, bends and tees shall be truly cylindrical and

uniform in section.

‘Where adjacent items of plant are installed on separate foundations any interconnecting

Pipework shall incorporate a device, which will take into account differential settlement that

may occur. The pipes and shall be suitable to withstand the stresses and strains involved in

the operation of the plant,

Above ground pipes shall be hot dip galvanized and painted as per Specification for

steelwork in the subsection for painting. Sections involving welded parts shall also be hot

dip galvanized after fabrication. Special care shall be taken to ensure that openings are fully

cut out and that obstructions do not remain in the waterway.

Piping network shall be designed to withstand maximum water hampering. Approved

computer generated calculations shall be submitted for DEWA approval

No pipework shall be run in trenches carrying electrical cables.

Pipes shalll be not less than 25mm bore unless otherwise authorized by the Engineer.

No underground buried pipe shall be used. All pipes shall be inside trouches. Firemain

pipeline at road crossing shall pass through trenches with heavy duty lightweight trench

cover. Trench shall have a minimum width of 600mm. A clearance of 150mm is to be

provided below the flange edges of the pipeline in the trench and 150mm above the hand-

wheel or. Stem of the vaive in the pipeline. Suitable lifting tools shall be provided for lifting

the trench covers. If the weight of the each piece of trench cover exceeds 50kg, lifting

equipment shall be supplied under this contract.

All piping systems shall be arranged with adequate falls in the direction of flow, except where

otherwise approved by the Engineer. At the points of drainage, drain pockets of ample size

and approved construction shall be fitted. Where ever U bend comes, provide drain valve

with plug.

The details of design and construction shall be to approval. Pipework shall be sized on the

basis of hydraulic calculations, which shall also be submitted for approval. The size of pipes

and deluge valves shall be as per hydrostatic calculation.

Fire main trenches shall have drain facility and it should be connected with substation drain

facility.

16.13.11 Template Pipes

The position of all closing pipes shall be approved and special care shall be taken to ensure

that no permanent stresses are set up in any pipeline or items of connected plant when

closing lengths are jointed.

16.13.12 Pipe Joints

All required butt-welded joints shall be made by an approved process prior to galvanizing.

Sufficient flanged joints shall be provided to enable the pipe work to be dismantled for

cleaning and removal of attached equipment.

At terminal points and at points where castings adjoin and where, in the opinion of the

Engineer, it is undesirable to use a butt-welded joint, @ bolted seal weld or plain-flanged joint

of approved design shall be provided.

16-16 FICHTNER

ENERGOPROJEKT ENTEL

16 Fire Protection

You might also like

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Qurain W-Drawing Status List MELCO KW 11 05 07Document55 pagesQurain W-Drawing Status List MELCO KW 11 05 07sreeagile.esNo ratings yet

- RelaySet co-ordinaDocument2 pagesRelaySet co-ordinasreeagile.esNo ratings yet

- 12W TPN 400V Lvac Distribution BoardDocument1 page12W TPN 400V Lvac Distribution Boardsreeagile.esNo ratings yet

- Main 33kV Switchroom DC Scheme SH 5 of 5Document1 pageMain 33kV Switchroom DC Scheme SH 5 of 5sreeagile.esNo ratings yet

- AC Schematic Diagram for 13233kV Transformer Protection+GT1Document1 pageAC Schematic Diagram for 13233kV Transformer Protection+GT1sreeagile.esNo ratings yet

- 022 R01 Cable Schedules Multi Core CablesDocument1 page022 R01 Cable Schedules Multi Core Cablessreeagile.esNo ratings yet

- F-3 Achilles Template For Stage 1 InitiationDocument7 pagesF-3 Achilles Template For Stage 1 Initiationsreeagile.esNo ratings yet

- Scan10 - Section7to 10projDocument52 pagesScan10 - Section7to 10projsreeagile.esNo ratings yet

- Appendix B2 - Scope of Supply and Work - SWYDDocument2 pagesAppendix B2 - Scope of Supply and Work - SWYDsreeagile.esNo ratings yet

- D-NDA - ABB Discloser Rev1Document3 pagesD-NDA - ABB Discloser Rev1sreeagile.esNo ratings yet

- Dividor 6Document1 pageDividor 6sreeagile.esNo ratings yet

- Drawing List F FTG DRGSDocument2 pagesDrawing List F FTG DRGSsreeagile.esNo ratings yet