Professional Documents

Culture Documents

TSB0426

Uploaded by

Planta Damiana2Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TSB0426

Uploaded by

Planta Damiana2Copyright:

Available Formats

C

New Bremen, Ohio 45869 USA

Technical Service

Bulletin No. 426

Phone 419/629-2311

crown.com

1

C

1

T

H

C

P

2

V

R

2 B

T A

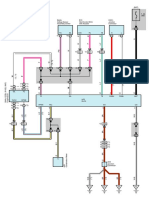

SUBJECT: Valve Calibration Procedure for Software -

V

P

A

V

S

P

C

Version 122676-001-08 Through 122676-001-11

2

C

C V

V 1 P P 6

4 C V V

C

1 S

PVA

MODEL: RR/RD 5000, RR/RD 5000S

8846

CAUTION

Before performing any work, be sure to refer to and follow all

recommended safety precautions set out in the applicable

Crown Service Manual. In addition, Crown recommends that all

mechanics wear appropriate protective items, such as safety

glasses, work gloves, and steel toed shoes, whenever performing

maintenance work on Crown equipment.

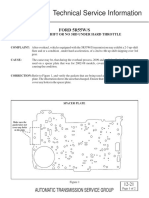

Software version 122676-001-08 through 122676-001-11 has a parameter to adjust the PVA (accessory) Main I crack

current level and valve Main G for each unique valve in order to limit the maximum accessory speed variation. Ref.:

Main I = Offset, Main G = Gain. The following procedure has been developed by Crown to simplify PVA (accessory

valve) calibration.

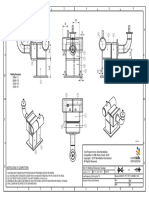

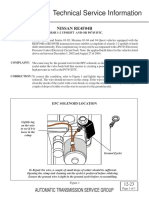

Hydraulic Pressure Gauge

104812

Manifold Gauge Port

Requires Mating Coupler 123321

8859P

ILLUSTRATION 1

7067 3/01

PAGE 1 OF 2 Printed in U.S.A.

TSB.426 (Continued)

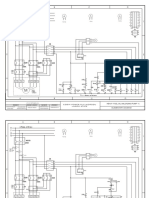

PVA - PROPORTIONAL VALVE CALIBRATION

Make sure Features menu is

set up correctly.

-F1 = 36 or 24 volt

-F2 = 2 or 5 pedals

-F11 = Hi speed lift - Get into analyzer mode A3.18

RR/RD 5000S Only (M2 current)

Select for hign

performance

lift motor only

Extend the carriage fully, then retract

to about half way and allow it to come

Install presure gage at port to a stop. Wait several seconds.

G on Main Hydraulic Observe the current at A3.18.

manifold block

Enter a value of 200 at the

*Is A3.18 between

service menu C6.3.1 No

acceptable values

See below

Extend the carriage fully, then retract

to about half way and allow it to come Yes

to a stop. Wait several seconds.

Observe the pressure at G.

Truck hydraulic system OK.

Is the pressure at G

Add 20

between 725 and 895 KPa Yes

to C6.3.1

(105 and 130 psi)

There is a faulty hydraulic

component located

No somewhere in system

Decrease C6.3.1 by 10 Check operation and/or contamination of:

1. PVA Valve

2. PCA Valve

3. Check for comtamination in ORF1

Extend the carriage fully, then retract 4. Pump

to about half way and allow it to come 5. Motor

to a stop. Wait several seconds.

Observe the pressure at G.

*Acceptable values of A3.18

-RR 5010 = 75 - 90

Is the pressure at G -RD/RR5020, RD/RR5060, RD/RD5080 = 45 - 60

between 725 and 895 KPa No -RD/RR5060, RD/RR5080 w/190 mm

(105 and 130 psi) (7.5 in.) motors = 65 - 80

Yes

Measure the time to move the fork

carriage from fully retracted to fully

extended

Increase the setting of C6.4.1

Is the time between If time is less then 2.0 sec. for

2.0 and 2.5 sec. for RR or No RR or 4.0 for RD. Decrease the

4.0 and 5.0 sec. for RD Setting of C6.4.1 if time is

larger then 2.5 sec. for RR or

5.0 sec fro RD

Yes

8847

3/01

PAGE 2 OF 2 Printed in U.S.A.

You might also like

- A B C D E: Adjacent LotDocument4 pagesA B C D E: Adjacent LotKarl SantiagoNo ratings yet

- Tapcon 230 Expert 6655746 ENDocument2 pagesTapcon 230 Expert 6655746 ENParthiban.PNo ratings yet

- Tapcon 230 Basic 6655745 ENDocument1 pageTapcon 230 Basic 6655745 ENPalash DahakeNo ratings yet

- StationDocument1 pageStationTahirJabbarNo ratings yet

- Wsc2015 Tp10 PV TW Assembly Iso A PreDocument1 pageWsc2015 Tp10 PV TW Assembly Iso A PreCristyan ReisNo ratings yet

- Schematic - Automatic Irrigation System - A2Document1 pageSchematic - Automatic Irrigation System - A2ESA FALLAH ROYANINo ratings yet

- Part 7Document1 pagePart 7mamad mamadNo ratings yet

- 徐重QAY800 原理图-17Document1 page徐重QAY800 原理图-17Andre SantosNo ratings yet

- CH-BB-DET-EL-33-Transfer Station - Cabling Layout and InterfacesDocument1 pageCH-BB-DET-EL-33-Transfer Station - Cabling Layout and InterfacesMahmoud HusseinNo ratings yet

- Latihan 3 Week 2Document2 pagesLatihan 3 Week 2Leekhee MahendraNo ratings yet

- Pusat Pendidikan Dan Pelatihan Industri Sekolah Menengah Kejuruan - Smak Bogor Laboratorium Tempat Uji Kompetensi (Tuk) SmakboDocument1 pagePusat Pendidikan Dan Pelatihan Industri Sekolah Menengah Kejuruan - Smak Bogor Laboratorium Tempat Uji Kompetensi (Tuk) SmakboRahmah WulanNo ratings yet

- 1500mm Lowest Point of Erf Septic Tank Municipal ConnectionDocument3 pages1500mm Lowest Point of Erf Septic Tank Municipal ConnectionSteven VanNo ratings yet

- Modbus 1Document2 pagesModbus 1Lộc Phạm Bùi ĐìnhNo ratings yet

- A - Full EngineDocument1 pageA - Full EngineThái TrangNo ratings yet

- Layout Pagar 1Document1 pageLayout Pagar 1Nindy FebrianiNo ratings yet

- DCU1 Chematics PDFDocument11 pagesDCU1 Chematics PDFyao nestorNo ratings yet

- UKZN Map - WestvilleDocument1 pageUKZN Map - WestvilleSonia NaickerNo ratings yet

- Installation, Operating and Service Manual: 7-LC56-24B 7-L56-24B 7-L56-32B 7-L56-45BDocument8 pagesInstallation, Operating and Service Manual: 7-LC56-24B 7-L56-24B 7-L56-32B 7-L56-45Bnermeen ahmedNo ratings yet

- Stage 1: CONTACT: Strategic Map and OverviewDocument221 pagesStage 1: CONTACT: Strategic Map and OverviewJon EggersNo ratings yet

- Q-05 Domae: K5M K5D K5YDocument1 pageQ-05 Domae: K5M K5D K5YrosaNo ratings yet

- DLC3 01 01Document1 pageDLC3 01 01kaka100% (1)

- 7 Caves 22+500 - PLAN & PROFILE 1Document1 page7 Caves 22+500 - PLAN & PROFILE 14jhe Di4sNo ratings yet

- App Drafttrans NPDocument4 pagesApp Drafttrans NPCONDOR C8No ratings yet

- United Nations: Its History and Milestones: Event #1: League of Nations Is EstablishedDocument20 pagesUnited Nations: Its History and Milestones: Event #1: League of Nations Is EstablishedNeelesh BhandariNo ratings yet

- Tangent Amp-50-Service-ManualDocument4 pagesTangent Amp-50-Service-ManualRaika ZamboniniNo ratings yet

- Ky Red Zone MapDocument1 pageKy Red Zone MapBryce ShreveNo ratings yet

- Kromatogram HPLC (SMPL)Document2 pagesKromatogram HPLC (SMPL)Sabina ShafaNo ratings yet

- E Exercicio 7 VentiladorDocument1 pageE Exercicio 7 VentiladorDejan AntanasijevicNo ratings yet

- 徐重QAY800 原理图-16Document1 page徐重QAY800 原理图-16Andre SantosNo ratings yet

- Wsc2015 Tp10 PV TW Assembly Iso e PreDocument1 pageWsc2015 Tp10 PV TW Assembly Iso e PreCristyan ReisNo ratings yet

- 10 PPMDocument2 pages10 PPMDamar RukmanaNo ratings yet

- Power Layout Plan Lighting Layout Plan: A B C A B CDocument1 pagePower Layout Plan Lighting Layout Plan: A B C A B CAnna PascualNo ratings yet

- Shop Drawing: Section A-A or Top ViewDocument1 pageShop Drawing: Section A-A or Top ViewAzzam NashrullahNo ratings yet

- Dcp3-Electrical System - Tunnel T1: Co CoDocument71 pagesDcp3-Electrical System - Tunnel T1: Co CoRajesh RajendranNo ratings yet

- Dassault Systemes: Drawn by Date Size Drawing Number REV Drawing TitleDocument1 pageDassault Systemes: Drawn by Date Size Drawing Number REV Drawing TitleCPA IMNo ratings yet

- SURVEYING CAD Layout1 PDFDocument1 pageSURVEYING CAD Layout1 PDFOscar Jr SaturninoNo ratings yet

- Hfo Unloading PumpsDocument2 pagesHfo Unloading PumpsAdetunji Babatunde TaiwoNo ratings yet

- Incidence Map June 21Document1 pageIncidence Map June 21Debbie HarbsmeierNo ratings yet

- Incidence Map 09282021Document1 pageIncidence Map 09282021haeli spearsNo ratings yet

- KY Red Zone Map: 11/24/21Document1 pageKY Red Zone Map: 11/24/21Bryce ShreveNo ratings yet

- Ubicacion de Cisternas SR - PilarDocument1 pageUbicacion de Cisternas SR - PilarSolita Gonzales ArevaloNo ratings yet

- Tapcon 230 Pro 6787371 ESDocument2 pagesTapcon 230 Pro 6787371 ESHoward LamonNo ratings yet

- Tapcon 230 Basic 6787368 ESDocument1 pageTapcon 230 Basic 6787368 ESMaximiliano SanchezNo ratings yet

- Tapcon 230 Expert 6787385 ESDocument2 pagesTapcon 230 Expert 6787385 ESCristhian SaízNo ratings yet

- North American Fire - All Dual-Fuel Burners: CombustionDocument3 pagesNorth American Fire - All Dual-Fuel Burners: CombustionJose Antonio Jose Antonio SilveiraNo ratings yet

- Incidence Map 01262022Document1 pageIncidence Map 01262022Debbie HarbsmeierNo ratings yet

- KitchenDocument1 pageKitchenapi-3749658No ratings yet

- Kran ProgramDocument1 pageKran ProgramWojciechNo ratings yet

- 12N, 300v.phDocument1 page12N, 300v.phHoài NaNo ratings yet

- Anexo N°2 EGP - EEC.D.27.PE.P.58025.16.092.01 Montalvo Ver02 O&MDocument1 pageAnexo N°2 EGP - EEC.D.27.PE.P.58025.16.092.01 Montalvo Ver02 O&MJosue Rojas de la CruzNo ratings yet

- CM: The Next Generation of MetricsDocument4 pagesCM: The Next Generation of MetricsAhteshInamdarNo ratings yet

- Lift-1: W 3 W 2 W 5 W 6Document1 pageLift-1: W 3 W 2 W 5 W 6Nurholis SetiawanNo ratings yet

- asbILO19 (4) - ModelDocument1 pageasbILO19 (4) - ModelDanilo JuaresNo ratings yet

- Kusen Pintu Kayu Type 51 & 61Document3 pagesKusen Pintu Kayu Type 51 & 61Glen SangariNo ratings yet

- Kusen Pintu Kayu Type 51 & 61Document3 pagesKusen Pintu Kayu Type 51 & 61Glen SangariNo ratings yet

- Matemática: Prof. Raul BritoDocument2 pagesMatemática: Prof. Raul BritoHarry KaneNo ratings yet

- Ns Iocl Tal E001Document1 pageNs Iocl Tal E001Titus PraveenNo ratings yet

- 12 Major Currency PairsDocument3 pages12 Major Currency PairsNeo AzrinNo ratings yet

- Electrical System Troubleshooting - AustrailianDocument286 pagesElectrical System Troubleshooting - AustrailianPlanta Damiana2100% (1)

- Mack Fuse BlockDocument1 pageMack Fuse BlockPlanta Damiana2No ratings yet

- Mack FXL - Front Axle +steer - ServiceDocument150 pagesMack FXL - Front Axle +steer - ServicePlanta Damiana2No ratings yet

- Leu - Electrical TroubleshootingDocument12 pagesLeu - Electrical TroubleshootingPlanta Damiana2No ratings yet

- Mack Diff 92-93 & 112-113 Series-ServiceDocument154 pagesMack Diff 92-93 & 112-113 Series-ServicePlanta Damiana2100% (1)

- Dci-6 Engine - ServiceDocument150 pagesDci-6 Engine - ServicePlanta Damiana2No ratings yet

- Freedom-Md Trucks - Air Conditioning-ServiceDocument86 pagesFreedom-Md Trucks - Air Conditioning-ServicePlanta Damiana2No ratings yet

- CRD 125 - Bevel Gear ReplacementDocument14 pagesCRD 125 - Bevel Gear ReplacementPlanta Damiana2No ratings yet

- CRD 126-#2 Diff Carrier - OverhaulDocument25 pagesCRD 126-#2 Diff Carrier - OverhaulPlanta Damiana2No ratings yet

- Mack AC SpecDocument1 pageMack AC SpecPlanta Damiana2No ratings yet

- Engine Oil AnalysisDocument32 pagesEngine Oil AnalysisPlanta Damiana2No ratings yet

- Crd125-126 Diff Carrier - ReplacementDocument8 pagesCrd125-126 Diff Carrier - ReplacementPlanta Damiana2No ratings yet

- Technical Service Information 12-47Document1 pageTechnical Service Information 12-47Planta Damiana2No ratings yet

- Technical Service Information 12-57Document3 pagesTechnical Service Information 12-57Planta Damiana2No ratings yet

- Technical Service Information 12-60Document5 pagesTechnical Service Information 12-60Planta Damiana2No ratings yet

- Bogie Anchorage ReplacementDocument15 pagesBogie Anchorage ReplacementPlanta Damiana2No ratings yet

- Technical Service Information 12-58Document3 pagesTechnical Service Information 12-58Planta Damiana2100% (1)

- Technical Service Information 12-61Document4 pagesTechnical Service Information 12-61Planta Damiana2No ratings yet

- Technical Service Information 12-59Document8 pagesTechnical Service Information 12-59Planta Damiana2100% (1)

- Technical Service Information 12-56Document10 pagesTechnical Service Information 12-56Planta Damiana2No ratings yet

- Technical Service Information: Automatic Transmission Service GroupDocument1 pageTechnical Service Information: Automatic Transmission Service GroupPlanta Damiana2No ratings yet

- Technical Service Information 12-55Document2 pagesTechnical Service Information 12-55Planta Damiana2No ratings yet

- Technical Service Information: HONDA ODYSSEY 2007 - 2010Document1 pageTechnical Service Information: HONDA ODYSSEY 2007 - 2010Planta Damiana2No ratings yet

- Technical Service Information 12-46Document1 pageTechnical Service Information 12-46Planta Damiana2No ratings yet

- Technical Service Information 12-48Document2 pagesTechnical Service Information 12-48Planta Damiana2No ratings yet

- Technical Service Information 12-51Document1 pageTechnical Service Information 12-51Planta Damiana2No ratings yet

- Technical Service Information 12-53Document1 pageTechnical Service Information 12-53Planta Damiana2No ratings yet

- Technical Service Information 12-45Document2 pagesTechnical Service Information 12-45Planta Damiana2No ratings yet

- Technical Service Information: DODGE/JEEP 45/545RFEDocument2 pagesTechnical Service Information: DODGE/JEEP 45/545RFEPlanta Damiana2No ratings yet

- Technical Service Information 12-52Document3 pagesTechnical Service Information 12-52Planta Damiana2No ratings yet

- Jurnal Vol. IV No.1 JANUARI 2013 - SupanjiDocument11 pagesJurnal Vol. IV No.1 JANUARI 2013 - SupanjiIchsan SetiadiNo ratings yet

- AAR Shell ProgrammingDocument13 pagesAAR Shell ProgrammingMarimuthu MuthaiyanNo ratings yet

- Mindray PM 9000 User ID10240 PDFDocument378 pagesMindray PM 9000 User ID10240 PDFJuan FernandoNo ratings yet

- Caso Estudio: Reliability Analysis of Power Distribution System. A Case StudyDocument6 pagesCaso Estudio: Reliability Analysis of Power Distribution System. A Case StudyCarlos HernandezNo ratings yet

- Tourbier Renewal NoticeDocument5 pagesTourbier Renewal NoticeCristina Marie DongalloNo ratings yet

- Uts Cmo Module 5Document31 pagesUts Cmo Module 5Ceelinah EsparazNo ratings yet

- Flip The Coin - EbookDocument306 pagesFlip The Coin - EbookAjesh Shah100% (1)

- Vishal: Advanced Semiconductor Lab King Abdullah University of Science and Technology (KAUST) Thuwal, Saudi Arabia 23955Document6 pagesVishal: Advanced Semiconductor Lab King Abdullah University of Science and Technology (KAUST) Thuwal, Saudi Arabia 23955jose taboadaNo ratings yet

- Windows System Shortcut CommandsDocument2 pagesWindows System Shortcut CommandsVenkatesh YerraNo ratings yet

- Principles To Action (Short)Document6 pagesPrinciples To Action (Short)nsadie34276No ratings yet

- Watch One Piece English SubDub Online Free On Zoro - ToDocument1 pageWatch One Piece English SubDub Online Free On Zoro - ToSadeusuNo ratings yet

- ISO-3046-4-2009 (Gobernador de Velocidad)Document8 pagesISO-3046-4-2009 (Gobernador de Velocidad)David GastelumNo ratings yet

- Four Hour Body Experiment Tracker TemplateDocument4 pagesFour Hour Body Experiment Tracker Templatechanellekristyweaver100% (1)

- Biscotti: Notes: The Sugar I Use in France, Is CalledDocument2 pagesBiscotti: Notes: The Sugar I Use in France, Is CalledMonica CreangaNo ratings yet

- Cpar ReviewerDocument6 pagesCpar ReviewerHana YeppeodaNo ratings yet

- Em FlexicokingDocument8 pagesEm FlexicokingHenry Saenz0% (1)

- Evolis SDK Use Latest IomemDocument10 pagesEvolis SDK Use Latest IomempatrickNo ratings yet

- Jurnal 1 Ieevee LPF PDFDocument4 pagesJurnal 1 Ieevee LPF PDFNanda SalsabilaNo ratings yet

- Sanskrit Lessons: �丘��恆� � by Bhikshuni Heng HsienDocument4 pagesSanskrit Lessons: �丘��恆� � by Bhikshuni Heng HsiendysphunctionalNo ratings yet

- GA Power Capsule For SBI Clerk Mains 2024 (Part-2)Document82 pagesGA Power Capsule For SBI Clerk Mains 2024 (Part-2)aa1904bbNo ratings yet

- Essay Final ProjectDocument7 pagesEssay Final Projectapi-740591437No ratings yet

- 1st Problem Solving Assignment - Barrels of Apples - M383 Sp22.docx-2Document4 pages1st Problem Solving Assignment - Barrels of Apples - M383 Sp22.docx-2Kor16No ratings yet

- MPT EnglishDocument5 pagesMPT Englishkhadijaamir435No ratings yet

- Navi-Planner User ManualDocument331 pagesNavi-Planner User ManualRichard KershawNo ratings yet

- LYNX 40 Drilling Mud DecanterDocument2 pagesLYNX 40 Drilling Mud DecanterPierluigi Ciampiconi0% (1)

- Guidelines For Plenipotentiary - 1Document6 pagesGuidelines For Plenipotentiary - 1Oladimeji Ibukun IjaodolaNo ratings yet

- Grasa LO 915Document2 pagesGrasa LO 915Angelo Carrillo VelozoNo ratings yet

- IPS PressVest Premium PDFDocument62 pagesIPS PressVest Premium PDFLucian Catalin CalinNo ratings yet

- Barista Skills Foundation Curriculum enDocument4 pagesBarista Skills Foundation Curriculum enCezara CarteșNo ratings yet

- Atlascopco XAHS 175 DD ASL Parts ListDocument141 pagesAtlascopco XAHS 175 DD ASL Parts ListMoataz SamiNo ratings yet