Professional Documents

Culture Documents

W9180B W9123B英文说明书5550644

Uploaded by

Supri Rhifa'i ArdiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

W9180B W9123B英文说明书5550644

Uploaded by

Supri Rhifa'i ArdiCopyright:

Available Formats

Original instruction a) Do not force the power tool. Use the correct power tool for your application.

a) Do not force the power tool. Use the correct power tool for your application. The correct

i) Keep bystanders a safe distance away from work area. Anyone entering the work area must Dear Customer,

power tool will do the job better and safer at the rate for which it was designed. WARNING

GENERAL SAFETY INSTRUCTIONS b) Do not use the power tool if the switch does not turn it on and off. Any power tool that wear personal protective equipment. Fragments of workpiece or of a broken accessory may fly Thank you for buying a KEN power tool. Should you have any questions, vagueness or second thoughts

away and cause injury beyond immediate area of operation. about our products, we recommend you to contact our experts in Sales and Service Departments, who

cannot be controlled with the switch is dangerous and must be repaired. The vibration emission level given in this information sheet has been measured in accordance

WARNING! Read all instructions. Failure to follow all instructions listed below may result in j) Hold power tool by insulated gripping surfaces only, when performing an operation where the will advise you and help you find the right answers to the set questions. Please contact our local distributors

c) Disconnect the plug from the power source and/or the battery pack from the power tool with a standardised test given in EN 60745 and may be used to compare one tool with another.It

electric shock, fire and /or serious injury. The term "power tool" in all of the warnings listed below cutting accessory may contact hidden wiring or its own cord. Cutting accessory contacting a or dealers directly.

before making any adjustments, changing accessories, or storing power tools. Such preven- may be used for a preliminary assessment of exposure.The declared vibration emission level

refers to your mains operated power tool. "live" wire may make exposed metal parts of the power tool "live" and shock the operator.

tive safety measures reduce the risk of starting the power tool accidentally. represents the main applications of the tool .However if the tool is used for different

k) Position the cord clear of the spinning accessory. If you lose control, the cord may be cut or

d) Store idle power tools out of the reach of children and do not allow persons unfamiliar applications,with different accessories or poorly maintained, the vibration emission may We declare under our sole responsibility that the product described under “Technical Data” fulfills

SAVE THESE INSTRUCTIONS. snagged and your hand or arm may be pulled into the spinning accessory.

with the power tool or these instructions to operate the power tool. Power tools are danger- differ.This may significantly increase the exposure level over the total working period.An all the relevant provisions of the directives 2006/42/EC and the following harmonized standards

1) WORK AREA l) Never lay the power tool down until the accessory has come to a complete stop. The spinning

ous in the hands of untrained users. estimations of the level of exposure to vibration should also take into account the times when documents have been used:EN 60745-1; EN 60745-2-3.

a) Keep work area clean and well lit. Cluttered and dark areas invite accidents. e) Maintain power tools. Check for misalignment or binding of moving parts, breakage of accessory may grab the surface and pull the power tool out of your control.

the tool is switched off or when it is running but not actually doing the job.This may

b) Do not operate power tools in explosive atmospheres, such as in the presence of flammable m)Do not run the power tool while carrying it at your side. Accidental contact with the spinning

parts and any other condition that may affect the power tool’s operation. If damaged, significantly reduce the exposure level over the total working period. Identify additional safty Winnenden, 2012-06-06

liquids, gases or dust. Power tools create sparks which may ignite the dust or fumes. accessory could snag your clothing, pulling the accessory into your body.

have the power tool repaired before use. Many accidents are caused by poorly maintained measures to protect the operator from the effects of vibration such as:maintain the tool and the

c) Keep children and bystanders away while operating a power tool. Distractions can cause you to n) Regularly clean the power tool,s air vents. The motor,s fan will draw the dust inside the housing

power tools. accessories.keep the hands warm,organisation of work patterns.

lose control. f) Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting edges and excessive accumulation of powdered metal may cause electrical hazards.

o) Do not operate the power tool near flammable materials. Sparks could ignite these materials. Rainer Kumpf

are less likely to bind and are easier to control. Director Product Developement

2) ELECTRICAL SAFETY p) Do not use accessories that require liquid coolants. Using water or other liquid coolants may

g) Use the power tool, accessories and tool bits etc. in accordance with these instructions,

a) Power tool plugs must match the outlet. Never modify the plugs in any way. Do not use any result in electrocution or shock. Shanghai KEN Tools CO.,Ltd.

taking into account the working conditions and the work to be performed. Use of the

adapter plugs with earthed grounded power tools. Unmodified plugs and matching outlets will No.5 Xinrong Rd., Xinqiao Town,Songjiang District, Shanghai China

power tool for operations different from those intended could result in a hazardous situation.

reduce risk of electric shock. Kickback and Related Warnings

b) Avoid body contact with earthed or grounded surfaces such as pipes, radiators, ranges and 5) Servicea) Have your power tool serviced by a qualified repair person using only identical Kickback is a sudden reaction to a pinched or snagged rotating wheel, backing pad, brush or any SYMBOL

refrigerators. There is an increased risk of electric shock if your body is earthed or grounded. replacement parts. This will ensure that the safety of the power tool is maintained. other accessory. Pinching or snagging causes rapid stalling of the rotating accessory which in turn

,

c) Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the causes the uncontrolled power tool to be forced in the direction opposite of the accessory s rotation at V :Volts :Double insulation :Please read the instructions carefully

risk of electric shock. Safety Warnings Common for Grinding Operations: the point of the binding. before stariting the machine.

Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power tool. a) This power tool is intended to function as a grinder tool. Read all safety warnings, instructions, For example, if an abrasive wheel is snagged or pinched by the workpiece, the edge of the wheel that Hz :Hertz :Wear eye protection

d) Keep cord away from heat, oil, sharp edges or moving parts. Damaged or entangled cords increase illustrations and specifications provided with this power tool. Failure to follow all instructions is entering into the pinch point can dig into the surface of the material causing the wheel to climb out :Waste electrical products should not

W :Watts :Wear ear protection be disposed of with household waste.

the risk of electric shock. listed below may result in electric shock, fire and/or serious injury. or kick out. The wheel may either jump toward or away from the operator, depending on direction of

,

e) When operating a power tool outdoors, use an extension cord suitable for outdoor use. Use of a b) Operations such as sanding, wire brushing, polishing or cutting-off are not recommended to the wheel s movement at the point of pinching. Abrasive wheels may also break under these :Safety alert :Wear a dust mask Please recycle where facilities exist.

cord suitable for outdoor use reduces the risk of electric shock. be performed with this power tool. Operations for which the power tool was not designed may conditions. Check wity your Lccal Authority or

f) If operating a power tool in a damp location is unavoidable, use a residual current device (RCD) create a hazard and cause personal injury. Kickback is the result of power tool misuse and/or incorrect operating procedures or conditions and ~ :Altenating Current n。:No load Speed retailer for recycling advice .

protected supply. Use of an RCD reduces the risk of electric shock. c) Do not use accessories which are not specifically designed and recommended by the tool can be avoided by taking proper precautions as given below. min-1:Revolutions or reciprocations per minute

:CE conformity.

manufacturer. Just because the accessory can be attached to your power tool, it does not assure safe a) Maintain a firm grip on the power tool and position your body and arm to allow you to resist

3) PERSONAL SAFETY operation. kickback forces. Always use auxiliary handle, if provided, for maximum control over kickback

a) Stay alert, watch what you are doing and use common sense when operating a power tool. Do not d) The rated speed of the accessory must be at least equal to the maximum speed marked on the or torque reaction during start-up. The operator can control torque reactions or kickback forces, if

use a power tool while you are tired or under the influence of drugs, alcohol or medication. A power tool. Accessories running faster than their rated speed can break and fly apart. proper precautions are taken. SAFETY

moment of inattention while operating power tools may result in serious personal injury. e) The outside diameter and the thickness of your accessory must be within the capacity rating of b) Never place your hand near the rotating accessory. Accessory may kickback over your hand.

b) Use personal protective equipment. Always wear eye protection. protective equipment such as dust your power tool. Incorrectly sized accessories cannot be adequately guarded or controlled. c) Do not position your body in the area where power tool will move if kickback occurs. Kickback a. Only use our recommendedsanding wheelsand the specially-designed safety guard for the wheels. It will

,

mask, no-skid safety shoes, hard hat, or hearing protection used for appropriate conditions will reduce f) The arbour size of wheels, flanges, backing pads or any other accessory must properly fit the will propel the tool in direction opposite to the wheel s movement at the point of snagging. be dangerous and could not protect your safety if using other sanding wheels which aren’t designed

personal injuries. spindle of the power tool. Accessories with arbour holes that do not match the mounting hardware d) Use special care when working corners, sharp edges etc. Avoid bouncing and snagging the for power tools.

c) Prevent unintentional starting. Ensure the switch is in the off-position before connecting to power of the power tool will run out of balance, vibrate excessively and may cause loss of control. accessory. Corners, sharp edges or bouncing have a tendency to snag the rotating accessory and b. The safety guard must be stably fixed onto the tool and adjusted into the best position, only expose the

source and/or battery pack, picking up or carrying the tool. Carrying power tools with your finger g) Do not use a damaged accessory. Before each use inspect the accessory such as abrasive wheels cause loss of control or kickback. minimum part of the wheel in front of the operator. The safety guard will protect the operator from being

on the switch or energising power tools that have the switch on invites accidents. for chips and cracks, backing pad for cracks, tear or excess wear, wire brush for loose or e) Do not attach a saw chain woodcarving blade or toothed saw blade. Such blades create frequent hurt by the exploded sanding wheels or incidentally touching the wheels.

d) Remove any adjusting key or wrench before turning the power tool on. A wrench or a key left cracked wires. If power tool or accessory is dropped, inspect for damage or install an kickback and loss of control. c. Only use the wheels limited to our recommended usages. For example, never grind or cut by the side

attached to a rotating part of the power tool may result in personal injury. undamaged accessory. After inspecting and installing an accessory, position yourself and part of the cutting wheel. The pressures applied on the side part of the wheel may make it damage

e) Do not overreach. Keep proper footing and balance at all times. This enables better control of the bystanders away from the plane of the rotating accessory and run the power tool at maximum IMPORTANT: Hold power tool by insulated gripping surfaces, when performing an d. Always choose the undamaged flanges with correct specifications and shapes for your wheels. The

power tool in unexpected situations. no-load speed for one minute. Damaged accessories will normally break apart during this test time. operation where the cutting accessory may contact hidden wiring or its own cord. Cutting proper flanges can reduce the risk of wheel breakage. The flanges for cutting wheel might be different

f) Dress properly. Do not wear loose clothing or jeweler. Keep your hair, clothing and gloves away h) Wear personal protective equipment. Depending on application, use face shield, safety goggles accessory contacting a "live" wire may make exposed metal parts of the power tool "live" and could from the flanges for grinding wheels.

from moving parts. Loose clothes, jeweler or long hair can be caught in moving parts. or safety glasses. As appropriate, wear dust mask, hearing protectors, gloves and workshop give the operator an electric shock. e. Do not use the left worn wheel from the big size power tools. The wheel for big size power tools is not

g) If devices are provided for the connection of dust extraction and collection facilities, ensure these apron capable of stopping small abrasive or workpiece fragments. The eye protection must be suitable for the small size power tools and may be broken during high-speed operation.

are connected and properly used. Use of these devices can reduce dust related hazards. capable of stopping.flying debris generated by various operations . The dust mask or respirator must f. Ensure the wheel you use is complete without any damage. There should be no breakage by hammering

be capable of filtrating particles generated by your operation. Prolonged exposure to high intensity the wheel lightly with a wooden hammer. The valid date for the wheel should not exceed one year unless

4) POWER TOOL USE AND CARE noise may cause hearing loss. it passes the running test and approves OK.

-1- -14- -13- -2- -3- -12- -11- -4-

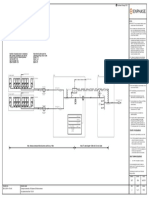

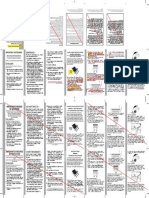

■OPERATION PARTS LIST ANGLE GRINDER ◆ Assemble or Disassemble the Emery Wheel ◆ Effective and Safe Grinding and Cutting Methods

. Tool requires no special maintenance, but after some time you must control the parts that are

Observe correct mains voltage: The voltage of Equip the downward pressure plate on the output . Please use the correct part of the emery wheel, submitted to wear-and-tear under normal operating conditions. This includes the control and

65

No. Code Name Remark No. Code Name Remark Outer flange replacement of carbon brushes and grease in reducing gear housing. Take the tool to an authorized

64

the power source must agree with the voltage axis, and then equip the emery wheel on the otherwise it is easy to be damaged.

specified on the nameplate of the machine.

1 317002A Press-button 35 319055 Dust protector

downward pressure plate, screw the upper

. The users can get satisfied effects if the users service centre.

. Keep the tool and supply cord clean. Keep ventilation slots clean and open. Wipe the surface of the

Wheel give 1/2 strength compared with the own weight

63

◆ Subsidiary Handle 2 151002 Spring 36 114071 Washer Φ22

pressure plate on the output axis (Picture Four). tool with a soft cloth!

. It is not allowed to use household cleaning agents that contain petrol, trichloroethylene, ammonia

62

3 162077 Gear case 37 251008 Retainer 37 of the tool. Over strength is easy to make the tool

Please use subsidiary handle in order to do work

61

engine and emery wheel damaged because of

66

Inner flange

60

137038 Pinion 9180B/9180BI 38 442136 Armature and chlorides. These substances corrode and damage plastic parts of the tool.

safely and conveniently. Subsidiary handle can be overload.

. Generally speaking, please keep the grinding . Excessive sparking generally indicates the presence of dirt in the motor or abnormal wear on the

57 58 59

4

67

assembled on the both sides of the tool body 137040 Pinion 9123B/9123BI 39 319056 Retainer

carbons.

(Picture One). 5 261009 Nut M8×1 40 211019 Bearing 608-2Z and cutting part of the emery wheel and disc in the . In case of electric or mechanical failure, send the tool to a KEN authorized service centre for repair.

56

scope of 15 to 30 degree with the surface of

69

Pin 41 331031 Bearing sleeve

55

6 145012

processing object.

. When you use new emery wheel, please don’t

54

7 211028 Bearing 6000-2RS 42 321066 Air deflector ■SERVICING AND REPAIRS

53

move the tool toward B direction, otherwise, the If servicing is required, contact one of our listed service centers. It is not allowed and dangerous to

8 334003 Rubber pin 43 221033 Screw ST5×75 B A

52

processing object is easy to cut-off. When the perform any individual work on the tool.

51

9 252005 Retainer 14 44 441136 Stator

50

◆ Have the tool repaired by authorized persons.

41

margin angle of the emery wheel turns round, the

49

picture 1 Big gear 45 313115 Motor housing picture 4 ◆ Any repairs of the tool in unauthorized service centers is performed at own responsibility.

40

137037 9180B/9180BI picture 7

48

10 tool can be moved towards two directions of A and

◆ The owner of the tool is responsible for all works on the tool that were not performed in

47

39

137039 Big gear 9123B/9123BI 47 221008 Screw ST4×14 B (Picture Seven).

◆ Protective Shield of the Emery Wheel Press the self-locking button, use the special authorized service center, and therefore he losses the claim for guarantee.

11 251009 Retainer 40 48 433038 Right Brush cap

45

Please aim the convex end of the emery wheel wrench to screw the upper pressure plate tightly Wrench

12 243008 Wave washer 49 221008 Screw ST4×14 ◆ Replace the Electric Brush ■WASTE DISPOSAL AND ENVIRONMENT PROTECTION

38

44

shield to the slot mouth of the front cover, and then (Picture Five).

Bearing 50 431075 Carbon brush The tool has set the electric brush limited position The machine, accessories and packing should be sorted for environmental-friendly recycling.

rotate the shield body to 180 degree (Picture Two).

13 211094 6203-LLU

equipment especially, please replace the electric Only for EC countries: C u t O ff

Angle M ach in e

Grinder

51 434020 Brush holder

43

14 333072 O ring

brush if there’s big sparks or the rotation stops ◆ Do not dispose of power tools into household waste!

15 114116 Washer 52 153008 Spire Spring According the European Guideline 2002/96/EC for Waste Electrical and Electronic Equipment and

37

42

16 161044 Front cover 53 221102 Screw ST4.2×20 during the running. Please use screwdriver to its implementation into national right, power tools that are no longer usable must be collected

36

screw the lid of the electric brush and take out the separately and disposed of in an environmentally correct manner.

35

17 221106 Screw M5×20 54 437002 Connector

wearing electric brush and install the new ones,

34

18 115024 Dust cover 55 449001B Soft starter 9180BI

and please use hands to try and confirm it can slide ■TECHNICAL DATA

33

19 133088 Spindle 56 436022 Terminal

Safety Guard freely in the slot, and then install and screw the lid

32

20 276004 Key 57 436033 Terminal block 9123BI Brush Cap Type 9180B S1M-SH03-180 9123B S1M-SH02-230 9180BI S1M-SH04-180 9123BI S1M-SH03-230

31

of the electric brush. Please replace two brushes at

30

Inner flange 58 436049 Terminal block Self-locking button

26

21 139045 Size of Emery Wheel 180×6×22(mm) 180×6×22(mm)

7614NB

22

21

25

24

23

the same time, and use the specified “KEN” brand 230×6×22(mm) 230×6×22(mm)

611023 Grinding wheel 9180B/9180BI 59 314137 Right handle 9180B

27

electric brush (Picture Eight). SIM-SH03-180

29

22 Maximum Using

picture 2 611024 Grinding wheel 9123B/9123BI 60 445021 Switch picture 5 Circumference Speed of

the Emery Wheel 80m/s 80m/s 80m/s 80m/s 9123B SIM-SH02-230

28

23 139035 Outer flange 61 318016 Cord clamp picture 8

Tighten the fastening screw (Picture Three). ◆ Switching on/off Current Source 220-240V~ 50Hz 220-240V~ 50Hz 220-240V~ 50Hz 220-240V~ 50Hz

Fasten the Screw

24 232013 Screw M8×25 62 222002 Screw

※Please make sure the machine is shut off and the ■PRACTICAL TIPS 9180BI SIM-SH04-180

112052 Guard 9180B/9180BI 63 332005 Cord sleeve ◆ Please use the cymbal shape emery wheel which linear velocity is higher than the speed stipulated Rated Input Power 2450W 2450W 2450W 2450W

25 switch can be freely reset before connected to

112056 Guard 9123B/9123BI 64 411032 Power cord power.

on the name plate of the body, and use correct grinding and cutting face to do the processing. Don't 9123BI SIM-SH03-230

use the upside face and side face of the emery wheel. Rated Speed 8000/min 6500/min 8000/min 6500/min

26 627016 Side handle 65 314136 Left handle

20

19

11

13

12

18

14

15

16

10

17

◆ The using emery wheel must be in complete and perfect working condition, it has no disruption

1

4

5

8

2

3

9

6

27 234027 Screw M14×55 66 433037 Left Brush cap For tool with lock-on switch sound if beat it slightly with wooden mallet, the reserving period of the emery wheel shall not over Weight 4.9kg 4.9kg 4.9kg 4.9kg

28 221101 Screw ST4.8×37 67 431080 Carbon brush(Safety) To start tool, hold Trigger B. Release Trigger B to one year, it only can be used after making tests of turn and hardness if the period has passed one year.

◆ Don't insert the electric source plug into the socket when assemble or disassemble the emery

Soft Starter √ √

29 319057 Support 69 623006 Wrench stop. For continuous operation, hold Trigger B and

wheel. The maximum circumference speed of all the emery wheels shall not less than 4800m/min. Noise L pA:94.3dB(A) K pA :3.0dB(A) LWA:105.3dB(A) K WA:3.0dB(A)

30 114114 Washer 70 713489 Side handle asm push Trigger A. To stop tool in hold position, press ◆ Prohibit doing grinding and cutting work on the condition that the protective shield has been 2 2

31 341017 Washer trigger and release. dismantled. When putting away the tool, please do switch off the current source and wait for the a h:5.9m/s (max handle) Uncertainty K:1.5m/s

emery wheel completely stops. Vibration

32 114115 Washer 2

a h:7.6m/s (aux handle) Uncertainty K:1.5m/s

2

For tool with lock-off switch

5550644

33 337036 Ring Trigger A Trigger B ■MAINTENANCE AND CARE

KEN Holding Co., Ltd.

Special Wrench 1PC Side Handle 1PC

34 211093 Bearing 6301-LLU To start tool, push trigger A and then hold trigger . Unplug the tool from the socket before performing any works on the tool! Standard

Spare Parts Safety Guard 1PC Operating Handbook 1PC http://www.kenpowertools.com

picture 3 B. Release trigger B to stop.

@2015.08

KEN and KEN logo are registered trademarks of KEN Holding Co.,Ltd. All rights reserved. No other company may use KEN logo

-5- -10- -9- -6- -7- -8- unless it has the express written permission of KEN Holding Co.,Ltd. ,or is licensed by KEN Holding Co.,Ltd.to do so. original instructions

You might also like

- PXPSS-089 Manual Ed4Document2 pagesPXPSS-089 Manual Ed4DanNo ratings yet

- Dewalt DC845KA ManualDocument7 pagesDewalt DC845KA Manualtestmonger5237No ratings yet

- Manual Dewalt DW-292Document5 pagesManual Dewalt DW-292rocha.bestNo ratings yet

- Redmi Buds 3 Lite-User ManualDocument1 pageRedmi Buds 3 Lite-User ManualDragutin StojkovicNo ratings yet

- Dewalt dw130v Operators Manual PDFDocument6 pagesDewalt dw130v Operators Manual PDFJL AlexanderNo ratings yet

- NHA31477 25 QSG P5x20Document5 pagesNHA31477 25 QSG P5x20samy.musNo ratings yet

- Wireless Stereo Headphone System: How To UseDocument2 pagesWireless Stereo Headphone System: How To UseMon BoualNo ratings yet

- 71cdnCXyIGLDocument1 page71cdnCXyIGLIstamsetty HanumantharaoNo ratings yet

- MFL38868794Document2 pagesMFL38868794kk1116No ratings yet

- R-CA80092 TALADRO ELECTRICO DEWALT d25123Document7 pagesR-CA80092 TALADRO ELECTRICO DEWALT d25123Vero YotagriNo ratings yet

- NTS-660 Series Total Station Instruction ManualDocument236 pagesNTS-660 Series Total Station Instruction ManualPrashanth Reddy TummuluriNo ratings yet

- CD Micro System SC-PM600 Operating InstructionsDocument2 pagesCD Micro System SC-PM600 Operating InstructionsdavidspyNo ratings yet

- DS K1T341A Series Face Recognition Terminal - QSG - V1.0 - 20210730Document2 pagesDS K1T341A Series Face Recognition Terminal - QSG - V1.0 - 20210730Cristian PulidoNo ratings yet

- MR-JE - Safety Installation Manual IB (NA) 0300194E-D (08.13)Document1 pageMR-JE - Safety Installation Manual IB (NA) 0300194E-D (08.13)Puji AntoroNo ratings yet

- InstallDocument2 pagesInstallpqcrackerNo ratings yet

- Before Reading This User ManualDocument2 pagesBefore Reading This User ManualJeancarlos DominguezNo ratings yet

- Free Rider & Rocker Instruction ManualDocument1 pageFree Rider & Rocker Instruction ManualBen SzapiroNo ratings yet

- E4 Charger Instruction Manual Features Fast Charge 2S-4S BatteriesDocument1 pageE4 Charger Instruction Manual Features Fast Charge 2S-4S BatteriesJess PoseyNo ratings yet

- Teléfono Inalámbrico 26928GE1 - GE2 - IBDocument2 pagesTeléfono Inalámbrico 26928GE1 - GE2 - IBalgoncarNo ratings yet

- Wis24141gbDocument10 pagesWis24141gbJacky NplNo ratings yet

- SONY Compact Disc Player cdpcx153 PDFDocument93 pagesSONY Compact Disc Player cdpcx153 PDFJULIUSNo ratings yet

- 小米生态链产品包装图纸Document1 page小米生态链产品包装图纸Stani Jude JohnNo ratings yet

- Boss FV-500H - OMDocument1 pageBoss FV-500H - OMbaggy trousersNo ratings yet

- Service Manual: Viewsonic Pj501/Pj551Document62 pagesService Manual: Viewsonic Pj501/Pj551Andrey KhodanitskiNo ratings yet

- NVE49946 17 QSG P5x30Document5 pagesNVE49946 17 QSG P5x30samy.musNo ratings yet

- User ManualDocument2 pagesUser ManualdurgaprasadnaikNo ratings yet

- DV 410V K OperatingInstructions0418Document101 pagesDV 410V K OperatingInstructions0418Anonymous 8bbVmLtQNo ratings yet

- Wireless: Quick-Start GuideDocument2 pagesWireless: Quick-Start GuideJOSE CAMPOSNo ratings yet

- Owner's Manual Manuel de l'utilisation Bedienungsanleitung Manuale di Istruzioni Manual de Instrucciones Gebruiksaanwijzing Instruktionsbok Инструкция ПользователяDocument52 pagesOwner's Manual Manuel de l'utilisation Bedienungsanleitung Manuale di Istruzioni Manual de Instrucciones Gebruiksaanwijzing Instruktionsbok Инструкция ПользователяJózsef VargaNo ratings yet

- Dish Washe R Use RMA Nual: Tgdw6Ss Tgdw6BkDocument13 pagesDish Washe R Use RMA Nual: Tgdw6Ss Tgdw6BkRossa Dwi DianitaNo ratings yet

- GDS-1000B Quick Start Guide ADocument2 pagesGDS-1000B Quick Start Guide Aketab_doostNo ratings yet

- 305609486 MiCOM P220 TechnicalGuide EnDocument412 pages305609486 MiCOM P220 TechnicalGuide Enjigyesh29No ratings yet

- PanasonicKX TG2122WDocument2 pagesPanasonicKX TG2122WPayphone.com100% (1)

- Wireless Smart Otoscope: FCC Warning: Quick Start Guide Product Size Fault Analysis and TroubleshootingDocument1 pageWireless Smart Otoscope: FCC Warning: Quick Start Guide Product Size Fault Analysis and TroubleshootingNickNo ratings yet

- Safety Guide: Warning Parts and ControlsDocument2 pagesSafety Guide: Warning Parts and Controlsjulio ariasNo ratings yet

- Safety precautions and performance specs for D/A conversion modulesDocument2 pagesSafety precautions and performance specs for D/A conversion moduleschiruNo ratings yet

- X32 Manual FoldableDocument2 pagesX32 Manual FoldableMartín OksNo ratings yet

- Schneider Electronics Manual Provides Safety InstructionsDocument38 pagesSchneider Electronics Manual Provides Safety Instructionsdoraemon007No ratings yet

- User Manual Test Surftest SJ - 210Document200 pagesUser Manual Test Surftest SJ - 210Bùi Đại CaNo ratings yet

- 4090-9101 Modulo Zona ZAMDocument2 pages4090-9101 Modulo Zona ZAMJ Luis CallasNo ratings yet

- Omron E5cwlDocument1 pageOmron E5cwlgillang1No ratings yet

- CRX7 ManualDocument1 pageCRX7 Manualjose thiagoNo ratings yet

- GM-X962 GM-X862: Owner's ManualDocument17 pagesGM-X962 GM-X862: Owner's ManualLightning LeeNo ratings yet

- BG4000 (Usa)Document2 pagesBG4000 (Usa)Cindy Carolina CiroNo ratings yet

- 1 Appearance 2 Installa On: DS-K1T341A Series Face Recognition TerminalDocument2 pages1 Appearance 2 Installa On: DS-K1T341A Series Face Recognition Terminalcgf_arNo ratings yet

- Getting Ready Safety Precautions: User'S Guide Guía Del Usuario WarningDocument2 pagesGetting Ready Safety Precautions: User'S Guide Guía Del Usuario WarningManickamEllampoorananNo ratings yet

- Getting Ready Safety Precautions: User'S Guide Guía Del Usuario WarningDocument2 pagesGetting Ready Safety Precautions: User'S Guide Guía Del Usuario WarningMaiNo ratings yet

- Número de Enchufes Por Equipo - Rev2Document7 pagesNúmero de Enchufes Por Equipo - Rev2Hch IesNo ratings yet

- Typical Enphase SLD 3ph ResiDocument1 pageTypical Enphase SLD 3ph Resielectromec technologyNo ratings yet

- Installation Manual For BNWAS HighlanderDocument48 pagesInstallation Manual For BNWAS HighlanderZakaria ChowdhuryNo ratings yet

- Quick-Start Guide: Installation For Lights With One Wall Switch (Single-Pole)Document6 pagesQuick-Start Guide: Installation For Lights With One Wall Switch (Single-Pole)EdNo ratings yet

- User Manual 3971431Document1 pageUser Manual 3971431Avinash MalviyaNo ratings yet

- 99MAD014M4 Digimatic CaliperDocument2 pages99MAD014M4 Digimatic CaliperermankurNo ratings yet

- Installation Instructions Instructions D'installation Instrucciones de InstalacionDocument4 pagesInstallation Instructions Instructions D'installation Instrucciones de InstalacionAldemar EscalanteNo ratings yet

- 4616584-0C_NE-C101-FP_IM_M06_220322Document2 pages4616584-0C_NE-C101-FP_IM_M06_220322Food BitesNo ratings yet

- Wahl Clippers Instructions PDFDocument2 pagesWahl Clippers Instructions PDFmukadeNo ratings yet

- Tan-Delta and Capacitance Test Set For HT Generator/Motor TestingDocument3 pagesTan-Delta and Capacitance Test Set For HT Generator/Motor Testingmustafa180567% (3)

- 3&) #% 43D1800A /ms #Autionă Ăăăăăăăăăăăăăăăăăăăăăăăăăăăă Specificationăăăăăăăăăăăăăăăăăăăăăăăăăă 3cheme ( (Sorghgudzlqj 4his Dnual Include TheDocument37 pages3&) #% 43D1800A /ms #Autionă Ăăăăăăăăăăăăăăăăăăăăăăăăăăăă Specificationăăăăăăăăăăăăăăăăăăăăăăăăăă 3cheme ( (Sorghgudzlqj 4his Dnual Include TheRoque Ciro Di CesareNo ratings yet

- Before Reading This User ManualDocument2 pagesBefore Reading This User ManualbatuhanoyalNo ratings yet

- Risk Assessment - KitchenDocument3 pagesRisk Assessment - KitchenOlivia BrookesNo ratings yet

- Waiver, Release and Hold Harmless AgreementDocument1 pageWaiver, Release and Hold Harmless AgreementMohammed KhanNo ratings yet

- Business Law-MBA (GTU)Document439 pagesBusiness Law-MBA (GTU)keyurNo ratings yet

- Secondary Survey for Trauma PatientsDocument18 pagesSecondary Survey for Trauma PatientsJohn BrittoNo ratings yet

- Kinesiology of The HipDocument13 pagesKinesiology of The HipRadoje DakićNo ratings yet

- Knee RehabDocument15 pagesKnee Rehabapi-629723642No ratings yet

- Owner Manual PDFDocument532 pagesOwner Manual PDFwalter.ozeNo ratings yet

- How Pemf Therapy Affects The Body ?Document2 pagesHow Pemf Therapy Affects The Body ?Num NutzNo ratings yet

- FORGE WORLD VEHICLE UPDATES FOR 6TH EDITION 40KDocument3 pagesFORGE WORLD VEHICLE UPDATES FOR 6TH EDITION 40Kperetv@yahoo.comNo ratings yet

- FIRST AID Is The Immediate Care Given To A Person Who Have Been Injured or Suddenly Taken IllDocument4 pagesFIRST AID Is The Immediate Care Given To A Person Who Have Been Injured or Suddenly Taken IllNat CatalanNo ratings yet

- Burning One Man ForceDocument187 pagesBurning One Man ForceSandra GarzaNo ratings yet

- Pediatric Surgery Symposium - Minimally Invasive Surgery ProceduresDocument5 pagesPediatric Surgery Symposium - Minimally Invasive Surgery ProceduresKadelsy BristolNo ratings yet

- Scapular Region: Figure 17.1 Scapular Muscles (Posterior View)Document12 pagesScapular Region: Figure 17.1 Scapular Muscles (Posterior View)Anjali TanwarNo ratings yet

- Hw2000i Portable Inverter GeneratorDocument46 pagesHw2000i Portable Inverter GeneratorAlberto EspinozaNo ratings yet

- IIHF Rulebook 2010-2014Document84 pagesIIHF Rulebook 2010-2014Levente SikoNo ratings yet

- Osteopathic Structural ExamDocument27 pagesOsteopathic Structural ExamFernando100% (1)

- TP401 PDFDocument112 pagesTP401 PDFDaniel Tovar Romero50% (2)

- 5 6289750532911268052 PDFDocument472 pages5 6289750532911268052 PDFvasanthrslv100% (6)

- Waiver Undertaking OjtDocument1 pageWaiver Undertaking OjtYsabel CarilloNo ratings yet

- LG LED TV ManualDocument36 pagesLG LED TV Manualmph_88No ratings yet

- Burn ManagementDocument19 pagesBurn ManagementKavimathy SukumaranNo ratings yet

- x02 Midterm - BarQDocument4 pagesx02 Midterm - BarQezmailer75No ratings yet

- Contract of BailmentDocument20 pagesContract of BailmentRounak BhagwatNo ratings yet

- ISO 11226 2000 PosturalDocument28 pagesISO 11226 2000 PosturalAna Claudia OsorioNo ratings yet

- Annual Report 2009 - 2010Document56 pagesAnnual Report 2009 - 2010St George's Healthcare NHS TrustNo ratings yet

- 37 - First Integrated Bonding Insurance Co vs. HernandoDocument1 page37 - First Integrated Bonding Insurance Co vs. HernandoN.SantosNo ratings yet

- Hope 3 Module 6 Quarter 2Document16 pagesHope 3 Module 6 Quarter 2Marchan Dalapo-Llacuna CorowanNo ratings yet

- Total Knee ReplacementDocument33 pagesTotal Knee Replacementpolarbear121212No ratings yet

- Peepers by C.L. KattanDocument132 pagesPeepers by C.L. KattanDurrod University PressNo ratings yet

- Lux Mundi Academy 1st Quarter Exam ScienceDocument3 pagesLux Mundi Academy 1st Quarter Exam ScienceLeonilo C. Dumaguing Jr.No ratings yet