Professional Documents

Culture Documents

OMD 2005 RWO Manual en 6

OMD 2005 RWO Manual en 6

Uploaded by

ShanmugamoorthyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

OMD 2005 RWO Manual en 6

OMD 2005 RWO Manual en 6

Uploaded by

ShanmugamoorthyCopyright:

Available Formats

Bilge Alarm Monitor OMD 2005 for SKIT S DEB 0.25-10.0 6.

Edition V301115002 Page 1

Operating and Maintenance Instructions

B i l g e A l a r m M o n i t o r O M D 2 0 0 5

3

f o r S K I T / S D E B 0 . 2 5 . . . 1 0 . 0 m / h

I M O R e s o l u t i o n M E P C . 1 0 7 ( 4 9 )

RWO GmbH • Marine Water Technology • Bremen • Germany Issue: 20.08.2008

Bilge Alarm Monitor OMD 2005 for SKIT S DEB 0.25-10.0 6.Edition V301115002 Page 2

Table of Contents

Page

1. Bilge Alarm Device.................................................................................................................................3

1.1. General .................................................................................................................................................... 3

1.2. Scattered light measuring method ........................................................................................................... 3

1.3. Safety warnings and tips .......................................................................................................................... 4

1.4. Adjustment ............................................................................................................................................... 5

1.5. Displays and Alarms ................................................................................................................................ 5

1.6. Design of the Bilge Alarm Device............................................................................................................. 5

2. Technical Specification Bilge Alarm Monitor OMD 2005....................................................................7

3. Installation of the Bilge Alarm Monitor OMD 2005..............................................................................7

4. Electrical connections ...........................................................................................................................8

4.1. General wiring information ....................................................................................................................... 8

4.2. Connections of the Bilge Alarm Monitor OMD 2005................................................................................. 8

4.3. Possible connections by the customer ..................................................................................................... 9

5. Operation ................................................................................................................................................9

5.1. Important Notes ....................................................................................................................................... 9

5.2. Commissioning ........................................................................................................................................ 9

5.3. Functional Tests..................................................................................................................................... 10

5.4. Alarm...................................................................................................................................................... 10

5.5. Monitor control functions ........................................................................................................................ 10

5.6. Programming Mode................................................................................................................................ 11

5.7. Recorder (option) ................................................................................................................................... 13

6. Calibration ............................................................................................................................................14

7. Monitor operation.................................................................................................................................14

7.1. Operating instructions ............................................................................................................................ 14

7.2. Monitoring operation and alarm events during operation ....................................................................... 15

8. Maintenance .........................................................................................................................................15

9. Troubleshooting...................................................................................................................................16

9.1. Fault finding ........................................................................................................................................... 16

9.2. Memory Card (refer to Fig. 4)................................................................................................................. 17

10. List of Spare Parts ...............................................................................................................................18

11. Exchange Parts Service ......................................................................................................................18

11.1. General .............................................................................................................................................. 18

11.2. Exchange Equipment Service ............................................................................................................ 18

11.3. Exchange of electronic components .................................................................................................. 19

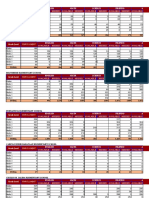

Table list

Table 1 IMO-type test certificates...........................................................................................3

Table 2 Pos.-No of the Bilge Alarm Device ............................................................................6

Table 3 Technical Specification..............................................................................................7

Table 4 Connections of the Bilge Alarm Monitor ....................................................................8

Table 5 Programming Mode .................................................................................................11

Table 6 Fault finding .............................................................................................................16

Table 7 List of Spare Parts ...................................................................................................18

RWO GmbH • Marine Water Technology • Bremen • Germany Issue: 20.08.2008

Bilge Alarm Monitor OMD 2005 for SKIT S DEB 0.25-10.0 6.Edition V301115002 Page 3

1. Bilge Alarm Device

1.1. General

The Bilge Alarm Monitor OMD 2005 has been designed acc. IMO requirements to be

used to fulfil Marpol 73/78 with 15ppm oily water separator and has a specification

and performance which exceeds the requirements of the IMO (International Maritime

Organisation) specifications for Bilge Alarm Monitors contained in Resolution

MEPC.107 (49). All monitors are inspected and tested to the related I.M.O.

requirements at the factory prior to delivery.

The Bilge Alarm Monitor OMD 2005 is supplied with 2 works-adjusted alarms: alarm

1 at 14ppm and alarm 2 at 15ppm ex factory.

If an alarm set point is exceeded, the alarms are shown at the front panel and the

appropriate relays are switched. In case of malfunction, the System LED at the front

panel will change from flashing green to permanent red and the appropriate relay will

switch the contacts to alarm.

For the data logging function the Bilge Alarm Monitor OMD 2005 requires a status

input from the oily water separator and a feedback signal from the sample water 3-

way valve position switch. See Fig. 2, Pos.6.

Furthermore a 0(4) - 20 mA (equal to 0 - 30ppm oil content) signal output is available

for the connection of a recorder or external meter proportional.

The water sample is taken from the vertical water flow before of an orifice to have

enough sample water supply pressure.

The following National IMO-type test certificates in accordance with MEPC.107(49)

are available, issued by the national authorities of the countries listed below.

The list is an interim one and might be incomplete, as further national certification has

been applied for.

Country National Authority Country National Authority

Germany SEE Canada DEPARTMENT OF

BERUFSGENOSSENSCHAFT TRANSPORT

CANADA SAFETY AND

SECURITY MARINE SAFETY

Europe MED-EC Conformity USA U. S. DEPARTMENT OF

TRANSPOR-TATION UNITED

STATES COAST GUARD

0736

Table 1 IMO-type test certificates

1.2. Scattered light measuring method

An optical sensor array measures a combination of light scattered and absorbed by

oil droplets in the sample water. The sensor signals are processed by a

microprocessor to produce linearised output.

At exeeding of the adjusted limiting values (see item 1.1) 2 oil alarm relays are switched

after the adjusted time delay (ex works 2 sec.).

The microprocessor continuously monitors the condition of the sensor components

and associated electronics to ensure that calibration accuracy is maintained over the

time and different environmental conditions.

RWO GmbH • Marine Water Technology • Bremen • Germany Issue: 20.08.2008

Bilge Alarm Monitor OMD 2005 for SKIT S DEB 0.25-10.0 6.Edition V301115002 Page 4

The following diagram below shows the principle of scattered light measuring.

reference beam

light receiver

light emitter

IR LED

measuring cell tube scattered

light receiver

oil particles

Fig. 1

1.3. Safety warnings and tips

The following symbols are used in this user manual:

Both symbols describe an immediately threatening danger.

Failure to observe this warning can result in death or severe

injury.

Danger

Indicates a possibly dangerous situation. Failure to observe this

warning can result in death or severe injury.

Attention

Indicates important information and necessary action. A failure to

observe can result in damage to, or malfunction of, the oily water

separator.

Important

Information Indicates tips for use or other useful information.

RWO GmbH • Marine Water Technology • Bremen • Germany Issue: 20.08.2008

Bilge Alarm Monitor OMD 2005 for SKIT S DEB 0.25-10.0 6.Edition V301115002 Page 5

1.4. Adjustment

The Bilge Alarm Monitor OMD 2005 is delivered with a works calibration according

the IMO-requirements.

The "Zero" point is also works calibrated and can be re-adjusted on site by using the

programming mode and clean water. See sections 5.3 / 5.6.

The calibration is not permitted. This has to be done according IMO Regulations by

the manufacturer or persons authorised by the manufacturer.

1.5. Displays and Alarms

In the Bilge Alarm Monitor OMD 2005 are two independent alarm circuits available.

Both can be set separately from 2 to 15ppm.

The alarm point 1 is set at 14ppm and alarm point 2 is set at 15ppm ex works. Both

alarm circuits can be adapted to the operation conditions. The set point of alarm 1

can be changed according to the requirements on site between 2ppm and 14ppm

and the alarm 2 can be set between 2ppm and 15ppm. For a proper operation of the

adsorber bypass, the alarm circuit 1 must be at least 1 ppm lower adjusted as the

alarm circuit 2. An alarm point setting above 15ppm is accordingly to the IMO

requirements not possible.

The lower the value of the alarm circuit 1 is adjusted, all the

shorter is the life time of the adsorber cartridges.

Information

The adjustment can be done in the programming mode as described in section 5.6

“Programming Mode”.

In this mode also the individual adjustment of the time delays for the alarms (both

alarm circuits are set to two seconds ex works) and the change between 0 - 20 mA or

4 - 20 mA output can be done.

Both alarm circuits are also related with a LED on the front panel.

In case of malfunction the “System” LED will indicate any type of internal fault of the

Bilge Alarm Monitor OMD 2005. This LED is flashing green in normal condition and is

permanent red in alarm condition. Additional to the alarm LED's each alarm circuit is

equipped with a relay with potential free alarm contacts. These contacts can be used

for external processing of the signal or for control of further functions.

If a malfunction or failure of the power supply occurs, all 3 relays will switch to alarm

condition.

1.6. Design of the Bilge Alarm Device

There are 3 main parts which are contained in a Bilge Alarm Monitor OMD 2005:

• The computer unit is mounted into an epoxy powder painted steel housing to

protect the display PCB with the data logger and the main board PCB with the

terminals for environmental influences.

• The separate measuring cell is made of an anodized aluminium body with inlet

and outlet block in stainless steel. This rugged design protects the optical

electronic and correspond with the computer unit via a plugged data cable.

• The valve assembly contains a special handle to sense the position of the valve.

This assembly is connected to the measuring cell by an easy to handle fitting to

enable the exchange of the cell for frequently adjustment according the IMO

requirements.

RWO GmbH • Marine Water Technology • Bremen • Germany Issue: 20.08.2008

Bilge Alarm Monitor OMD 2005 for SKIT S DEB 0.25-10.0 6.Edition V301115002 Page 6

All components are mounted to a stainless steel mounting plate for easy wall or

bulkhead installation. It is also possible to split the computer unit from the measuring

cell if the available space is not sufficient. For this version divided mounting plates

are available.

2

1

water

outlet ¼“

OUT 1/4"

Oil Monitoring Device OMD-2005

11

4

5

3

ON Alarm 1 Alarm 2 System 6

7

OK

8

9

RWO

DECKMA HAMBURG

Marine 12

Water www.deckma.com

Technology

10

DH 75450 CLEAN WATER 1/4"

DE C K M A H AM B U RG

FLUSHING

SAMPLE 1/4" WATER INLET ¼“

SAMPLE

WATER

Fig. 2 INLET ¼“

1 Computer Unit 5 Handle 9 3 - Way Valve

2 Head Screw 6 Contact Switch 10 Mounting Plate

3 Connection Fitting 7 Spacer 11 Desiccator

4 Measuring Cell 8 Valve Plate 12 Communication Cable

Table 2 Pos.-No of the Bilge Alarm Device

RWO GmbH • Marine Water Technology • Bremen • Germany Issue: 20.08.2008

Bilge Alarm Monitor OMD 2005 for SKIT S DEB 0.25-10.0 6.Edition V301115002 Page 7

2. Technical Specification Bilge Alarm Monitor OMD 2005

Range: 0 – 30 ppm, Trend up to 50 ppm

Accuracy: According IMO MEPC. 107(49)

Linearity: Up to 30 ppm better than ± 2 %

Display: Green Graphic Display

Power Supply: 24 V – 240 V AC or DC

Consumption: < 15 VA

Alarm Point 1 Adjustable between 2 – 14ppm

Terminal X10/11: (Works adjustment 14ppm)

Alarm Point 2 Adjustable between 2 – 15ppm

Terminal X13/14: (Works adjustment 15ppm)

Alarm 1 Delay: Adjustable between 1 – 540 sec.

(for annunciation purpose) (Works adjustment 2 sec)

Alarm 2 Delay: Adjustable between 1 – 20 sec.

(for control purposes) (Works adjustment 2 sec)

System Fault Alarm: Red LED

Terminal X16 – 18

Alarm Contact Rating: Potential free 1 pole change over contacts,

Alarm 1, 2 and system fault 3 A / 240 V

Alarm Indication: Red LED's

Output Signal: 0 – 20 mA or 4 – 20 mA, reversible

ext. Load < 150 Ω

Sample Water Pressure: 0,1 – 10 bar

Sample Flow: Approx. 0,1 - 4 l/min depending on pressure

Ambient Temperature: + 1 to + 55° C

Sample Water Temperature: + 1 to + 65° C

Roll: Up to 45°

Size (over all): 360 mm W x 240 mm H x 100 mm D

Degree of Protection: IP 65

Weight: 7,3 kg

Pipe Connections: R 1/4" Female

Table 3 Technical Specification

3. Installation of the Bilge Alarm Monitor OMD 2005

According MEPC.107(49) the layout of the installation should be arranged so that the

overall response time (including the response time of the Bilge Alarm Monitor OMD

2005) between an effluent discharge from the oily water separator exceeding 15ppm,

and the operation of the Automatic Stopping Device preventing overboard discharge,

should be as short as possible and in any case not more than 20 seconds.

The device assembled ready at the RWO oily water separator fulfils this demand.

RWO GmbH • Marine Water Technology • Bremen • Germany Issue: 20.08.2008

Bilge Alarm Monitor OMD 2005 for SKIT S DEB 0.25-10.0 6.Edition V301115002 Page 8

4. Electrical connections

At electrical voltages > 42 V. Direct contact with live parts may

cause serious injury or death. Before works at electrical facilities

the power supply has to be interrupted (switch off the main switch,

remove or switch off the fuses). Work on live parts should only be

Danger carried out by qualified electricians.

4.1. General wiring information

All wiring is ready connected to the control panel of the oily water separator.

4.2. Connections of the Bilge Alarm Monitor OMD 2005

Fig. 3

Terminal description

X 1 to 2 Power supply 24 V AC from OWS

X 4 to 5 Power supply output (same as supply voltage)

X 7 to 8 Spare power supply output (same as supply voltage)

X 10 to 12 Potential free contact alarm circuit 1 (change over)

X 13 to 15 Potential free contact alarm circuit 2 (change over)

X 16 to 18 Potential free contact system fault (change over)

X 19 to 20 Flow direction switch

X 22 to 23 Input status OWS

X 25 to 26 Input spare switch

X 28 to 29 Analog signal output 0(4)-20 mA for a recording device etc.

X31 to 32 Power supply output for automatic cleaning device valve

(optional, not part of the standard scope of supply)

Table 4 Connections of the Bilge Alarm Monitor

RWO GmbH • Marine Water Technology • Bremen • Germany Issue: 20.08.2008

Bilge Alarm Monitor OMD 2005 for SKIT S DEB 0.25-10.0 6.Edition V301115002 Page 9

Close front cover complete after electrical installation. Water

inside the instrument may result in corrosion and malfunction.

Information

The monitor is supplied ready-to-use, including all accessories ordered.

The signals of the alarm circuits 1 and 2 are processed in the OWS control unit. At

exceeding of the adjusted limiting value for the alarm circuit 2 a common alarm relay

is activated in the OWS control unit.

4.3. Possible connections by the customer

The following electrical connections should be made, if required:

• Connection of a common alarm annunciation to the control room.

Connection at the common alarm relays at the OWS control unit (terminal X1 14 to

X1 16). Indicates among other things “exceeding limiting value alarm circuit 2”

• Connection of a “monitor system fault” alarm to the control room.

Connection at the monitor alarm relay output (terminal X16 to 18)

• Connection of an external recorder .

For the recording of the analogue signal 0(4)-20 mA connect the recorder with the

terminals X28/29 of the monitor.

5. Operation

5.1. Important Notes

a) This equipment must be installed and operated in strict accordance with the

instructions contained in this manual. Failure to do so will impair the safety and the

life time of the device.

b) Installation and servicing must be undertaken by a competent and suitably skilled

person.

c) Before the execution of maintenance work make sure that the power supply is

interrupted.

d) All national or local codes of practice or regulations must be observed and, where

applicable, are deemed to take precedence over any directive or information

contained in this manual.

e) To avoid wrong measurements, only quick separating detergents / cleaner should

be used.

f) In case of freezing conditions the measuring cell should be emptied complete.

5.2. Commissioning

Once the installation and wiring connections have been completed, check if all

electrical wiring is done perfectly and that all mechanical connections are correct and

seated properly, carry out the following checks:

a) Switch the oily water separator to „ON“. Check whether the Power LED lights up.

Check the power supply to the oily water separator if necessary.

b) Check that the power supply is connected to the terminals 1 + 2 of the terminal

block.

c) Check the wiring of the automatic stopping device and to the alarm system is

according the IMO Requirements.

d) Check that the grounding has been made according to the relevant regulations.

e) Check all piping connections for leaks and rectify as appropriate.

RWO GmbH • Marine Water Technology • Bremen • Germany Issue: 20.08.2008

Bilge Alarm Monitor OMD 2005 for SKIT S DEB 0.25-10.0 6.Edition V301115002 Page 10

5.3. Functional Tests

a) Run oil free water through the instrument to clean the system.

b) Switch on the instrument and make sure, that the Power LED is illuminated and

the display is

showing the initial

display for about 15

sec. After that time

it will change to the

standard display,

showing the actual measurement value.

c) During oil free water is flowing through the Bilge Alarm Monitor OMD 2005 check

the Zero standard adjustment according section 5.6 “Programming Mode”. The

display should be between "0" to “2” and the status will show “FW”. If the display

varies by greater values, it may be that air bubbles are present. If this is the

case, the cause must be identified and avoided.

d) If "Zero" need to be adjusted, this can be done in the programming mode as

described in section 5.6 “Programming Mode”.

5.4. Alarm

Please note for better understanding:

• in alarm status the position of the alarm switch is open (potential-free,

Information de-energised)

• if the power supply is interrupted or the system is not in service, the

position of the alarm switch is also in alarm position open,

(potential-free, de-energised)

The alarm circuit will be closed as soon as the main switch of the

OWS control box is in „off“ position i. e. no alarm signal will be

transmitted as long as the oily water separator is not in service.

When oily water flows through the instrument the display will show the actual value of

oil content. If the oil concentration exceeds the adjusted limiting values of the alarm

circuits, the alarm indicator of the appropriated alarm circute will be illuminated in

intervals during the selected time delay before it change to steady light and the

associated alarm relay will operate

5.5. Monitor control functions

The Bilge Alarm Monitor OMD 2005 is delivered with a works adjustment according

the IMO-requirements (pre settings: alarm circuit 1 -. 14ppm, alarm circuit 2 –

15ppm).

To investigate the performance of the OWS continuously and to protect the adsorber,

periodically every 5 minutes a sample is taken from sample point after OWS / before

adsorber to check the actual oil content in the effluent of the OWS.

If the oil content will be below the limiting value of the alarm circuit 1 (14ppm) again,

the 3-way bypass valve (OWS pos. 58) will change to adsorber bypass. If the oil

content after the OWS is still higher or equal than 14ppm the water flow remains via

the adsorber.

If the oil content is even or higher than the limiting value of the alarm circuit 2

(15ppm) at the sample point after adsorber, the water will be recirculated by the 3-

way diverting valve (OWS pos. 23) to the bilgewater tank and the alarm signal is

activated to the ship’s alarm system. If the oil content is below 15ppm the water will

be discharged overboard.

RWO GmbH • Marine Water Technology • Bremen • Germany Issue: 20.08.2008

Bilge Alarm Monitor OMD 2005 for SKIT S DEB 0.25-10.0 6.Edition V301115002 Page 11

5.6. Programming Mode

In the programming mode the alarm set points,

k ard

b ac for

w the time delays, the signal output and the zero

row rd row

r wa Ar can be modified. It is also possible to recall the

eA for

bl ter row ble

Do

u

En Ar Do

u factory default values at any time. The clock is

factory set for GMT, Greenwich Mean Time,

and cannot be changed.

tto

n n There are 8 push buttons to control the

tt on u tt on u tto

Bu K "B " Bu o lB functions of the display. In general are the

"-" "O "+ To

upper buttons for the data logger and the lower

OK buttons for changing the display to the different

pages of the menu.

Table 5 Programming Mode

Pressing the OK button will

give more detailed information

about the status

After start the display will show

the initial display followed by the

actual measured oil content. This

display will also be shown, if no

input at the different menu’s has

been done for a designated time

To get into the menu press the At the service menu the To change the value,

tool button. Select the required alarms, time delays, the press the “+” or “-“ button.

point by using the „+“ or „-„ Offset and the output signal Confirm with “OK”.

button. Press the „OK“ button to can be modified within the

confirm. limits. Select the required

values by using the „+“ or „-„

button. Press the „OK“ button

to confirm.

RWO GmbH • Marine Water Technology • Bremen • Germany Issue: 20.08.2008

Bilge Alarm Monitor OMD 2005 for SKIT S DEB 0.25-10.0 6.Edition V301115002 Page 12

Select the required value by To change the value,

using the „+“ or „-„ button. press the “+” or “-“ button.

Press the „OK“ button. Confirm with “OK”.

Select the required value by To change the value,

using the „+“ or „-„ button. press the “+” or “-“ button.

Confirm „OK“ button. Confirm with “OK”.

To get into the menu press the The display will show the

tool button. Select the required actual status of the data

point by using the „+“ or „-„ logger. To get back to the

button. Press the „OK“ button. standard display press the

tool button or the OK button.

Function of the scrolling buttons Press the “Enter” button to get The detailed information of

for data logger time history into the history. Select the the selected date and time

displays: required date and time by will be displayed. With the

using the buttons. buttons listed on the left

> 15 sec Forward The dotted vertical line shows you can further scroll. To

the actual position. get back to the history

> and + 2 min Forward

graph, press the “Enter”

>> Fast Forward Press the “Enter” button to Button again.

show details

>> and + Very Fast Forward To get back to the start

- 15 sec Backward display, press the “OK”

button.

< and + 2 min Backward

<< Fast Backward

<< and + Very Fast Backward

RWO GmbH • Marine Water Technology • Bremen • Germany Issue: 20.08.2008

Bilge Alarm Monitor OMD 2005 for SKIT S DEB 0.25-10.0 6.Edition V301115002 Page 13

To get into the menu press the The temperature of the

tool button. Select the required measuring cell and the

point by using the „+“ or „-„ sample water will be shown

button. Press the „OK“ button.

To get into the menu press the The system details will be

tool button. Select the required shown.

point by using the „+“ or „-„

button. Press the „OK“ button.

To get into the menu press the Information about the

tool button. Select the required software version and the web

point by using the „+“ or „-„ address will be shown.

button. Press the „OK“ button.

Table 5 Programming Mode

All changed values have to be confirmed by pressing the " OK " button. Otherwise the

existing values are valid.

Both alarm circuits can be set to an individual value between 2 to 15 ppm. Alarm time

delay circuit 1 can be set between 1 sec up to 9 min and alarm time delay circuit 2

between 1 to 20 sec.

The time delay for both alarm circuits is works adjusted to 2 sec..

Do not change the time delay, because these signals are needed

Information

in the RWO OWS control for the control of the adsorber bypass.

All adjustments can be changed on site by using the buttons at the front panel. The

adjustment can only be done in the programming mode. To enter this mode, press

the tool button and select with “+” and “-“. During the programming mode the Bilge

Alarm Monitor OMD 2005 continues in measurement and the yellow “Set Mode” LED

is on.

5.7. Recorder (option)

If a recorder is required for continuous recording of the oil content in the effluent,

RWO can offer a single-channel recorder of type DEGU. The Bilge Alarm Monitor

OMD 2005 has an output signal (either 0 - 20 mA or 4 - 20 mA) available for this

purpose.

RWO GmbH • Marine Water Technology • Bremen • Germany Issue: 20.08.2008

Bilge Alarm Monitor OMD 2005 for SKIT S DEB 0.25-10.0 6.Edition V301115002 Page 14

6. Calibration

According MEPC.107(49) Bilge Alarm Monitor OMD 2005 have to be protected

against access beyond the checks of instrument drift, repeatability of the instrument

reading and zero adjustment. For this reason the instrument is electronically sealed,

so that only the manufacturer or his authorised persons, equipped with the related

tools, are able to get access for changing the calibration.

To provide a simple procedure for check the instrument aboard ship, the Bilge Alarm

Monitor OMD 2005 is constructed in that way, that the zero check also confirms the

instrument drift within the specifications.

Calibration and repeatability check

a) Switch off the power supply and stop any water flow.

b) Clean the sample tube accurately by using the cell cleaning brush as described

under section 8 “Maintenance”. Make sure, that the “zero” point is correct at ± 0.

c) Run clean water through the instrument.

d) Switch on power supply

e) If it is sure, that clean water without any air bubbles is in the instrument, the

reading should be 0ppm ± 2ppm.

f) Continue as described under section 5.2 and 5.3.

7. Monitor operation

Up to 0,25 m³ OWS capacity the whole water flow through the Bilge Alarm Monitor.

For a OWS capacity over 0,25 m³ a part of the water of the oily water separator is led

via a bypass through the monitor. For this, a back-pressure orifice plate (oily water

separator pos. 11) is built into the main flow between the pump and the 3-way

recirculation valve (oily water separator pos. 23). The amount of the flow through the

monitor is, as a rule, already set up in the factory.

7.1. Operating instructions

a) Switch on the power supply.

b) Allow a period of time for water entering the sample tube.

c) Flow oil free water through the system for a few minutes and check that the display

show 0 to 2ppm. If not, clean proper before adjusting the Bilge Alarm Monitor OMD

2005 according section “8. Maintenance”.

d) Switch the instrument sample supply from the clean water supply to the separator

sampling point connection.

e) The instrument is now ready for use.

RWO GmbH • Marine Water Technology • Bremen • Germany Issue: 20.08.2008

Bilge Alarm Monitor OMD 2005 for SKIT S DEB 0.25-10.0 6.Edition V301115002 Page 15

7.2. Monitoring operation and alarm events during operation

a) When water containing oil flows through the device, the oil concentration is

indicated by the display. The alarm LED’s, (see Fig. 2) show green.

b) If the oil concentration should exceed the pre adjusted limiting values of both alarm

circuits, the alarm LED’s change from "GREEN" to "RED" and both relays (alarm

relay 1 and 2) switch over after 2 seconds. The OWS control unit process these

signals and controls with that

• the adsorber by pass

• the recirculation valve (OWS pos. 23)

• the common alarm relay

8. Maintenance

AT WEEKLY INTERVALS:

a) Flush the cell with oil free water.

b) Isolate the instrument from both, sample and oil free water supply.

c) Unscrew and remove the cell cap.

d) Insert the Cell Cleaning brush into the cell and clean it with upwards and

downwards motion through the entire length of the cell several times.

e) Remove the Cell Cleaning brush and replace the cell cap.

f) Reconnect the oil free water supply and allow this to flow through the instrument

for a few minutes.

g) Observe that the display is showing "0" to “2”. If not, clean again.

h) Examine the color of the desiccator (Fig. 2, pos. 11). Blue color is indicating an

active moisture absorber. If the color is light blue or white, the desiccator should be

replaced.

The desiccator assures a humidity below 40% inside the measuring cell housing to

avoid wrong measurement resulting due to condensation at the surface of the cell

glass tube and damage of the electronics around the glass tube. The replacement

is easy done without opening the instrument. Just unscrew the old desiccator out

of the front panel and replace it by a new one. The protection cap of the spare unit

can be also used as a tool.

i) Reconnect the instrument to the separator sampling point.

RWO GmbH • Marine Water Technology • Bremen • Germany Issue: 20.08.2008

Bilge Alarm Monitor OMD 2005 for SKIT S DEB 0.25-10.0 6.Edition V301115002 Page 16

9. Troubleshooting

9.1. Fault finding

The Bilge Alarm Monitor OMD 2005 will indicate several malfunctions in the status

line of the display. Pressing the “OK” button will lead into an information window,

similar to the items listed in the table below.

Status Reading System-Alarm- Alarm- Reason Servicing

circuit circuit 1,2

LED Alarm

OK 0..49 Green / No Normal Normal operation -

Blinking operation

OK EE Green / No Alarm Measurring value is out Wait until oil

Blinking of range: content is within

Oil content too high, dirty the range, clean

sample tube sample tube

FW ! 0..49 / EE Green / No Alarm Freshwater is enabled -

Blinking

Sample? EE Red / Yes Alarm Monitor is not able to Check sample,

Steady measure the sample: no clean sample tube

water in, oil content much

too high, no light

transmission possible

Com? EE Red / Yes Alarm No communication Check connection

Steady between computer unit between computer

and measuring cell unit and

measuring cell

Datalog? 0..49 / EE Red / Yes Alarm Datalogging is not Insert the active

Steady possible: memory card

no card in

Datalogging is not Insert the active

possible: memory card

a read only card is in

Datalogging is not Activate card or

possible: insert the active

a new card is in memory card

Int.Err Red / Yes Alarm Internal error Restart the system

Steady

Table 6 Fault finding

RWO GmbH • Marine Water Technology • Bremen • Germany Issue: 20.08.2008

Bilge Alarm Monitor OMD 2005 for SKIT S DEB 0.25-10.0 6.Edition V301115002 Page 17

Terminals Main PCB with Holder Computerhousing Protection Cover

Display PCB

19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 Measuring Logger /

F1 F2 PE PE PE + - PE PE

POWER PILOT VOLT. FLOW STATUS RES OUTPUT CLEAN Cell Display

24-240V IN PILOT OUT RES ALARM 1 ALARM 2 SYSTEM FAULT

L N PE L N PE A B PE NO COM NC NO COM NC NO COM NC

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

Status LED's: Memory

D7 Power ON Card Display PCB

D11 Microprocessor (blinking) D15 Status Separator

D12 Measuring Cell (blinking) D16 Status Water Supply

D13 Display (blinking) D17 Spare

D14 Spare D18 Status Datalogger

D19 Alarm 1 OFF D23 Alarm 1 ON

D20 Alarm 2 OFF D24 Alarm 2 ON

D21 System Fault OFF D25 System Fault ON

D22 Spare D26 Spare

Fig. 4

9.2. Memory Card (refer to Fig. 4)

The Memory Card is located inside the door of the computer housing. It is suitable for

the life of the instrument, as it is calculated to the according MEPC 107(49) required

storage time of at least 18 month. When the card is full, the oldest entry will be

overwritten, so that a replacement is not necessary.

Under normal use the card should not be taken out, as this is linked with the specific

system. The card can be read in other Bilge Alarm Monitors OMD 2005, but writing is

only possible in the related system.

RWO GmbH • Marine Water Technology • Bremen • Germany Issue: 20.08.2008

Bilge Alarm Monitor OMD 2005 for SKIT S DEB 0.25-10.0 6.Edition V301115002 Page 18

10. List of Spare Parts

Note: These spare parts are not part of scope of standard delivery.

You can order these spare parts from RWO.

Pos.-No. Description Ident-No.

PLC complete 51109EM014

Frontfoil 51109EM013

Chip card 51109EM012

Main PC board 51109EM011

Display PC board 51109EM010

Cover for display 51109EM009

9 3/2-way valves 51109EM008

5 Handle for 3-way-valve 51109EM007

6 Reed switch with cable (contact switch) 51109EM006

4 Measuring cell complete 51109EM003

2 Head screw 51109EM005

O-ring for head screw 51109EM001

Manual cell cleaning unit (optional) 51109EM004

12 Communication cable PLC measuring cell 51109EM015

11 Desiccator 51108EM027

Cell cleaning brush 51106OCD45

Fuse T2A 51311020M1

Fuse T1A 51311010M1

Table 7 List of Spare Parts

11. Exchange Parts Service

11.1. General

All Bilge Alarm Monitors in our range are inspected and tested to I.M.O. requirements

at our factories prior to delivery.

In normal use the Bilge Alarm Monitors should operate correctly and without fault

over a long period of time requiring only small amounts of maintenance to be carried

out as outlined in the instruction manuals.

11.2. Exchange Equipment Service

If, in spite of the care mentioned above, it should come to an equipment failure, we

recommend you to order a complete exchange monitor from us.

This ensures that, after the exchange, you have a monitor on board that has been

overhauled and tested in our factory.

The defective device which has been replaced should then be sent back to us

immediately.

If you return the defective Bilge Alarm Monitor OMD 2005 to us within a reasonable

period of time (30 days), RWO will only charge costs for the exchange monitor.

Otherwise we must charge the full sum shown on the invoice which accompanies the

exchange monitor we send to you.

Experience has shown that this offers the customer the most reasonable price and

ensures at the same time that a device is employed which meets the IMO

specifications.

RWO GmbH • Marine Water Technology • Bremen • Germany Issue: 20.08.2008

Bilge Alarm Monitor OMD 2005 for SKIT S DEB 0.25-10.0 6.Edition V301115002 Page 19

Note:

Accordingly to the rules of the MEPC.107(49) § 4.2.11. At the renewal of the IOPP

certificate the unit must be checked by the manufacturer or a person authorised by the

manufacturer. Alternative the unit can be replaced by a ready calibrated Bilge Alarm

Monitor. The special design of the OMD-2005 permits that only the measuring cell must

be replaced, because this part is the only relevant part for the calibration. The

certificate with the date of the last calibration must be stored on board to be in the

position to present the certificate to the authorities.

If for any reason the computer unit also must be replaced it must

be sure that the memory card remains on board for at least 18

month. The new computer unit is equipped with a memory card

of his own. The old memory card only can be read in the new

Important unity, storage of data can carried out only on the newly delivered

card.

For more details see chapter 9.2

11.3. Exchange of electronic components

Because of small variations in the characteristics of components of the same type, it

is recommended to calibrate the Bilge Alarm Monitor OMD 2005 after repair and

replacement of such components (except for relays, fuses, etc.). This calibration work

only may be carried out by the manufacturer or a person authorised by the

manufacturer.

Otherwise it can come to faulty display values and, if the display value is very low, to

exceeding the allowable limit of oil in water.

For the above reasons, only the possibility to order to a service exchange Bilge Alarm

Monitor OMD 2005 from us remains.

RWO GmbH • Marine Water Technology • Bremen • Germany Issue: 20.08.2008

Bilge Alarm Monitor OMD 2005 for SKIT S DEB 0.25-10.0 6.Edition V301115002 Page 20

Important contact numbers

RWO Repair and Service

Tel: 49-421-53705100

Fax: 49-421-53705440

RWO - Spares service

Tel: 49-421-53705228

Fax: 49-421-53705442

RWO - Plant sales

Tel: 49-421-53705220

Fax: 49-421-53705442

e-mail: rwo@veoliawater.com

homepage: www.rwo.de

IMPORTANT!

When you will order spare parts or exchange Bilge Alarm Monitors, please give us

the serial number of the oily water separator and of the Bilge Alarm Monitor OMD

2005 (see cover sheet of the operating instructions or the name plate on the oily

water separator and on the main PCB of the Bilge Alarm Monitor OMD 2005).

RWO GmbH • Marine Water Technology • Bremen • Germany Issue: 20.08.2008

You might also like

- Rwo Ows PDFDocument51 pagesRwo Ows PDFNandakishore PradeepNo ratings yet

- OMD21 E2Document25 pagesOMD21 E2cengiz kutukcuNo ratings yet

- Operating and Maintenance InstructionsDocument20 pagesOperating and Maintenance InstructionsJano Goñi100% (1)

- Manual Skit Deb 1.8 Facelift v2 EngDocument24 pagesManual Skit Deb 1.8 Facelift v2 EngSimonaMauna0% (1)

- OMD 2005 RWO Manual en 5Document20 pagesOMD 2005 RWO Manual en 5Val ShaNo ratings yet

- FWG - JWSP-26-C100 - N-012053Document32 pagesFWG - JWSP-26-C100 - N-012053sridharNo ratings yet

- Jowa Odme Cleantoil 9000Document6 pagesJowa Odme Cleantoil 9000CRIS SEDANTO0% (1)

- Manual SKIT DEB 1.8 Facelift V2 ENG PDFDocument97 pagesManual SKIT DEB 1.8 Facelift V2 ENG PDFSimonaMauna100% (1)

- Graviner Omd mk6 Iom Manual 1 59812 k001 Rev 6 PDFDocument109 pagesGraviner Omd mk6 Iom Manual 1 59812 k001 Rev 6 PDFtralalaNo ratings yet

- Electronic Fuel Viscosity Controller New Model English Tib 771 GB 0215Document50 pagesElectronic Fuel Viscosity Controller New Model English Tib 771 GB 0215irfanWPK100% (2)

- Manual InstructionsDocument34 pagesManual InstructionsАндрей100% (4)

- Jowa OdmeDocument2 pagesJowa OdmeFaisal anwarNo ratings yet

- Radar TankDocument48 pagesRadar TankMuhammad NuhNo ratings yet

- 109080-q Smart Cell - Bilge - ManualDocument29 pages109080-q Smart Cell - Bilge - Manualabuzer1981No ratings yet

- BICENTENARIO EM 22 Consilium Marine AB PLANOS Y MANUAL FINAL PDFDocument60 pagesBICENTENARIO EM 22 Consilium Marine AB PLANOS Y MANUAL FINAL PDFPedro Morales CepedaNo ratings yet

- AD-0377-C C20 - Alarm Monitoring Control and Power ManagementDocument317 pagesAD-0377-C C20 - Alarm Monitoring Control and Power ManagementMic Utu67% (3)

- ACC20 Digital Governor UnitDocument2 pagesACC20 Digital Governor Unitsike_99100% (1)

- JOWA Seaguard Bilge AlarmDocument2 pagesJOWA Seaguard Bilge AlarmPrinceBabuNo ratings yet

- Evt30 Upgrade Kit Manual PDFDocument29 pagesEvt30 Upgrade Kit Manual PDFFanus AwekeNo ratings yet

- Aa 0397a Acc20 Sulzer Rta Instruction ManualDocument141 pagesAa 0397a Acc20 Sulzer Rta Instruction ManualMahmoud KhalafNo ratings yet

- 910-001000 CS3004 Installationl USCG E1 05 2 E PDFDocument63 pages910-001000 CS3004 Installationl USCG E1 05 2 E PDFFendi MarihotNo ratings yet

- 050 - X52-62-72 - User-Interface - SW - 1 - 1 - 8 With SCRDocument36 pages050 - X52-62-72 - User-Interface - SW - 1 - 1 - 8 With SCRАнтон СорокаNo ratings yet

- ACC20 Digital Governor Unit PDFDocument2 pagesACC20 Digital Governor Unit PDFCezaryNo ratings yet

- 03Document47 pages03LekembauerNo ratings yet

- Jowa Backflush ProcedureDocument2 pagesJowa Backflush ProcedureMYO WINNo ratings yet

- DARLAS SERES ODME S 300 2 PCBs Removal Instructions For MK3 Hengstler Printer UpgradeDocument8 pagesDARLAS SERES ODME S 300 2 PCBs Removal Instructions For MK3 Hengstler Printer UpgradeDen CakraNo ratings yet

- CS4000 Service and Maintenance E6 10 1 E PDFDocument74 pagesCS4000 Service and Maintenance E6 10 1 E PDFOcupucNo ratings yet

- MDocument36 pagesMmajdi2013100% (1)

- Viscochief EVT-10C Viscosity Transducer: Marine & Diesel EquipmentDocument18 pagesViscochief EVT-10C Viscosity Transducer: Marine & Diesel EquipmentИван ПарлапановNo ratings yet

- Auto Filter ManualDocument22 pagesAuto Filter Manualaron james empigNo ratings yet

- OMD 2005 ManualDocument33 pagesOMD 2005 ManualFootie11No ratings yet

- User's Manual: Oil Content Meter Model GQS-206Document19 pagesUser's Manual: Oil Content Meter Model GQS-206Bhayu alfianNo ratings yet

- Poet h1470 Mgps ManualDocument19 pagesPoet h1470 Mgps ManualAbdel Nasser Al-sheikh YousefNo ratings yet

- Furuno Fm3000 VHFDocument76 pagesFuruno Fm3000 VHFZaw Khaing WinNo ratings yet

- Service Training ElectricDocument64 pagesService Training ElectricКеня КеняNo ratings yet

- 15.flow Switch For Piston Cooling OilDocument10 pages15.flow Switch For Piston Cooling OilKaleb Z king webNo ratings yet

- 污水处理器Document78 pages污水处理器Vikas SinghNo ratings yet

- Ushio ReinetsuDocument1 pageUshio Reinetsuironite100% (2)

- Ar Air Circuit Breaker: Technical Selection CatalogueDocument92 pagesAr Air Circuit Breaker: Technical Selection CatalogueSoumya RoyNo ratings yet

- Installation Manual: Alfa Laval Copenhagen A/SDocument144 pagesInstallation Manual: Alfa Laval Copenhagen A/SaNo ratings yet

- 721 Digital Dual Engine Marine Control 02822B PDFDocument122 pages721 Digital Dual Engine Marine Control 02822B PDFPriyawan Sukisno100% (1)

- SHaft Earthing DEVICEDocument16 pagesSHaft Earthing DEVICEFlo MarineNo ratings yet

- KONGSBERG - Alarm Monitoring Control and Power Management INSTRUCTION MANUALDocument357 pagesKONGSBERG - Alarm Monitoring Control and Power Management INSTRUCTION MANUALNikola Veža100% (2)

- Rectifier Board For CS4000Document4 pagesRectifier Board For CS4000dangthutqmNo ratings yet

- Fresh Water GeneratorDocument13 pagesFresh Water GeneratorPrem Cesc NathNo ratings yet

- Delomatic - Multi-Function System System Data: DEIF Generator Unit Control PanelDocument4 pagesDelomatic - Multi-Function System System Data: DEIF Generator Unit Control Panellukasberg100% (1)

- T1000 MinervaDocument18 pagesT1000 MinervaFaizulNo ratings yet

- Boiler Setting ProceduresDocument19 pagesBoiler Setting Proceduressumit100% (1)

- Mackay Service VAF Oilcon Annual Inspection Checklist MK6Document5 pagesMackay Service VAF Oilcon Annual Inspection Checklist MK6Cleverson SchmidtNo ratings yet

- Navtex Manual - FurunoDocument84 pagesNavtex Manual - FurunoBob TigerNo ratings yet

- Factory Acceptance Test Procedure: Doc - No.: AO-1022-EI Ll-Sep-96Document27 pagesFactory Acceptance Test Procedure: Doc - No.: AO-1022-EI Ll-Sep-96dhamuNo ratings yet

- Jcy-18xx - Battery Replacement Kit Mpxp34064 (7zxjd0095) E - JDocument10 pagesJcy-18xx - Battery Replacement Kit Mpxp34064 (7zxjd0095) E - JcrishanNo ratings yet

- Amplified Batteryless Telephone System: VSP 12 WayDocument20 pagesAmplified Batteryless Telephone System: VSP 12 Wayvu minh tienNo ratings yet

- Part1 Sound Power Tele. LC-800Document17 pagesPart1 Sound Power Tele. LC-800Tammy Jim Tanjutco100% (1)

- OMD 24 Manual en 02Document24 pagesOMD 24 Manual en 02Ernesto Denis67% (3)

- Jotran Sart ManualDocument24 pagesJotran Sart Manualsathish kumar100% (3)

- OMD21 - E2: Oil Mist DetectorDocument25 pagesOMD21 - E2: Oil Mist DetectorRK PanchalNo ratings yet

- (Installation Manual) N-015745 - v00 - JWP-26-C100 - INDocument51 pages(Installation Manual) N-015745 - v00 - JWP-26-C100 - INjwfqcw74mfNo ratings yet

- Sart User ManualDocument24 pagesSart User Manualalin grecuNo ratings yet

- Operator'S Manual: Voyage Data Recorder (VDR)Document48 pagesOperator'S Manual: Voyage Data Recorder (VDR)Edwin NyangeNo ratings yet

- A Multi-Threaded Socket-Based Java ServerDocument3 pagesA Multi-Threaded Socket-Based Java ServerOliver ZakariaNo ratings yet

- Perform Data Pre-Processing On Sample Data Set (Student - Arff)Document4 pagesPerform Data Pre-Processing On Sample Data Set (Student - Arff)adityaNo ratings yet

- Volatile Matter (Including Water) of Vinyl Chloride Resins: Standard Test Method ForDocument3 pagesVolatile Matter (Including Water) of Vinyl Chloride Resins: Standard Test Method ForNabeel H. Al-SaighNo ratings yet

- IGCSE Electrochemistry NotesDocument14 pagesIGCSE Electrochemistry Notestettehsackey100% (12)

- Lillian McCullough Berghane v. Radio Corporation of America, 217 F.2d 490, 3rd Cir. (1954)Document6 pagesLillian McCullough Berghane v. Radio Corporation of America, 217 F.2d 490, 3rd Cir. (1954)Scribd Government DocsNo ratings yet

- Beam Deflection Tables: Cantilever BeamsDocument8 pagesBeam Deflection Tables: Cantilever BeamsBelle SolaceNo ratings yet

- Id Dcu Marine 2.1Document152 pagesId Dcu Marine 2.1Anonymous uEt1sNhU7lNo ratings yet

- Body Voided SlabDocument56 pagesBody Voided SlabShivendra KumarNo ratings yet

- Bq4847/bq4847y: RTC Module With CPU SupervisorDocument5 pagesBq4847/bq4847y: RTC Module With CPU Supervisorelhandasya MedicalNo ratings yet

- FEM Assignment One - Abel WubeDocument5 pagesFEM Assignment One - Abel WubeAbelNo ratings yet

- The Development of A Teachers Self Efficacy Instrument For High School Physical Education TeacherDocument6 pagesThe Development of A Teachers Self Efficacy Instrument For High School Physical Education Teachercoroline0% (1)

- The Effect of Co-Solvents On The Antibacterial Activity of ParabenDocument10 pagesThe Effect of Co-Solvents On The Antibacterial Activity of ParabenDamariscpNo ratings yet

- TPC Aptitude TestDocument3 pagesTPC Aptitude TestBibin Raj B SNo ratings yet

- Interconnection Diagram - Diler 156000Document11 pagesInterconnection Diagram - Diler 156000misabozinovicNo ratings yet

- Geo F2 (Kilombero Prenecta 19)Document6 pagesGeo F2 (Kilombero Prenecta 19)De Silver BettoNo ratings yet

- 608 Us Toolox Toolox Dimensional RangeDocument2 pages608 Us Toolox Toolox Dimensional RangeFernanda AndradeNo ratings yet

- Vix CollectionDocument49 pagesVix Collectionfordaveb100% (1)

- Mechanics of Deformable Bodies Module 2Document19 pagesMechanics of Deformable Bodies Module 2eysNo ratings yet

- The Poincar E-Lindstedt Method: The Van Der Pol Oscillator: Joris VankerschaverDocument2 pagesThe Poincar E-Lindstedt Method: The Van Der Pol Oscillator: Joris VankerschaverSaikat GopeNo ratings yet

- Chapter 6-State ManagementDocument79 pagesChapter 6-State ManagementHeng PhinNo ratings yet

- ROSE Concept' of Fluid ManagementDocument7 pagesROSE Concept' of Fluid ManagementRanu AnggaraNo ratings yet

- Galvanic Corrosion of Zinc Anode and Copper Cathode Cell PDFDocument6 pagesGalvanic Corrosion of Zinc Anode and Copper Cathode Cell PDFsoekarnoNo ratings yet

- Design of PM Synchronous and Brushless DC MotorsDocument8 pagesDesign of PM Synchronous and Brushless DC MotorsEdinson VasquezNo ratings yet

- AnswersDocument26 pagesAnswersEllen WangNo ratings yet

- Boss FV-500H - OMDocument1 pageBoss FV-500H - OMbaggy trousersNo ratings yet

- Manual Evo DSP Plus TT 10-20-30!40!60 Ita EngDocument100 pagesManual Evo DSP Plus TT 10-20-30!40!60 Ita Enghytham.midani.63No ratings yet

- Topic 4 - Bigger and Smarter TelescopesDocument5 pagesTopic 4 - Bigger and Smarter Telescopesapi-208538578No ratings yet

- 3rd Quarter Status of Modules (Available and Needed)Document52 pages3rd Quarter Status of Modules (Available and Needed)Mhalou Jocson EchanoNo ratings yet

- Research Relying On Experience or Observation Alone Often Without Due Regard For System or TheoryDocument25 pagesResearch Relying On Experience or Observation Alone Often Without Due Regard For System or TheoryShoumikAutonuNo ratings yet

- Intro StatsDocument109 pagesIntro StatsEshita VarshneyNo ratings yet